Blog

How To Repair Damaged Armoured Power Cables

October 1st, 2018-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cable Repair Kits | LV Low Voltage | Heat Shrink Wraparound Kits By 3M

The following damaged cables were identified in a works rectification report for the site subcontractor to remedy and repair – repairing damaged cables is not uncommon where often complex cable configurations and large diameter power cables must be installed or pulled onto containment or into trench under pressure from working conditions on site.

The BS5467 power cables form part of the gantry supplies to a LV cable installation of a building service project where work access was confined to a restricted corridor area.

The damaged low voltage feeder cables were classified as non-conformant by the Electrical Manager due to the sheath damage and consequent exposure of the armoured power cables to moisture or contaminants – the root cause analysis attributed “bad supervision” as the reason for the cable damage and better management of cable installation methods required to prevent reoccurrence.

The confirmed corrective action was to re-instate the cable sheath and repair the damaged cables using heat shrink cable repair kits manufactured by 3M Electrical – the versatile and reliable wraparound repair kits permit immediate repair of nicks, slits and tears to cable sheaths onsite without resort to replace or disconnect the power cable supply.

Where “hot-working” is disallowed and access to a disconnected cable circuit is feasible the tubular cold shrink repair sleeve could be used – heat shrink is a layflat design which effectively “wraps around” the damaged cable section and is then sealed and closed using the provided fixing channel and rail.

Where the inflicted cable damage has penetrated into the wires of the armoured cables we recommend you review our range of armoured cable joints.

Pictured: Damaged BS5467 XLPE Insulated, SWA Armoured Power Cables 4 Core 120sqmm Stranded Copper Conductors

LV, MV & HV CABLE JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

T&D are Specialist Distributors of products to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems – we are highly customer responsive and absolutely committed to providing a world-class service.

We provide expert technical support and supply from a multi-million pound stock holding:

| Cable Joints, Terminations & Connectors | Earthing & Lightning Protection |

| Cable Accessories, Lugs & Glands | Circuit Protection & Fuses |

| Cable Cleats & Clamps | Electrical Safety Equipment |

| Cable Pulling & Laying Equipment | Arc Flash Clothing & Protection |

| Cable Duct Seals & Transit Systems | Surge Arresters & Bushings |

Jointer Training – MV Cable Terminations & Separable Connectors (Module 1)

September 27th, 2018

MV & HV Jointer Competency Training Courses

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cable Jointer Training

Requirements, Expectations & Rewards

Thorne & Derrick, the International Distribution Partners of Nexans Power Accessories, have united to provide an industry commitment to ensuring the safe and reliable installation of MV-HV Cable Accessories – a series of 10 Training Modules are available to support the training requirements for Cable Jointers upskilling from LV to MV to HV with tailored courses at 11kV, 33kV and 66kV voltage levels.

The Modules cover MV & HV Cable Terminations, Joints & Separable Connectors.

Get Nexans Competent Not Familiar

These Jointer Training Courses are not introductory “Familiarisation” courses – each prospective candidate will be vetted prior to acceptance onto the course. If suitably qualified and experienced the candidate will be accepted onto the course – they will be required to undertake MV cable preparation and submit a test piece of cable with their cable termination, joint or separable connector installed. The submission will then be tested for AC withstand and partial discharge (PD) in the new “state-of-the-art” Nexans Test Laboratory.

Upon successful completion of the Laboratory Test the candidate will be presented with a 3 Part Certificate of Competency.

MV Cable Terminations & Separable Connectors

Module 1

The 1 day Training Course will be targeted on product application only – requiring the candidate to install the product Competently. No cable preparation training will be provided. Attendees will be expected to be able to prepare MV cables for a range of Medium Voltage Cable Accessories.

| Training Framework | Plan |

| Training Mode | Single Core XLPE Polymeric Power Cable |

| Duration | 1 Day 9am-5pm |

| Attendees | Min 2 Max 6 |

| Goals & Learning Objectives | Time Frames, Measurability, Observability. Less than 10pC @ 2Uo |

| Equipment Included | Cable, Accessories, PPE, Training Boards & Lunch |

| Equipment Requirements | Cable Prep & Jointing Tools – Steel Toe Cap Boots |

Jointer Training Schedule

| Training Schedule | Course Contents |

| Introductions | Welcome Health & Safety Training Acknowledgements – Privacy Policy PABG |

| Competency | Understanding Equipment MV Cable Construction & Cable Preparation Electrical Stress & Stress Control MV Cable Termination Failures |

| Practical | MV Cable Preparation Installation MV Cable Termination Failures |

| Testing | Equipment Testing In Shielded Room For AC Withstand & Partial Discharge (PD) |

| Conclude | Technical / Product Support 3 Part Jointer Competency Certificate, Including Test Report |

Book A Training Course

Call Thorne & Derrick to enquire about course costs, dates or to request a booking form.

- Training Centre Co-Ordinator: Martin Wigham 0191 4104292

The Jointer Training Course is carried out at:

NexansTraining Centre

Units 1 & 2 Good Hope Close,

Normanton Industrial Estate, Normanton,

West Yorkshire,

WF6 1TR

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Cables, Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and separable connectors.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Cable Terminations | Heat Shrink | Cold Shrink | Push-On | Separable Connectors | MV HV

➡ Read: Thorne & Derrick Announce Distribution Agreement & Contract With Nexans

Design Guide For Feeder Pillars & Pre-Wired Electrical Equipment

September 20th, 2018

Feeder Pillars

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Feeder Pillars

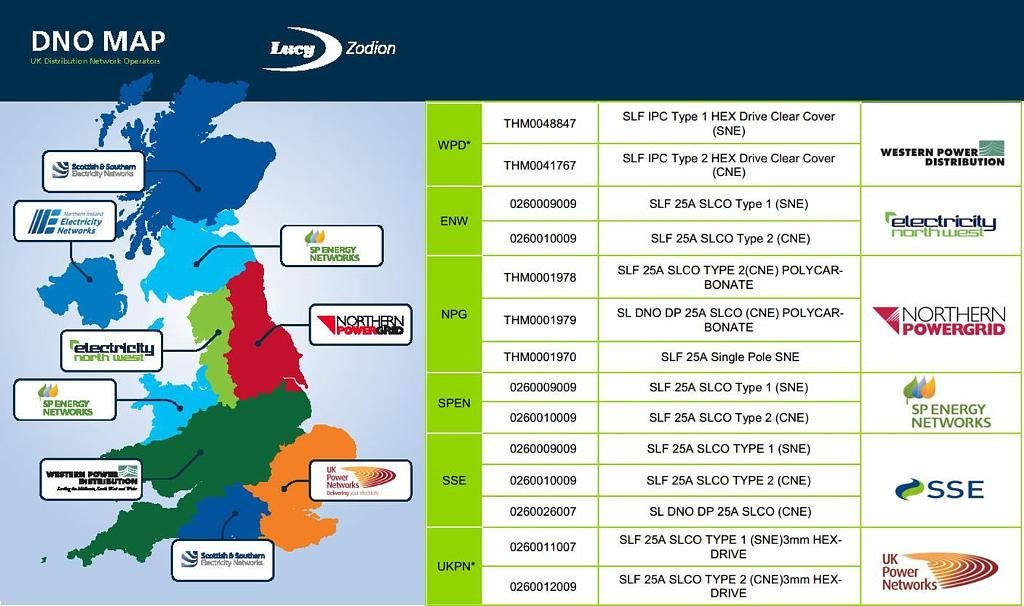

The following information is required by Lucy Zodion to enable the design and specification of feeder pillars to provide LV Electricity Distribution – utilising Fortress type steel pillar enclosures available in galvanised or stainless steel the power distribution pillars can be customised by an in-house Electrical Engineering Team to client and project requirements.

Thorne & Derrick have partnered with Lucy Zodion to provide a free technical support and electrical circuit design service – this includes internal wiring, 3D modelling and pillar schematics using AutoCAD software which is submitted to client for final approval prior to manufacture of the pre-wired electrical distribution pillar.

Effectively a “plug and play” solution to on-site power distribution – alleviating the design stress and cost from the contractor as the pillars are manufactured off-site without requirement to assemble the components and carry out internal wiring to ensure the project programme continues without disruption or delay.

Typically, the following information is required to generate the design of the feeder pillar in either single phase or 3 phase.

Electrical Specification

- DNO/REC Equipment

- DNO/REC Space Required

- Incoming Supply: 1 Phase | 3 Phase

- Cable Size Type Specification: Single | Multicore | Armoured SWA | Unarmoured | Voltage | Conductor Cross Section sqmm

- Incoming Isolation: SW Fuse | SW Disconnect | None | Amp Rating

- Distribution Board Type: Single Phase | 3 Phase | None

- Distribution Board Notes

- Number Of Outgoing Ways:

- Type: SP | TP

- Outgoing Way Protection Devices:

- Number Of BS88 Fuses:

- Number Of RCBO’s:

- Number Of MCB’s:

- Are Outgoing Terminals Required:

- Direct Connect To Distribution Board:

- Outgoing Cable Sizes:

Group Switching

- Time Clock: Normal | Solar | Analogue | Digital

- Contractor Control: Incoming Supply | Outgoing Ways

- Number Of Outgoing Ways Switched:

- Override Switch: Yes | No

Feeder Pillar Extras

- Light

- RCD Socket

- Heater

- Normal Thermostat

- Tamperproof Thermostat

- Commando Sockets

- DC Immune RCD

- Cat Flap

- Feeder Pillar Details

- Minimum Pillar Size: Height | Width | Depth

- Maximum Pillar Size: Height | Width | Depth

- Lucy Fortress Feeder Pillar Part Code (if known)

The safe electrical isolation and termination of low voltage cables all feeder pillars can be supplied with earth bars mounted to the backboard – pictured here is an 8 way earth bar terminating LV green-yellow insulated earth cables 600/1000V.

💡 The Lucy Westminster range of retractable pillars provide “pop-up power” onsite, outside and on demand when temporary electricity is required.

Type Tests Of Feeder Pillars

Prior to factory despatch and in line with electrical testing according to standard BS EN 61439 all mechanical and electrical cable terminations and connections are checked before despatch of the distribution pillars.

Once delivered to site it is recommended the installation guide is observed and if any technical queries arise please do not hesitate to contact us – check all terminal connections prior to energisation or commissioning to ensure no cable compression, damage or loosening of the connections has occurred during transportation or installation.

Should you require any commercial or technical support relating to the design, supply and installation of pre-wired feeder pillars please contact us.

Cut Outs – Lucy Zodion DNO Approved Street Lighting Cut Outs

LV, MV & HV CABLE JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

T&D are Specialist Distributors of products to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems – we are highly customer responsive and absolutely committed to providing a world-class service.

We provide expert technical support and supply from a multi-million pound stock holding:

| Cable Joints, Terminations & Connectors | Earthing & Lightning Protection |

| Cable Accessories, Lugs & Glands | Circuit Protection & Fuses |

| Cable Cleats & Clamps | Electrical Safety Equipment |

| Cable Pulling & Laying Equipment | Arc Flash Clothing & Protection |

| Cable Duct Seals & Transit Systems | Surge Arresters & Bushings |

Read our Blog with Lucy Zodion: Cut-Outs & Isolators – What’s the Difference?

Battery Operated Torque Gun – Lithium Type Industrial Bolting Tool

September 17th, 2018-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick are Specialist Distributors of Battery Operated Cable Crimping & Cutting Tools – this is supported by a range of battery type torque guns specified to reduce worker injury and improve Health & Safety with a reduction in hand-arm vibration related injuries associated with the use of conventional hand-held power tools.

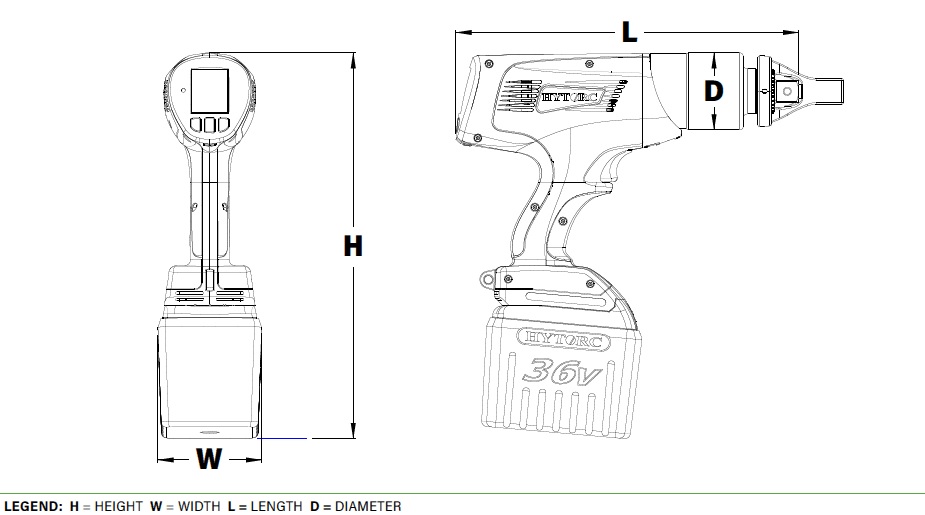

Battery Operated Torque Gun

Lithium Series battery operated torque guns are the ultimate solution for portability and convenience on industrial bolting jobs. With the world’s first 36-volt industrial battery system, these tools are ready for heavy industrial use. The lightweight design of the torque tools and dual speed capability make this system the go-to choice for industrial maintenance, contracting and production environments worldwide.

The Lithium Series was designed from the ground up using aerospace-grade materials to provide a compact design with industrial durability and power. The metal frame cut from a solid piece of aluminium alloy protects the tool from damage on industrial jobs. The 36-volt battery provides sufficient power to get through the toughest bolted joints.

Industrial-Grade Power

With a simple switch, the Lithium Series goes from high speed rundown mode to accurate final torque mode eliminating the need for multiple systems on a job. The precision machined gearbox provides constant power without the vibration and noise found in impact guns. Adjust the power through the digital readout on the back of the gun to fine-tune the torque output for any job.

Dual Speed Bolting

The Lithium Series makes torque and angle bolting simpler than ever before. The desired torque can be entered in Imperial or Metric followed by the desired angle. When the trigger is pulled the tool will automatically apply the torque, pause, and then apply the programmed angle. When complete the light on the back of the tool will turn green and a short beep will be heard.

Data Recording

Battery Operated Torque Gun – Dimensions

Lithium Type Industrial Bolting Tool

Specification

Should you require any further information or advise in order to select or purchase the most suitable Battery Operated Torque Guns & Tools please do not hesitate to contact us.

| Lithium Series Part Number | H | W | L | D | Square Drive | Weight | Torque | |

| mm | kg | Nm (Min) | Nm (Max) | |||||

| BTM-0700 | 326 | 88 | 290 | 66 | 19 | 4.64 | 203 | 949 |

| BTM-1000 | 326 | 88 | 290 | 66 | 19 | 4.82 | 271 | 1626 |

| BTM-2000 | 335 | 88 | 330 | 81 | 25 | 6.45 | 440 | 2710 |

| BTM-3000 | 338 | 88 | 358 | 87 | 25 | 7.39 | 678 | 4065 |

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Jointing & Installation Equipment.

LV MV HV cable accessories used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

Hover over our Interactive Electricity Grid to learn more about our product ranges.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

T&D are Main Stockists of Cutting & Crimping Tools manufactured by Cembre

|

|

|

|

|

|

|

|

|

|

Substation & Overhead Line Electrical Safety Equipment

Manufactured by CATU Electrical to enable the safe construction, maintenance and repair of underground cables and overhead lines network up to EHV (400kV).

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES

Power Distribution Feeder Pillars For Carpark Lighting Schemes Located In Flood Plane Area

September 12th, 2018

T&D Main UK Suppliers Of Lucy Zodion Feeder Pillars

Feeder Pillars

Case Study 2

Thorne & Derrick, the Specialist Distributor for Lucy Zodion, the UK’s market-leading manufacturer of standard and custom engineered feeder pillars recently supplied a bespoke power distribution pillar for a carpark lighting scheme located in a flood plane area of the UK – the LV power supply required upgraded power distribution system following damage and devastation caused by the floods of 2017.

Lucy Zodion developed customer specific feeder pillars for installation in the retail park with a 2 metre tall pair of pre-wired power distribution enclosures. The pillars with ingress protection of IP66 ensure water entry is minimised during flood conditions.

The 100A three phase DNO power supply of low voltage electricity ensures outdoor areas are sufficiently illuminated to provide safe and secure evening access to the car park zone within the retail park.

For further information about the complete range of pillars please see Lucy Fortress Feeder Pillars.

Power Distribution Feeder Pillars

Features

- Durable – feeder pillars made from heavy duty stainless steel, the pillar shells are durable to withstand extreme weather conditions, while protecting the low voltage electrical equipment within for prolonged use and public safety. As the site is prone to flooding, Lucy Zodion developed taller feeder pillars that elevated components to one meter above ground level.

- Safe – with water ingress a key consideration for the pillar designs, Lucy Zodion provided a electrical power distribution solution that would protect interior components, even when submerged in water (for up to 30minutes). This was made possible by ensuring the feeder pillar IP66 ingress protection. Further IP68 cable glands were installed within the pillar’s pre-wired terminals to ensure external wiring was protected once entering the enclosure.

- Bespoke – Due to the nature of the project and the location of the pillars, standard products were not suitable for the specification. Lucy Zodion helped to ensure pillars were designed to include:

-

- 1 Lucy Zodion Photocell to control the lighting scheme with an additional time-clock should carpark lighting require further programming

- 2 A switch fuse included and distribution section populated with MCB’s to power and control supply from the electricity company to the lighting scheme

- 3 An internal anti-condensation heater within each enclosure to keep inner components dry aiding longevity of both the pillar and the devices within

- 4 An LED service light in each feeder pillar as well as a twin service socket to aid routine maintenance when routine checks and upgrades take place

-

Pictured: Customised feeder pillars completed assembled and build prior to despatch from Lucy Zodion factory.

Fortress Feeder Pillars From Lucy Zodion : Galvanised & Stainless Steel 20+ Sizes

Feeder Pillars

T&D distribute the complete range of Lucy Zodion pillars for low voltage power distribution to the building services, rail, construction, utilities, oil and gas, retail and leisure, ports, airports and heavy industries – GRP feeder pillars, cast iron, galvanised and stainless steel types customised to your application:

- Pre-Wired Power Distribution Panels (Outdoor IP65 & Underground Retractable)

- Substation Power, Cable Distribution & LV Interconnection Panels (Onshore Wind)

- DNO Single & 3 Phase Network Pillars (25A-800A)

- Network Rail & Electrification – Station & Trackside Pillars (incl. London Underground)

- Low Voltage Connections – New Housing & Commercial Development Pillars (LV)

- Defence Estates MoD – Load Shedding Fuse Pillars

- Lighting Feeder Pillars – Street, Road, Flood, Sports Stadium & Car Parks

- BT Telecommunications & Interface Pillars

- Environment Agency – Rivers, Coastal & Waterways

- Cast Iron Electrical Distribution Pillars – National Heritage & Historic Buildings

- Also: Street Lighting Cut Outs

➡ For further information about how Lucy Zodion provide control and power distribution products for street lighting applications, please review the Lucy Titan (Cut-outs) and Lucy Trojan (Isolators) ranges of products.

➡ Contact us to discuss how T&D and Lucy Zodion can provide innovative custom design solutions and ex stock delivery of standard feeder pillars to your project.

Read our Blog with Lucy Zodion: Cut-Outs & Isolators – What’s the Difference?