Blog

Offshore Wind & Subsea Power Cables | Market Trends by ORE Catapult

December 1st, 2021

The following article, exploring offshore wind subsea power cables, has been republished with the kind permission from the authors: Othmane El Mountassir & Charlotte Strang-Moran from ORE Catapult | Published September 2018 | AP-0018

Installation, Operation & Trends

By the end of 2018, installed offshore wind power capacity will reach a total of 30.2GW, with 22.9GW of generation in Europe and 7.3GW across the rest of the world. The UK remains the global leader in offshore wind, with a total capacity of 6,385MW and an additional capacity of 3.2GW entering operation by 2020. As the industry’s generation capacity continues to grow, so does the need for developing reliable, high-capacity transmission cable technologies.

Subsea power cable failure is frequently reported as an issue for offshore wind farm operators. Such failures are reported to account for 75-80% of the total cost of offshore wind insurance claims – in comparison, cabling makes up only around 9% of the overall cost of an offshore wind farm. A lack of available data on cable failures led ORE Catapult to develop an interactive tool for internal use, which captures information about UK offshore wind projects and their power cables’ lifecycle from the installation to the operational phase.

This paper summarises some of the most pertinent insights on cable failures gleaned from the Catapult’s use of the tool and sets forth suggestions on how to improve knowledge-sharing in the offshore wind community to reduce the impact of future failures.

Headlines

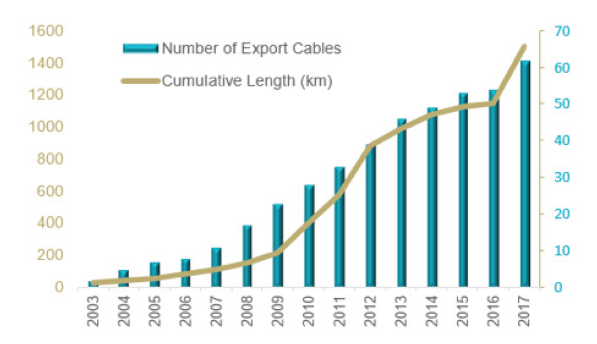

- The UK’s operational offshore wind farms are using 62 export cables totalling a length of 1,499km and over 1,806km of inter-array cables to transport the 6,385MW of electrical generation.

- A total of 43 array and export cable failures have been reported since 2007. Issues associated with manufacturing and/or installation are reported to be the most common cause of cable failure.

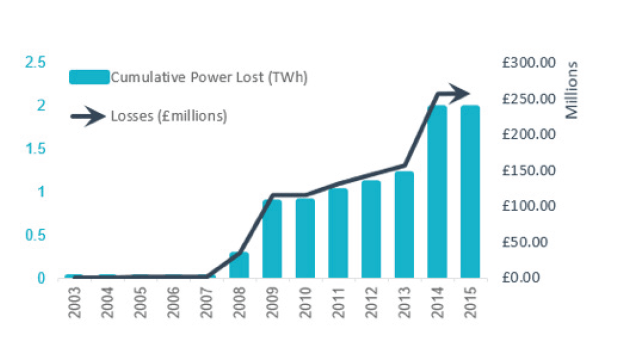

- From 2014 to the end of 2017, recorded cable failures at UK offshore wind projects have led to a cumulative loss of power generation of approximately 1.97TWh.

UK Offshore Wind Trends

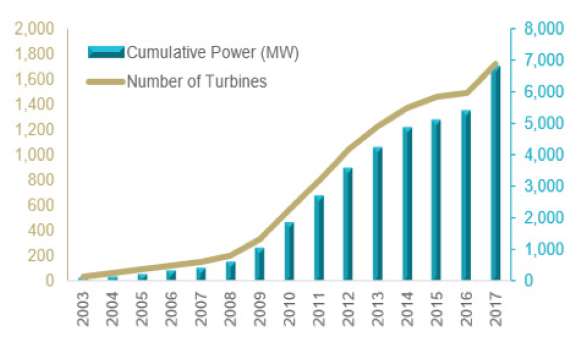

The UK generates more electricity from offshore wind than any other country in the world. Operational offshore wind farms are currently generating 6,738MW using 1717 turbines.

In 2017, the UK installed 1681MW, representing more than half of the new offshore wind power capacity built in Europe. It is forecasted that by 2020, there will be a record-breaking year for new capacity – largely driven by delayed wind farms and the deployment of large-capacity turbines in the 7MW 8MW range. The following figures provide an insight into current UK offshore wind sector trends.

Wind Development: By the end of 2018, installed offshore wind power capacity will reach a total of 30.2GW worldwide, with 22.9GW of generation in Europe and 7.3 GW in rest of the world. The UK remains the European country with the largest installed capacity, reaching a total capacity of 7,851 MW by the end of 2018.

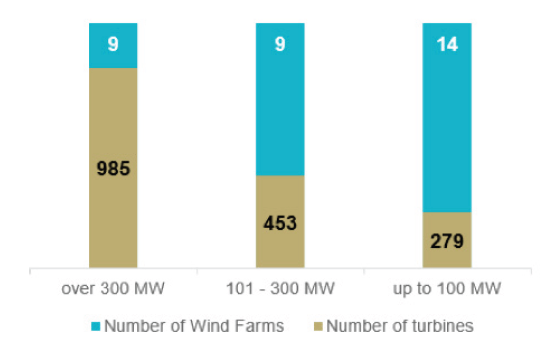

Farm Capacity: By categorising wind farms into three ranges of generation capacity, it can be seen that the larger the capacity range of the wind farms, the higher the number of wind turbines being used. It is expected that this trend will change with the deployment of higher-capacity turbines, reducing the number required.

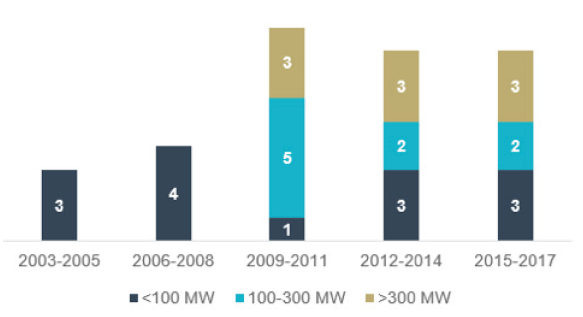

Progressive Trends: Since the development of the first demonstrator projects in 2003, the UK’s offshore wind sector has witnessed strong growth, supported by government incentives and investor confidence in the sector. This can be demonstrated in the figure above, where we can see over the years an increase in the number of offshore wind farms and demonstrators with different generation capacities.

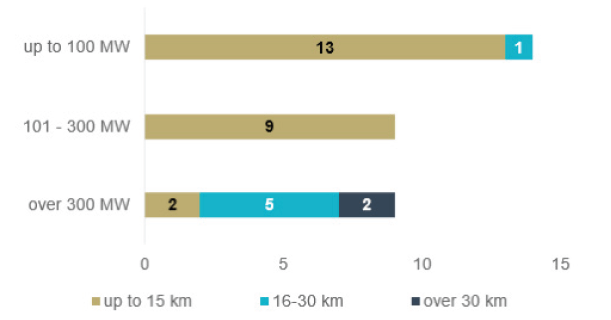

Distance from Shore: The UK’s geographic location makes it ideal for offshore wind generation. Early developments from the Round 1 and Round 2 leasing phases were relatively small and close to shore. In contrast, recent projects and future developments have seen and will see this distance increase to the 50-90km range from shore to take advantage of the wind strength in these areas.

Subsea Cable Trends

The rapid growth of the offshore wind sector has led to the development of a number of new subsea cable technologies. This was mainly supported by a robust cable-related supply chain with leading organisations in manufacturing, services and academia present across the UK. The demand for subsea power cables will continue to grow at a fast pace to support both future offshore wind development and the subsea power interconnector sector.

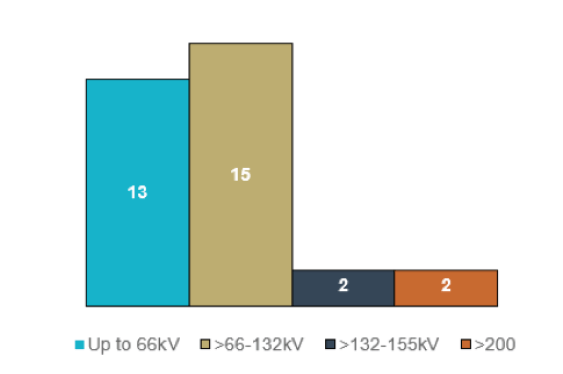

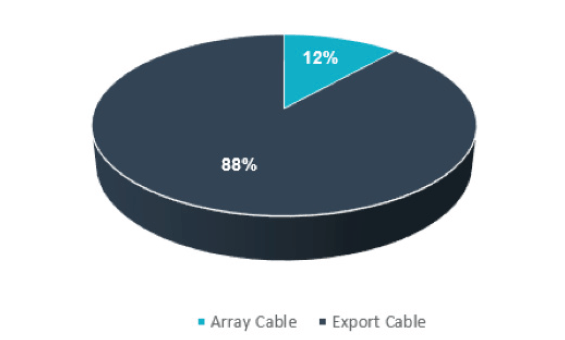

Export Cables are vital for transmission of the generated power to the grid. The UK’s operational offshore wind farms are using 62 export cables totalling a length of 1,499km. The voltage levels of these cables range from 33kV for nearshore wind farms without offshore substations, and up to 132kV, 150kV and 220kV for further-offshore sites with one or two substations.

Export Cable Trends: Research and development activity has led to the development of new cable technologies. Since 2013, over 80% of projects in Europe have deployed export cables with a voltage greater than 150kV. Reflecting the rapid development of cable technologies, 80% of projects commissioned in 2018 will be using cables with a voltage level greater than 200kV.

Array Cable Development: There are over 1,806km of inter-array cables in UK waters. To maximise generation revenue and achieve Levelised Cost of Energy reductions, offshore wind projects will continue to increase in size.

As such, the lengths of array cabling used is expected to increase due to the increased number of turbines and the distance between them.

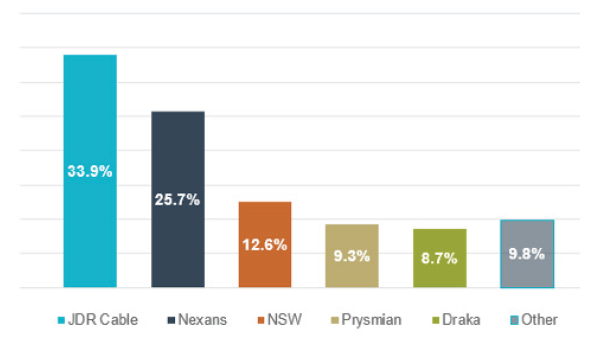

Array Cable Manufacturers: The cable market is generally global in nature and there are a number of suppliers available. A notable UK success has been achieved with JDR cables, which has supplied numerous UK offshore wind projects, as well as several overseas projects. The expansion of the market and growth of an indigenous UK supply chain is expected to help reduce costs.

Cable Failure Trends

According to industry data obtained by the Catapult, cables account for the largest number of insurance claims in the offshore wind sector. Though subsea cable failures are reported often, publicly-available information remains scarce. The following figures, gleaned from the Catapult’s internal cable database, provide an insight into reported subsea power cable failures in the UK’s offshore wind sector.

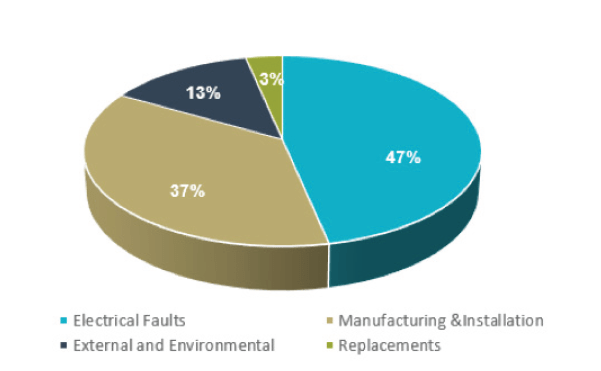

Cable Failure: Incidents relating to the installation and operation of subsea power cables are found to be the most costly cause of financial losses in offshore wind industry. Since 2007, 43 known failures of wind farm array and export cables were reported. The issues associated with these failures vary in nature.

Causes of Failure: Issues associated with the manufacturing and/or installation phase are reported to be the most common cause of cable failure. The failure events reported include cases where unplanned faults have occurred, or when planned, pre-emptive repairs have been required to avoid the likelihood of fault.

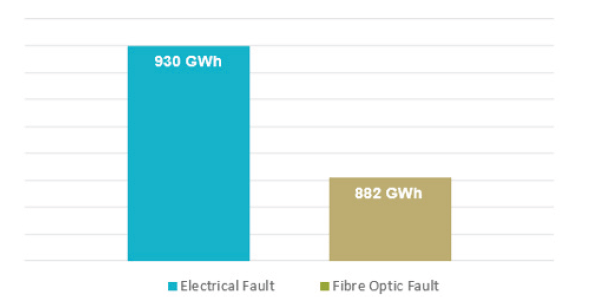

Fibre Optic and Electrical Faults: In the UK’s offshore wind sector, recorded faults of electrical origin were found to be higher than fibre optics failures. To date, power losses due to fibre optics failure reached an estimated value of 600GWh, while losses due to electrical faults were estimated at 1,160GWh. It should be noted that electrical failures may sometimes lead to the failure of fibre optics.

Costs of Failure: The cost of a cable failure can be considerable, taking into account repair costs and generation revenue loss. From 2014 until the end of 2017, recorded cable failures at UK projects have led to a cumulative generation loss of approx. 1.97TWh, equating to approx. £227M*. This figure demonstrates beyond doubt that the sector is still in need of innovative cable installation and repair technologies. *Based on a strike price of £115/MWh.

Discussion and Next Steps

The UK has a robust subsea cable-related supply chain, encompassing manufacturing, service providers and academia. However, there is still a lack of communication between stakeholder groups. For example, the standardisation of cable installation practices may lead to fewer installation issues, while the dissemination of learned experiences can be used to predict or avoid certain failures and also bridge innovation gaps in manufacturing. However, this is only possible if the parties involved are willing to share the required records. There is a consensus from market stakeholders that subsea cable project activities are currently dispersed, and a more structured and co-ordinated process is required to pull promising technology and ideas through development and demonstration. However, proposed concepts aimed at developing a subsea cable database, which informs and enables stakeholders to identify and bridge gaps in innovation – has been met with scepticism from a number of systems owners and operators; questions remain over whether a live, regularly-updated database would be providing ongoing value and longevity.

To ensure the successful development and implementation of appropriate technologies and processes aimed at reducing cable failures within the offshore wind industry, ORE Catapult is acting as a driver for a number of initiatives such as the Offshore Wind Innovation Hub, subsea cable innovation challenges, and technology demonstration opportunities for SMEs at its Levenmouth Demonstration Turbine. The Catapult also anticipates launching a publicly-available web-based platform dedicated to subsea power cables. To help solve some of the challenges around offshore wind subsea cable applications, ORE Catapult has developed a dedicated internal database and an Offshore Wind Innovation Hub strategic programme dedicated to subsea power cables and future systems. The aim of the internal cable database platform is to provide quantitative information and evidence to support building a consensus to solve common cable issues, while the Offshore Wind Innovation Hub was established to co-ordinate the sector’s innovation needs and provide a comprehensive view of the research funding opportunities available.

It is beyond question that the offshore wind sector will continue to expand further over the coming decades. Future wind farms will make use of higher-capacity turbines and will be located further offshore: with that comes the requirement for robust cable technologies and safe installation and operational practices. The sector must learn from the wider industry and share information and lessons learned so that costs can continue to fall, helping the wider offshore wind supply chain continue its trajectory of growth.

Further Reading

Lead-Free Cables | The Future for Offshore Wind Farms

Providing Electrical Safety & PPE to Offshore Wind Farm Workers

Pipe & Cable Seals for Offshore Windfarm Substations, Enclosures & Foundation

LV, MV & HV JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

See how T&D support, supply and service the Renewable Energy industry.

MV HV Cables 11kV 33kV 66kV | Cable Joints, Terminations & Connections

NEW | Ripley Cable Stripping Tools to Improve Safety & Reliability

November 23rd, 2021

NEW Ripley Stripping Tools Improve Safety And Reliability

IMPROVE SAFETY AND RELIABILITY

Cable Stripping Tools

The following blog has been republished alongside the below video from Utility Service Agency, where they demo their favourite Utility Tool® tools for improving safety and reliability during cable preparation.

“What I like about this tool is that it’s very easy to see your blade when you’re doing your chamfer in the field.”

Improve reliability and safety at the same time; take the knife out of your hand and put the Ripley Tools in your hand.

Utility Tool from Ripley offer two by two and four by four cable strippers with bushings. The bushings on each side are specifically designed for the conductor sizes you need. “Take about a twelve to 14 inch cut of all those sizes, and send them off to Ripley tools to get your specifically sized bushing.”

|

|

“To use these tools, just run it down to your spot, I have my hand as a stopper. Perfect cut. No scoring. Safe. Good to go.”

For those that need more adjustability on the system, the WS 71 and WS 72 Series provides mid span. Just tighten it down and again, run it right down. If you want to take the WS 71 and 72 and make them into one tool, take the US07-7000.

This is new tool from Ripley is capable of doing end strips and also your midspan strips all in one tool. “We used to have two tools for your chamfering. Now we have one tool.”

We also have a US10 7000 which performs a 30 degree chamfer, and then we have a US10 7001 which performs a 45 degree chamfer. See below for further product specification.

US07 Series

Adjustable 600-1000V Secondary Cable Stripper

Introducing the new US07 Adjustable Cable Stripper that quickly and easily end strips or midspan strips cable insulation with no conductor damage on 8 to 1000 kcmil secondary cables. The tool utilizes a size adjustment clamping system to swiftly adjust and lock onto the insulation. Its compact, low friction, thermoplastic, impact-resistant polymer v-jaw and body provides a stable and precise clamping platform in any space.

- Equipped with safe, recessed blade to prevent potential injury & blade damage

- Quickly adjusts to suit THHN, XHHW & USE secondary cables with 0.3″ to 1.375″ (7.6 mm to 35 mm) cable diameters, eliminating the need for bushings

- Easily adjusts with detent actuated knob & fine adjustment knob to match insulation thickness for fast stripping without conductor damage

- Features a replaceable, machined & ground tool steel blade

- Combines the end & mid-span strip performance of the UtilityTool® WS 71 & WS 72 with added features, stability & cable sizes

- Durable bronze bushings provides longevity

US10 Series

URD Cable Insulation Chamfering Tool

The new innovative US10 Cable Insulation Chamfering Tool utilizes a size adjustment clamping system to quickly and easily adjust and lock onto the insulation. Its compact, low friction, thermoplastic V-jaw construction and PTFE-coated aluminium frame provides a stable and precise clamping platform in any space.

- Easily adjusts to suit XLPE & EPR insulation materials on 0.5″ to 2.36″ (12.7 mm to 60 mm) cable diameters

- 30 degree or 45 degree angle bevel models perform with a factory-set chamfer depth of 0.075″ (1.905 mm), adjustable from 0″ to 0.150″ (0 mm to 3.81 mm); 15-35 kV

- Equipped with safe, recessed blade to prevent potential injury & blade damage

- Features a replaceable, machined & ground tool steel blade

See our complete range of Jointing Tools for the preparation and stripping of LV MV HV cable prior to the installation of joints, terminations and connectors.

LV, MV & HV JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Sealing Cables For Cable Drum Storage | Part 3

November 22nd, 2021

Sealing Cables

Stephen Harrison – Training & Technical Manager at Current Training Service Pty Ltd

In Part 1 and 2 of the series we discussed how to correctly seal cable ends and explored the different types of cable end caps which have been designed for pulling cables and storage.

Part 3 will explain about water getting into cables when storing cable drums outside.

When cable drums are stored outdoors with end caps attached, the sun and other elements may cause the end cap to move and break the glue seals allowing moisture to migrate into the cable. If this happens, the cables are now in a poor state for installation as there may be some traces water in the cables prior to installation.

This is not an ideal situation.

The use of black sealant mastic and end caps will ensure the seal will not move or crack and water is less likely to penetrate the cables.

It’s important for your cables, which are being stored, to have the best chance of being in a pristine condition when you need to pull them in.

There are many “backyard” ways of sealing cables: PVC insulation tape wrapped around the ends of the cable, cloth and tape wrapped around the ends, plastic bags with tape wrapped around, and sometimes no end caps at all. The best way of sealing cables is with heat shrink or cold apply end caps and mastic.

To recap from Parts 1 & 2, when pulling cables and leaving the cables in pits etc, consider using triple end seals for added protection. When storing cable drums outdoors, consider using a drum storage for extra sealing and storage.

- Cable Pulling & Laying | Sealing Cables Whilst Installing | Part 1

- Cable End Caps | Cable Pulling & Storage | Part 2

Cable Pulling Cable Laying Equipment

Further Reading

Cable Pulling Calculation Example From Brugg Cables

Secure Spiking of Underground LV & HV Cables | Cable Spiking & Cutting Tools

Cable Pulling & Cable Laying Equipment

ICP Showcase | Smith Brothers Ltd

November 12th, 2021

Pictured: Class-leading workmanship and Jointer competency demonstrated in the installation of NKT separable connectors shown here terminating medium voltage power cables at 33kV into Siemens 132-33kV 130MVA power transformer.

Project | Lucite (Billingham)

Sector | Chemical Manufacturing

Date | November 2011

Smith Brothers Ltd is a large, turnkey electrical contractor with over 20 years’ experience. Since their inception in 1999, they have worked on a vast portfolio of projects throughout the UK and overseas, both as an ICP and EPC contractor on schemes up to 132kV. Offering a range of services and can cater for everything from the delivery of a turnkey project – including design, the supply and commissioning of equipment and cabling installations from LV up to 132,000 volts (220,000V in ROI).

Jointing & Cabling Services

Cable and jointing services provided by Smith Brothers Ltd including cable management, installations and fault finding.

- Cable Jointing | Turnkey installation – cable management, joints and terminations, cable ladder racking, cable tray and basket systems civil works and cable pulling

- Cable Testing | Certified testing with HV pressure testing up to 80,000 volts (80kV) DC and VLF testing up to 94,000 volts (94kV)

- Cable Fault Location | Cable and fault location, identification and cable spiking

- Energisation | Network switch-ons – trained and certified to act as an authorised person for switching on client networks and projects

Services by Smith Brothers

• Cabling & Jointing

• Containerised Substations

• Extra High Voltage (EHV)

• Engineering, Procurement & Construction (EPC)

• Emergency Callouts

• Industrial, Commercial, Manufacturing

• Maintenance & New connections

• Onshore & Offshore Jointing

• Optical Fibre Installation

• Power System Design

• Switchgear & Transformers

• Testing & Commissioning

Nov 2020 | Lower Strensham – Western Power Distribution (WPD). Smith Brothers Contracting Ltd was commissioned by Next Energy to provide turnkey electrical engineering services for the development of a 125-acre solar farm in Strensham, Worcestershire.

Dec 2020 | The Grange – Western Power Distribution (WPD). Smith Brothers Contracting Ltd was commissioned by Next Energy to provide turnkey electrical engineering services for the development of a 125-acre solar farm in Strensham, Worcestershire.

Nov 2016 | Western Power Distribution (WPD) – North Steads Wind Farm – Northern Power Grid (NPG) 33kV Loop In Loop Out.

Smith Brothers was employed by I & H Browns to undertake the balance of plant electrical works of North Steads Wind Farm. This 18MW Wind Farm development consists of nine Senvion 2.05MW turbines which are connected to NPG’s 66kV network, The contract covered the following scope of works:

Design, supply, installation and commissioning of the electrical equipment within the substation building, including:

- 66kV ceiling end structure

- 24MVA ABB power transformer 66/33kV ONAF c/w neutral earthing resistor

- 33kV wind farm array switchboard -ZABB ZX02

- AUX transformer with LV auto/changeover switchboard

- Design, supply, installation and commissioning of the 33kV wind farm array cables between the substation and the nine wind turbines

- Design, supply, installation and commissioning of the fibre optic cables interconnecting the wind turbines

- Installation and commissioning of the Senvion’s free-issue SCADA equipment, installed within the SCADA room of the substation building

- Testing and Commissioning of the protection interfaces with NPG

- Design, supply, installation and commissioning of the substation small power and lighting

- Energisation of the wind farm site

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX and Shrink Polymer Systems.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at MV HV.

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

BOOK REVIEW | The European Arc Flash Guide By Mike Frain CEng FIET MCMI

November 5th, 2021-

uploaded by Chris Dodds - Thorne & Derrick Sales + Marketing Manager

The European Arc Flash Guide

By MIKE FRAIN CEng FIET MCMI

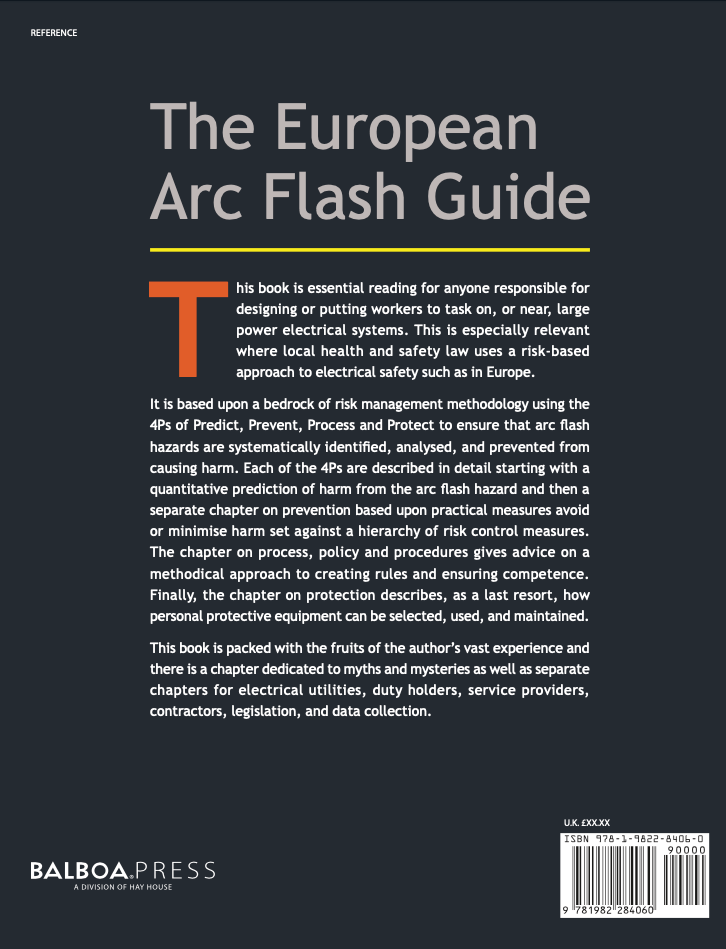

This publication is a must-read book which provides a practical approach to the management of arc flash risk in electrical power systems for designers, duty holders, consultants, service providers and health and safety specialists.

An arc flash can cause minor injuries, third degree burns and potential death as well as other injuries including blindness, hearing loss, nerve damage and cardiac arrest.

Purchase your copy today by clicking the BUY NOW on the image below.

Overview

This book is essential reading for anyone responsible for designing or putting workers to task on, or near, large power electrical systems. This is especially relevant where local health and safety law uses a risk-based approach to electrical safety such as in Europe.

It is based upon a bedrock of risk management methodology using the 4Ps of Predict, Prevent, Process & Protect to ensure that arc flash hazards are systematically identified, analysed, and prevented from causing harm.

Each of the 4Ps are described in detail starting with a quantitative prediction of harm from the arc flash hazard and then a separate chapter on prevention based upon practical measures to avoid or minimise harm set against a hierarchy of risk control measures.

The chapter on process, policy and procedures gives advice on a methodical approach to creating rules and ensuring competence. Finally, the chapter on protection describes, as a last resort, how personal protective equipment can be selected, used, and maintained.

This book is packed with the fruits of the author’s vast experience and there is a chapter dedicated to myths and mysteries as well as separate chapters for electrical utilities, duty holders, service providers, contractors, legislation, and data collection.

Book Details

- ISBN-10: 1982284064

- Publisher: Balboa Press UK

- Publication date: 20th September 2021

- Pages: 306

- Dimensions: 59(w) x 27.94(h) x 2.11(d)

Available from: Amazon, Balboa Press and Barnes & Noble

Chapters

Introduction

- 1 Purpose and Scope

- 2 What is Arc Flash?

- 3 Risk Assessments and the Four P Guide

- 4 Prediction

- 5 Prevention & Minimisation

- 6 Process, Policies & Procedures

- 7 Protection

- 8 Data Collection

- 9 Electrical Duty Holders

- 10 Service Providers and Contractors

- 11 Electrical Utilities

- 12 Myths & Mistakes

- 13 Complex Software Guide

- 14 Hazard & Severity Calculators

- 15 Why Do Arc Flash Calculations?

- 16 Rules, Codes & Legislation

The Online European Arc Guide

Whilst the book gives you the how to manage arc flash risk, the online European Arc Guide gives you the tools to carry it out. It’s accessible from phones, tablets, and laptops which provides the tools and together with the book is a practical and valuable resource to discover and manage dangerous levels of electrical incident energy in the workplace. Click the link here – www.ea-guide.com

About The Author Mike Frain

Mike Frain is an expert for the BSI live working technical committee TC78, Convenor for the IEC arc flash working group, Project Team Leader for the IEC arc flash guidance for end users project team, vice chair of the IET Engineering Safety Policy Panel and heads up the IET arc flash working group. He has extensive experience delivering electrical safety consultancy and arc flash system studies throughout Europe and beyond for large blue-chip organisations.

MIKE FRAIN CEng FIET MCMI

- IEC Convenor for the Arc Flash Working Group

- IEC Team Leader for PT 902 Arc Flash Guidance

- BSI Expert for Technical Committee 78 Live Working

- IET Vice Chair of the Engineering Safety Policy Panel

ARC FLASH CLOTHING

Stockists & Suppliers

ProGARM is a specialist UK Arc Flash Garment and Accessories manufacturer, delivering the ultimate in arc flash protective clothing without compromising on comfort – Thorne & Derrick provide competitive prices and fast delivery for the complete range of ProGarm arc flash clothing designed to protect people and save lives. ProGarm offer a wide range of mens and womens arc flash garments providing comfortable protection to our clients in the LV HV Electrical Power & Substation sectors of the onshore and offshore renewable, rail, utility, data-centre and energy storage sectors.

Arc Flash | Polo Shirts | | Coveralls | | Sweatshirts | Helmets | Insulating Gloves

THORNE & DERRICK | SPECIALIST ELECTRICAL DISTRIBUTORS | MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales | Nexans Euromold MONO JTS | Pfisterer Connex | 3M Cold Shrink