Jointers Blogs

Cable Jointing – An Art or Science?

March 26th, 2021Both.

Whether lashing in a Straight 6 resin joint to power a domestic shower or jointing 110kV cables to energise Brisbane, the cable jointer must concentrate during all stages of cable stripping, measurement and joint installation.

Make an error with your measure, flirt with failure.

Of course cable failures keep cable jointers busy.

But self-inflicted cable failures caused by bad jointing and the “jointer” will soon be hanging up his crimper.

Quick joke. What’s the difference between a Jointer and a Doctor? A Doctor buries his mistakes – a jointer digs his up! Tumbleweed rolls through Blog.

Cable failures caused by poor jointing are costly.

Reputation damage plus consequential losses incurred by a power cut then multiplied by cost of the supply restoration as a formula is simply incalculable.

However, the ability to understand and apply complex mathematical formulae is a required staple of an EHV jointers skill-set.

Andrew Brezovsky is amongst many other things an EHV jointing legend and social media megastar. I suggest you Connect with Andrew on LinkedIn now – but don’t forget to hit the back button and rejoin us for a lesson in advanced cable jointing.

Cable Jointing Science

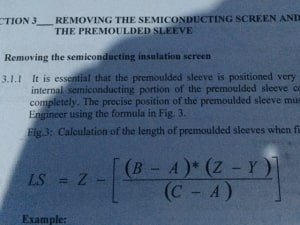

In todays lesson, Andrew considers the importance of the theoretical formula and the practical skill required in calculating and installing premoulded sleeves when jointing 110kV cable.

Removing the semi-conducting screen and installing the premoulded cable joint sleeve is a critical stage of jointing 110kV cables.

“So the calculation of the length of the premoulded sleeves when fitted is relying on the length of the mould, inner bore diameter of the tube, insulation diameter and the inner bore of the mould,” says Andrew.

Therefore, referring to the featured image above the calculation for the length of the premoulded sleeves is as follows:

- LS = length of cable joint mould when landed

- Z = overall length of mould as supplied

- A = inner bore diameter

- C = diameter of PVC tube

- Y = diameter of sleeve on PVC tube

- B = cable insulation diameter

Cable Jointing Art

“Here are a few shots from the mould loading process. The mould is being forced onto that PVC tube with the machine and silicone oil used as cable lubricant. The landing position is calculated individually for every cable joint to the point of a millimetre. You have to be good with your maths as the formula as you now know is complicated,” informs Andrew.

Images by EHV Cable Jointer : Andrew Brezovszky (EHV Cable Jointer – Energex Australia).

Images by EHV Cable Jointer : Andrew Brezovszky (EHV Cable Jointer – Energex Australia).

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

3M QS1000 Joint & 3M QTIII Termination – 11kV Triplex Cold Shrink Joints & Terminations

March 26th, 2021Images Courtesy of: Danny Williamson (LV HV Cable Jointer).

Danny is pictured below, jointing and terminating 11kV Triplex cables into medium voltage Schneider Ringmaster RN2c (RMU).

Schneider Ringmaster is a compact highly reliable solution for both indoor and outdoor MV distribution networks up to 13.8kV.

The 11kV joints and terminations were completed using Northern Power Grid (NPG) specification 3M QS1000 and 3M QTIII Cold Shrink kits – terminations include Sicame mechanical shearbolt cable lugs.

Alroc cable strippers are pictured removing the red XLPE cable outer sheath which is the stage before the HV jointer must bend back the copper screen wires and remove the bonded semi-con layer.

Danny is also Pfisterer Connex size 1,2,3 3/S 3XL trained and authorised for live LV cable jointing on GTC networks and we look forward to featuring more examples of his work soon.

➡ Should you wish to feature and showcase your cable jointing skills on our Photoblog simply submit images with accompanying description to [email protected].

Good Housekeeping, Best Cable Jointing

“Some people tend to forget to treat all cables with same respect, whether they’re 11kV or 400kV. Any cable jointing area should be clean, neat and tidy – cable jointing tools handy and kept clean. Cables off the floor, away from dirt, dust etc. Danny Williamson has done that, he even has a tarpaulin over his head, sometimes you can only cook with what you’ve got, he has made an effort which is absolutely commendable,” commends Andrew Brezovszky.

3M QS1000 Cable Joint – 11kV. Cold Shrink tubes parked up the cable in the trench as the jointer uses connector holding tools to steady the mechanical connector as the shear-off bolts are installed. Copper wire screens secured with constant force springs are over-wrapped with 3M tape.

NPG specification Tapetile Cable Tile awaits roll-out to provide effective protection to the underground 11kV power cables.

Jointing Tools. Perfect 11kV cable preparation using appropriate cable jointing tools. Cold Shrinking. The inner spiral from the 3M QTIII cable termination is unwound and the Cold Shrink tube with in-built stress control collapses onto the 11kV cable. Cold shrink jointing technology has virtually replaced heat-shrink material on UK DNO 11kV-33kV networks.

Cold Shrinking. The inner spiral from the 3M QTIII cable termination is unwound and the Cold Shrink tube with in-built stress control collapses onto the 11kV cable. Cold shrink jointing technology has virtually replaced heat-shrink material on UK DNO 11kV-33kV networks.

Connecting the 3M QTIII cable terminations onto the 11kV RMU bushings.

3M QTIII Cold Shrink Terminations Complete – 3M 92EE717 type universal bushing boots insulate the termination and protect against flashover. Copper wire screen entwined, identified with PVC insulation tape and bonded to earth stud. Heat shrink cable glands used to provide mechanical retention to the 11kV cables.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Extraordinary Fibre Earth Wire Pull

March 26th, 2021

Image courtesy of: Paul Everett MIET – Owner/Operator at UNS Limited.

Pictured: Extraordinary Fibre Earth Wire Pull

“Fibre earth wire pull completed today in Suffolk over 11 tower spans.”

Terminal tower in 132kV compound. Crossing over 2 x dual carriageways, 1 x 25kV electrified railway, 1 x 33kV overhead line, 3 x 11kV overhead lines, 1 x minor road.”

Included 1 x catenary system launch and 10 scaffold sides with 3 nets. “1 portable generation set connection, 1 x 11kV outage to create network mods and a further 11kV outage on day.” Paul Everett.

LOW, MEDIUM & HIGH VOLTAGE CABLES

LV MV HV PULLING & JOINTING EQUIPMENT

T&D supply UK and international contractors responsible for Low & High Voltage Power Cabling, Pulling, Jointing & Civil Engineering with cable duct, duct seals, lubricant, cable covers and tape tiles specified for 11kV/33kV installations.

PRODUCT OVERVIEW

| Cable Rollers | Cable Socks |

| Cable Drum Jacks | Cable Drum Trailers |

| Cable Winches | Conduit Rods |

| Cable Lubricants | Cable Blowing Equipment |

| Cable Protection – Tapetile 11kV | Stokbord 33kV | Cable Duct – Power, Fibre, Telecoms |

| Joints, Terminations & Connectors MV HV | Cable Duct Seals |

| Cables MV HV 11kV 33kV | Cable Jointing Tools |

Further Reading

11kV Cable Pulling – What Is The Maximum Distance For Ease of HV Cable Pulling Between Manholes

MULETAPE CALCULATOR | How To Select The Right Cable Pulling Tape For The Job

Cable Pulling For Alith Project 110kV XLPE Power Cable

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Cleating 11kV 3 Core & Single Core Cables With LV Pilot Cables

March 16th, 2021

Cable Cleats

Image Courtesy Of: Sam Rowe – Estimator at F B Taylor (Cable Contractors) Ltd

These 11kV cables have been pulled in and cleated using stainless steel trefoil and 2 bolt nylon cable cleats to ladder racking.

Cable cleats are used to fix, clamp and support cables – cleats provide effective short circuit protection, support and retention to LV, MV and HV power cable systems when installed at intervals to circuits to secure electrical installations.

The cable cleats provide restraint and prevent excessive cable movement resultant from fault-current magnetic forces – cleats must be suitably rated for cable size (outside diameter) and anticipated fault current (peak fault level kA).

Correctly specified cable cleats will withstand the forces corresponding to the values of the peak prospective short-circuit current.

Power cable system designers, engineers and specifiers must consider the correct cable fixing or securing system to provide safe and adequate restraint and protection of LV, MV or HV cables – cable cleats restrain movement of cables during electrical fault conditions.

Cable cleats are available to suit all environmental conditions (onshore and offshore), industrial applications and operating voltages – specialist cable fixings for fire resistant, low smoke zero halogen (LSF LSOH) and quadrafoil (Quad) cable installations.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Switchboard Building – 2 x 2500A Switchboards With Generator ACB & B/C

March 16th, 2021

Image Courtesy of: Daniel Probert – Senior Electrical Engineer at Johnson & Phillips (Capacitors) Ltd.

Johnson & Phillips (Capacitors) Ltd are market-leading providers of LV – HV Power Engineering Services throughout the UK and internationally. They offer services such as cable jointing, retrofitting, switchgear systems to 8500A, transformer testing, maintenance and repairs.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.