Cable Pulling & Laying

Cable Pulling & Laying | Sealing Cables Whilst Installing | Part 1

September 23rd, 2021

Cable Pulling & Installation

Stephen Harrison – Training & Technical Manager at Current Training Service Pty Ltd

Pulling cables is an art, with bending radii, side wall pressures to consider whilst pulling the cables and loadings of cables, the list goes on. All cable pulling data is available from the cable manufacturer on these values, before pulling cables please check and verify the cable pulling calculations and values.

Water is devastating to cables and when a cable does start to let water in, it can diminish the life span of that cable causing so many problems. Some of the problems maybe treeing and or oxidisation etc.

How many times do people pull cables into installations without correctly sealing the cable ends and finding out that water has penetrated the cables whilst under installation?

End caps are designed to seal the cable either whilst being installed or being left for periods of time awaiting terminating or jointing.

![]()

The humble end cap will not work alone on the cable a few things have to be done before it is effective and seals your cables;

- Select the correct end cap for the installation, either storage, pulling. (There are several types)

- When the selection has been made, prepare the cable outer sheath. This will require abrading and cleaning any mud off, so when mastic, glue or hot melt adhesive attaches the outer sheath it creates a seal.

- The cap, depending on the manufacturer may need mastic under for extra sealing especially when installing the cable and leaving it for a period buried or in a pit in water, or 2 caps mastic and a heat shrink sleeve maybe required.

In Part 2, I will explain the different types of cable end caps which have been designed for pulling cables and storage.

➡ Read part 2 here Cable End Caps | Cable Pulling & Storage | Part 2

Cable Pulling Cable Laying Equipment

Further Reading

Cable Pulling Calculation Example From Brugg Cables

Secure Spiking of Underground LV & HV Cables | Cable Spiking & Cutting Tools

Cable Pulling & Cable Laying Equipment

Onshore Cable Pulling Starts At Seagreen Offshore Wind Farm

September 6th, 2021

Cable Pulling & Laying

Work is underway to pull cabling through 19.5 kilometres of underground ducts which will connect the GBP 3 billion Seagreen Wind Farm to the Scottish National Grid.

The cable pulling is the latest stage in the cable installation process and another milestone in the construction of the 1,075MW 114-turbine development 27 kilometres off the coast of the county, which when operational, will power up to 1.6m homes throughout the country.

Once finished, the cabling will reach from where the project makes landfall in Carnoustie to a new dedicated substation currently under construction in Tealing.

Onshore Electrical Infrastructure Project Manager, Steven Reid from SSE Renewables is responsible for the cable installation project.

”The start of the cable pulling process marks an important achievement in the delivery of the onshore electrical transmission infrastructure following significant efforts from the Project Team and the support of various stakeholders,” Reid said.

”Again, I‘d like to express our thanks to all who live along the route for their co-operation and understanding as the project has progressed up to this stage of delivery. Working with our Contractor Nexans, we now look forward to continue to deliver the installation of the 19km of cabling safely and with the least amount of disruption possible to the surrounding community.”

Electrical Arc Flash Protection for Offshore Wind Farm WorkersSeagreen is a joint venture between SSE Renewables and Total.

First power at the wind farm is expected by early 2022 with full power coming on stream in 2022/23.

Seagreen selected Montrose Port as the home for the operations and maintenance base for the 114-turbine development in October 2019.

See how T&D support, supply and service the Renewable Energy industry.

Cable Pulling & Cable Laying Equipment

Concrete Trough for Rail Industry Cables | A Case Study

August 20th, 2021

Concrete Cable Trough

As part of Network Rail’s substantial Railway Upgrade Plan to increase capacity across the Great Western Main Line, the significant re-signalling project between Paddington and Reading is continuing to make significant progress.

New cabling is currently being installed as part of a variety of infrastructure projects between Paddington and Heathrow junction. These infrastructure projects include Crossrail works on the Elizabeth Line, the upgrading of the signalling infrastructure from track circuits to axle counters and the safer faster isolation works.

➡ See our range of Insulated Rail Track Tools

Upgrading Cable Routes

Colas Rail is supporting the signalling infrastructure upgrade works through telecoms, civils, electrification and power support. The project aims to deliver a more reliable railway for London and all passengers travelling to the West and Wales, ultimately putting the passenger first. Many of the cable routes on this section of the infrastructure are reaching capacity and therefore are being upgraded by Colas Rail to accommodate the extra cable required.

As part of the cable installation process, Colas Rail has commissioned Anderton Concrete, market leader in the supply of cable protection products to the UK’s rail industry, to supply over 6000 metres of precast concrete troughing to successfully increase cabling capacity.

Facilitating the seamless transition from existing ground routes to new routes, the Anderlite straight concrete troughs have been manufactured in half lengths of 500mm to increase on-site efficiencies. The troughing lids have been manufactured at a standard length of 1metre to provide further cost and resource benefits.

Over 3000 metres of troughing has already been installed by Colas Rail’s engineers, with the project predicted to be finalised by this summer.

Anderlite 500 Concrete Trough

Daniel Clouth, Project Manager at Colas Rail Ltd., said: “A project of this scale and nature requires optimum communication and collaboration from all parties to ensure its successful delivery. It is therefore crucial that the level of materials we require are on site at the key access points, when we need them.

“Having worked with Anderton Concrete across previous rail projects, we were confident that the team could deliver the volume of troughing we required, whilst also taking a bespoke approach to the specification of the product to ensure on-site efficiencies were increased.”

With the UK’s railway network experiencing a doubling of passenger levels over the last 20 years, Network Rail’s Railway Upgrade Plan will deliver a more reliable railway that ensures new trains can run alongside existing rail services to deliver quicker and easier journeys for passengers.

Neil Cross, National Sales Manager for Anderton Concrete, said: “As a longstanding partner of Colas Rail, it has been fantastic to collaborate with them for the re-signalling of the Great Western Main Line.

“With this project, it was imperative we could meet tight deadlines and supply high volumes of product with just a few days’ notice. As Anderton Concrete is at the heart of building for the UK, our extensive range of precast concrete products are manufactured at our headquarters in Cheshire, which places us in a strong position to guarantee that our troughing solutions can be on site in the shortest lead times, without compromising on quality.”

Anderton Concrete’s extensive portfolio of troughing, signal bases and complementary rail products are designed to comply with Network Rail standards and as a result, have full Network Rail Approval status, Certificate No. PA05/00318 & PA05/05810 and RISQS accreditation.

As the durable Anderlite concrete cable trough range is up to 30% lighter than traditional materials, it offers increased installation and sustainability benefits to reduce manual handling concerns, associated cost and resource implications and the overall environmental impact of the project.

Colas Rail

A subsidiary of the Colas Group, Colas Rail are part of over a hundred years of experience in delivering major innovations across our sector. Every day, thousands of trains run on tracks built or maintained by Colas Rail.

Colas Rail is a leading provider of railway infrastructure services – providing design, engineering, project management, construction and maintenance solutions for the light rail, metro, mainline and high-speed markets.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick are leading Specialist Distributors & Stockists of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment to the Rail industry. Low, Medium & High Voltages

Power Products ♦ Cables & Accessories ♦ Electrical Equipment

Cable Drum Handling | A Guide by LEONI Cables

July 30th, 2021

Guidelines for cable drum handling during transport and storage

Transport

Cable drums must be handled with care.

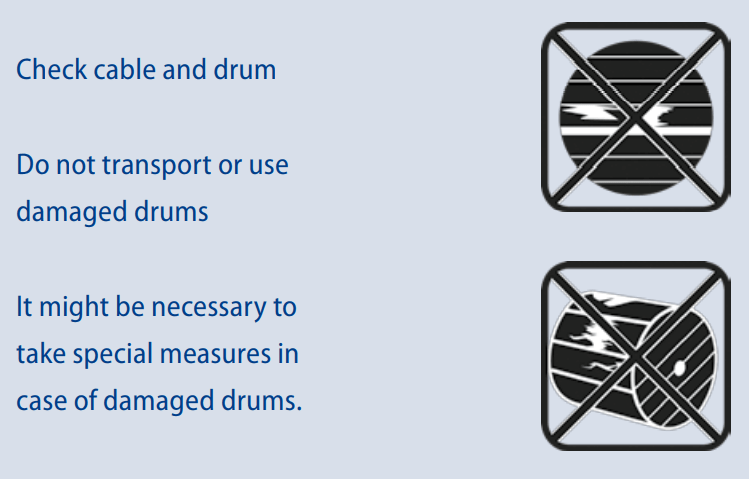

Improper handling procedures or cable drum handling equipment can easily cause damage like broken drums or visible or invisible damage of the cable itself.

Main danger comes from invisible damages leading to unusable cables.

Therefore some base guidelines shall be followed. The cable itself must always be protected and may not be touched improperly during transport and storage. A drum, damaged by handling or showing signs of wear or rotting must be checked. Special handling procedures may be necessary.

If a wooden drum is handled and/or stored properly as described in this document LEONI Kerpen GmbH gives warranty for stability and usability for a period of up to 18 months after delivery. In case of wooden drums show signs of damage from transportation any warranty obligation given for cable drums and any subsequent cable problems resulting from it are null and void.

Beside the general guidelines, please refer to the cable data sheet for additional information regarding temperature range and possible special requirements for transport and storage.

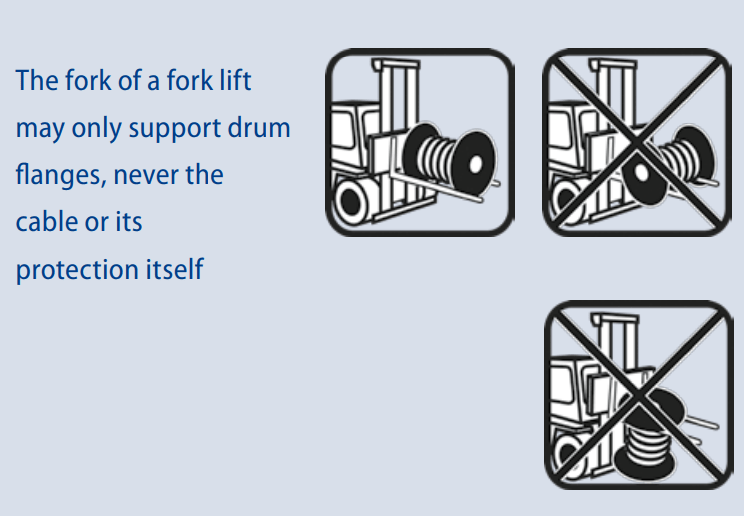

- Lifting cable drums with a fork lift is only allowed from the “flange side”. The fork may never touch the cable or its protective cover to avoid damage. The fork must support both flanges while lifting.

- If lifting a drum with a crane an axle or a spreader beam must be used to avoid lateral pressure on flanges.

- Suitable devices must be used for loading and unloading in order to avoid damage to the cable and the drum. Drums may never be dropped from a truck, ramp or container.

- Cable drums should only be transported with suitable vehicles and must be fixed, so that they cannot shift during transportation. The same applies in case cables are transported in a container.

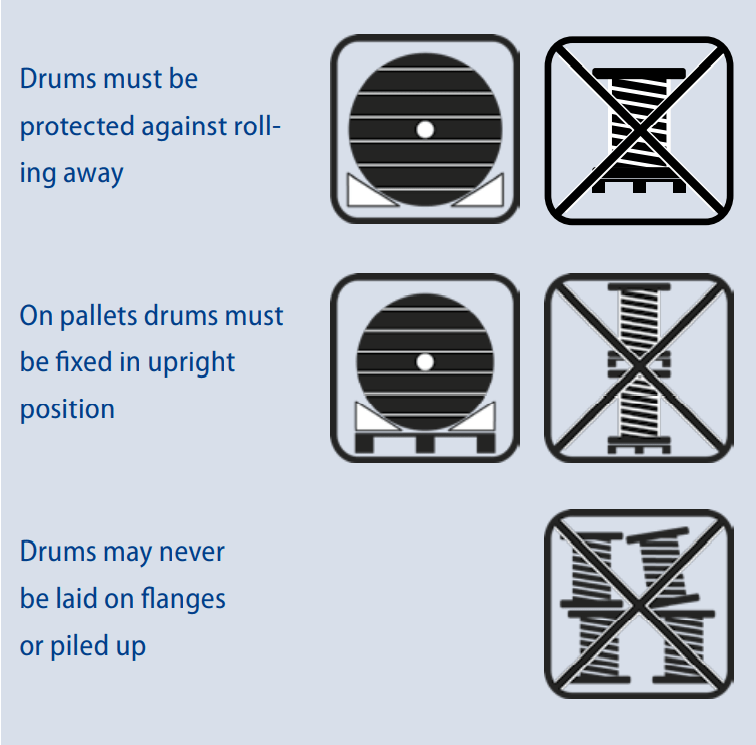

- During transport and storage drums shall always be in upright position.

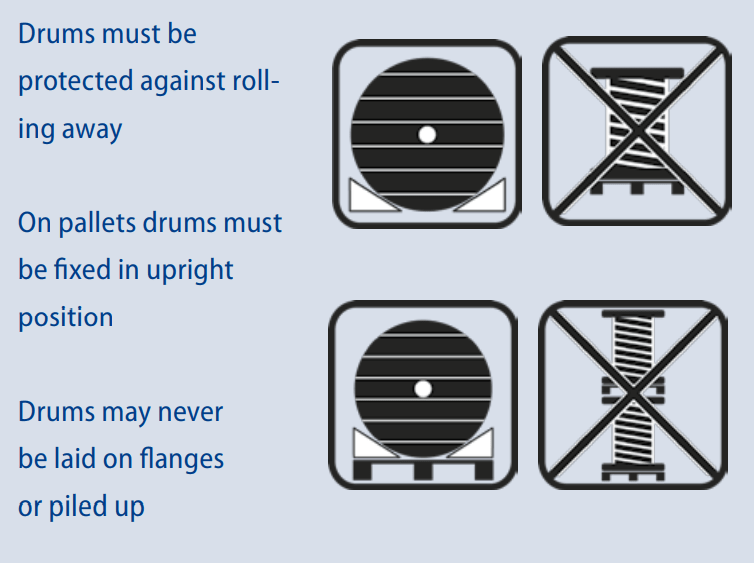

Drums must be protected against rolling away. On pallets drums must be fixed in upright position. Drums may never be laid on flanges or piled up.

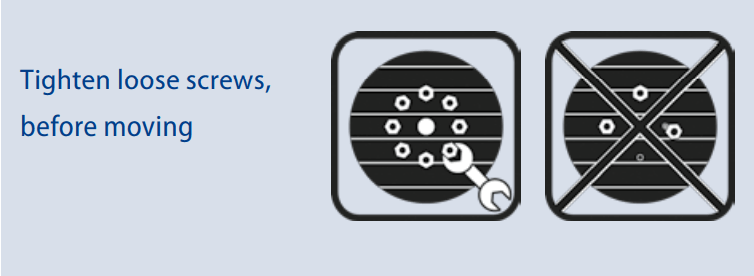

- All screws holding the flanges must be checked and tightened before moving the drums.

- In case of dry and hot weather conditions screws have to be tightened as required to compensate for shrinking of wood. Tightening of screws shall be done with a torque wrench. The force shall be as mentioned on the drum or as follows:

| Drum Size | Force |

| 700–1400 mm | 80 Nm |

| 1600–2200 mm | 100 Nm |

| 2500–2800 mm | 120 Nm |

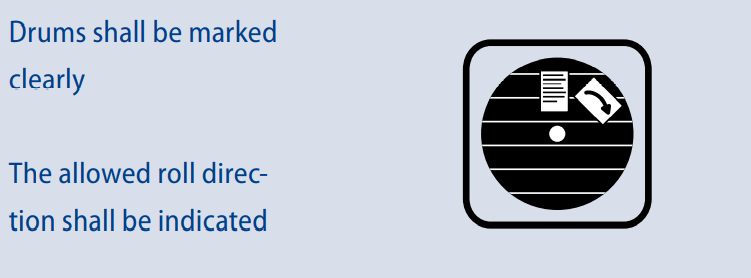

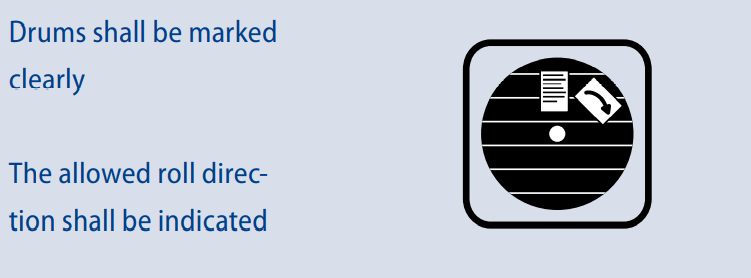

- Drums with cables may only be rolled over short distances and on a firm and even surface in the direction which is indicated on the drum (label with arrow and inscription “Roll This Way”).

- Each drum is identified by an unique drum number. In case a cable or part of it is rewound onto another drum, it is recommended to note the original drum number, otherwise backtracking is impossible.

- Drums must be labelled to allow easy and quick identification of the cable:

– identification labels showing cable type, length, code no., etc.

– other markings.

- The maximum temperature for transportation is indicated in the data sheet, section “Transport and Storage”.

- Due to interdicted stress during transportation, nails used to fix the two layers of a flange might be forced to shift into the inner side of a drum. Drums damaged or overstressed (e.g. dropped on a flange) needed to be checked carefully from the outside. Nails in question have to be removed by pliers before rolling or turning the drum to avoid continuous damages of outer sheath by rotating cable layers.

It is always a sign of incorrect cable handling, when hats of nails are sticking out of the inner flange of a cable drum. This movement is caused by shifts of the 2 wooden flange layers against each other under interdicted force while moving the drum.

In addition, multiple damages might occur by such a nail hat, due to unavoidable but “normal” movements of a cable on a cable drum while being un-drumed.

Cable Rollers

Cable Drum Storage

Cable drums shall be stored safely. Improper storage conditions can easily cause damage to cable drums or cables themselves. Therefore some base guidelines shall be followed.

The cable itself must always be protected and may not be touched improperly during transport and storage.

Check drums before moving. Check for nails, which might have shifted out of the inner side of the flange. Remove it from the surface before rolling or moving the drum.

A damaged drum must be checked. Special procedures may by necessary, like rewinding on a new drum.

If a wooden drum is handled and/or stored properly as described in this document LEONI Kerpen GmbH gives warranty for stability and usability for a period of up to 18 months after delivery. In case wooden drums show signs of damage from handling and/or storage any warranty obligation given for cable drums and any subsequent cable problems resulting from it are null and void.

Beside the general guidelines, please refer to the cable data sheet for additional information regarding temperature range and possible special requirements for transport and storage.

- Cables for indoor use shall be stored indoor.

- Cables for outdoor use may be stored outside. Their allowed temperature range for storage should cover the conditions defined for storage. See cable data sheet, section “Transport and Storage”, for any details.

- All cables on drums shall be protected with suitable protection package, such as black plastic sheeting, lagging, etc.

- Cables (especially with black sheath) exposed to direct sunlight will become warmer than the ambient temperature. It must be ensured that the temperature of the cable will not exceed the allowed maximum temperature for storage. See cable data sheet, section “Transport and Storage”, for any details.

To avoid direct exposure to sunlight the cable shall be protected with suitable package, such as a dark foil, and/or by storage in shadow.

- Cable ends must be fixed on the drum to avoid getting loose during transport, handling or storage.

- Cable ends shall be sealed with caps against ingress of water.

- Drums must be labelled to allow easy and quick identification of the cable and of main handling issues:

– identification labels showing cable type, length, code no., etc.

– a label to indicate the allowed roll direction (“Roll This Way”)

- Drums must be handled and stored always in upright position, standing on the flanges. The ground must be firm, even, well-drained and stable, so that the flanges cannot sink in. Pressure on flanges must be equal on complete flange surface in contact with ground.

- Drums must be protected against rolling away while stored.

- The drums shall not be standing in direct contact with water or damp soil to avoid rotting of the drum.

- Drums may never be transported or stored lying on a flange. Damages to cable or drum are likely in this case. Lying and handling horizontally is only acceptable for small drums and light weight cables.

- Cables shall be stored in areas without influence of high heat or close to (open) fires. Areas where chemicals, petrol, etc. could be spilled over them must be avoided.

- If stored in a secure and suitable area, periodical inspections of the drums are recommended, at least quarterly. In case of direct exposure to weather, sunlight, etc. the interval between inspections should be shortened.

- Damaged drums must be checked carefully. It might be necessary to take special care during transport or installation or to rewind the cable on another drum.

Further Reading

Cable Drum Handling | Halogen Free Shipboard Cables Recommendations

HV Cables | Underground Cable Tunnel Pull 400kV By ABB

Cable Drum Handling | Jack Towers for LV to EHV Power Cable Lifting & Site Handling

Cable Drum Handling & Laying Cables | A Guide from Nexans

Cable Pulling | 37km Offshore Cable to Connect NnG to Onshore Substation

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct | Cable Grips

Cable Management | How To Protect Outdoor Electrical Cables

July 23rd, 2021

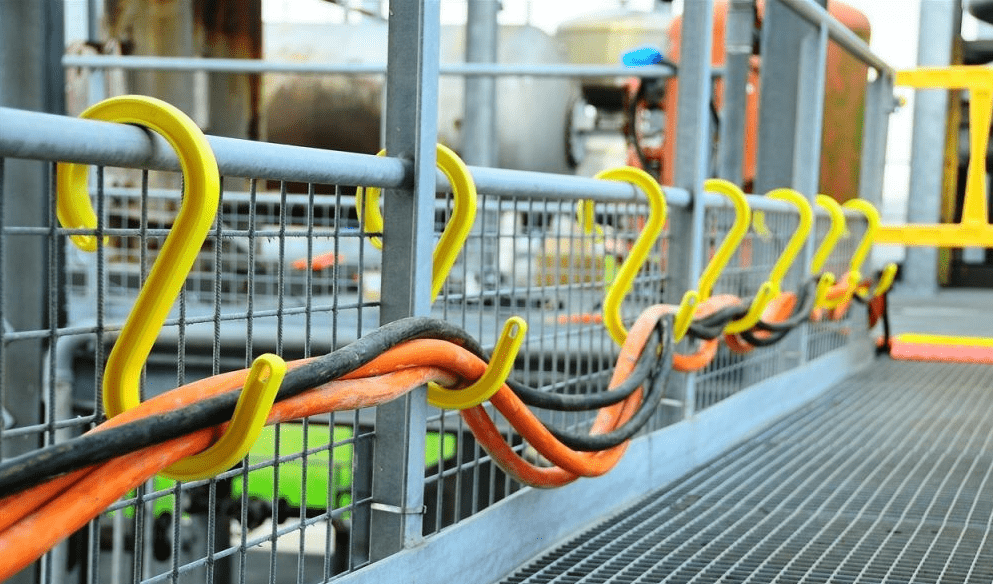

Cablesafe Cable Hooks

Cable Management & Cable Protection

Usage of safe electric cables and electrical safety outdoors is as significant as it is indoors. Cables are protected so that they are able to sustain in detrimental conditions and outdoor environment. Protection is primarily needed from external influences like mechanical damage, temperature, water and other such factors. Nonetheless, the electric cables should be protected in such a way that it allows continued passage of electricity.

Assurance of a safe working environment requires strong and durable protection against any electrical hazards, and to achieve it cables must be able to handle voltage safely and insulation must be tough enough for the environment. Furthermore, the connections must be reliable and cable covers can be used to provide protection against external environmental factors.

Cable Management | How To Protect Outdoor Electrical Cables

In working environments, the cables run across the path of vehicles and pedestrians increasing the risk factor. To prevent accidents, cable and hose protectors can be used which are suitable for all type of industries including construction sites and traffic signals.

In large work areas where heavy machinery and tools are used, loose cables can create a trip hazard and cause fatalities or injuries. Moreover, loose wires may lay across in the way of machines, making itself more prone to damage and accident. Highlighting the trailing cables with anti-slip marking tape and floor stands will minimize trip hazards on worksite, and loose wires can be protected using cable protectors which offer defence against damage from vehicles and pedestrians. Heavy duty cable protectors and cable ramps are ideal for high walking-traffic in high traffic areas like warehouses, construction sites, markets, etc. These durable cable covers allows traffic to pass over without imposing any considerable damage to cables.

Cable Management | How To Protect Outdoor Electrical Cables

Cable ramps are easy to use and possess a convenient button-down lid to insert and remove the cables easily. Hence, these industrial cable covers and cable ramps are used extensively in commercial and industrial settings, as they minimize trip hazards and protect electrical cables.

Cable management is an imperative component to ensure the protection of electrical cables because it helps to maintain basic functionality and promotes safe working conditions.

Cable management systems like cable trays and reels form a rigid structure to support and protect the electrical cables against insulation damage, cable damage, crosstalk and overheating.

Cable protection high quality systems like conduit system and trunking system can be used for complex configurations, making it capable to securely carry different types of cables at a time. In order to reduce the safety risk, the electrical cables can be protected using heavy duty cable ties and nylon cable ties (or cable cleats) which is an effective way to organize and manage the electrical cables. Conclusively, it is highly significant to protect the electrical cables effectively, otherwise these cables can cause harm and pose a serious safety risk.

Cable Management | Cable Cleats, Cable Clamps, Cable Hangers, Cable Ties

Stokbord Drum Cable Protection for Underground Utility Cables

CABLE SAFETY HOOKS & EQUIPMENT

OSHA maintains general industry regulations on walking and working surfaces that guard workers against hazards and the risk of injury including clutter, protruding objects and wet conditions. These Health & Safety hazards can harm everyone in a facility, regardless of title or job responsibilities.

Slips, trips, and falls cause nearly 700 fatalities per year and many more injurious accident in the workplace according to the Bureau of Labor Statistics. The CableSafe range of products ensure all cables, wires and hoses are suspended off the ground especially in high traffic work areas such as production floors, machinery spaces and deck level areas where maintenance is being carried out.

CableSafe Safety solutions are critical cable essentials and are well proved construction safety products.

Cable Safety Equipment | Cable Stand | Cable Bridge | Cable Rail | Cable Guard | Dropped Object Prevention Mats

FURTHER READING

- UKPN Cable Protection Tapes & Covers (LV MV HV)

- ENA-TS 12-23 : Cable Tiles & Cable Covers For Use With LV 11kV 33kV & HV Cables

- Stokbord Drum | Cable Protection for Underground Utility Cables

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Cubis Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.