Blog

Cable Laying & Pulling – Installing LV-HV Cables Into Trench

April 29th, 2021

Thorne & Derrick | Cable Laying & Pulling Equipment Distributors | LV MV HV

-

Uploaded By Chris Dodds – Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick | Specialist Distributors of Cable Pulling Equipment | LV MV HV up to 400kV

Today, in Part 2 of a 2 part series covering Cable Pulling & Laying Equipment, Thorne & Derrick look at the equipment requirements and preparation for cable pulling when installing cables into cable trench. In Part 1, we discussed the procedures and equipment requirements for cable pulling and laying into ducts.

Cable Pulling Equipment & Preparation

Trench

In Part 2 of our series of articles about Cable Laying & Pulling Equipment, we look at the equipment and process requirements for pulling and laying cables in an open trench.

Open trench cable laying is often used as opposed to laying cables directly into cable ducts. This method of laying cables into the ground tends to be used where the cables in use are of a higher voltage (MV HV Cables) and therefore have a greater outside cable diameter.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

The Preparation Of The Cable Trench

Prior to the cable being laid, the cable trench must be dug and prepared properly.

This means that the trench must be of adequate size to allow for the cables and ducting required.

Different cables will require different sized cable trenches – the higher the cable voltage, the bigger the cable and therefore the bigger the cable trench required.

The trench width and depth also depends on the where the cable trench is being dug. For instance, a cable being laid underneath a public footway will not be laid as deep as one under arable land that is to be ploughed.

When a trench is to be dug, it should be sufficient to allow the installer to install the cables and ducting at the correct depth for the cable being used.

It should also allow the cables to be installed within the bending radii specified.

The cable should be installed within the specified pulling dimensions and without damaging the cable sheaths.

When laying a cable into an open trench, there are 8 key components within the typical equipment layout used excluding the trench and the cable.

- Cable Winch – the cable winch is situated at the end of cable trench and is designed to be simple and robust. The winch provides smooth and controlled pulling of the cables through the trench. It is the cable pulling winch that provides the actual pulling of the cable. There is a number of different cable winches available dependant on the type of cable being pulled. Winches vary between telecommunications, power cables and lightweight cabling.

- Winch Wire Rope – the winch wire rope is attached to the cable in order for it to be pulled through. The wire rope gives extra strength and allows for heavier cables to be pulled through. In addition, the use of the winch wire prevents any potential damage being caused to the cable sheath.

- Swivel Link – the swivel link provides the connection between the cable and the winch wire rope. Each swivel link is designed and used to allow the wire to rotate when being pulled and avoid kinking or twisting. The extra layer of protection provided by the swivel link means damage to the cable sheath is reduced even further.

- Cable Socks – cable socks or stockings are available in either stainless steel or Kevlar but are traditionally constructed of high tensile, galvanised steel wire. Often called cable socks or grips, these are another level of protection between the cable and the cable winch. Fitted to the end of the cable, they are attached to the swivel link and avoid direct contact with the cable. All pilot and telephone, LV, 11kV, 20kV, 33kV, 66kV and 132kV cables should be normally pulled in using a correctly sized cable sock which is securely fixed to the LV-HV cable. More complex cable pulls may require the use of a cable pulling eye attached directly to the cable conductors.

- Straight Cable Rollers – the straight line rollers are, as the name suggests, for use in the straight part of the trench. Varying in size and weight, the straight rollers are selected by the size of the trench they are to be used in. The rollers enable to the cable to be pulled through without making contact with the base of the trench which would damage the cable outer sheath. Full range of cable trench rollers are available – cable pullers should check that cable rollers are in serviceable condition moving easily on their spindle and with rolling surfaces free from damage. Leading cable rollers are usually placed at the cable trench side at the cable pulling end with slide rollers on bends and “hoop” type rollers along straight cable section runs. Contractors can use inverted skid plates shall be used to prevent the cable or pulling wire rising into obstructions. At cable duct entries a bell mouth should be attached at end end with cable rollers positioned to give central access into the bell mouth.

- Corner Rollers – Angled corner rollers are to be used within the trench where there is a bend in the trench. Typically these incorporate a vertical and horizontal roller to allow for the pulling of the cable. Providing the same level or protection as the straight rollers they are both used alongside each other.

- Draw Off Roller – the draw off roller is the first piece of equipment the cable will come into contact with. When the cable is pulled through the open trench, the draw off roller leads the cable straight from the drum into the trench. The cable is then pulled through the trench with the draw roller acting as an initial guide for the cable.

- Cable Drum Trailer – the cable drum trailer is used to transport the cable drum. In addition the trailer is also used to stabilise the cable drum whilst the cable is being pulled through the trench.

Duct rods provide a strong, lightweight, labour saving solution for installing cables into ducts or pipes with or without draw ropes.

Cable Protection

Installation Of Cable Trench Covers & Cable Protection Tiles

All cables and ducts laid into cable trrench should be over-protected by a cable protection cover or tape depending upon the highest voltage cable to be protected within the cable duct – typically in the UK the following cable protection tapes and covers are used for LV, MV and HV cables.

Marker tile tapes or Stokbord covers are installed over the cable in the appropriate trench drawings – usually there is no requirement to install either above approved cable ducts installed using trenchless techniques (i.e. directional drill) but either may be installed if it is deemed that additional MV-HV cable protection is required. When Tile Tape is used it should be cut cleanly and installed so that the medium/high voltage cable is fully covered along the whole length of the installed cable duct.

- LV Service Cable 40m x 200mm x 2.5mm Tile Tape

- LV Mains Cable 40m x 200mm x 2.5mm Tile Tape

- 11kV MV Cables 40m x 200mm x 2.5mm Tile Tape

- 22kV MV Cables 40m x 200mm x 2.5mm Tile Tape

- 33kV MV Cables 1000mm x 244mm x 9mm Stokbord

- 66kV MV Cables 1000mm x 244mm x 9mm Stokbord

- 132kV MV Cables 1000mm x 244mm x 9mm Stokbord

More info ➡ Tile Tape | Stokbord

Duct Seals

Where electricity, pilot and telephone cables are installed into electricity cable ducts the utility engineering standard would normally recommend all cable ducts entering substations and buildings to be duct sealed to prevent the ingress of water and gas – this also applies to 33kV, 66kV and 132kV high voltage substation cables where cable transits are required.

Thorne & Derrick distribute an extensive range of Duct Sealing & Cable Transit Systems to protect utility assets and provide flood protection to substations from water entry via unsealed cable ducts and building penetrations.

Cable Pulling & Cable Laying Equipment Suppliers & Distributors

Thorne & Derrick International distribute the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct – products also supplied for fibre optic blowing, subsea trenching, offshore umbilical installations and pulling armoured cables onto cable tray.

Cable Blowers | Cable Lubricant | Duct Rods | Cable Socks | Cable Jacks | Cable Rollers | Cable Protection Covers MV HV | Cable Joints MV HV | Duct Sealing

Cable Laying & Pulling – Installing LV-HV Cables Into Duct

April 29th, 2021

Thorne & Derrick | Cable Laying & Pulling Equipment Distributors | LV MV HV

-

Uploaded By Chris Dodds – Thorne & Derrick Sales & Marketing Manager

Today, in Part 1 of a 2 part series covering Cable Pulling & Laying Equipment, Thorne & Derrick look at the equipment requirements and preparation for cable pulling when installing cables into ducts. In Part 2, we discuss the requirements for cable pulling and laying into cable trench.

Cable Pulling Equipment

& Preparation Duct

Cables installed into cable ducts are typically used on projects where the cable duct is buried deep into the ground, sometimes up to 1200mm depth – this includes LV Low Voltage, MV Medium Voltage or HV High Voltage ducted power cables.

Guidelines for the minimum depths for the installation of underground cables are stipulated by the DNO depending on whether cables are laid direct into cable trench or installed in suitable cable ducts depending on ground location types:

- Footways, Grass Verges Or Private Property

- Carriageways (including Road Crossings)

- Normal Agricultural Land

Arrangement of the cable trench will depend upon the cable voltages typically LV, 11kV, 20kV, 33kV, 66kV and 132kV.

LV cables could include Service Cables (Single Phase Concentric | 3 Phase Concentric | Split Concentric) and Mains Cables (3 Phase Waveform).

Auxiliary multi-core and multi-pair cables are usually laid at similar depths to the power cable with which they are associated. Pilot and telephone cables installed alongside 11kV and 33kV cable circuits shall normally be installed at LV cable minimum depths of cover.

So for instance, the installation of 33kV power cables into class 1 cable duct is usually covered in the local DNO’s Approved Equipment Register, Guidelines or Excavation and Cable Installation Manual. Additionally, engineering construction standards provided by UK DNO’s will cover the installation of new LV, 11kV, 20kV, 33kV, 66kV and 132kV cables, plus associated pilot and telephone cables.

For the protection of LV MV HV cables Thorne & Derrick distribute a complete range of underground protective cable ducting

Prior To Cable Pulling

Due to the nature of the cables that are often installed in these applications, there are a number of checks that must be carried out prior to beginning the cable pull:

- The cable duct lines must be checked for any obstructions and anything that is found must be removed. This is often done with the use of duct brushes or ‘foam pigs’ which are pulled through the duct.

- It is essential to ensure that the cable duct is of adequate size to accommodate the cable due to be pulled. This is done by pulling through a 3 metre length of cable through the duct which is subsequently checked for damage prior to the full cable being installed.

- If, during these checks, the 3 metre length of cable has any damage greater than half the depth of the outer sheath the duct route must be repaired before the full length cable is pulled through. This protects the integrity of the final cable.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

There are a number of items of cable pulling equipment to be used when installing cables into duct lines. Cables can vary in size and voltage, however the same process and equipment is used. When installing cables, there is typically up to 9 different pieces of equipment used.

- Cable Winch – the cable winch is used for physically pulling the cable through the duct, reducing the need for manpower and increasing productivity. Electrically powered, the cable winch is much safer and reliable than manually pulling cables through.

- Rope Guide Roller – the rope guide roller is exactly as the name suggests – a roller to guide the draw ropes or cabling ropes that are coming out of the jointboxes or manhole. This is to reduce the damage and strain put on the ropes therefore prolonging the lifespan of the equipment used. The rope guide roller is made from an aluminium roller mounted onto a frame that has been plated with zinc.

- Cable Bellmouth – the duct bellmouth is used as a means of providing additional protection to the cable when it is being pulled through the duct. The rollers on the bellmouth ensure that the cable can be pulled in any required direction without any damage being caused. The bellmouth is located at the exit of the cable duct through which the cable is being pulled.

- Cable Drum Trailer Or Cable Jacks – the cable drum trailers and cable jacks are used as a means of storing and transporting cable drums. Cable drums are large wooden wheels which are used to hold cable. Cable drum trailers make the transportation of extremely heavy cable drums easier, safer and more reliable. Often equipped with braking and road lighting, the cable drum trailers are attached to the back of an appropriate vehicle such as a tractor to assist in the transportation of cables. Cable jacks are used as a means of supporting and stabilising the cable drums. Cable drums are located at the edge of the manhole cover or opening when installing cable into underground ducts for the cable to be easily rolled off.

- Swivel Link – the swivel link is zinc plated, solid steel link that is attached to the winch rope. This link can, as the name suggests, swivel a full 360° allowing the rope to be pulled through without any twists occurring.

- Conduit Rod – the conduit rod is fed through the manhole cover opening and is used to install draw or winch ropes. The rod is manually fed through the underground duct and is extremely easy to handle. The conduit rod comes with a range of accessories available such as flexible guide tips, end connectors and rod repair kits.

- Cable Socks – cable socks or stockings can also be called cable socks or grips. These cable socks are used to support the pulling of cables through a duct. Attached to the end of a cable prior to pulling, the cable stocking is an efficient method of support when pulling the cable

- Manhole Roller – the manhole roller is specifically designed to be placed at the entrance of the manhole to assist in the guiding of the cable. Not only does the roller make the cable installation easier, it also protects the cable from being scraped on the edge of the manhole. The manhole roller is constructed of a steel frame and aluminium rollers. Complete range of cable rollers are available also for cable trench applications.

- Cable Lubricant – cable lubricant is applied to the outside of the cables when being pulled through the duct. The lubricant assists in the pulling process by removing friction between the cable and the rollers. This not only speeds up the process but also prevents snagging and therefore damage to the cable.

Pictured: Cable Laying & Pulling Equipment – Ducts

Duct rods provide a strong, lightweight, labour saving solution for installing cables into ducts or pipes with or without draw ropes.

Cable Protection

All cables and ducts should be over-protected by a cable protection cover or tape depending upon the highest voltage cable to be protected within the cable duct – typically in the UK the following cable protection tapes and covers are used for LV, MV and HV cables:

- LV Service Cable 40m x 200mm x 2.5mm Tile Tape

- LV Mains Cable 40m x 200mm x 2.5mm Tile Tape

- 11kV MV Cables 40m x 200mm x 2.5mm Tile Tape

- 22kV MV Cables 40m x 200mm x 2.5mm Tile Tape

- 33kV MV Cables 1000mm x 244mm x 9mm Stokbord

- 66kV MV Cables 1000mm x 244mm x 9mm Stokbord

- 132kV MV Cables 1000mm x 244mm x 9mm Stokbord

More info ➡ Tile Tape | Stokbord

Duct Seals

Where electricity, pilot and telephone cables are installed into electricity cable ducts the utility engineering standard would normally recommend all cable ducts entering substations and buildings to be duct sealed to prevent the ingress of water and gas – this also applies to 33kV, 66kV and 132kV high voltage substation cables where cable transits are required.

Thorne & Derrick distribute an extensive range of Duct Sealing & Cable Transit Systems to protect utility assets and provide flood protection to substations from water entry via unsealed cable ducts and building penetrations.

Cable Pulling & Cable Laying Equipment Suppliers & Distributors

Thorne & Derrick International distribute the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct – products also supplied for fibre optic blowing, subsea trenching, offshore umbilical installations and pulling armoured cables onto cable tray.

Cable Blowers | Cable Lubricant | Duct Rods | Cable Socks | Cable Jacks | Cable Rollers | Cable Protection Covers MV HV | Cable Joints MV HV | Duct Sealing

11kV Sweated Ferrule With Crepe Paper Insulation & Lead Sleeve

April 28th, 2021Image Courtesy of: Dean Wilson (Owner Director at D.C. Jointing Ltd).

D.C. Jointing Ltd are Specialist Electrical Cable Jointers – a team of 15 skilled staff in all aspects of offshore and onshore cable jointing up to 132kV.

D.C. Jointing Ltd secured a prestigious 3 year Medium & High Voltage Cabling 11kV-66kV contract with WPD, a UK DNO, for the installation of 3M Cold Shrink Joints and Terminations – the awarded contract exemplifies the impressive reputation for quality workmanship provided by DCJ to UK DNO’s, IDNO’s and private networks.

The HV cable jointing success for D.C. Jointing demonstrates their versatile competency at jointing modern technology polymeric cables while also retaining “old-school” 11kV jointing expertise as evidenced in the featured photograph.

Location : Wimbledon, London UK

Date : 2003

11kV Sweated Ferrule With Crepe Paper Insulation & Lead Sleeve

Further Reading

- Pfisterer Connex Size 4 Terminations Connecting 66kV Gas Cable

- Transition Joint EHV – Oil To XLPE NKT Cable Joint

- Pfisterer Inner Cone Plugs Size 5s Connecting & Terminating 132kV EHV Cable

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Coning Time – 110kV Pfisterer Ixosil ESS123 Outdoor EHV Cable Termination + Video

April 28th, 2021Richie Rice, is a master craftsman and leading Pfisterer EHV Jointer with an incredible track record, reputation and skill-set.

“I have a wealth of experience in the EHV Extra High Voltage Cable Jointing Sector and have worked on XLPE, HVDC Light XLPE, Oil/Gas Filled Cable Systems from Jointing & Terminating to VLF/ Sheath Testing. I am certified from some of Europe’s Leading Manufacturers of GIS/ODSE Cable Terminations & Straight / Sectionalised / Cross Bonded Cable Joints up to 275kV,” comments Richie.

Thorne & Derrick are Main Distributors & Stockists for the Pfisterer range of Medium Voltage Power Products including Connex Plugs, Cable Jointing Tools, Sicon Connectors, Surge Arresters and Electrical Safety Equipment.

Image Courtesy : Richie Rice

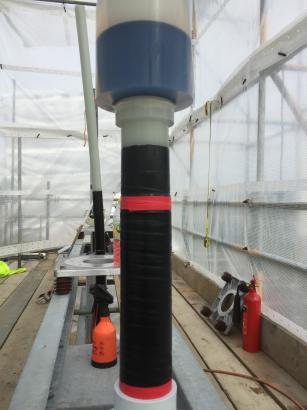

Rather than “glassing” the semi-con screen the cable jointer used an Alroc Chamfering tool and then sanded to achieve the perfect transition. The red tape locates the bench mark for the resting position of the cone. Pfisterer Sicon type shearbolt top connectors are incorporated into top plate.

Pictured : Pfisterer Sicon Cable Lug

Pictured : Pfisterer Ixosil Cable Termination

- Richie Rice – EHV Jointer, Project Portfolio

1. Bruckanna Windfarm (Templetuohy Co Tipperary)

Cable Jointing/Terminating & Testing on 20kV Collector System for 14no Siemens 3MW WTGs

2. Killhill Windfarm (Cashel Co Tipperary)

Cable Jointing/Terminating & VLF Testing on 33kV Collector System for 16no Enercon 2.3MW WECs

3. Mountlucas Windfarm (Daingean Co Offally)

Cable Jointing /Terminating & Testing on 20kV Collector System on 84MW Windfarm 28no Siemens 3MW WTGs

4. Monanicha Windfarm (Roscrea Co Tipperary)

Cable Jointing/Terminating & VLF Testing on 20kV Collector System on 36MW Windfarm 15no Nordex 2.4MW WTGs

5. West of Duddon Sands 155kV Export Circuits (NKT Denmark)

Omega Jointing & GIS Terminations for 108 WTG Project

6. London Array Offshore Windfarm (Tyco)

Cable Terminating & Testing on 33kV Collector Circuits on Worlds Largest Windfarm

Pfisterer Ixosil ESS Cable Termination

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Euromold by Nexans | 11kV Cable Terminations (WPD UK DNO Approved)

April 28th, 2021Images courtesy of: PWR-X Cable Jointing Specialists – Manchester, UK

Pictured: 11kV Nexans Euromold Terminations

DNO: WPD

The cable jointing team at PWR-X recently completed two sets of terminations to help meet a clients outage. “We always go the extra mile to meet our clients demands. Whilst ensuring our works is carried out to the highest standards!”

nexans euromold

Thorne & Derrick are Main Distributors for the complete range of Nexans Euromold Connectors, Joints and Terminations for medium voltage cables utilising EPDM rubber, cold-shrink, push-on and heat shrink technologies. We distribute from stock and provide expert technical support for the Euromold range of Separable Connectors – the European manufactured connectors are manufactured from high quality EPDM rubber and include elbow, straight and tee connectors supplemented by a complete range of 11kV-33kV bushings.

Separable connectors are typically used to terminate cables on power systems and circuits distributing MV-HV electricity at 6.6kV, 11kV, 33kV and 66kV.

Nexans Euromold are the leading European manufacturer of Medium & High Voltage Cable Connectors & Accessories for MV-HV energy and electricity distribution – providing an underground cable accessory range including premoulded EPDM rubber separable connectors for cables and Euromold epoxy bushings for cable termination into gas insulated electrical equipment transformers and switchgear.

Euromold connectors can be “piggy-backed” to allow for multiple stacked cable connections per phase – ATEX certified cable connectors are available to safely terminate and connect MV-HV cables into electrical equipment situated in potentially explosive atmospheres including Zone 1 and Zone hazardous areas.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.