Cable Crimping – Lugs & Tools

Klauke EK30IDML | Hydraulic Crimping Tools Testimonials

May 31st, 2023

Klauke have recently introduced the professional panel building kit containing the EKWF120ML and EK30IDML battery-powered hydraulic crimping tools. A selection of Klauke testers were selected to try the crimping tools and give feedback.

The cable installation tools can be easily used to crimp quickly and safely without changing inserts. Interested in discovering more feedback from the job site?

We are excited to share with you the testimonials of three Klauke testers from Instagram who already put the EK30IDML tool to work.

Klauke Tool Tester #1

Felix @wahlfe

Why did you apply to become a tester?

I met Peter Nowak from Klauke at an event in Berlin, and he introduced me to Klauke’s battery-powered hydraulic pressing and cutting machines. When I saw that Klauke testers were being sought, I thought I should definitely apply to become a tester.

Did the tool make your everyday work easier? Which features are particularly worth mentioning?

Yes, definitely. The compact design and easy handling made the EK30IDML a great help on some construction sites.

Do you use other Klauke products? If so, which ones?

Yes, a K05, the EK50ML and, of course, a lot of consumables such as wire end ferrules, cable lugs and connectors.

Klauke Tool Tester #2

Christian @elektrotechnik_gallob

Why did you apply to be a tester?

I applied to be a tester because I follow the motto “Work smart, not hard”. Every new tool that makes my everyday work, or the work itself, easier, gets my interest. The offer to keep the press was tempting too, because of the regular purchase price. We have to be honest about that.

Did the tool make your everyday work easier? Which features are particularly worth mentioning?

I have been using the EK60UNV-L since 2004 when I started my own business. As already mentioned in the type designation, this hydraulic tool can be used universally – in my case for crimping cable lugs and wire end ferrules from 70mm², round crimping sector conductors and cutting top-hat rails. The big advantages of the EK30IDML over the EK60UNV-L are, on one hand, the size and weight and speed on the other hand. I have to crimp a 120mm² cable lug four times with the EK60UNV-L, while with the EK30IDML this is done with one crimp.

Are there other Klauke products in use? If so, which ones?

I recently purchased the EKWF120ML crimper. This press tool is THE ANSWER to all my problems.

Previously, the ferrules were pressed asymmetrically (trapezoid) and didn’t fit into terminals – all this is history with the EKWF120ML! I can also only report positive things about my beloved Klauke Micro – I have certainly been spared one or the other tendonitis here – not to mention the workflow.

Why did you apply to be a tester?

I wanted to see how much time and work could be saved by not having to change the press inserts.

Did the tool make your everyday work easier? Which features were particularly noteworthy?

Yes, it has. In my case, with pressings of 50 and 95mm², the tool has mainly increased time and labour savings without having to change inserts and carry or lose press inserts. In addition, it is a light crimping tool, even for quick work in between.

Do you use any other Klauke products? If yes, which ones?

Yes, there are several Klauke products I use such as ES 105 Cutting Tool, K05, Ultra ESG 50 (older model), Mini EKM 60/22 (the year 2014), Ultra EK 60/22 and several press inserts.

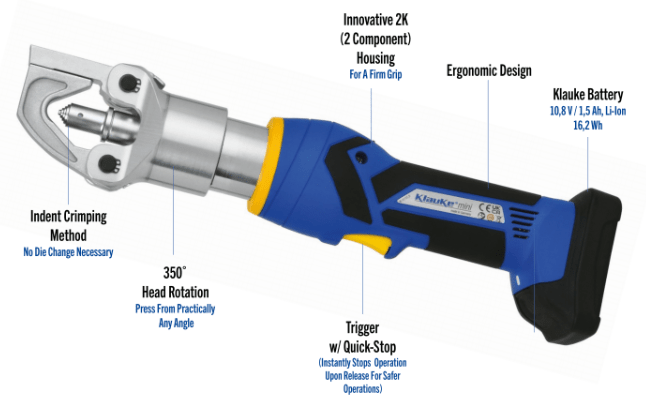

Klauke EK30IDML

Klauke EK 30 IDML – Features

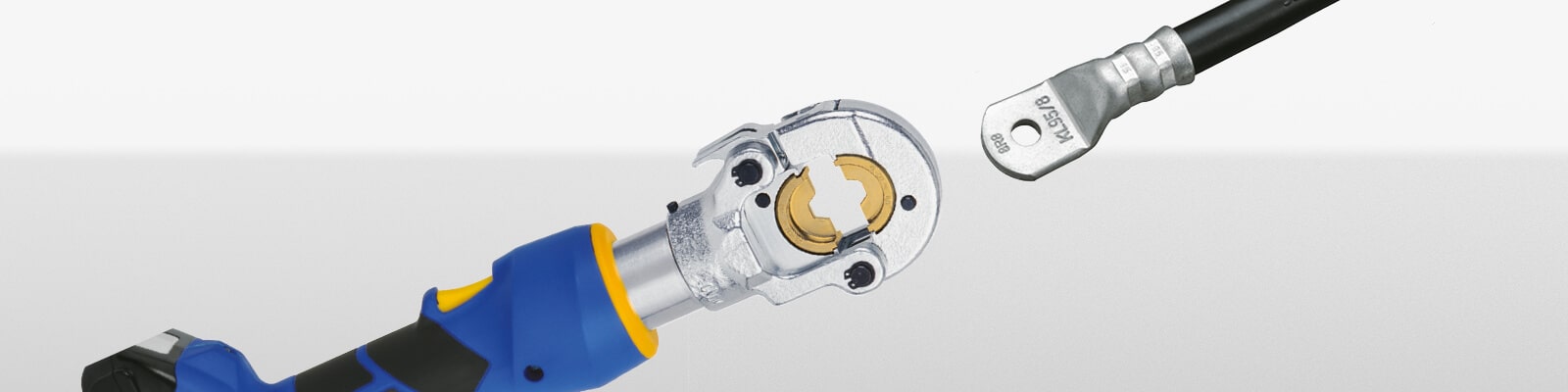

The Klauke EK 30 IDML is the ideal tool to crimp a wide range of cable lugs with reduced cost, it features the familiar indent crimping method, meaning a change of dies is not required with the tool.

The lightweight Klauke EK 30 IDML is ideal for working in areas where space is tight and the 10.8V Li-Ion, 1.5Ah rechargeable battery will last a full working day on just one charge. Battery operated cable crimping tools are equipped with LED indicators to display the remaining battery life at any time by pressing the adjacent button. The plastic housing with soft lining ensures comfortable and secure one-hand operation.

Advantages of the EK 30 IDML Hydraulic Cable Crimping Tool

- Powerful 10.8 V Li-Ion battery technology with battery charge indicator

- Closed head, flip top style, rotatable

- Simple and safe: one-button operating concept for controlling all tool functions

- Automatic retraction when operation is complete

- Maintenance display via LED

➡ Contact Thorne & Derrick for the full range of Cable Cutting & Crimping Tools

CRIMPING CABLES, LUGS & TOOLS

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a complete range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

➡ Associated Brands & Products | Klauke | Cembre | Pfisterer Sicon | Cable Crimping & Cable Cutting Tools

New Tool For Crimping Wire Ferrules & Wire End Sleeves | Klauke K507 WF

May 26th, 2023

Crimping wire ferrules

& Wire End Sleeves

In the electricity field a job is done right when it’s done safely. Having at hand ergonomic tools you can always count on makes the difference and always increases efficiency.

Thorne & Derrick are leading suppliers of cable lugs and crimping tools from Klauke for Low, Medium & High Voltage Cables – this includes a range of battery operated crimping tools.

Crimping wire ferrules can be a demanding task, and there are some situations where a single crimping operation doesn’t get the job done. The new K507 WF from Klauke makes this frustration a thing of the past.

The crimping tool features excellent pull-out values and can handle everything from stranded or straight conductors to thick or thin real cross-sections. The K507 WF works with wide interchangeable crimping dies, so a single crimp is enough to securely press most wire ferrules. The crimping profile suits all common conductors, and dies can be quickly replaced to enable work to be carried out easily.

Features & Benefits Of The K507 WF Crimping Tool

- Large cross section range from 0.5 – 50 mm²

- One crimping profile to suit all common conductors and cables

- Fast, easy replacement of crimping dies

- Fewer crimpings thanks to optimal application width

- With ratchet for consistently controlled crimp results

- Adjusting disc to compensate for the natural tool wear

Another practical advantage for daily work is that the K507 WF enables you to easily pre-clamp workpieces, which makes work even easier. Simply insert the sleeve beforehand into the tool – this way you don’t need any “third hand”. Weighing in at only 657 grams, the tool is very lightweight and suitable even for the most confined spaces.

The new K507 WF also lets you easily handle all standard conductors from 0.5 to 50 mm². The crimping dies can be securely stowed inside the tool handle, so while working you always have everything you need at hand.

Crimp Tool Ordering Information

Contact Thorne & Derrick to order or request further information.

| Klauke Tool Part Number | Klauke Tool Description |

| AE5071 | Crimping dies for cable end-sleeves, 0.5 – 10 mm² |

| AE5072 | Crimping dies for cable end-sleeves, 10 – 25 mm² |

| AE5073 | Crimping dies for cable end-sleeves, 35 – 50 mm² |

| K507WF | Crimping tool with interchangeable dies for wire end sleeves |

| ZAE5072 | Crimping dies for twin cable end-sleeves 2 x 6 – 2 x 16 mm² |

Do you have a Klauke Micro in your toolbox? Good news! You can use the K507 crimping dies for your Klauke Micro as well!

See the full video below, demonstrating the Klauke 508 WF Crimping Tool.

CRIMPING CABLES, LUGS & TOOLS

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a complete range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

➡ Associated Brands & Products | Klauke | Cembre | Pfisterer Sicon | Cable Crimping & Cable Cutting Tools

Hexagonal Crimping For Aluminium & Copper Cable Conductors

May 2nd, 2023

For aluminium and copper: hexagonal crimping according to DIN 48083 Part 4

Thorne & Derrick are leading suppliers of cable lugs and associated crimping tools from Klauke for Low, Medium & High Voltage Cables – this includes battery operated crimping tools with hexagonal crimping dies.

Hexagonal crimping is one of the more traditional crimping profiles. It is most frequently used in practice, as it is suitable for both copper and aluminium conductors. With this crimping profile, the single strands are deformed over a large horizontal area.

Hexagonal crimping is typically used for copper compression cable lugs according to DIN 46235 and aluminium compression cable lugs according to DIN 46329. This crimping profile can also be used to crimp solid cables with full tension.

Hexagonal crimps can be found in panel building industries as a manufacturer specific crimp and also as a DIN standard lug crimp for example in utilities (aluminium and copper conductors including 11kV and 33kV power cables).

The major benefit of hexagonal crimping relates to the central application of force, which is applied in equal measure from all sides and has an effect over a large contact surface. The individual stranded wires of the conductors are deformed as a whole in equal measure without being damaged.

The result is good mechanical stability and a secure connection.

Due to the consistent crimping involved, hexagonal cable crimping is also suitable for the medium and high-voltage range.

manufacturer-dependent hexagonal crimping

In addition to standardised hexagonal crimping, manufacturer-dependent hexagonal crimping is also allowed in the copper sector for conductor classes according to DIN 60228, Class 2. This crimping has been specifically developed for tubular cable lugs. As a result, it is essential you always revert to a manufacturer-specific system.

Freedom of Choice: Wide or Narrow Cable Crimping

Wide and narrow crimping is available depending on the tool selected. This will primarily depend on the cross-section and power of the tool in question. It is possible, for example, to use narrow crimping to crimp a 300 mm² tubular cable lug with a six-tonne battery-powered hydraulic tool. However, this will require several crimpings, something that will of course involve additional time. Therefore, you must take care that you make the right selection when purchasing a tool and ensure it is matched to the range of applications.

Compression cable lugs according to DIN, Cu

- For round conductors, e.g. according to DIN EN 60228 Cl. 1, 2, 5 and 6

- For non-tension copper cables, e.g. according to DIN 48201-1

- For pre-rounded multi-stranded sector shaped conductors

- With code number for clear tool assignment

- Cable lugs to DIN 46235

Klauke Compression cable lugs according to DIN, Copper

Compression cable lugs according to DIN, Al

- For non-tension connections of aluminium conductors to DIN EN 60228 and aluminium cables to DIN EN 50182

- For pre-rounded sector shaped conductors

- Cable lugs to DIN 46329

- Filled with contact grease for optimum transfer resistance

Klauke Compression cable lugs according to DIN, Aluminium

CRIMPING CABLES, LUGS & TOOLS

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a complete range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

➡ Associated Brands & Products | Klauke | Cembre | Pfisterer Sicon | Cable Crimping & Cable Cutting Tools

Klauke Cable Crimping & Cutting Tools | the world‘s first battery hydraulic crimping and cable cutting tools with Tri-Insulation Barrier technology that provides users with 1000V protection against electrical shocks.

Copper Terminal Lugs | NEW Range of Electrical Connectors from Cembre

March 16th, 2023

Copper Terminal Lugs

Copper Terminal Lugs by Cembre

Cembre has introduced two new terminals DR-NST into the existing DR-N copper terminal range for high quality and reliable LV & MV electrical connections:

Cembre DR16-10N-NST (Conductor Size 16mm2)

Cembre DR25-10N-NST (Conductor Size 25mm2)

The Cembre DR-N series of cable lugs are manufactured from electrolytic copper tube Cu-OF CW008A conform to UNI EN 13600.

Which are the main features?

- the annealing process optimizes the structural features of the material allowing an easier crimping and it guarantees the use of the electrical connector even with mechanical solicitations of various nature;

- the barrel entrance of the lug is chamfered to allow an easier and correct conductor insertion and its length facilitates precise positioning in the crimping tool die;

- cable lug dimensions are according to DIN 46235

UL listed for US and CANADA per UL486A-486B up to 35kV.

Cable cutting and crimping tools manufactured by Cembre are used to cut or crimp most types of low, medium and high voltage cables including EPR, PILC, XLPE, PVC insulated cables with copper or aluminium conductors, lead sheath, steel wire armour (SWA) or wire braid.

- Cembre Tools

- Mechanical Tools

- Ratchet Tools

- Hydraulic Tools Cable Cutters | Hydraulic Crimping Tools

- Battery Operated Tools

- Crimping Tools | Hydraulic Pressheads

Cembre tools are used for cutting and crimping underground cables or overhead lines to support the installation of LV-HV power cables and conductors into switchgear, substations, transmission and distribution networks – tools are the highest quality for the compression of connectors, lugs and joints in high voltage electrical cable installations in both indoor and outdoor locations from LV up to 33kV.

Cembre HT131-C Cable Crimping Tool | the industry leading and most extensively used hydraulic crimping tool for the connection and compression of electrical connectors, lugs and splices up to 400sqmm. This new model, self contained, robust and sturdy, will accept all semi-circular slotted dies, common to most 130 kN tools. The Cembre HT131-C tool features a double speed action: a fast advancing speed for rapid approach of the dies to the connector and a slower more powerful speed for crimping. For ease of operation and comfort of the operator the tool head can be fully rotated through 180 degrees. The built-in safety valve will by-pass the oil supply when the maximum pressure is reached, and the pressure release system can easily be operated at any stage of compression.

Stockists & Suppliers for the Cembre range of Electrical Connectors & Tools

Cable Lugs | How To Correctly Crimp & Connect Aluminium & Copper Conductors

March 1st, 2023

Cable Lugs

How To Correctly Combine Aluminium & Copper Cable Lugs

Are you installing, maintaining and connecting Aluminium power cables?

Here’s a useful article by Klauke to explain why you should use bi-metal cable lugs when transitioning to copper bus-bars or jointing Copper to Aluminium cables.

Thorne & Derrick can make recommendations to overcome the potential problems encountered when cable jointing aluminium to copper cables and provide guidance on best practice to avoid potential corrosion problems within resin cable joints up to 3.3kV/33kV.

Combining aluminium and copper can be problematic.

High-quality Al/Cu compression cable lugs are perfect for coupling and connecting aluminium conductors with copper elements. A compound in the aluminium connecting material improves the contact properties. Aluminium-copper connectors are necessary for the skilled connection of aluminium and copper conductors.

We want to focus on the not-so-simple task of connecting aluminium and copper.

As previously mentioned, aluminium is used quite often, but not always on its own. As copper has been the material of choice for decades, and continues to be used, there are problems in safely connecting both materials. In practice, electrical engineers are faced with this challenge more and more often.

Connecting aluminium and copper is required more often than you might think.

For example, it is necessary if an aluminium ring conductor is located in an industrial area, but the adjacent plants are supplied via copper conductors. Even in transformer stations, aluminium conductors need to be connected to copper bars.

Electrical engineers are confronted with the problem that aluminium and copper are not easily connected. For a durable and secure connection, special Al/Cu cable lugs and connectors should be used.

Aluminium/copper: a special Cable connection

Aluminium has proven itself to be corrosion-resistant in practical situations.

However, aluminium is generally an extremely reactive material that oxidises quickly. The durability of the material is down to a resistant oxide layer that is formed on its surface when atmospheric oxygen is applied – a process also known as self passivation.

If an electrically conductive liquid, such as condensation, comes into contact with an aluminium and copper connection, this results in an electrochemical reaction and the subsequent formation of contact elements.

The difference in potential by means of the electrochemical series plays a key role in this process. The contact element is formed by the copper electrode (anode), the electrolyte (water) and the aluminium electrode (cathode).

The voltage generated as a result is shorted by the contact between copper and aluminium. The aluminium is deposited and/or corroded in line with the current flow that is generated.

This process is visible as a vibrant oxidation mark and is applied to even the very smallest copper particles on the aluminium – with this being a permanent reaction as the copper does not therefore corrode. If there is an electrical connection, the consequence is an increase in the contact resistance, which can result in a temperature rise and, in the worst case scenario, a fire.

When combining copper and aluminium, it is therefore essential than you aim to prevent moisture from getting into the junction between both materials under any circumstances. In spaces where condensation builds up, you will therefore need to protect the contact point between copper and aluminium by way of special processing methods.

Use of aluminium/copper cable lugs and connectors is the most important step here. These items do not have any so-called creepage distances in which conductive liquid that is ultimately responsible for kicking off the oxidation process can accumulate.

As a result, aluminium/copper compression cable lugs and connectors are also particularly suitable for use in offshore wind turbines. There is also the option to use tin plated aluminium cable lugs. This solution should only be used in spaces that are kept constantly dry, as even small amounts of damage to the tin layer are enough to start the contact corrosion process.

Al/Cu compression cable lugs

Compression cable lugs which are developed for the special connection of aluminium conductors and copper bars are made of electrolytic aluminium (E-Al). They feature an attached copper mounting bracket according to EN 13600.

Aluminium conductors at a glance

Pursuant to DIN 60228, four different types of aluminium conductors are available – some of which require special processing methods. The following conductor types are available:

- single-stranded round conductors, class 1 (re)

- single-stranded sector shaped conductors, class 1 (se)

- multi-stranded round shaped conductors, class 2 (rm)

- multi-stranded sector shaped conductors, class 2 (sm)

The abbreviations and other information can be found among the markings on the Al/Cu compression cable lugs. This will help you to determine which cable lug is best for which aluminium connector.

The markings »8 KL16 50 rm 70 se« mean

- 8: Metric bolt dimensions of the connecting bolt bore (in this case M8 bolt)

- KL: Manufacturer code (Klauke in this particular instance)

- 16: Tool code

- 50 rm/sm: Nominal cross-section of the conductor in mm², when using a round or sector shaped multi-stranded conductor

- 70 re/se: Nominal cross-section of the conductor in mm², when using a round or sector shaped single-stranded conductor

For crimping Al/Cu compression cable lugs, we recommend using a hexagonal crimping die, according to DIN 48083 Part 4, or EKM60ID. Incidentally, Klauke aluminium inserts are silver, whereas copper inserts are gold/yellow. It is therefore very easy to tell them apart.

Al/Cu connectors: securely jointed Cables

Klauke offers reduction connectors to ensure that aluminium and copper are securely joined. Reduction connectors are often used in network repairs – more specifically in the production of non-tension connections for aluminium conductors in accordance with DIN EN 60228, and copper conductors in accordance with DIN EN 60228.

The connectors are made of two components: aluminium parts (E-Al) and copper parts (pursuant to EN 13600). The aluminium side generally has a larger diameter, because the lower conductivity is compensated by a correspondingly higher nominal cross-section.

As with compression cable lugs, the aluminium side of the connector also contains a compound, which is prevented from running out and drying out by a protective cap.

To ensure safe results when processing the Al/Cu compression joints, follow the relevant copper and aluminium processing specifications.

When using compression connectors underground, make sure that the joints are protected from moisture. It is best if you use a cast resin joint. The joint permanently protects the connections from moisture, dust and the penetration of foreign bodies.

Lastly, an important note on aluminium and copper cable lugs and compression joints. Do not expose these products to bending stress, otherwise there is a risk of breakage at the contact point between the two materials. Use in the overhead line sector is therefore not possible.

Crimping Cables, Lugs & Tools

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

Further Reading

- Solving 33kV Solar Cable Operational Issues Relating to Water Immersion

- Jointing, Grounding & Terminating DC Solar Cables

- Earthing Armoured Cables To Safely Protect LV AC Cables In The Solar Industry

Thorne & Derrick are Specialist Distributors to Solar EPC’s & High Voltage Jointing Contractors working on the design, construction and maintenance of UK, European and international projects supplying an extensive range of LV HV Solar Cables, Jointing, Substation & Electrical Eqpt. Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

We stock LV HV Solar Cables, Accessories & Electrical Equipment to enable the construction, maintenance and operation of utility-scale PV installations – our products connect 600V/1500V solar cables into combiner boxes, inverters, transformers and energise switchgear up to 33kV/132kV for high voltage grid connections.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

View our Solar Capability LV HV