Blog

ATEX Cable Joints – Jointing Cables In Hazardous Areas Zone 1 & Zone 2

January 15th, 2018

Cable Joints & ATEX

Uploaded By: Chris Dodds - reading time 5 minutes

The ATEX Directive covers an extensive and diverse range of equipment potentially including electrical equipment and cable accessories used on fixed offshore oil and gas platforms, in petrochemical plants, mines, flourmills and other areas where a potentially explosive atmosphere may be present – these are commonly referred to as “hazardous areas” and categorised according to the potential explosion risk into Zones under the European Directive known as ATEX.

In this post we clarify the situation with respect to the relationship between the product category “LV Cable Joints” and the European hazardous area ATEX Directive.

ATEX

A potentially explosive atmosphere exists when a mixture of air and flammable gases, vapours, mists, or dusts combine in a way that can ignite under certain operating conditions – this is referred to as a hazardous area and depending on the concentration levels this is categorised into Zones according to degree of risk as referenced below.

The ATEX Directive 2014/34/EU covers equipment and protective systems intended for use in potentially explosive atmospheres.

The Directive defines the essential health and saftey requirements and conformity assessment procedures, to be applied before products are placed on the EU market. It is aligned with the New Legislative Framework policy, and it is applicable from 20 April 2016, replacing the previous Directive 94/9/EC.

A Guidance document on the ATEX Directive transition from 94/9/EC to 2014/34/EU (371KB) is available as a download below, with a list of frequently asked questions and answers.

In very broad terms, there are 3 pre-conditions for the ATEX Directive to apply to the

electrical equipment and cable accessories for use in potentially explosive atmospheres and hazardous areas:

a) must have its own source of ignition;

b) be intended for use in a potentially explosive atmosphere (air mixtures); and

c) be under normal atmospheric conditions.

When used as directed, 3M cable joints and cable accessories do not have a source of ignition. The firing of an explosive atmosphere may be caused by a short circuit, but when installed according to 3M instructions, their cable joints (both resin and Cold Shrink) are safe against short circuits. To conclude, 3M cable joints and Cold Shrink accessories are not within the scope of the ATEX Directive.

T&D Approved Abtech Distributors | Hazardous Area Enclosures

Hazardous Area Zones

- Zone 1 – according to ATEX a place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

- Zone 2 – according to ATEX a place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, persists for a short period only.

3M Scotchcast 1402FR Cable Joints

Cable Joints

Why Specify & Install 3M Cable Joints?

Although cable joints are not formally certified according to ATEX there are several minimum specification and performance requirements for cable joints when being used to connect, repair or joint cables in hazardous areas.

Standard industrial cable joints will not provide adequate electrical insulation and mechanical protection – they utilise polyurethane resins which are not hydrocarbon resistant and will suffer chemical and molecular breakdown overtime when exposed to aggressive and corrosive atmospheres. Eventual failure of the cable joint will cause power outage and the need to cut-out the failed cable joint and re-joint using a suitable product.

3M LVI-3 type cable joints include specially formulated 3M Scotchcast 1402FR resin – this resin is hydro carbon resistant, flame retardant, halogen free and chemical resistant for use in hazardous area locations.

For this reason, 3M Scotchcast is the industry standard for hazardous area cable jointing and offshore cable joints where ATEX Directive stipulates Zone 1 or Zone 2 certified equipment must be installed – this range of cable joints suitable for power, control and instrumentation cables are approved and in service at LukOil, Royal Dutch Shell, Total, Chevron, Exxon Mobil and many other international onshore and offshore oil and gas exploration companies.

Article 500 of the National Electrical Code (NEC)

What Is NEC?

The National Electrical Code (NEC), or NFPA 70, is a regionally adoptable standard for the safe installation of electrical wiring, cables and equipment in the United States forming part of the National Fire Codes series published by the National Fire Protection Association (NFPA), a private trade association.

According to NEC, Hazardous (Classified) Locations (HL) are defined as areas where fire or explosion hazards may exist due to the presence of flammable gases, vapors, dusts or fibers/flyings. The 2014 National Electrical Code (NEC) – NFPA 70 categorises these locations by Classes, Divisions and Zones and imposes strict requirements for wiring methods in these locations.

The 2014 National Electrical Code (NEC) – NFPA 70 categorises these locations by Classes, Divisions and Zones and imposes strict requirements for wiring methods in these locations.

Hazardous locations are broken into different categories called Classes and Divisions per the 2014 NEC Article 500 Hazardous (Classified) Locations, Classes I, II, and III, Divisions 1 and 2. The process of classifying a potential hazardous area workplace or location is often complex, so it is generally determined by the plant engineering staff. “Class I, Division 1” is the most hazardous classification, but “Class I, Division 2” is the type most common to cable users. The various classifications are summarised in the table below. Class I and II materials are further subdivided by the NEC into “Groups” (A, B, C, etc.) as shown.

However, the type of Group has no effect on the type of cable required – T&D can recommend suitable cable joints, termination or explosion proof cable glands and connectors for all Class and Division applications.

| Class | Group (NEC 500.6) | Division (NEC 500.5) | |

| 1 | 2 | ||

| I – Gases, Vapors & Liquids | A: Acetylene B: Hydrogen, etc C: Ether, etc D: Hydrocarbons, fuels, solvents, etc |

Explosive or ignitable gases or vapors are present under normal operating conditions | Explosive or ignitable gases or vapors are not normally present (but may accidentally exist) |

| II – Dusts | E: Metal dusts F: Carbon dusts G: Flour, grain, wood or chemical dusts |

Combustible dust is in the air under normal operating conditions | Dust is not normally in the air in ignitable concentrations (but may accidentally exist) |

| III – Fibers & Flying | Textiles, wood chips, etc (ignitable but not explosive) | Easily ignitable fibers or flyings are handled, manufactured or used | Easily ignitable fibers are stored or handled. |

Conclusion

Should you require specification or technical support to enable the selection for purchase of the correct 3M Cable Joint to joint low/medium/high voltage cables (LV-MV-HV) in hazardous areas please do not hesitate to contact us, this includes 11kV/33kV joints and terminations.

Thorne & Derrick hold the largest European stocks of 3M Resin Cable Joints and Cold Shrink cable accessories for use in potentially explosive atmospheres – we provide expert technical support, product specification and customer service to the UK and international oil, gas and petrochemical industries.

Installing Hazardous Area Cable Joints Using 3M Scotchcast Resin Jointing Kits

➡ Watch 3M Video

Cable Accessories & Electrical Equipment – ATEX Certified For Hazardous Areas

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D are Specialist Distributors of Hazardous Area Lighting & Industrial Power Distribution products to UK and international customers – we guarantee expert technical support across an extensive range of core products with ATEX and IECEx certification for potentially explosive atmospheres.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Transits, Cable Glands, Arc Flash Clothing/Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

132kV Cable Covers – Protecting High Voltage Power Cables In Underground Cable Trench

January 12th, 2018

Here, Stokbord Cable Covers are showing providing protection and covering high voltage 132kV power cables in an underground cable trench as part of an HV Cable Diversion project. Image: Prysmian.

- Product Category: Cable Covers & Protection MV HV EHV

- Featured Product: Stokbord Cable Covers

- Voltage: 132kV

➡ Further reading: Cable Protection & Covers For MV HV Power Cables

Installing Cable Covers

To Protect High Voltage &

Extra High Voltage Cables

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Cable Spikers, Earthing & Lightning Protection, Electrical Safety, Cable Transits, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

- Stockists for: 132kV Surge Arresters

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Cable Protection & Covers For MV HV Power Cables

January 12th, 2018

Uploaded By: Chris Dodds - reading time 5 minutes

Cable Covers

Centriforce Tapetile and Stokbord underground cable protection tiles and covers are the market leading, heavy duty utility protection system for protecting underground cable and pipes – this includes low voltage, medium voltage and high voltage power networks working at 11kV/33kV up to and including 132kV/275kV extra high voltage cables.

T&D supply the most extensive range of Centriforce Cable Protection products from stock for delivery throughout the UK to most UK DNO specifications in both Tapetile and Stokbord ranges – used to protect MV-HV Underground Cables & Joints.

Tapetile

& Stokbord Covers

Stokbord Cable Covers – 33kV Cable Protection For Underground MV-HV Cables

Tapetile – 11kV Cable Protection For Underground MV-HV Cables

See the complete Centriforce range: MV HV Medium & Voltage Cable Protection Products

➡ The following Selection Table outlines the current approved Cable Protection Systems for UK DNO’s for underground medium and high voltage cables.

| Northern Powergrid | Centriforce | Tapetile | 150×2.5mmx40m |  |

| Northern Powergrid | Centriforce | Tapetile | 200×2.5mmx40m |  |

| Northern Powergrid | Centriforce | Stokbord | 1000x244x12mm |  |

| Scottish Power | Centriforce | Tapetile | 200×2.5mmx40m |  |

| Scottish Power | Centriforce | Stokbord | 1000x244x12mm |  |

| UK Power Networks | Centriforce | Tapetile | 200×2.5mmx40m |  |

| UK Power Networks | Centriforce | Stokbord | 1000x244x9mm |  |

| Western Power Distribution (WPD) | Centriforce | Stokbord | 1000x450x12mm |  |

| Western Power Distribution (WPD) | Centriforce | Stokbord | 1000x244x12mm |  |

| Scottish & Southern Energy (SSE) | Centriforce | Stokbord | 1000x244x12mm |  |

| GTC | Centriforce | Tapetile | 150×2.5mmx40m |  |

| GTC | Centriforce | Tapetile | 200×2.5mmx40m |  |

| National Grid | Centriforce | Tapetile | 200×2.5mmx40m |  |

| National Grid | Centriforce | Stokbord | 1000x300x14mm |  |

| National Grid | Centriforce | Stokbord | 1000x450x14mm |  |

Centriforce Benefits

Centriforce Stokbord and Tapetile heavy duty plastic underground cable covers have virtually replaced concrete cable covers, tiles and plates for several reasons:

- Clearest warning of underground buried cables to third parties

- Can be custom made with sizes to suit specific utility cable protection for 11kV, 33kV, 66kV and 132kV

- Contains bold warning text and UK DNO logo for clear cable identification

- Damage to medium and high voltage cables less likely therefore reducing the cost of repairs, jointing and outages

- Lightweight and easy to install cable covers irrespective of weather and soil conditions

- Durable with good impact resistance

- Rotproof and resistant cable covers to wide range of soil conditions

Electrical Explosion – An 11kV Cable Strike

Two construction companies have been fined £90,000 after workers were seriously burned, and one scarred for life, after they cut into a live 11kV electrical cable. Unprotected underground cables distributing medium and high voltage electricity pose serious health and safety dangers.

UK DNO’s

T&D are Specialist Distributors to the UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and High Voltage Jointing Contractors of an extensive range of Cable Joints, Substation, Distribution, Tooling & Installation Equipment approved by the utilities:

- Electricity North West – ENW

- ESB Networks

- NIE – Northern Ireland Electricity Networks

- SPEN – Scottish Power Energy Networks

- SSE – Scottish & Southern Energy Networks

- UKPN – UK Power Networks

- WPD – Western Power Distribution

- NPG – Northern Power Grid

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Transits, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Insulating Matting – IEC 61111 Specifications & Selection For Switchboard Matting

January 11th, 2018

Uploaded By: Chris Dodds - reading time 5 minutes

Insulating matting is a essential component of electrical safety and is specified and installed to provide protection against electrical shock and hazards around electrical equipment, such as switchboards and switchgear – this can include Low Voltage, Medium Voltage & High Voltage.

As part of a facilities standard risk assessment, where a potential for electrocution is present, then electrical insulating safety matting (commonly referred to as switchboard or switchgear matting) is recommended in the HSE’s Safe Working Practices for Electricity At Work document (HSG85) where it references BS EN 61111: 2009 (Live Working: Electrical Insulating Matting British Standards Institution).

“providing and using correct personal protective equipment (PPE) to reduce the

risk of contact with live parts or earth, eg insulating gloves, insulating matting

(see BS EN 61111:200917). If there is a risk of burns from arcing or flashover

that cannot be avoided, consider the use of adequately rated, thermally

insulating, flame-resistant, arc flash clothing or PPE (including face/eye protection).” HSG85

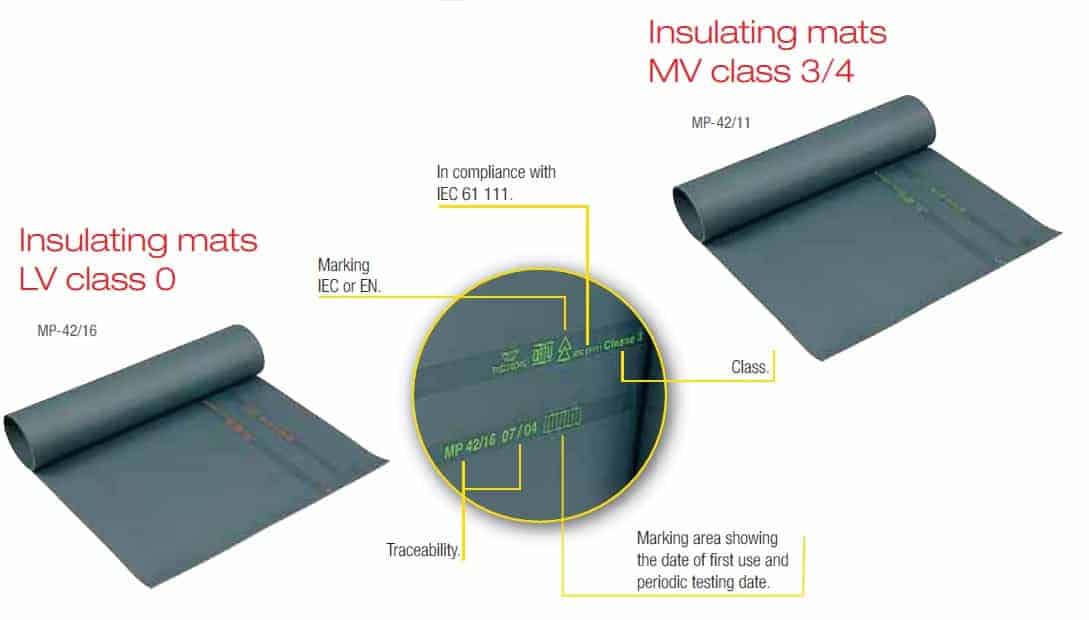

The range of CATU insulating matting conforms to the standards set out in IEC 61111 and provides MV-HV electrical protection for personnel working on medium and high voltage switchgear, switchboards, control panels and transformers.

working on medium and high voltage switchgear, switchboards, control panels and transformers.

The IEC 61111 standard sets out the requirements that must be met and supersedes the standard CLC/TS 61111:2006 and includes the following significant technical points:

- General review of the requirements and test provisions

- Modification of the test procedure for slip resistance matting

- Specification of standard and alternative types of electrodes for the proof test

- The conditioning time for low temperature folding test of insulating matting

IEC 61111:2009 is applicable to electrical insulating matting made of elastomer for use as a floor covering for the electrical protection of workers on electrical installations, including 11kV and 33kV substations.

LV MV HV Insulting Matting Explained

Selection of insulating mats for specific applications depends on the worker exposure to operating voltage and matting is tested to withstand certain specified voltages – referred to as the safe working voltage detailed below. Electrical safety matting is tested to a higher voltage than the certified use voltage – the voltage at which the matting is certified to is the Safe Working Voltage.

CATU Electrical insulating matting is specified and tested to IEC 61111 Category C with working temperatures to – 40°C for the following voltages:

- LV Insulating Matting – Class 0 Safe Working Voltages 600V 1000V

- MV HV Insulating Matting – Class 3 Safe Working Voltage 3.3kV 6.6kV 11kV 15kV 26.5kV

- MV HV Insulating Matting – Class 4 Safe Working Voltage 3.3kV 6.6kV 11kV 15kV 33/36kV

Products that are covered by the IEC 61111 standard include live working, electrical insulating materials, insulating matting, elastomers, floor coverings, electrical safety, electric shocks, safety devices, occupational safety, classification systems, grades (quality), marking and testing.

See live working tools for further information about insulated tools in accordance with IEC Standards for working on energised low voltage cables.

Protecting Jointers & Electrical Engineers When Working Live On Cables & Switchgear – comprehensive ranges of insulating matting and insulated tools.

Catu Electrical insulating matting

Electrical insulating matting is available in roll form for placement and rolling-out in front of medium/high voltage switchgear rooms, motor control centres (MCC), traction power substations and UPS rooms.

Portable pre-cut insulating mats are available to provide protection to site engineers and cable jointers working on electrical installations in plant and lift control gear rooms – often used to provide electrical protection when 11kV/33kV jointing, terminating and glanding cables into electrical distribution equipment.

➡ Class 0 Matting | Class 1 Matting | Class 2 Matting | Class 3 Matting | Class 4 Matting

| CATU Electrical Product Reference | Insulating Class | Min Voltage | Max Voltage | Matting Thickness | Mat Dimensions | Weight |

| CATU MP-11/11 | 0 | ≤1000 V | ≤1500 V | 2 mm | 1 x 1 m | 2.9 Kg |

| CATU MP-11/16 | 0 | ≤1000 V | ≤1500 V | 2 mm | 0.6 x 1 m | 1.4 Kg |

| CATU MP-42/11 | 3 | ≤26500 V | ≤39750 V | 3 mm | 1 x 1 m | 4.5 Kg |

| CATU MP-42/16 | 3 | ≤26500 V | ≤39750 V | 3 mm | 0.6 x 1 m | 2.9 Kg |

| CATU MP-42/66 | 3 | ≤26500 V | ≤39750 V | 3 mm | 0.6 x 0.6 m | 1.8 Kg |

| CATU MP-60/05-1 | 4 | ≤36000 V | ≤54000 v | 5 mm | 0.6 x 1 m | 4.4 Kg |

| CATU MP-100/02-10 | 0 | ≤1000 V | ≤1500 V | 2 mm | 1 x 10 m | 29 Kg |

| CATU Electrical Product Reference | Insulating Class | Min Voltage | Max Voltage | Matting Thickness | Mat Dimensions | Weight |

| CATU MP-60/03-5 | 3 | ≤26500 V | ≤39750 V | 3 mm | 0.6 x 5 m | 14 Kg |

| CATU MP-60/03-10 | 3 | ≤26500 V | ≤39750 V | 3 mm | 0.6 x 10 m | 28 Kg |

| CATU MP-100/03-5 | 3 | ≤26500 V | ≤39750 V | 3 mm | 1 x 5 m | 25 Kg |

| CATU MP-100/03-10 | 3 | ≤26500 V | ≤39750 V | 3 mm | 1 x 10 m | 53.5 Kg |

| CATU MP-60-/05-5 | 4 | ≤36000 V | ≤54000 V | 5 mm | 0.6 x 5 m | 28 Kg |

| CATU MP-60/05-10 | 4 | ≤36000 V | ≤54000 V | 5 mm | 0.6 x 10 m | 44 Kg |

| CATU MP-100/05-5 | 4 | ≤36000 V | ≤54000 V | 5 mm | 1 x 5 m | 45 Kg |

| CATU MP-100/05-10 | 4 | ≤36000 V | ≤54000 V | 5 mm | 1 x 10 m | 89 Kg |

Complete range of LV-HV Insulating Matting for all medium and high voltage switchgear, switchboard and substation electrical safety protection up to 33kV.

Recommendations For Use & Storage of Matting

It is vital to store and use electrical insulating mats in the correct manner in order to prolong their lifespan and ensure they continue to function and provide the insulation levels required. When storing or transporting the matting it should be properly stored and should not be bent or deformed.

The insulated mats should also not be stored or used close to any excessive heat sources or exposed to direct sunlight for long periods. The ideal storage temperature for the mats is between 10°C and 21°C.

When using and installing any insulating matting, a visual inspection should be carried out first. If the mats are dirty they should be cleaned with soap and water and then dried, respecting the operation temperatures mentioned previously.

Ideal operating temperatures are between -40°C and 55°C and the mats should not come into contact with any chemical products as this can also damage the rubber. When installing the mats, place them on a clean smooth floor devoid of any aggressive elements.

Once installed, periodic inspection of the insulating matting should be carried out and mats should not be used if they have not been electrically tested for 12 months.

Typically, Class 1, 2, 3 and 4 matting should be tested every 12 months in accordance with IEC61111 – often a visual inspection for low voltage Class 0 insulating matting is adequate depending on matting condition. Aged matting showing clear deterioration should be subject to routine dielectric test to check and ensure insulating levels are maintained.

Insulating Matting FAQ’s

How Do Insulating Mats Work?

Rubber is a natural dielectric material and therefore inhibits the flow of electric charge as a result of its molecular structure preventing the free flow of electrons.

Where Should I Use Insulating Matting?

Insulating matting should be installed in front of low, medium and high voltage switchboards, in front of machine control gear, in plant and lift gear control rooms and as portable protection for site engineers working on live electrical equipment.

Matting should also be used in conjunction with electrical safety equipment such as insulating gloves, insulating boots and in some cases arc flash protection clothing.

What Sizes Are Mats Available In?

The working voltage and size of matting is dependent upon the class of the mat. CATU insulating matting is supplied in 5m or 10m long rolls and as either 0.6m wide, 1m wide or 1.2m wide dependent on class. The thickness of the matting is also dependent on voltage class.

What Is The Double Triangle?

Matting with the “double-triangle” symbol confirms the insulating matting is suitable for live working according to IEC 60417-5216.

♦ Further Reading

For more reading about Electrical Safety, read the T&D blog:

- Electrical Safety – Arc Flash Accidents & Electrocution In LV-HV Installations

- Can Arc Flash Clothing Save Cable Jointers Lives?

- Arc Flash Calculation – Selecting Clothing & PPE To Protect Lives Against Arc Hazard

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Transits, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Saipem

January 11th, 2018- Client: Saipem

- Company Type: EPC

- Location: International

- Sector: Oil, Gas & Chemicals

Thorne & Derrick are Approved Vendors to Saipem of LV, MV & HV Cables, Accessories, Jointing, Substation & Electrical Eqpt.

T&D provide an outstanding service to UK and international customers – we are highly customer responsive and absolutely committed to providing a world-class service.

We supply UK and international businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

We provide global express delivery from stock at competitive prices.

![]()

Export Services ♦ International Delivery ♦ Certification ♦ Packing ♦ Inspections ♦

Thorne & Derrick International

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu Electrical, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment