Blog

Tools for Stripping MV & HV Peelable Semicon Screened Cables

April 21st, 2022

Alroc ORACL Tool

Screen Scoring Tools

Alroc manufacture a range of cable jointing tools for the removal and stripping of outer cable sheath, semi-conductor screen and insulation from LV, MV, HV and EHV power cables – this includes precision engineered manual and motorised cable installation and preparation tools for Power, Transmission & Distribution cables.

The ORACL by Alroc enables the cable jointer or user to longitudinally score the peelable semiconductive layer from medium/high voltage cables (typically 33kV) in order to peel it off carefully by hand – this is a key stage of MV HV cable preparation prior to the installation of Power Cable Accessories including joints, terminations and connectors.

The Screen Scoring Tool has an adjustable scoring depth of four different lengths (0.4 / 0.6 / 0.9 / 1.1 mm) and is lightweight in design.

Screen Scoring Tool Capacity

- Diameter: 10 – 100 mm or 0,394 – 3,937 inch

- Scoring Depth: 0.4 / 0.6 / 0.9 / 1.1 mm or 0.016 / 0.024 / 0.035 / 0.043 inch

- Min Remaining Length: 10mm

Spare Part

LSO – Spare blade for peelable semiconductor

Associated Tool

DSP – Peelable semiconductor lifter

MVS – Stop for tools

Screen Scoring Tool Dimensions

- Length: 135 mm

- Width: 55 mm

- Height: 35 mm

- Weight Without Box: 0,16 Kg

- Packaging: Box

| Part Number | Diameter | Tool Capacity | Dimensions | Packaging | |||

| Scoring Depth | Min Remaining Length | Length | Width | Height | |||

| Alroc ORACL | 10 – 100 mm or 0,394 – 3,937 inch | 0.4 / 0.6 / 0.9 / 1.1 mm or 0.016 / 0.024 / 0.035 / 0.043 inch | 10mm | 135 mm 5,315 in |

55 mm 2,165 in |

35 mm 1,378 in |

Box |

Thorne & Derrick | Stockists & Distributors for the Alroc Range of Cable Jointing & Preparation Tools

Contact us with your Enquiry.

Thorne & Derrick protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.

Conductor Repairs | CatchBlock OHL Catenary Roller From Slingco

April 20th, 2022

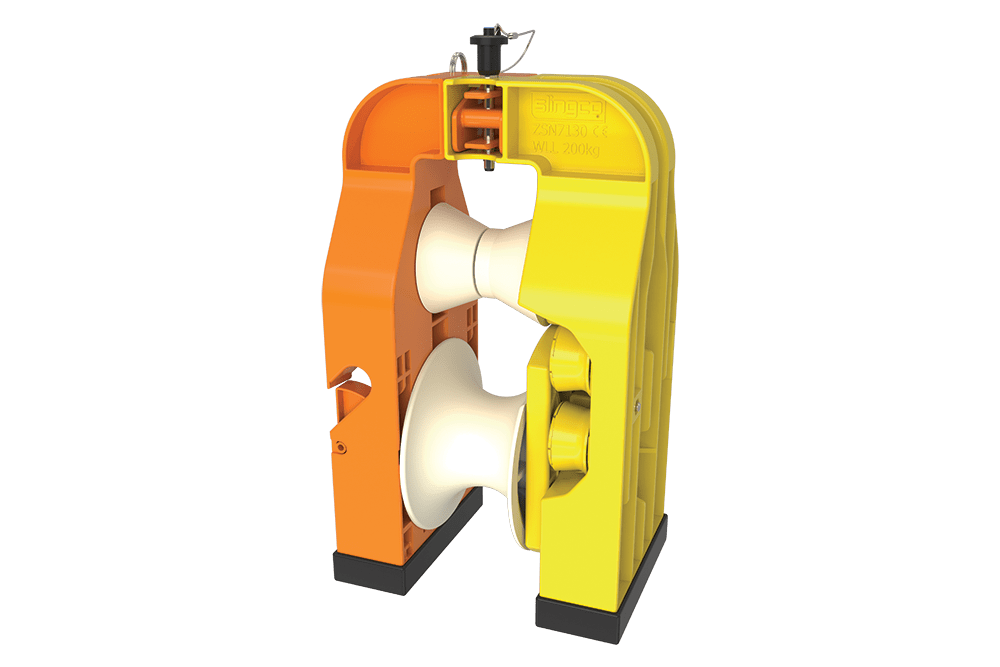

CatchBlock

Conductor Repairs

CatchBlock OHL Catenary Roller From Slingco

Slingco has developed a range of products to vastly improve conductor replacement. The Catchblock, the Conductor Replacement Roller (CRR) and our range of specialist cable socks and grips.

The challenges faced by the OHL (Overhead Line) industry due to the growing number of electrical infrastructure projects built beneath existing transmission and distribution networks – alongside increasingly stringent OHL regulations – can make maintenance costly, time-consuming and challenging.

Replace OHL conductor in half the time with no need for possession orders

CatchBlock

Lightweight, robust and easy to deploy, CatchBlock helps to increase efficiency and reduce costs.

CatchBlock is an innovative overhead line (OHL) catenary roller system.

A two-rope system, allowing the replacement of old-for-new conductors. In the event of conductor failure during this process, Catchblock enables the recovery of both ends without having to lower the system.

Removes the need to erect and dismantle scaffolding, significantly reduces the risk of accidents and harm to site workers and reduces cost and project timeframe.

Designed to deploy a twin-rope system, it allows the recovery and redeployment of broken conductors without the need to take possession of road/rail or client/third party property or infrastructure.

CatchBlock Features & Benefits

- Removes the need to close down essential infrastructure for conductor repairs or in the event of an emergency

- Cuts down the need for scaffolding, reducing accident risk

- Lightweight, robust, weatherproof and easy to deploy

- Twin rope system allows for recovery and redeployment

- Flexible – CatchBlock isn’t specific to a single tug design

- High conductor range, including the ability to allow mid-span joints/repair sleeves to pass through safely

- Blocks can be connected for use on multiple bundle conductor systems

Conductor Replacement Roller (CRR)

Provides a simple, conductor-deployed protection system using a lightweight aramid rope.

The CRR unit enables the safe exchange of conductors in three easy steps:

- Laying out the pulling cable, e.g. with an electric pulling robot.

- Tensioning the CRR Block assembly.

- Feeding a new conductor through the cable pulleys of the CRR Block.

The rollers have a spring loaded gripping feature to secure the rope laterally without impinging any rotational movement as the rollers rotate around the axis of the conductor.

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

➡ See Also Further Reading

- Cable Laying, Installation & Support Products | MV HV Windfarm

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

- NOF Members Thorne & Derrick and Slingco Ltd Supporting Cables in the Offshore Wind Industry

Earlier this year, Thorne & Derrick welcomed Phil Day from Slingco Limited, the world-leading manufacturer of cable pulling and support socks, swivels, cable protectors, wire rope assemblies and accessories. Phil provided an Offshore Wind focussed company presentation to our Sales Team (pictured left-to-right Sarah Henderson, Carl Cox, Jonathan Hewitt, Phil Day, Jeff Jhanke, Natalie Lundie and Chris Dodds.

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct

Arc Flash Risk In Wind Turbine Renewables?

April 19th, 2022

Why Is Electrical Safety Important?

April 19th, 2022

Electrical Safety In The Workplace

- Special thanks to MD at Electrical Safety UK for the kind permission to republish

Electrical safety

Identify Electrical Safety Hazards

You cannot smell, hear, or see electricity, so making sure you have the right systems in place to manage this hazardous energy is critical to the wellbeing of your employees and your Company.

There are two major hazards of electricity:

- Electric Shock

- Arc Flash

Electrical safety is important because hazards such as arc flash and shock can result in death if you are exposed to them. Fortunately, the likelihood of this occurring is relatively low. However, the control measures that prevent these hazards require careful management, attention to detail and technical competence.

Injuries that can result from electric shock are as follows:

- Cardiac arrest due to the electrical effect on the heart

- Muscle, nerve, and tissue destruction from a current passing through the body

- Thermal burns from contact with the electrical source

- Falling or injury after contact with electricity

Injuries that can result from arc flash are as follows:

- Burns from the high temperatures produced by the arc

- Blindness from the ultra-violet light produced by the arc

- Hearing loss caused by the pressure wave from the arc blast

Comply with Electrical Safety Legislation

Not surprisingly there is legislation in place that aims to regulate these electrical hazards. The three main ones are:

- Health and Safety at Work Act – Primary piece of legislation covering occupational health and safety in Great Britain. It sets out the general duties which:

- employers have towards employees and members of the public

- employees have to themselves and to each other

- certain self-employed have towards themselves and others

- The Electricity at Work Regulations – expand on the rules regarding electrical safety in the Health and Safety at Work Act 1974. Employers are given duties and responsibilities to make sure that all work activity that uses or may be affected by electricity is done safely, and that all foreseeable risks are assessed and minimised as much as possible.

- Management of Health & Safety at Work Regulations 1999 – Employers are required to undertake an assessment of the risks to the health and safety of their employees and other people who may be affected by their work activity.

More Electrical Safety Products for LV MV HV Cables, Conductors, Substations & Overhead Lines

Managing Electrical Risk is Important

We will now try to answer the question: What should you have in place to manage electrical risk?

In a nutshell, it is important have an Electrical Safety Management System in place. What does that consist of, you may ask? It depends upon the size of your organization, but let us assume you are a large company, you should have something like the following in place:

- Electrical Safety Rules – including training, compliance, and auditing.

- Electrical Safety Instructions typically these may cover subjects such as:

- Arc Flash

- Live Working

- Design Standards

- Earthing Systems

- Tools and Test Equipment

- Hazardous Areas

- Lightning Protection

- Electrical Maintenance

- Electrical Isolation and Immobilization

- Fault finding and phasing out

- Excavations and cartridge tools

- Ageing and obsolescence

- Fire Systems

- Electrical Permit System – typically:

- Low Voltage Permit to Work

- Limitation of Access

- High Voltage Permit to Work

- Isolation Certificate

- Sanction for Test

- Sanction for Live Work

- Electrical Authorisation System – You should have different levels of authorisation for electrical personnel that limits what work they can do. You may have several different levels of authorisation such as:

- Senior Authorised Person

- Authorised Person

- Competent Person

Take our free electrical safety self assessment for a formal report on your current situation.

Within each category there can also be different levels of authorisation dependent upon the competency required to undertake certain tasks.

1. Electrical Competency Management System:

This should describe how you manage electrical competence, from recruitment through to technical competence requirements for each electrical role within your organisation.

2. Organisational Arrangements:

This should describe who is responsible for electrical safety and how your organisation is set up to manage electrical safety, including individual roles and responsibilities.

Electrical Safety Management is our core business. We provide expert consultancy and advice services for blue chip organisations across Europe concerned with the safe management of risk associated with all electrical work activities.

Electrical Safety UK provide a multi-faceted holistic approach including a full electrical safety management programme, project management and policy documentation all bespoke to the client’s requirements including fully accredited and bespoke training courses and personnel assessment programmes.

2 Genesis Business Park

Sheffield Road

Rotherham

S60 1DX

Tel: 0800 652 1124

Tel: 01709 961 666

Email: [email protected]

To find out more information click here

Electrical Safety Providers

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.

Cable Socks – Proper Usage, Maintenance & Inspection for Pulling-in Cable

April 19th, 2022

Thorne & Derrick | Jointing, Termination & Pulling Equipment

Cable Socks

Have You Inspected Your Cable Socks?

Inspecting cable socks (also known as a cable grip and cable stocking) is not an exact science, but is crucially important to ensure safe cable pulling operations, maximum grip strength and grip longevity. There are a number of variables that can weaken cable socks that are not immediately obvious on visual inspection. However, there are some important and simple checks that you can do routinely to mitigate product wear, deterioration and potential accidents from happening.

When inspecting a cable grip, it is critical to know the potential damage and trouble spots. Below highlights the type of damage you need to be aware of prior to beginning any pulling project with your cable socks.

CABLE Sock INSPECTION

Safety is Slingco & Thorne & Derrick’s primary concern.

The products manufactured by Slingco are safety critical and must be used by competent trained personnel – it is essential to choose the right cable grip for the job. Inspecting a cable grip is not an exact science. There are a number of variables that can weaken a cable grip that are not immediately obvious on visual inspection.

This is why we work to Factors of Safety.

It is important to know the difference between Working Load and Approximate Break Load, and how to use the Factor of Safety to calculate the Working Load Limit for the cable grip that will be utilized. To maximize grip performance, we highly recommend utilizing banding on the ends of cable grips, as shown in the figure below.

WLL = ABL ÷ FoS

Cable Grip Factor of Safety (FoS) *

- Overhead Pulling – 5 : 1

- Underground Pulling – 3 : 1

- Cable Supporting – 10 : 1

WORKING LOAD LIMIT

The Working Load Limit (WLL), sometimes also known as the safety working load, is the mass that the equipment being used can safely hold, pull, or lower without breaking. In short, it’s the maximum load that can be applied to the product safely when in general service.

The Approximate Break Load (ABL) is the load at which a new grip can be reasonably expected to break. This is measured on a straight line pull only, as side pulling, or angular loads, will produce different results.

The Working Load is calculated by dividing the Approximate Break Load (ABL) by the Factor of Safety (FoS). No component in the system should exceed the working load for the cable grip.

The Factor of Safety (FoS) is the “extra” coverage of the breaking load over the over the working load expected. Factor of Safety is often noted as “X to 1” or “X:1”. The Factor of Safety accommodates normal spikes in load tension that may occur when under load.

Note: Slingco recommends double banding the ends of cable socks.

When you are inspecting a cable sock, it is critical to be able to identify damage or potential trouble spots. The following are some of the types of damage you should be aware of prior to beginning a pulling project with your cable grips. If these are observed, replacement of grip should be considered.

Pulling & Supporting Power & Subsea Cables in the Wind Sector | These cable socks manufactured from offshore/marine grade type 316 Stainless Steel are suitable for use in the renewable energy sector in applications such as cable installation (onshore and offshore), cable support inside wind turbines and cable management – used to pull, protect and support wind turbine cables. Pictured: June 2020 : the first of two export cables, each 37 kilometres in length, has been installed at the nearshore of Thorntonloch Beach as part of construction of the Neart na Gaoithe (NnG) Offshore Wind Farm.

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

➡ See Also Further Reading

- Cable Laying, Installation & Support Products | MV HV Windfarm

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

- NOF Members Thorne & Derrick and Slingco Ltd Supporting Cables in the Offshore Wind Industry

Earlier this year, Thorne & Derrick welcomed Phil Day from Slingco Limited, the world-leading manufacturer of cable pulling and support socks, swivels, cable protectors, wire rope assemblies and accessories. Phil provided an Offshore Wind focussed company presentation to our Sales Team (pictured left-to-right Sarah Henderson, Carl Cox, Jonathan Hewitt, Phil Day, Jeff Jhanke, Natalie Lundie and Chris Dodds.

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct