Blog

Connecting the Circuit | One Woman’s Journey to Rewire the HV Jointing Industry

September 18th, 2025

In an industry where women in High Voltage Engineering careers is rare, Francesca Distefano is rewiring the possibilities for what it means to be a leader in this male-dominated workplace.

With several years major projects experience and proven competency for the installation of market-leading brands including Pfisterer Connex, Nexans Euromold and NkT, Fran is excelling in her field and hopefully inspiring more women to write their own future and likewise thrive in the electrical power industry.

Francesca’s work powers our world; employed on critical infrastructure projects from data centres to digitise our economy and offshore wind farms that power our planets renewable energy future towards the global goal of Net Zero 2050.

Her personal journey, fuelled by resilience and the support of allies, highlights both the challenges women still face in the industry and the immense opportunities ahead.

Q&A WITH FRAN

HV Jointer | 66kV GWO’s | Gold Card Electrician | SSTS | 18th Edition

Jointing LV HV Cables UK & International Projects | Onshore & Offshore

Q: Fran, you’ve carved out an impressive career in the traditionally male-dominated role of HV Jointer. What inspired you to pursue this path, and how did you overcome challenges as a woman in the industry?

Fran: My journey began with the support of my family, especially my Dad, who’s a carpenter. He encouraged me to break away from traditional norms and pursue what made me happy. When I started I faced scepticism—some wrongly assumed I couldn’t handle the job as Jointer simply because of my gender.

But I focused on proving my skills through hard work, dedication and investment in training. Being physically fit and confident in my abilities helped me earn respect. Surrounding myself with supportive colleagues, like mentors Steve and Paul, and my boyfriend Ian, who brought me into HV, made all the difference.

Q: What aspects of your work bring you the most satisfaction?

Fran: The tangible impact of my work is incredibly rewarding. Whether it’s helping power hospitals, schools or data centres, knowing I’m contributing to essential infrastructure is fulfilling. I take pride in delivering high-quality work, and when others admire the results, it’s a great feeling.

Q: You’ve highlighted the importance of mentorship. How did these relationships shape your career?

Fran: Mentors like Steve, Paul, and Ian were pivotal. They taught me the ropes, stood by me during tough times, and helped me grow into the professional I am today. Their belief in me gave me the confidence to push forward, even when I doubted myself.

Q: What are the biggest challenges women still face in the industry today?

Fran: The lack of facilities, like female changing rooms and toilets, is a glaring issue. Many sites aren’t designed with women in mind, which adds unnecessary stress. There’s also the constant feeling of being “watched” or underestimated. But I’m optimistic—more women joining the field will drive change and companies are starting to adapt.

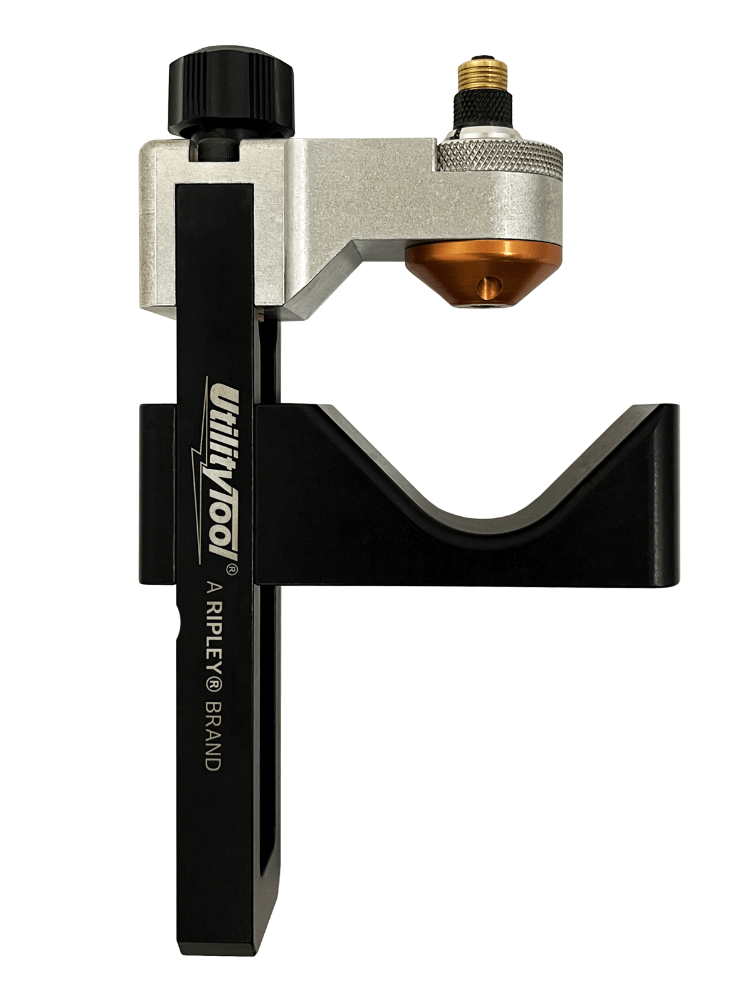

Q: As an HV Jointer which tools are indispensable to your work?

Fran: The Ripley US15 and US02 are my go-to Jointing Tools – the professionally engineered tools make stripping outer sheaths and cable semi-cons effortless, ensuring clean, precise work. These cable preparation tools have revolutionised efficiency especially in highly critical projects including offshore wind power and renewable energy.

|

|

| US02 Bonded Semicon Shaving Tool | US15 Sheath Stripping Tool |

Q: What advice would you give to women considering a career in HV Cable Jointing?

Fran: Don’t let fear hold you back. Yes, it’s intimidating at first, but the opportunities are endless—from joining to management or testing. The industry needs skilled workers, and women bring unique perspectives. Stand your ground, prove your worth, and don’t let anyone deter you.

Q: How can we encourage more women to join this field?

Fran: Showcasing the job’s rewards—travel, financial stability, and the pride of creating something lasting—is key. Breaking stereotypes and highlighting trailblazers can inspire others. Companies should also improve on-site facilities and actively recruit women.

Q: Where do you see opportunities for women in HV engineering over the next decade?

Fran: With global projects booming, women can make their mark internationally. As pioneers, we can reshape perceptions and inspire the next generation. I’ve already seen positive changes, and I hope the trend continues—more inclusivity, better facilities, and a stronger female presence on sites.

Q: Any final words for aspiring women engineers?

Fran: Go for it 100%. This industry is tough but incredibly rewarding. Be the change you want to see, and remember—you belong here just as much as anyone else.

Thorne & Derrick are Specialist Distributors of LV HV Cable Installation, Jointing, Substation & Hazardous Area Electrical Equipment to international energy providers, EPC’s and HV Jointing Contractors working on the design, construction and maintenance of UK, European and international projects – T&D are servicing the utilities, wind, solar, battery storage, rail, oil/gas, hydrogen and the explosive atmosphere sectors.

T&D are Main UK Distributors of Medium Voltage Cable Joints, Terminations & Connectors from 3M Electrical, Lovink, Nexans Euromold, Pfisterer Connex and Sudkabel.

Excellence in Energisation | Thorne & Derrick & SudKabel

September 5th, 2025

With global electricity demand forecast to double by 2050, Thorne & Derrick are strengthening and extending their world-class supply-chain by a Strategic Distribution Agreement (SDA) with a market-leading manufacturer of High Voltage Cable Accessories – our business can now provide technical specifications, competitive pricing and delivery commitments for Sudkabel Joints & Terminations to enable transformer, switchgear and overhead line connections of 66/132kV polymeric cables up to 2000sqmm.

The innovative range of Sudkabel Cable Accessories are designed to the highest standard, each cable accessory offering unique design, performance and application. The wide range of high specification cable accessories include:

- EHSVS & EHTVS Compact Cable Terminations

- Plug-in Cable Terminations 66kV 72.5kV

- Outdoor Cable Terminations with Liquid Insulation

- Gas-Filled Plug-in Outdoor Cable Terminations

- Dry Outdoor Cable Terminations 66kV to 245kV

- Heat Shrink Cable Joints 72.5kV 170kV

- High Voltage Cable Material for Cable Accessories

This powerful SDA delivers exceptional opportunity for Thorne & Derrick to support Grid-scale projects and further drive our sustainable energy future towards Net Zero – this includes the supply-off National Grid Type Registered HV Cable Accessories to UK DNO Approvals for 66/132kV distribution voltages.

Further value-added services provided by Thorne & Derrick include the provision of SudKabel Certified Jointers to execute project installations within the UK and EU – if you are interested in gaining manufacturer Authorisation for SudKabel Cable Accessories please contact Chris Dodds, Thorne & Derrick.

Our Key Account and Sector Business Managers at Thorne & Derrick will be in contact to formally introduce the SudKabel High Voltage Cable Accessories range to you, however in the meantime should you wish to discuss any project requirements at 66/132kV please contact :

Thorne & Derrick International

Pioneering Safety in Onshore & Offshore Wind: First Graduates of New GWO High Voltage Cable Pulling Standard

August 12th, 2025

The Wind Academy

The Wind Academy, the UK leading facility delivering GWO and Technical Trade Training Courses, has marked a major milestone in onshore and offshore wind technician training with the successful delivery of the first-ever GWO High Voltage Cable Pulling (HVCP) Training Standard.

Hosted at their brand-new Training Facility at the Port of Blyth, this pilot programme has produced some of the very first professionals in the world to gain certification under this innovative new standard — developed by the Global Wind Organisation (GWO) to boost safety, reduce cable damage, and improve operational uptime across the wind sector.

What is the HVCP Module?

The HVCP module forms part of the new GWO High Voltage Training Standard and equips participants with the skills, safety awareness and confidence to carry out high voltage cable installation both onshore and offshore.

Aimed at commissioning and service technicians, this standard supports work in HV operations or cable pulling under a Safe System of Work (SSOW). The HV Standard has been highly requested by many of the leading members of the Global Wind Organisation with input from Cubico Sustainable Investments, ENERCON, ENGIE, GE Vernova, Nordex Group, Northland Power Inc., Ørsted, RWE, Siemens Gamesa, SSE Renewables and Vestas.

Key Learning Areas

The HVCP module covers the following core areas:

- Safe handling & cable pulling — techniques for working safely in wind-turbine environments

- Damage identification & inspection — how to spot and document cable faults during and after installation

- Mechanical stresses & tool use — understanding loads and selecting/using the right tools

- Basic electrical field theory — essential HV concepts to work safely around cables

- Team coordination & communication — roles, signalling and handovers on complex jobs

- Risk mitigation & PPE — ergonomics, PPE and safe work practices

- Final cable loop installation & restoration — finishing checks and site reinstatement

Why This Matters for the Industry

By standardising HV cable pulling procedures and ensuring rigorous training, the new GWO HVCP standard helps:

-

Prevent costly cable damage during installation

-

Protect worker safety in challenging offshore conditions

-

Maintain uptime and reliability of wind farm assets

GWO High Voltage Standard

The GWO High Voltage Standard will enable participants to support work related to high voltage equipment and systems as per the specific module focus area and detailed topics within. The High Voltage Standard is divided into the following two modules:

High Voltage Operations

The training target audience includes workers required to operate and make safe high voltage equipment and systems, under a documented safe system of work, including commissioning technicians and service technicians, both onshore and offshore.

High Voltage Cable Pulling

The training target audience includes workers required to perform or supervise high voltage cable pulling operations, including offshore pre-assembly technicians, as well as installation technicians and service technicians completing replacement of high voltage cables, both onshore and offshore.

HV Jointer Training at the Wind Academy

The Wind Academy also provides brand-specific Cable Termination Courses for leading cable accessory manufacturers including Nexans (Euromold), Pfisterer (Connex), 3M Electrical, and NKT.

Thorne & Derrick

Leading Specialist Electrical Distributor to the Global Renewable Energy Industry

Thorne & Derrick supply High Voltage Cable Accessories, Jointing Tools & Power Distribution Equipment up to 66kV – we hold several Framework Supply Agreements with international energy providers, OEM’s and High Voltage Power Energy Companies.

From the largest stocks in the UK & EU we supply global projects with HV Cable Accessories to energise projects – this includes Nexans Euromold, Pfisterer Connex & 3M Cold Shrink Separable Connectors, Joints & Terminations at 11kV/33kV/66kV.

This is complemented by the most extensive stocks of Cable Preparation, Cutting, Crimping & Spiking Tools for insulation, screen, sheath removal of MV & HV cables including Alroc, Ripley, Hivotec, Cembre, Klauke, Boddingtons and PENTA.

OSHA’s First Arc Flash Safety Update in 20 Years — What It Means for You

August 12th, 2025In November 2024, OSHA released its first significant update to arc flash safety guidance in nearly 20 years. The revision is designed to reduce arc flash incidents and align safety practices with the NFPA 70E: 2024 standard.

This Article from CBS ArcSafe covers the implications to industry of this significant electrical safety guidance renewal and outlines their extensive range of remote-racking products for the safer operation of LV MV HV electrical equipment, including circuit breakers.

“It’s been two decades since OSHA updated its arc flash safety guidance. That just changed — and it’s a big deal.”

Electrical Safety Myth-Busting & Best Practices

Jump to:

Myth-Busting Electrical Safety

Defining Arc Flash Boundaries

Raising Arc Flash Hazard Awareness

Protecting Electrical Workers

How CBS ArcSafe Helps

In a recent article, Denise Green, Vice President of Operations at Group CBS, reviews the OSHA updates in depth and shares an outline of the changes, the implications they have on the industry, and their impact on employees and employers alike.

In addition to adherence to industry standards, remote operations help ensure safety when working with potentially dangerous electrical equipment. Arc flash safety solutions from CBS ArcSafe allow technicians to remote racking systems and switch equipment from outside the arc flash boundary.

What’s New in OSHA’s Arc Flash Safety Update?

Myth-Busting Electrical Safety

- Myth: De-energized equipment is automatically safe.

Reality: Without proper lockout/tagout, dangerous energy may remain. - Myth: Low-voltage systems cannot cause arc flash.

Reality: Arc flashes can happen at relatively low voltages — OSHA now requires appropriate PPE for energized work above 50 V.

“Any energized work above 50 V requires appropriate PPE — low voltage doesn’t mean no hazard.”

Defining Arc Flash Boundaries

OSHA clarifies three approach zones used to reduce shock and arc blast injuries. These align with NFPA 70E Tables for voltage, fault current and incident energy.

- Limited Approach Boundary — safe distance for unqualified workers.

- Restricted Approach Boundary — qualified workers with PPE only.

- Arc Flash Boundary — distance where incident energy reaches 1.2 cal/cm², enough to cause second-degree burns.

Raising aRC fLASH Hazard Awareness

- Inspect for damaged equipment before work.

- Always verify de-energization and follow lockout/tagout.

- Wear correctly rated arc flash PPE based on the hazard assessment.

Protecting eLECTRICAL Workers

OSHA supplies an Employer Guide and three concise worker one-page sheets covering hazard assessment, administrative controls, PPE selection and training.

Safety is a system, not an afterthought. The update encourages using the hierarchy of controls — elimination, engineering, administration, and PPE — and involving workers in safety programs to move from reactive to proactive safety practices.

How CBS ArcSafe Helps

As a distributor of CBS ArcSafe, Thorne & Derrick provide technologies that reduce worker exposure – this is a customer focussed, consultative process involving site surveys to assess risk and deliver user training to ensure optimum use of CBS ArcSafe remote racking equipment.

Remote racking and switching devices allow technicians to operate breakers and switchgear from outside the arc flash boundary.

- Remote racking & switching solutions

- Arc flash & power system studies

- Field services & equipment maintenance

- Extensive inventory of low- & medium-voltage equipment

“Safety starts before the spark.”

Remote Racking Systems

Universal Rotary Remote Racking System CBS ArcSafe RRS-1

A versatile remote racking system designed for safe and reliable operation of low, medium, and high voltage circuit breakers.

Lightweight Rotary Remote Racking System CBS ArcSafe RRS-1 LT

Compact and lightweight remote racking system ideal for confined spaces and quick deployment in the field.

Dual-Mode Rotary Remote Racking System CBS ArcSafe RRS-4

Features dual operational modes for enhanced flexibility and safety in remote racking applications.

Partner with Thorne & Derrick

Partner with Thorne & Derrick for your next electrical safety upgrade.

We provide technical expertise, online demos, and reliable specification and supply of CBS ArcSafe remote racking and switching solutions.

Electrical Safety for Low & High Voltage Power Systems

Thorne & Derrick are the UK’s leading Specialist Distributor of Electrical Safety Equipment to provide protection to personnel, plant and assets depending on the reliable operation of underground power cables and overhead line conductors.

We protect substation engineers, AP’s & SAP’s, cable jointers, overhead linesmen and utility workers with PPE and electrical safety products including insulating gloves, voltage detectors, insulating matting and portable earthing – we stock and supply products to ensure worker safety when carrying out maintenance, repair and construction on LV MV HV switchgear, substations, cables and electrical equipment from market-leading manufacturers including PENTA and Catu Electrical, part of the Sicame Group.

UK & Export Sales | Technical Support | Customer Service & Sales

Step-by-Step Guide for a 33kV T-Boot Termination

August 8th, 2025In this guide, Harvey Ross (HV Harv) demonstrates the key stages of a 33kV T-boot termination on a Nexans GT1 incomer. This process requires accuracy to ensure a watertight seal, maintain insulation integrity, and meet manufacturer specifications. Using specialist tools – including the Ripley Tools, US15 Pro Max, US02 & US10, as well as the ALROC LH2 – Harvey shows how each stage can be completed efficiently and to a high standard. All tools featured are available from Thorne & Derrick, jointing tool stockists, suppliers & distributors, trusted by HV professionals worldwide. The video below shows the full process, with our step-by-step breakdown following.

jointing Tools Used in This T-Boot Termination

Ripley US15 Pro MAX

High-precision insulation removal tool designed for fast, consistent results on medium and high-voltage cables.

Ripley US02

Reliable semi-con screen removal tool ensuring smooth, damage-free stripping for high-voltage cable preparation.

Ripley US10

Lightweight tool engineered for quick and precise chamfering of conductor ends to improve termination quality.

Alroc LH2

Heavy-duty cable cutter with a flexible cutting head for easy access to cables in confined spaces.

PF CLeaning Wipes

Industrial-grade wipes for effective cleaning and surface preparation during cable jointing and termination work.

All of these tools are available from Thorne & Derrick (Power and Cables) – trusted by LV, MV & HV professionals for safety, precision, and performance.

Cable Preparation & Initial Measurements

-

Measure the Bushing

-

Begin by measuring the bushing depth.

-

Measure back 285mm from the bushing end.

-

Sand 65mm of insulation to ensure a watertight seal.

-

-

Clean the Surface

-

Wipe the prepared surface thoroughly with a PF cleaning wipe.

-

XLPE Insulation Removal with Ripley US15 Pro Max

-

Remove Outer Insulation

-

Use the Ripley US15 Pro Max to make a circumferential cut, then transition to a spiral cut.

-

This tool excels in tight spaces and removes thick insulation with ease.

-

-

Finish the Cut

-

Use a hooked cable knife (a “hold-to-fall knife”) to flick out the final insulation section.

-

-

Remove Water Barrier & Copper Tape

-

Strip off the water blocking layer.

-

Remove the copper binding tape.

-

Clean the outer sheath again with a PF wipe.

-

Install Mastic & Prepare the Screen

-

Apply Water Mastic

-

Apply mastic around the cable as per kit instructions.

-

-

Bend Back Copper Screen Wires

-

Fold the screen wires back neatly in preparation for earth bonding.

-

Stress Control & Semi-Con Removal

-

Measure for Stress Control Tube

-

Mark 65mm from the screen cut to guide the positioning of the stress control tube.

-

-

Remove Semicon Layer

-

Use the Ripley US02 to remove the semi-conductive layer down to 30mm.

-

Tie off and sand as necessary for a smooth surface.

-

Cable Stripping & Chamfering

-

Strip Primary Insulation

-

Using the ALROC LH2, set the blade to the depth of the lug barrel.

-

Strip the insulation cleanly.

-

-

Chamfer the Conductor

-

Use the Ripley US10 to add a smooth chamfer to the end of the insulation.

-

This compact tool creates a clean finish, reducing stress points.

-

-

Prep Conductor

-

Tape the conductor end to prevent strand splay.

-

Clean the insulation and apply the termination grease (usually supplied with the kit).

-

Connector Assembly & Final Termination

-

Install Stress Control Tube

-

Slide it down to the 65mm marker created earlier.

-

-

Install Lug

-

Prep the conductor.

-

Slide on the lug and shear it off according to manufacturer torque ratings.

-

Clean and reapply grease.

-

-

Fit the T-Boot

-

Apply termination grease to:

-

The lug

-

Stress control tube

-

Inside of the T-body boot

-

-

Slide the boot on facing the correct direction.

-

Final Steps: Earth Bonding and Securing

-

Mount the Termination

-

Push the booted termination onto the bushing.

-

Fit the cleat to secure the assembly.

-

-

Dress Earth Wires

-

Straighten and align the copper screen wires.

-

Use one wire to wrap and secure the bundle for a clean finish.

-

Complete 33kV T-Boot Termination

What you now have is a fully installed Nexans 33kV T-boot termination, completed with precision using high-quality Ripley cable preparation tools.

Want to place an order for the tools used in this termination? Contact our team of experts – offering 40+ years of industry experience, we distribute the most extensive range of 11kV 33kV 66kV MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including Südkabel, 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX and Shrink Polymer Systems.