Blog

Cable Lugs & Crimping Tools Using The Hexagonal Crimp Method

September 3rd, 2018

Cable Lugs & Crimping Using The Hexagonal Crimp Method

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Hexagonal Crimping Of Cables

Thorne & Derrick International, based in the UK, are leading suppliers of cable crimp lugs and associated crimping tools for Low, Medium & High Voltage Cables and Power Systems – this series of articles by Klauke discusses the theory and practise of installing compression type cable lugs and connectors.

Klauke cable lugs and crimping tools are used by Jointers, Linesmen, Panel Builders and Electrical Engineers to install underground cables and overhead line conductors on power, transmission and distribution networks including LV MV & HV systems, 11kV-33kV.

➡ Download 2018 Klauke Cable Lugs catalogue and see the complete range of tools for cutting and crimping cables.

In this Article we cover the following:

- Hexagonal crimping is suitable for both copper and aluminium conductors

- A professional hexagonal crimp generally requires use of crimping dies which match sizes of conductors and connecting material

- The classification of manufacturer specific crimping dies and cable lugs is rather regulated by the cross section of the cable

- The primary application of standardised hexagonal crimps is with electric utilities within a range from 10kV up to 30kV

- Depending on the tool narrow or wide cable crimps can be used

Hexagonal crimps for aluminium and copper

In daily practice hexagonal crimping is the most common kind of crimping of cable lugs and cable connectors for medium/high voltage power cables and systems.

The reason is very simple – this type of crimp is suitable for both copper and aluminium conductors. Hexagonal crimps can be found in panel building industries as a manufacturer specific crimp and also as a DIN standard lug crimp for example in utilities (aluminium and copper conductors including 11kV and 33kV power cables).

Technically the hexagonal crimp is characterised by a centrical and constant force effect applied during the crimping operation from all sides and creating a larger contact area.

Hexagonal crimps are suitable for both copper (above) and for aluminium (below)

The individual strands of the conductors are being deformed homogeneously in their entirety without any damage. The results are good electrical properties of these connections.

Mechanical and electrical properties of tubular and DIN compression cable lugs are being defined by the IEC 1238 part 1. It defines the requirements that an electrical connection has to fulfil for a permanent safe operation within intended applications.

The cross section of a hexagonal crimp performed with a manufacturer recommended tool shows the uniform positioning of conductors in the cable lug

Apart from mechanical pull out tests also electrical durability tests are included. The field of application of hexagonal crimps comprises the processing of conductors as per:

VDE 0295 Classification

- Class 1: round solid conductors

- Class 2: round stranded conductors

- Class 5: round fine stranded conductors

- Class 6: round finest stranded conductors

Conductor types acc. to DIN VDE 57295: round solid, round stranded, fine stranded, compacted

In addition hexagonal crimps per DIN 46235 and DIN 44267 can also be used for processing of non-tension and full tension connections of aluminium cables per DIN 48201 Part 1 of aluminium ropes per DIN EN 50182.

The correct Crimping tool

For processing cable lugs per DIN 46235 crimping dies with die codes per DIN 48083 can be used. This combination enables hexagonal crimps per DIN 46235 and 46267. For hexagonal crimps of standard tubular cable lugs it is suggested to strictly observe manufacturers tool recommendations.

Hexagonal crimps are exposed to high loads. For this reason only high quality tools should be used which in addition feature special functions guaranteeing correct and safe crimps. Battery powered crimping tools of the latest generation give an acoustic warning if the required crimping force has not been reached.

High quality mechanical crimping tools can only be opened when the crimping operation has been completed. Until then an integrated locking device blocks the tool – a totally completed cable crimp is important as the required compression of the crimp material is only reached at the end of the crimp phase.

Preparation For a professional crimp

A professional hexagonal crimp generally requires use of crimping dies which match sizes of conductors and connecting material. That means that cable lugs and connectors need to correspond to the dimensions of the conductor and crimping die.

Incorrect Crimping |

Incorrect Crimping |

Correct Crimping |

| Incorrect and correct crimps in comparison: An incorrect crimp (crimping,middle: low force crimping, and usage of incorrect crimping tools can result in an increase in joint resistance and may jeopardise the installation) | ||

An incorrect combination can lead to low compression – excess compression crimps with potentially fatal consequences: Faulty cable crimps and lugs can lead to increased contact resistance with rise of temperatures which in the worst case can cause fire.

Incorrect or materials processed with in-appropriate tools can cause heavy defects on installations resp. electrical equipment

Cable lugs of poor quality and/or processing may cause fire

For this reason manufacturers of branded electrical and cable accessory products such as Klauke recommend for crimping operations their cable lugs and connectors solely use of their own appropriate crimping tools. High quality crimping dies can be recognised by a polished surface with rounded edges.

Example of a crimping die with polished profile

These crimping dies are precisely manufactured and guarantee a constant and neat deformation of copper or aluminium. Prior to the cable crimping operation the electrical engineer or cable joint must ensure that the conductors need to be brushed to achieve a metallic clean surface and that oxide layers have to be removed from the aluminium cables.

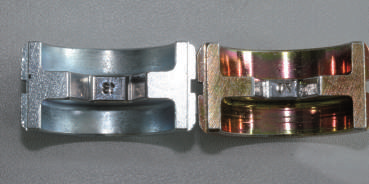

While stripping cable conductors it has to be observed that some are not being damaged and that bared length is more or less identical with insertion length of cable lug or connector. Crimping dies need to be clean and metallic bright. To avoid the incorrect die selection Klauke differentiates in colour, silver stands for aluminium dies and yellow gold for copper die sets.

Left: crimping die for aluminium, silver coloured; right: crimping die for copper (yellow-gold colour)

Tip: Klauke recommends to start crimping operations on cable lugs always from the palm towards the cable. In this case the compressed material can slide towards the cable end which hasn’t been crimped.

A cable lug or connector always needs to be crimped under consideration of the crimping direction and use of appropriate tools

Manufacturer specific hexagonal crimps

For hexagonal crimping operations we distinguish between two versions:

- The hexagonal crimp as per DIN 48043 Part 4

- The manufacturer specific hexagonal crimp

Within the standard copper range the so called manufacturer specific hexagonal crimps are used for cable types as per VDE 0295 class 2.

Permissible – manufacturer specific hexagonal crimp

Manufacturers with a reputation for quality such as Klauke offer hexagonal crimping dies for processing standard copper tubular cable lugs as per EN 13600 and approved cable conductor connections as per IEC 1238.

These cable lugs are being used for instance in the construction of electrical control cabinets because of design and smaller dimensions. To accomplish a professional crimp it is of great importance to use high quality tools. Only using such tools guarantee that a sufficient degree of compression is being achieved to insure optimum contact properties.

To achieve an IEC approved connection it is necessary that all components used match each other – this includes cable lug, crimping tool and suitable die set.

This concerns the cable lug and appropriate conductor but also the suitable appropriate crimping die and crimping tool – resulting in a safety engineered system.

The classification of manufacturer specific crimping dies and cable lugs is – other than with DIN standard crimps – not controlled by die codes; it is rather regulated by the cross section of the cable specified in sqmm.

Manufacturer specific crimp with indication of cross section

Every manufacturer is responsible for the electrical durability of connections being processed with their products – specified tests have to be provided as evidence.

As a professional and safe hexagonal crimping is dependent from an exact matching of crimping dies and cable lugs Klauke recommends for crimping their cable lugs solely use of their own tools as well. In case of special applications it is advisable to involve the preferably identical manufacturer of both tools and cable lugs.

Brand manufacturers will perform – if required – for the specific application pull out tests (accelerated tests) as per IEC and where applicable also tests of the electrical contact resistance and recommend depending on the results adequate tools and materials.

Hexagonal crimps for aluminium & copper

In particular when it comes to international projects and processing of specific cable types for instance in China or India IEC or customer specific standards can be complied with in terms of safety.

Standardised hexagonal crimping

The primary application of standardized hexagonal crimps is with electric utilities within a range from 10 kV up to 30 kV. The reason is the very homogeneous crimping which produces a consistent electrical field and consequently has a positive impact as to an unwanted field scattering.

Other than with indent crimps hexagonal crimps do not show any mechanical indent of material which in case of electrical field control needs to be balanced with a conductive compound.

Mainly for electric utilities: DIN standardised hexagonal crimp

Copper cable lugs as per DIN 46235 and copper connectors as per DIN 46267 part 1 can be crimped with crimping dies as per DIN 48083 T4.

For aluminium cable lugs as per DIN 46329 and compression connectors as per DIN 46267 part 2 and other aluminium connectors and cable lugs with appropriate tube dimensions as well hexagonal crimping dies as per DIN 48083 part 4 can be used.

Hexagonal profiles as per DIN comply with the dimensional specifications of DIN cable lugs and are standardized within given tolerances.

However, there are no specs given as to the crimp width which is either 5mm for copper or 7mm for aluminium. Identification marks on DIN cable lugs give important notes as to manufacturer, dimensions and design of cable lugs, which indicates the crimping tool resp. crimping die as necessity for crimping operations conforming to standards.

This inscription is found behind the manufacturer code.

For instance KL18 stands for

- KL: manufacturers code (in this case Klauke)

- 18: tool resp. die code

For a professional completion of a standardised crimp the tool code is decisive: The tool code of crimping die used has to conform with the tool code of the cable lug.

The imprinted tool code “18” on the cable lug (above) gives information on the crimping die to be used. The completed crimp (below) with imprint “18” on the cable lug proves that the correct crimping die was used

The die code is engraved mirror-inverted on the crimp surface of the crimping die and once crimping operation has been completed it is visible on the cable lug.

Tool codes correspond approx. with the tube dimensions of the cable lugs. For copper die codes range from 5 up to 58; this corresponds to cross sections from 6sqmm up to 1000sqm. In the same way hexagonal crimping dies for aluminium and appropriate tube dimensions of these cable lugs and connectors are standardised.

Tool code on the cable lug and imprinted code verify a correct crimp

Wide or narrow crimps

Depending on the tool narrow or wide crimps can be used. On a cable lug of 50sqmm cross section for instance one has the alter-native to do two narrow crimps or one wide crimp.

Narrow crimp (above) and wide crimp (below)

Tools with a crimping force of up to 6t (60kN) are suitable solely for narrow hexagonal crimps of 5mm width on copper. Tools with a crimping force of more than 12t (120kN) are suitable for wide crimps according to manufacturers instruction.

Usually the electrician prefers narrow crimps as tools are lower in weight and easier to handle. For cable assembly, however, wide crimps are preferred as they reduce the number of crimps required and consequently save time.

For standard tubular cable lugs mostly narrow crimps are being used. Mechanical and battery powered tools – lower in weight – and up to 60kN are being applied.

A special feature is with aluminium cable lugs: To compensate the lower conductivity of aluminium compared with copper the narrow crimp in this case is 7mm.

Also important: The DIN standard does not prescribe a specific crimp width either for copper or for aluminium.

This information is given by the manufacturer by means of wide and narrow markings on DIN compression cable lugs. It should be observed that cable lugs resp. connectors and tools including crimping dies come from one single source, e.g. a brand manufacturer.

Crimp marking indicate to narrow resp. wide crimping

Indent crimps

Old, but proved and tested: indent crimping constitutes the oldest type of crimping operations in electrical installations. In panel and control cabinet construction even today it is a widely used method of crimping copper – as classical indent crimp and “W” indent crimp.

Further Reading

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

Cable Lugs – Crimping Applications & Standards

Copper Cable Lugs For Special Applications

Indent Crimping Of Cables – Benefits & Limitations

Cable Lugs & Crimps – Hexagonal v Indent Methods of Crimping

DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

Copper & Aluminium – Crimping CU-AL Cables

Electrically Driven Crimping Tools For High Volume Applications

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Jointing & Installation Equipment.

LV MV HV cable accessories used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

Hover over our Interactive Electricity Grid to learn more about our product ranges.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

Substation & Overhead Line Electrical Safety Equipment

Manufactured by CATU Electrical to enable the safe construction, maintenance and repair of underground cables and overhead lines network up to EHV (400kV).

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES

Copper Cable Lugs For Special Applications

September 3rd, 2018

Copper Cable Lugs For Special Applications

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick International, based in the UK, are leading suppliers of cable crimp lugs and associated crimping tools for Low, Medium & High Voltage Cables and Power Systems – this series of articles by Klauke discusses the theory and practise of installing compression type cable lugs and connectors.

Klauke cable lugs and crimping tools are used by Jointers, Linesmen, Panel Builders and Electrical Engineers to install underground cables and overhead line conductors on power, transmission and distribution networks including LV MV & HV systems, 11kV-33kV.

➡ Download 2018 Klauke Cable Lugs catalogue and see the complete range of tools for cutting and crimping cables.

In this Article we cover the following:

- Crimping cables according to Class 5 & Class 6 DIN 57295 using Klauke “F” cable lugs

- Tube diameter is matched to the conductor size to guarantee a professional cable crimp

- Cable lugs for switch cabinets with special narrow palm cable lugs

- Crimping copper cables and conductors using stainless steel and nickel cable lugs

A well known problem for every electrician or cable jointer is trying to insert a stranded or fine stranded conductor into the cable lug or cable splice and some wires cannot be inserted. To avoid this problem renowned manufacturers offer specialist application connectors and cable lugs for the jointing and termination of LV MV HV cables.

Cable Lugs, Strandings & Conductors

With these specialist application cable lugs all types of cables can be used – the design and construction of the cable lug to be selected is determined by the cable stranding and conductor type. The cable conductor characteristics of cable types are as classified in the DIN Standard 57295.

Class 1 is a solid/round conductor providing both the smallest diameter and largest cross-sectional area (CSA in sqmm) – this is the simplest conductor but mechanically weak with solid conductors prone to breakage after several bending cycles. The cable conductors are categorised into Classes based on the total number of strands per conductor – the higher the Class, the more strands in the conductor:

- Class 1 Round single / solid conductors

- Class 2 Round multi-stranded conductors – typically 7 or 19 strands

- Class 5 Fine stranded conductors (Multi-stranded general flexible use)

- Class 6 Fine stranded conductors (Extra multi-stranded dynamic use)

DIN 57295: DIN VDE 0295:1980-09; VDE 0295:1980-09

Conductors of Cables & Flexible Cords For Power Installation (VDE Specification)

Conductor types acc. to DIN VDE 57295: round solid, round stranded, fine stranded, compacted

Cable Lugs For Fine & Very Fine Stranded Conductors

The above mentioned problem of spliced cables per Class 5 and Class 6 according to DIN 57295 is being avoided when using Klauke “F” type series cable lugs. These lugs are designed for processing larger cross section conductors in voltage applications up to the short circuit tested rating of the cable lug.

Compared with standard tubular cable lugs the “F type” lugs have a larger tube diameter – the cable lugs have a flared entry which eases cable location into the barrel of the lug.

Unprofessional and individually matched cable lugs can create serious safety defects in electrical installations.

The advantages are obvious – “F type” cable lugs ensure an easy and safe insertion of the conductor, the unravelling of the cable strands is avoided and the complete conductor fits into the cable lug prior to compression using appropriate crimping tools and die sets.

Cable lugs “F type” for fine stranded conductors for easy insertion with no splicing

This is also a safety-related issue – a reduction of the cross section area of the cable conductor caused by not inserting all the strands is being avoided and the complete cross section of the cable is maintained. Markings on the F-type cable lug barrel provide information of the product, e.g. manufacturer, dimension and design.

Marking “KL 12 150 F” indicates:

- KL: Manufacturer Klauke

- 12: Metric bolt size for connecting bolt: size M12

- 150: Cross section of conductor in sqmm

- F: Tubular cable lug design and construction

For professional crimping of F-type cable lugs the indent or quad point crimping method is recommended with the appropriate crimping tools and the correct indent profile.

F-type cable lug shows professional indent crimp

To avoid over or under compression the correct tooling is a pre-requisite. An incorrect crimping connection can result in increased joint resistance leading to an increase in temperatures and in the worst case in fire.

Klauke recommends use of their own crimping tools to achieve and guarantee professional crimps according to VDE standards. In addition to “F-type” cable lugs some manufacturers offer appropriate butt-connectors for splicing, extension and repair of cable conductors.

They also feature a flared entry and larger tube dimensions. A central restriction insures uniform insertion of the cable ends, and insure the crimping recommendations for F-type lugs are adhered to.

“F-type” cable lugs and butt connectors conform to the normative requirements of the EN 13600 standard and are manufactured from electrolytic copper for excellent conductivity.

A cross sectional view of an indent crimp (with manufacturers recommended tool) shows the even arrangement of conductor in the lug

For corrosion protection the cable lugs are available tin plated from cross sections ranging between 10sqmm up to 300sqmm. In addition to the normal design “F-type” cable lugs are also available as 45° resp. 90° angled versions as well as inspection holes to check whether the conductor is fully inserted prior to crimping-up the lug using the cable tool.

As with all other connections these products are subject to test standard IEC 1238 Part 1, which guarantees a safe electrical and mechanical connection has been achieved. Cable lugs manufactured by Klauke are subject to a special annealing process to help relieve material stresses and hardness.

This reduces the chance of material fracture and is an additional safety feature. The quality of cable lugs can often be recognised by visual characteristics. A burr free lug, a flat palm and a cleanly machined end are indicative of a high quality product.

Note: IEC 61238-1:1993 Is Now Withdrawn. Compression & Mechanical Connectors For Power Cables With Ccpper Or Aluminium Conductors – Part 1. Contact T&D.

Cable Lugs For Solid Conductors

For processing and crimping solid conductors (Class 1 DIN VDE 57295) the use of tubular cable lugs “E” type is recommended which are also manufactured from electrolytic tin plated copper. Their tube diameter is matched to the conductor size to guarantee a professional cable crimp.

Professional crimp on a solid conductor with matched tube dimension

Application is in all areas where solid conductors are being mostly used, e.g. manufacture of switchgear, transformers and engines.

A hexagonal indent crimping is being recommended – again it has to be observed that both cable lugs and crimping tools come from the same manufacturer.

Cable lugs for solid conductors can be recognized by their smaller tube diameter and the marking “E”. For example: KL 10 50 E.

Cross sections usually range from 6sqmm up to 50sqmm. The range is being completed by butt-, T- and cross connectors having the appropriate internal tube diameters.

Cable Lugs For Switch Cabinets

In many cases working area in switch cabinets is very tight and connecting conductors to high-power switchgears can be a problem In case of larger cross sections standard cable lugs do not fit into the compact connecting terminal.

Special cable lugs for switch cabinets (type SG) for safe connection also of conductors

For such applications many manufacturers have designed special narrow palm cable lugs (Klauke SG cable lugs) which fit comfortably.

Direct comparison of standard cable lugs (left) and cable lugs with narrow palm for switch cabinets

The narrow palm lug is also thicker than standard cable lugs ensuring the same amount of electrolytic copper has been used.

Despite a narrower palm no performance is lost. Thus these cable lugs therefore comply with a professional connection for stranded conductors according to DIN- VDE Class 2 as typically used in switch cabinets.

A hexagonal or indent crimp is recommended – conductor cross sections range from 35sqmm up to 300sqmm. The hole dimensions comply with industry sizes of connecting terminals, e.g. 6, 8, 10, 12 and 16mm.

Professional crimp on stainless steel cable lug for application in ambient temperatures of up to 400°C

Versions with inspection holes are also available – it is dangerous and incorrect to file the palm of a normal cable lug to the size of the connecting terminal. Such manipulation can result in increased temperatures and fire in the worst case.

Shows the thicker palm of SG cable lugs for switch cabinets, using the same amount of

copper as used in a standard cable lug.

Stainless steel cable lugs

for aggressive environments

Especially for adverse environments and for crimping copper conductors stainless steel and nickel tubular cable lugs have been designed. Stainless steel cable lugs are particularly acid and corrosion resistant and are typically used in chemical industries in areas exposed to sea water i.e. the earthing of masts on sailing yachts.

An additional benefit of these cable lugs is the temperature resistance. Consequently these lugs can be used in ambient temperatures up to 400°C.

At higher temperatures of up to 650°C – common in the construction of furnaces – nickel cable lugs represent the best solution. Both stainless steel and nickel cable lugs can be used for all common cable types.

A correctly crimped stainless steel cable lug used for applications where the environment can reach 400º C

Cross section ranges from 0.5sqmm up to 95sqmm. Generally an indent crimp is recommended. The same applies for stainless steel and nickel butt connectors with barrier.

Further Reading

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

Cable Lugs – Crimping Applications & Standards

Indent Crimping Of Cables – Benefits & Limitations

Cable Lugs & Crimps – Hexagonal v Indent Methods of Crimping

Cable Lugs & Crimping Using The Hexagonal Crimp Method

DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

Copper & Aluminium – Crimping CU-AL Cables

Electrically Driven Crimping Tools For High Volume Applications

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Jointing & Installation Equipment.

LV MV HV cable accessories used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

Hover over our Interactive Electricity Grid to learn more about our product ranges.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

Substation & Overhead Line Electrical Safety Equipment

Manufactured by CATU Electrical to enable the safe construction, maintenance and repair of underground cables and overhead lines network up to EHV (400kV).

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES

Klauke Cable Lugs & Crimping Tools | 2018 Catalogue Download

September 3rd, 2018Klauke

Thorne & Derrick | Distributed from Stock | Approved Supplier | UK & Export Sales

Klauke cable lugs are electrical compression connectors including: copper tube cable lugs and connectors (straight, angled crimp connectors for copper stranded and aluminium solid conductors), insulated cable lugs and connectors, stainless steel cable lugs and connectors, nickel cable lugs and connectors and DIN spec compression cable lugs and connectors.

➡ See below the current issue Klauke Catalogue – contact our Sales Team for prices, technical support or to place an order for cable lugs or installation tooling for cutting and crimping cables manufactured by market-leader Klauke.

Klauke cable lugs and crimping tools are used by Jointers, Linemen, Panel Builders and Electrical Engineers to install underground cables and overhead line conductors on power, transmission and distribution networks including LV MV & HV systems, 11kV-33kV.

➡ See our complete range of Cable Lugs, Crimps & Connectors LV MV HV.

Street Lighting Cut Outs – Lucy Zodion DNO Approved Cut Out Listing

September 3rd, 2018

Street Lighting Cut Outs

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cut-outs

Lucy Zodion street lighting cut-outs are approved for use on every UK DNO Network.

Thorne & Derrick together with Lucy Zodion can offer a range of SLF street lighting cut-outs (SLCOs) which are now approved for use by every Distribution Network Operator (DNO) in the UK.

The high level of specification status of their cut-outs for street lighting applications on both the UKPN and WPD networks is a clear demonstration of Lucy Group’s commitment to keeping LV electrical connections safe and reliable.

The Lucy Zodion SLF range of street lighting cut outs use high quality materials and provide a wide range of features that help ensure robust and reliable protection and isolation across a number of street lighting network types and applications.

Additionally, the Lucy Zodion brand of Fortress type feeder pillars are extensively specified and installed throughout the UK DNO LV Electricity Distribution network.

➡ For further information about how Lucy Zodion provide control and power distribution products for street lighting applications, please review the Lucy Titan (Cut-outs) and Lucy Trojan (Isolators) ranges of products.

Cut Outs

Here is the current street lighting cut out approval listing according to UK DNO designation:

| DNO Approved Products | DNO Area | ||

| DNO | Lucy Zodion Code |

Cut Out Description | |

| WPD* | THM0048847 | SLF IPC Type 1 HEX Drive Clear Cover (SNE) |

|

| THM0041767 | SLF IPC Type 2 HEX Drive Clear Cover (CNE) |

||

| ENW | 0260009009 | SLF 25A SLCO Type 1 (SNE) |  |

| 0260010009 | SLF 25A SLCO Type 2 (CNE) | ||

| NPG | THM0001978 | SLF 25A SLCO TYPE 2(CNE) POLYCARBONATE |  |

| THM0001979 | SL DNO DP 25A SLCO (CNE) POLYCARBONATE | ||

| THM0001970 | SLF 25A Single Pole SNE | ||

| SPEN | 0260009009 | SLF 25A SLCO Type 1 (SNE) |  |

| 0260010009 | SLF 25A SLCO Type 2 (CNE) | ||

| SSE | 0260009009 | SLF 25A SLCO TYPE 1 (SNE) |  |

| 0260010009 | SLF 25A SLCO TYPE 2 (CNE) | ||

| 0260026007 | SL DNO DP 25A SLCO (CNE) | ||

| UKPN* | 0260011007 | SLF 25A SLCO TYPE 1 (SNE)3mm HEXDRIVE |  |

| 0260012009 | SLF 25A SLCO TYPE 2 (CNE)3mm HEXDRIVE | ||

*sole supplier status

Street Lighting | House Service | DNO | Heavy Duty – complete range of Cut Outs

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

HV Joints & Terminations – Brands & Jointer Training

August 31st, 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

hEAT sHRINK Joints & Terminations

A myth pervades the UK contractor market that HV Cable Jointers MUST be re-trained and MUST be re-certified to install heat shrink cable joints and terminations according to the manufacturer/brand of kit.

Not true.

If a Jointer is conversant and competent to install Brand A of heat shrink product he is therefore conversant and competent to install Brand B, C, D….etc.

Since the development of heat shrink technology in the 1970’s competitor manufacturers have increasingly closed the gap between material quality and product performance.

This has been evidenced by the number of reputable manufacturers now able to provide 11kV and 33kV joints and terminations type tested by 3rd Party according to international recognised standard IEC60502-4.

Kits lists and installation instructions although not identical are very, very similar.

Vital to the life cycle performance and reliability of all HV Joints & Terminations operating at 11kV/33kV is the Jointers skill, experience and competency to execute cable preparation – essentially this involves the skilled use of specialist Jointing Tools to remove the outer cable sheath, semicon screen and insulation.

Typically, 90% of the installation time period for a heat shrink joint/termination is accounted for by the cable preparation process. The other 10% is “shrink-time”.

Let’s not underplay the Jointers need to possess excellent heat shrink techniques to shrink the kit components – this is clearly covered in all manufacturers Jointing Instructions and essentially provides recommendation on how to avoid scorching or over-heating of the tubes to achieve a smooth, wrinkle free installation.

Here, the flame is the name of the game and the torch-work by the Cable Jointer must basically involve heating but not burning the insulation, anti-track and stress control heat shrink tubes.

Trading Up, Down Or Sideways

Thorne & Derrick as a distributor at the sharp-end of the price point are exposed to increasing brand substitution with contractors brand affinity waning against a backdrop of tightening profit squeezes. Frankly, many brands are strong substitutes – heat shrink is heat shrink is heat shrink (up to a point) – and often brand loyalty is firstly commercial, secondly technical and thirdly emotional.

Price by itself should never decide the motive to buy. But generally price is the driver in the context of overall value for money and brand trust.

Last Words

In conclusion, Jointers skills are readily transferable across brands and contractors should not be prevented from attending site and installing HV Joints/Terminations purely on a brand basis – similarly if a commercial gain is to be secured from purchasing Brand A instead of any other Brand then the contractor should not be confronted by a doubt about the ability of their Jointer to correctly install that more cost-efficient value for money brand.

Discuss.

Stockists & Suppliers of MV HV Joints, Terminations & Connectors

Hover over our Interactive Electricity Grid to learn more about our product ranges – T&D are Specialist Distributors to DNO’s, ICP’s and NERS Registered Providers of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES