Cable Pulling & Laying

Stokbord® Cable Covers | A Faster & Safer Solution For Cable Damage Prevention

May 9th, 2022

Stokbord® Cable Covers continues to be an industry leading innovation

Stokbord® Cable Covers

Cable Protection

Sustainability has been at the heart of Centriforce’s operation since its inception. One of the UK’s pioneers for recycling over 40 years ago, Centriforce continues to pave the way in sustainable material innovation for a range of applications – from damage prevention for underground utilities with Stokbord® Cover and Stokbord® Drum, to agricultural protection and maintenance.

➡ Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Centriforce cable protection.

A UK manufacturer utilising UK waste, Centriforce reprocesses over 20,000 tonnes of discarded plastic material each year, such as plastic bottles, carrier bags and packaging film.

Saving plastic from landfill and extending its useful life, Centriforce supports various key industries by manufacturing over 9 million metres per annum of high-quality and 100% recyclable products – most notably Stokbord®. As such Centriforce is one of the largest independent recyclers of plastic waste into end use products.

Stokbord Cable Protection

Centriforce

Leading by example, Centriforce developed Stokbord® Cover as a faster and safer solution for cable damage prevention. Replacing traditional clayware and concrete with recycled polyethylene featuring brightly coloured warnings, Stokbord® Cover continues to be an industry leading innovation – globally recognised and DNO specified with compliancy including National Grid TS 3.05.07 and ENATS 12-23 Class 1 & 2 specifications.

Affirming Centriforce’s policy for continuous improvement, the company has developed Stokbord® Drum. Launched to acclaim in 2019, Stokbord® Drum supplies the internationally recognised Stokbord Cover on a single industrial reel.

Removing the need for workers in the trench and supporting installation efficiency, Stokbord® Drum is an incredible success in sustainable innovation. Stokbord® remains fully recyclable after use in application, extending the whole life of plastics and reducing the contribution to production waste.

Centriforce’s unremitting drive for innovation directs their entire operation and highlights their dedication to promoting sustainable manufacturing – supporting global efforts to secure our environmental future. Centriforce is therefore uniquely placed to help customers and suppliers improve recyclability and reusability of their products, and contribute to a sustainable and circular future for plastic.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

The below video shows Stokbord® Cable Covers from Centriforce and distributed by Thorne & Derrick that provide heavy duty, high impact, underground cable protection for fibre optic, low voltage, high voltage (11kV, 22kV, 33kV, 66kV) and extra high voltage (132kV-400kV) power cable networks.

Centriforce together with distributor UK Thorne & Derrick Tapetile and Stokbord underground cable protection tiles and covers are the market leading, heavy duty utility protection system for protecting underground cable and pipes – this includes low voltage, medium voltage and high voltage power networks working at 11kV and 33kV.

Stokbord Drum Cable Protection for Underground Utility Cables

FURTHER READING

- Stokbord Drum | Protection of High Voltage Electricity Cables

- Stokbord Drum | Cable Protection for Underground Utility Cables

- UKPN Cable Protection Tapes & Covers (LV MV HV)

- ENA-TS 12-23 : Cable Tiles & Cable Covers For Use With LV 11kV 33kV & HV Cables

- Stokbord Drum | Cable Protection for Underground Utility Cables

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

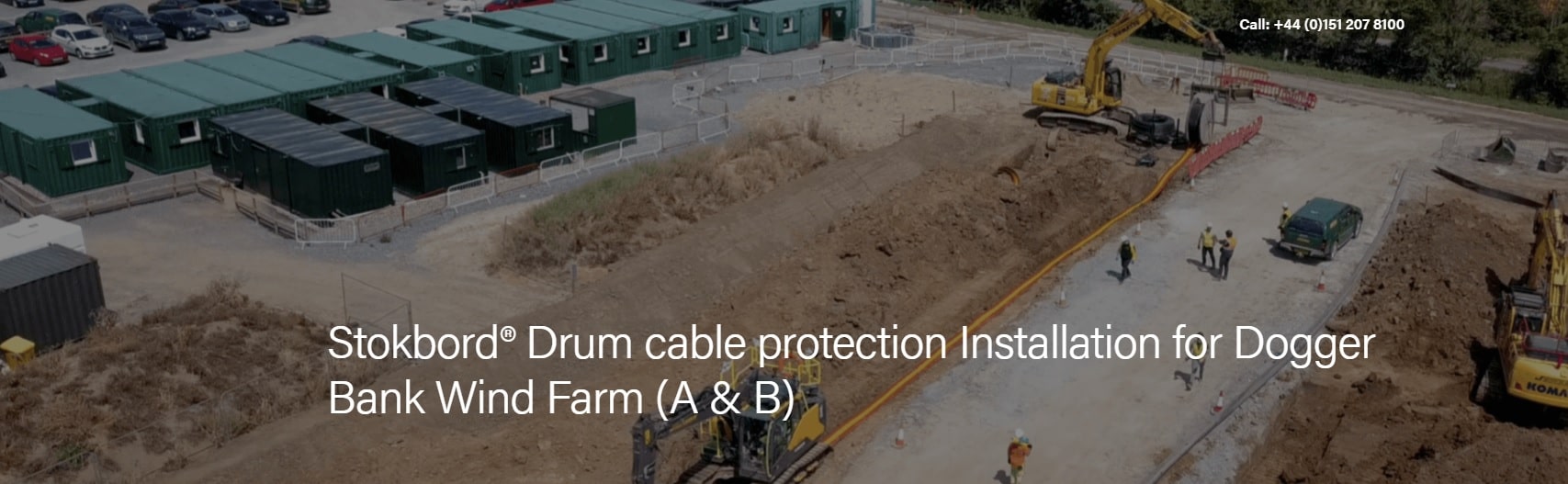

Stokbord® Drum Cable Protection Installation For Dogger Bank Wind Farm (A & B)

May 9th, 2022

Stokbord® Drum Cable Protection

Stokbord® Drum has shown its strength once again on one of the world’s largest renewable energy projects – Dogger Bank Wind Farm. Funded by SSE Renewables, Equinor and ENI, Dogger Bank Wind Farm will be the largest wind farm in the world, and once complete it will be capable of powering over 6 million homes in Britain.

As always, great infrastructure needs great protection. Centriforce are proud to share that Stokbord® Drum has been installed as part of the cable protection system for Dogger Bank Wind Farm (A & B).

Stokbord® Drum delivers heavy-duty utility protection in a single material strip, allowing operatives to install cable protection directly into the trench without needing to set foot into it. Centriforce wind their protection material directly onto an industrial reel which allows users to unroll the material into application, providing significant health and safety benefits alongside major time and cost savings.

Stokbord® Drum has been developed to provide a mechanical installation option decreasing the need for any manual work

➡ Centriforce, working through their distributor network including Thorne & Derrick stock and supply Stokbord cable covers and Tapetile cable warning tapes that offer clear visual warning and excellent cable impact protection for 11kV-33kV high voltage cables including EHV circuits operating at 66kV, 132kV up to 400kV.

Cable Protection Installation

These specifications make Stokbord® Drum the perfect partner for large scale projects as heavy-duty cable protection can be installed in a matter of minutes without the need for individual peg connection as required by traditional protection tiles.

Centriforce met with Jones Bros Civil Engineering on the East Riding Cable Route for Dogger Bank Wind Farm (A & B) to see how Stokbord® Drum supported their team on this project.

Commenting on the speed of installation, James Lockwood – Project Manager for Jones Bros Civil Engineering says “It is estimated we can install 250 metres of Stokbord® Drum within 3 minutes, using 2 men. In comparison, it could take up to 90 minutes using 4 operatives and traditional plastic covers.”

On this project, Stokbord® Drum has allowed operatives to install cable protection up to 30x faster than traditional methods. This is an incredible advantage for contractors. With fewer operatives required to work on a single 250m stretch of cable, Stokbord® Drum saves time and costs by allowing more operatives to cover greater distances in a shorter space of time.

Key Benefits of Stokbord® Drum:

- Ease and speed of installation – up to 30x faster to install than traditional plastic covers

- Significant reduction in manual handling costs

- Supports health & safety on-site

- Removes the need for workers to set foot in the trench

- Reduced risk of injury and accidents in trenches

Centriforce’s CEO Simon Carroll comments “We are very proud to support Dogger Bank Wind Farm with one of our greatest innovations, Stokbord® Drum. Centriforce developed Stokbord® Drum through our policy for continuous improvement, working directly with our trusted customers and partners to overcome the challenges frequently faced when installing heavy duty cable protection.

Stokbord® Drum delivers an easy-to-install solution that greatly increases application speeds while reducing the risk of injury and accidents occurring on-site. This product capability is perfectly matched to large scale projects such as Dogger Bank Wind Farm – enabling significant time and cost savings in every kilometre.”

Centriforce Stokbord® Drum on the way to site

Stokbord® Drum MV HV Cable Protection for Underground Utility Cables

Stokbord® Drum Cable Protection Installation For Dogger Bank Wind Farm (A & B)

As well as Dogger Bank, Stokbord Drum has been installed on major infrastructure projects including Triton Knoll, Hornsea 2, Seagreen and Viking Link

CABLE PULLING & LAYING EQUIPMENT LV HV

T&D supply Utilities & Approved Contractors with cable pulling products including cable rollers, cable socks and cable jacks to enable the installation of low voltage and high voltage cables intro trench or duct: this includes single core, 3 core and Triplex 11kV/33kV power cables and LV waveform, mains and service cables.

Cable Sock Damage | How To Ensure Safe & Reliable Cable Sock Performance

May 3rd, 2022

Cable Sock Damage & Maintenance

Cable Sock Inspection & Maintenance

How Can You Tell If They Are Safe To Use?

Inspecting a cable sock is crucially important to ensure safe cable pulling operations, maximum grip strength and grip longevity.

There are a number of variables that can weaken a cable sock that are not immediately obvious on visual inspection. However, there are some important and simple checks that you can do routinely to mitigate product wear, deterioration and potential accidents from happening.

When inspecting a sock, it is critical to know the potential damage and trouble spots. Below is a summary of the types of damage you need to be aware of prior to beginning any pulling project with your cable pulling socks.

Cable Sock Safety

Safety is Thorne & Derrick & Slingco’s primary concern. The products Slingco manufacture are safety critical and therefore they have their own fully certified test facility. This allows them to comprehensively test all socks prior to release from design. They design and manufacture to the highest specifications and test to destruction so you can be confident when using a Slingco product.

If you are in doubt about the serviceability of your cable sock, use a new sock! Thorne & Derrick carry large UK stock of cable socks so lead times are short.

The following are some of the types of damage you should be aware of prior to beginning a cable pulling project with your cable socks. If these are observed, replacement of sock should be considered.

DAMAGED PULLING EYE

The eye of the cable sock is very important. If any damage is found, replace sock immediately. Causes of eye damage include:

• Pulling loads at an angle as opposed to straight line pulling

• Misuse and wear from excessive use

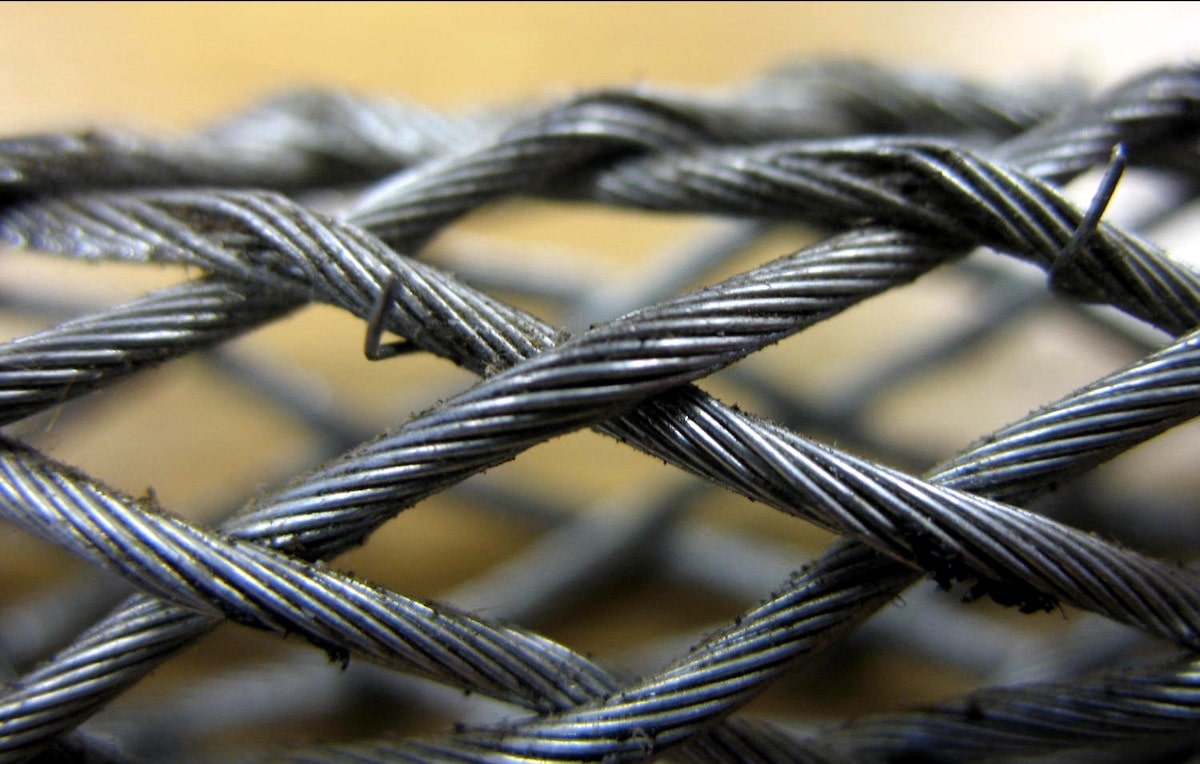

FRAYED WIRES

Frayed wires cause the cable sock to weaken significantly. The more wires damaged, the weaker the sock. Causes of fraying are:

• Excessive abrasion while cable is being pulled

• Becoming stuck or snagging during a pulling operation

Rusted Wire

Rust will weaken the strands of wire that make up the sock. If excessive rust is identified, replace sock. Causes of rust are:

• Socks left in moist conditions or stored damp after water exposure

• Water with high salinity content will cause rusting more rapidly

Bent & Broken Wires

Bent and broken wires have the same effect as fraying and cause the cable sock to weaken significantly. Causes of this type of damage are :

• Excessive abrasion while cable is being pulled

• General wear and tear over time

EFFECTS OF TORSIONAL BUILD UP

The most important factor when using a cable sock to pull wire is to eliminate torsion, or twisting of the cable grip assembly. It is important, when stringing high tension wires for electrical transmission and distribution, to use the proper components to eliminate torsion.

If wires are likely to develop torsion during a pull, line pulling swivels enable the torque to be released, which otherwise could cause damage to the wire or sock.

Advantages of Slingco Swivels include:

- Reduce torsion strain

- Are quality tested and inspected

- Come in bull-nose or rounded style

- Can be matched-up with Slingco’s heavy duty cable socks

Using a cable sock alongside the Slingco swivels to eliminate torsion is crucial

CABLE SOCKS & SUPPORT

ASSESSMENT OF SUITABILITY

There are many factors that must be taken into account when assessing the suitability of a sock for a proposed application, and when trying to calculate the working load limit.

These include:

- Size of cable sock in relation to size/shape of gripped object

- Stability of object(s) when gripped

- Sock surface of object(s)

- Resistive force of object(s)

- Anticipated path of movement, including possible obstructions

- Approximate breaking strength of the cable sock

- Condition of sock

- Suitability and compatibility of any attachments used

- Environment/operating conditions

- Persons at risk

➡ Please note: Slingco socks must be double steel banded securely before being pulled.

CABLE Sock SAFETY INFORMATION

- Ensure that the sock mesh fits the cable correctly

- Ensure that the cable fits up to the mid-point of the protective shoulder

- Clamp the ends of the cable sock when attaching the cable. Slingco recommend between 1.25” and 2.25” from the end of the sock – SECURE CLAMPING MUST BE USED ON SLINGCO SOCKS

- Never modify or attempt to repair any sock

- Ensure proper maintenance of the sock

- Check the condition of the sock, and that it is the correct size for the intended application – do not exceed the rated capacity

- Cable socks that are worn, bent, or otherwise damaged should not be used

- Cable socks are only to be used for temporary installations

- Pulling devices should only be attached via the pulling eye

- Cable socks must only be fitted and used by trained competent person(s)

➡ Slingco cable socks must not be used to their approximate breaking strength. A sensible Safety Factor must always be used. If in doubt contact the manufacturer or distributor that supplied sock.

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Thorne & Derrick distribute a complete range of Cable Pulling Products to support the safe installation of LV, MV & HV cables into underground ducts, conduits and trenches – this includes products to enable safe cable drum handling, lifting and support for cables operating at LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

We service the Power Transmission & Distribution industry in the wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

This includes standard Pulling, Laying & Stringing Products for underground cables, subsea umbilicals and overhead line conductors and also innovations such as Catchblock – a patented overhead line catenary roller system that guarantees that, if a conductor breaks during the stringing process, there will be no need to obtain road or rail possession. This also means reduced need for scaffolding, reduced risk of an accident and an overall more efficient operation.

➡ See Also Further Reading

- Cable Laying, Installation & Support Products | MV HV Windfarm

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

- NOF Members Thorne & Derrick and Slingco Ltd Supporting Cables in the Offshore Wind Industry

Earlier this year, Thorne & Derrick welcomed Phil Day from Slingco Limited, the world-leading manufacturer of cable pulling and support socks, swivels, cable protectors, wire rope assemblies and accessories. Phil provided an Offshore Wind focussed company presentation to our Sales Team (pictured left-to-right Sarah Henderson, Carl Cox, Jonathan Hewitt, Phil Day, Jeff Jhanke, Natalie Lundie and Chris Dodds.

Cable Rollers | Duct Rods | Cable Jacks | Cable Lubricant | Duct Seals | Cable Duct

Cable Pulling Socks For Array, Export, Umbilical & Subsea Cable Installations

April 26th, 2022

Cable Pulling Socks

For Array, Export, Umbilical & Subsea Cable Installations

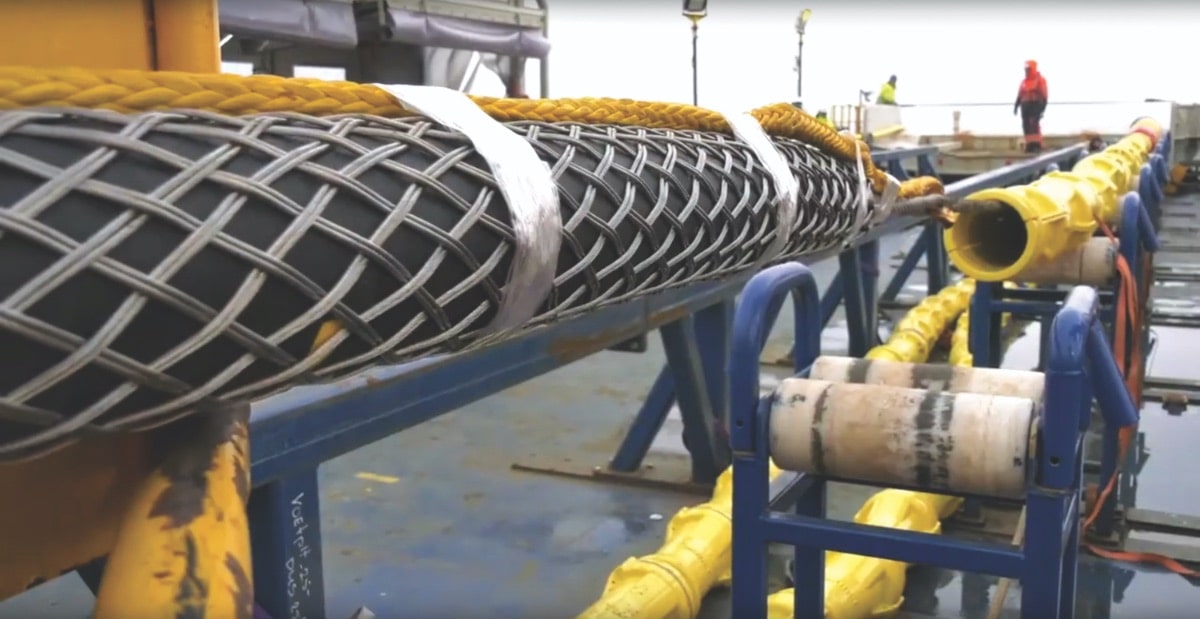

After 12 months of extensive research and development, Slingco are delighted to launch their new range of cable socks. Bringing you peace of mind with high-volume project capacity, quick availability, full testing details, and forty years experience.

Slingco have developed these marine cable pulling socks for installation of inter-array and export cables for offshore wind farms. The new socks have expanded ranges to suit common cable sizes used in offshore applications and have increased break loads. All of the new socks have a new ‘two over / two under double weave’ on the lattice which tightens up the angle of deflection over the end of the cable.

Slingco offers an extensive range of marine and hose restraint cable socks for onshore and offshore cable installation, including the support of cables inside wind turbines and general cable management.

- Single Eye, Double Eye, Lace Up Cable Socks

- Max Break Load 10Te – 90Te+

- Galvanised, Stainless and Aramid Socks

- Complete range to suit Cable OD range 10mm-350mm+

- Test reports & certification

- Large project delivery

- Quick availability

- 40+ years’ experience

- Award winning company

Slingco also manufacture a speciality heavy duty cable socks, suitable for large underwater pulls. Galvanised steel construction for extremely heavy duty large diameter pulls. Single eye, double eye and lace up. Sizes range from 100mm (4″) to over 355mm (14″).

Marine cable socks are designed, manufactured and tested to exacting standards to ensure safe and reliable operation under the most challenging condition

Features Of New Slingco Marine Cable Socks

- Cable range of 90mm to 285mm

- Break load tested and independently witnessed at Lloyds Register

- Manufactured to high quality standards in the UK

- Length has now been standardised from 2.5m to 3.5m

- Loadings have increased by 30%

WHY SLINGCO FOR MARINE Cable PULLING SOCKS?

- Award winning UK manufacturing facility produces between 2,500 to 6,000 cable socks per month

- Options such as Thimble eye, Shoulders, and Anodes are now available on request (manufactured to order), as are stainless steel cable socks and aramid cable socks, both of which have better corrosion resistance for prolonged subsea lay down durations

- Range of non metallic socks made from high strength aramid fibre, with UV coating for fibre optic offshore applications

- We have an impeccable track record, with recent projects including: Kincardine, EastAnglia1 &2, Borssele 1 & 2, Hornsea 1 & 2, Akita, Triton Knoll, Hornsea 2, Moray East, St Nazaire, Dolwin 6, Ostwind 2

- Slingco are DEME & NKT approved supplier for Dogger Bank A & B, the world’s largest wind farm – array cable installation due to start this year

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Thorne & Derrick distribute a complete range of Cable Pulling Products to support the safe installation of LV, MV & HV cables into underground ducts, conduits and trenches – this includes products to enable safe cable drum handling, lifting and support for cables operating at LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

We service the Power Transmission & Distribution industry in the wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

This includes standard Pulling, Laying & Stringing Products for underground cables, subsea umbilicals and overhead line conductors and also innovations such as Catchblock – a patented overhead line catenary roller system that guarantees that, if a conductor breaks during the stringing process, there will be no need to obtain road or rail possession. This also means reduced need for scaffolding, reduced risk of an accident and an overall more efficient operation.

➡ See Also Further Reading

- Cable Laying, Installation & Support Products | MV HV Windfarm

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

- NOF Members Thorne & Derrick and Slingco Ltd Supporting Cables in the Offshore Wind Industry

Earlier this year, Thorne & Derrick welcomed Phil Day from Slingco Limited, the world-leading manufacturer of cable pulling and support socks, swivels, cable protectors, wire rope assemblies and accessories. Phil provided an Offshore Wind focussed company presentation to our Sales Team (pictured left-to-right Sarah Henderson, Carl Cox, Jonathan Hewitt, Phil Day, Jeff Jhanke, Natalie Lundie and Chris Dodds.

Cable Rollers | Duct Rods | Cable Jacks | Cable Lubricant | Duct Seals | Cable Duct

Conductor Repairs | CatchBlock OHL Catenary Roller From Slingco

April 20th, 2022

CatchBlock

Conductor Repairs

CatchBlock OHL Catenary Roller From Slingco

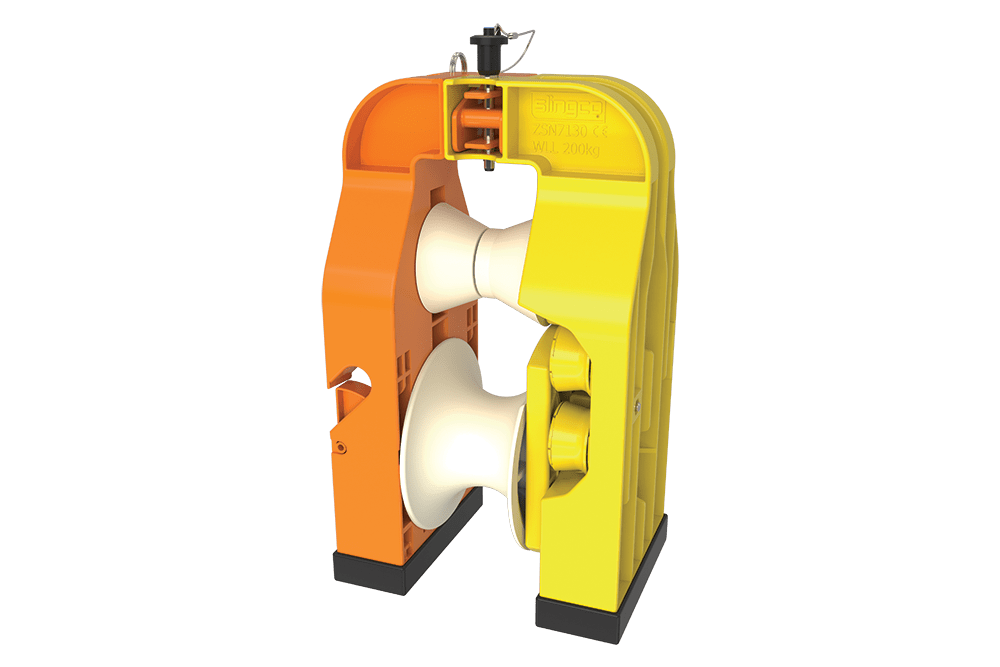

Slingco has developed a range of products to vastly improve conductor replacement. The Catchblock, the Conductor Replacement Roller (CRR) and our range of specialist cable socks and grips.

The challenges faced by the OHL (Overhead Line) industry due to the growing number of electrical infrastructure projects built beneath existing transmission and distribution networks – alongside increasingly stringent OHL regulations – can make maintenance costly, time-consuming and challenging.

Replace OHL conductor in half the time with no need for possession orders

CatchBlock

Lightweight, robust and easy to deploy, CatchBlock helps to increase efficiency and reduce costs.

CatchBlock is an innovative overhead line (OHL) catenary roller system.

A two-rope system, allowing the replacement of old-for-new conductors. In the event of conductor failure during this process, Catchblock enables the recovery of both ends without having to lower the system.

Removes the need to erect and dismantle scaffolding, significantly reduces the risk of accidents and harm to site workers and reduces cost and project timeframe.

Designed to deploy a twin-rope system, it allows the recovery and redeployment of broken conductors without the need to take possession of road/rail or client/third party property or infrastructure.

CatchBlock Features & Benefits

- Removes the need to close down essential infrastructure for conductor repairs or in the event of an emergency

- Cuts down the need for scaffolding, reducing accident risk

- Lightweight, robust, weatherproof and easy to deploy

- Twin rope system allows for recovery and redeployment

- Flexible – CatchBlock isn’t specific to a single tug design

- High conductor range, including the ability to allow mid-span joints/repair sleeves to pass through safely

- Blocks can be connected for use on multiple bundle conductor systems

Conductor Replacement Roller (CRR)

Provides a simple, conductor-deployed protection system using a lightweight aramid rope.

The CRR unit enables the safe exchange of conductors in three easy steps:

- Laying out the pulling cable, e.g. with an electric pulling robot.

- Tensioning the CRR Block assembly.

- Feeding a new conductor through the cable pulleys of the CRR Block.

The rollers have a spring loaded gripping feature to secure the rope laterally without impinging any rotational movement as the rollers rotate around the axis of the conductor.

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

➡ See Also Further Reading

- Cable Laying, Installation & Support Products | MV HV Windfarm

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

- NOF Members Thorne & Derrick and Slingco Ltd Supporting Cables in the Offshore Wind Industry

Earlier this year, Thorne & Derrick welcomed Phil Day from Slingco Limited, the world-leading manufacturer of cable pulling and support socks, swivels, cable protectors, wire rope assemblies and accessories. Phil provided an Offshore Wind focussed company presentation to our Sales Team (pictured left-to-right Sarah Henderson, Carl Cox, Jonathan Hewitt, Phil Day, Jeff Jhanke, Natalie Lundie and Chris Dodds.

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct