Blog

Crimping Tools & Die Sets For Aluminium Crimp Connectors – DIN Standard

August 28th, 2018

Crimping Tools | Die Sets | DIN Standard

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

The following information is provided to enable to selection and use of the correct crimping tools and die sets according to DIN Standard when installing Nexans Euromold type separable connectors – these cable connectors are used to terminate MV-HV cables into switchgear, transformers and medium/high voltage electrical equipment.

Specifically, the DIN Standard selection table below covers the connection, termination and crimping of aluminium conductor cables.

Please note when crimping aluminium cables:

* Uncompacted and compacted conductors

** Rotate each successive crimp 90 Degrees and remove flashes resulting from crimping.See the following image for crimp sequences.

DIN Standard Hexagonal Crimping Dies

| Cable Conductors * | Diameter Crimp Barrel (A) | DIN Die Index ** | Die Width Small | Die Width Large |

| 25 35 50sqmm | 12mm | 12 | 4 | 2 |

| 35sqmm | 14mm | 14 | 5 | 3 |

| 50sqmm | 16mm | 16 | 5 | 3 |

| 70sqmm | 18.5mm | 18 | 6 | 3 |

| 95sqmm | 22mm | 22 | 6 | 3 |

| 120sqmm | 23mm | 22 | 6 | 3 |

| 150sqmm | 25mm | 25 | 6 | 3 |

| 185sqmm | 28.5mm | 28 | 6 | 3 |

| 240sqmm | 32mm | 32 | 8 | 3 |

| 300sqmm | 34mm | 34 | 8 | 3 |

| 400sqmm | 38.5mm | 38 | – | 4 |

| 500sqmm | 44mm | 44 | – | 4 |

Thorne & Derrick distribute Cembre tools to enable the crimping of all types of copper or aluminium conductor cables in hexagonal or nest-indent formation.

DIN stANDARD

DIN, Deutsches Institut für Normung e.V. (German Institute for Standardization) develops standards for rationalisation, quality assurance, environmental protection, safety and communication in industry, technology, science as well as the public domain.

More Reading ➡

Cable Lugs & Crimping Tools – The DIN Standard 48083

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

BS6387 Fire Performance Cable Joint Kits For Prysmian Max-FOH LV Cables

August 28th, 2018

Cable Joints

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cable Joints

BS6387

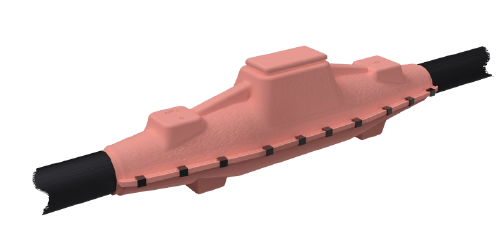

Prysmian FRZHMPJ are Fire Performance & Fire Resistant Cable Joints suitable to install as straight joints for LV Unarmoured and Armoured (SWA AWA) Max-FOH cables with copper conductors up to 1000V:

- Single Core 1.5sqmm-1000sqmm

- Multi Core 1.5sqmm-400sqmm

See the following download for the full and complete technical specification for Prysmian FRZHMPJ cable joints.

Cable Joint Kit Standards

The cable joint kits and shells include rigid glass reinforced phenolic joint shells which are fire retardant and LSOH (Low Smoke Zero Halogen) – the following fire tests have been conducted on the cable joints:

- BS EN 50393:2015 – Test methods and requirements for accessories for use on distribution cables of rated voltage 0.6/1 (1.2)kV.

- BS6387:2013 – Test method for resistance to fire of cables required to maintain circuit integrity under fire categories (Categories C, W & Z).

- IEC 61034-2:2005+A1:2013 – Measurement of smoke density of cables burning under defined conditions

♦ BS6387 – Test method for resistance to fire of cables required to maintain circuit integrity under fire conditions.

Thorne & Derrick are distributors for the complete range of Prysmian Cable Joints for the reliable and safe jointing of industrial, hazardous area and fire resistant power cables to BS6387 standard.

View our complete range of LV Cable Joints.

Triplex Terminations 11kV – NPG Northern Powergrid

August 28th, 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cable Terminations

The following information is uploaded to assist in the selection and specification of the correct Triplex terminations to suit 11kV XLPE insulated cables with copper wire screen typically in accordance with BS7870 – the cable terminations manufactured by 3M Electrical are Cold Shrink type from the QTIII range of indoor cable termination kits.

These MV HV Cable Terminations are approved for use by Northern Powergrid (NPG) jointers and their framework contractors for the termination of 11kV Triplex cables – a complete range of Cold Shrink Terminations are available for 11kV, 33kV and 66kV single and 3-core cables with XLPE or EPR type insulation.

| Cold Shrink Termination | 92-EP621-1-NY43 | 92-EP631-1-NY44 | 92-EP641-1-NY45 | 92-EP641-1-NY52 |

| NPG Catalogue Number | 163660 | 163661 | 163662 | 163663 |

| Cable Termination (CSA) | 95sqmm | 185-300sqmm | 400sqmm | 630sqmm |

| Suits XLPE Insulation Diameter | 16.3-27.4mm | 21.1-38.9mm | 26.7-45.7mm | 26.7-45.7mm |

For Example:

Northern Powergrid NPG – Bill Of Materials For 11kV Triplex Termination Kit NPG163662

Cable Termination Kit List – Triplex Terminations

- SED T110-T 3M Cold Shrink Cable Termination Body x 3

- NEDL80 Sicame ML4/14/12 Earth Lug (Copper Wire Screens Pictured)

- NEDL19 Sicame HVTM1/3-12B Brass Cable Lug (Stranded & Solid Core Conductors)

- Jointing Instruction 2919-0

Earthing & Terminating

11kV Triplex Copper Wire Screens

Sicame ML4 range of mechanical cable lugs are designed for the termination of stranded/solid/circular conductor cores – also used for the termination of earth screen wires of MV-HV polymeric cables as a component of Triplex terminations kits.

The mechanical lugs are manufactured in copper alloy and suitable for jointing either copper or aluminium cored conductor – see complete range of Sicame cable lugs.

NOTE: Triplex cable terminations are supplied as sets of 3 – to terminate 11kV cables onto private networks using heat shrink cable terminations please go to Triplex terminations.

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

Landlords Feeder Pillars – An Example Specification

August 28th, 2018

Feeder Pillars

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick are the leading designer, distributor and supplier in the UK of feeder pillars manufactured by Lucy Zodion – a complete range of standard, customised and pre-wired types from the Lucy Fortress range of feeder pillars are available to suit all LV Electrical Power Distribution requirements.

This includes power distribution pillars to provide LV electricity supply to new housing developments, multi-occupancy buildings and permanent supply kiosks for properties.

Here follows an example of a Landlords Feeder Pillar specification highlighting the flexibility and capability of Thorne & Derrick to liase with consultant engineers and specifiers to meet the needs and electrical power requirements of the residential, housing and accommodation market sectors.

FEEDER PILLARs

21.1 A new landlords service is to be provided as indicated on the drawing. This will consist of a weatherproof secure enclosure housing a distribution board, commonly referred to as a feeder pillar.

21.2 Provide a Thorne & Derrick International landlords feeder pillar. Type Fortress size 16 hot dipped galvanised feeder pillar finished in RAL 6026 complete with Yale lock and door activated internal lighting kit options.

21.3 Provide a concrete base for the feeder pillar in accordance with the manufacturers specifications.

21.4 Provide a MEM Memshield 3 125A 8 way TPN distribution unit to the landlords feeder pillar.

21.5 Provide attendance for electricity meter installation.

21.6 Provide 16sqmm 6491X single core PVC cable tails for DNO ISU in 100mm galvanised trunking.

21.7 Provide local isolator to DNO ISU electrical intake.

21.8 Cable from isolator to DB in 16sqmm 6944X (4 core cable) + 10sqmm CPC 6419X.

21.9 Refer to feeder pillar distribution board schedule for further details.

21.10 Provide 4 number 90mm twinwall cable ducts through concrete base for buried electrical service connections.

22 LANDLORDS SERVICES TO CANOPIES

22.1 The front canopies are to be to be partially stripped and altered.

22.2 Refer to the removal of services section for necessary removals and adaptations necessary to effect the works.

22.3 New ambient down lighting shall be provided to the canopies as detailed on the drawing. Provide new luminaires as detailed on drawing. The existing electrical and lighting circuits have been identified on the as installed information (provided for reference) and utilised for the new lighting. Each unit has an independent circuit. Identify existing feed and extend the circuit to the new luminaires. New cabling to be 1.5sqmm 3182B flexible Low Smoke Zero Halogen (LSZH) cable.

22.4 Provide connections to proposed canopy bus stop signs as detailed on the drawing. These signs shall be wired off the existing canopy lighting circuits. New cabling to be 1.5sqmmmm 3182B.

22.5 Dependant on phasing, alterations to the canopy will expose circuits running through one canopy onto the next. Allow to dress and protect these electrical circuits during the course of the works.

A downloadable specification form is available to initiate the electrical engineering design of all Lucy Zodion type feeder pillars.

Custom Feeder Pillars are readily available in a range of special and format feeder pillars to meet specific applications; they can be made from galvanised steel , or stainless steel and can be painted to suit the customers individual needs.

Galvanised & Stainless Steel | Cast Iron | GRP | Pre-Wired | Electrical Power LV

Largest UK Feeder Pillar Stocks – fast delivery from stock or on short lead-times

➡ Further Reading

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

Fire Stopping Cable Ducts

August 28th, 2018A Guest Article by Carl Pike – Director Filoform UK

The following contributed post provides an overview of the dangers of inadequately protected building penetrations and the need for duct sealing solutions with independently tested fire-proofing specification to protect people and property against the devastating effects of fire.

What is Fire Stopping?

Fire stopping has been brought more to the fore over the last few years than ever before.

The best way to explain the need of a fire-stop is to treat a multi-room dwelling or factory or any structure as a series of boxes or compartments. These boxes need to join physically by their walls or floors, even doors or windows. All these items are regulated and proven fire withstand products and procedures are in place to ensure any building is built or modified in accordance with the underlying need to stop fire spreading.

The fire tightness of one of these boxes is only as strong as the weakest entry point.

Did you know, fire can double in volume per minute it is lit. It doesn’t take long at this alarming rate to fill a room with fire. Fire does not respect any boundaries put in its place, but a certified system like ‘FiloSeal+HD FIRE‘ installed in the correct manner will stop or prevent the premature spread of fire to the next compartment through cable ducts, entries or penetrations.

Fire stopping got its foothold first in the marine industry. Probably because a loss of integrity of one compartment will mean a total loss of the vessel. It was in fact a development from the second World War German super sub captured by the Swedish that led to fire stopping products of a modular nature being developed by a company still going today. In the super sub, the system was used to prevent the rattle of pipes and wires within the sub, hence improving the sound signature of a hidden submarine.

Research we have done leads us to the improving of fire stopping on land as a direct result of several disasters in the USA starting with the 1906 San Francisco earthquake. This was followed by the New York garment district factory fire of 1911 and perhaps most scarily by the Browns Ferry Nuclear plant fire of 1975. This last event was caused by an open candle flame being used to detect air path leaks in foam based cable and pipe transit areas!

Not surprisingly, the nuclear industry was the first on land industry to take fire stopping seriously.

The use of the correct fire stopping product in the correct way and in the correct place ensures fire tightness of a compartment or room. There are plenty of products which work on floor/wall or ceiling wall interfaces. Many of these are flexible to allow for building expansion and contraction. Some other ways of sealing do not allow for this expansion; cements and mortars for instance. These materials do have their place but not always.

The last area we have not yet mentioned is the service penetrations into a room or compartment. These are the necessary services such as water, electricity and data cables which without them a room is almost useless.

Penetrations may come in via a wall, floor or ceiling. All must be adequately and correctly fire stopped. These services will need a flexible and re-enterable method of being sealed. The flexibility due to temperature expansion of both cables and pipes; the re-enterability due to the almost constant development of a buildings use and services.

Rockwool and insulation’s of the type are fire-retardant but are not in themselves a fire stopping method. They are perfectly suited to holding a system in place during installation but should never be relied upon to be the actual stop itself.

Fire stopping expanding foams

Please don’t get us started with this.

The use of so-called ‘fire rated’ foams for fire stopping of service penetrations or control joints is sadly becoming more prevalent everywhere. This trend could lead to serious consequences if a fire happens in a building where they’re used,

What do we mean by ‘fire rated foams’?

The fire rated foams we’re talking about are those that are delivered by way of an aerosol can or canister, which foam up when they’re dispensed – much like canned shaving foam.

They’re typically polyurethane based, and our understanding is they might all be coming from the same factory overseas, imported under many different product brands. To add to the problem, many are now dyed red or pink like above to signify their suitability for fire stopping applications. DON’T USE THEM!

Modular sealing systems work admirably out at sea where rigorous compliance is ensured on a day to day basis. On land, a more flexible system would work better; one where less is known up front about the exact cables or pipes to be found in any service penetration. One that can cope with irregular sized holes and mis-shaped ducts.

The correct system to use in service penetrations ON LAND

Their are many fire rated sealing systems available that claim their product is suitable for penetrations with cables present but you must really be careful and select the correct product for the situation you are sealing. Important note; a fire rating applies to an ‘as fire tested’ system, or an otherwise approved configuration. Only when a particular (and I must add proprietary) brand of product is installed in an identical way to the approved configuration does the entire system or configuration achieve the fire rating as described.

Filoform has heavily invested time and money into developing a fire rated duct sealing solution that offers the user and and end customer the following;

Flexible & Simple – a one box solution that has everything is one kit to seal a cable duct regardless of the size or number of cables running through the duct – we’ve kept selecting and installing our product ‘simple’ little upfront planning needed.

NON Hazardous – FiloSeal+HD FIRE contains no hazardous chemicals which makes COSHH and getting our product approved with any Health & Safety departments an easier process.

Many Resistances – Not only is our product fire resistant, tested to BS EN1366-3:2009, it also offers, 2 bar pressure resistance against water and gas / rat, rodent and termite protection (Mastotermes Darwiniensis) Northern Australian termites) and resists many harsh chemicals and gases, for example, Hydrogen Sulfide, Methane, Chlorine, Hydrocarbons and many more.

Expandable – We’ve developed FiloSeal+HD FIRE to easily be installed in circular ducts and also irregular shaped penetrations. FiloSeal+HD FIRE can be supplied with a retrofittable cable transit frame which is used if a structure or space will not allow fitting of a seal into the structure itself.

Affordable – Even with the heavy investment and time we spent designing and developing FiloSeal+HD FIRE, we’ve made this cable duct seal affordable but still offering extremely high quality components with proven test reports and a solid history of sealing solutions.

FiloSeal+HD FIRE provides a strong support system using the fire resistant hexagonal blocks made of our specially formulated material called ‘Formite’ which builds up like a honeycomb structure.

FiloSeal+HD FIRE is suitable for sealing empty or any cable configuration or pipes contained in one duct and also allows easy re-entry of the seal to add or remove cables or pipes as required.

FiloSeal+HD FIRE is very easy to apply regardless of the type of cable scenario in the cable ducts as it uses strong, but flexible hexagonal blocks to support the cable and provide a strong backing for the seal.

The unique design of the hexagonal blocks makes positioning and separation of the cables very simple while also providing a strong backing for the MD+ to be applied on.

- Up to 4 hours fire resistance in transit frames (single side)

- Up to 4 hours fire resistance in ducts

- Tested to BS EN1366-3 2009

- Up to 2 bar Pressure Resistance

- 100Kg pulling Force on the cables when sealed

- 10xd at 45º, with 1 bar pressure bending test

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist