Blog

PPE The Material Difference | Inherent v Treated Fabrics for Arc Flash Clothing & Protection

July 26th, 2021

Choosing the Right PPE for You

Arc Flash Clothing, PPE & Flash Protection Kits

In a world awash with baffling technical speak, we cut through the jargon to explain the difference between treated and inherent flame resistance and the considerations when weighing up which to buy when evaluating competing garments to protect against arc flash dangers.

The Big PPE Fabric Debate

If you’ve been browsing PPE catalogues searching for arc flash and flame-resistant (FR) workwear, you have probably noticed there are many ways to describe the nature of the fabrics the garments are made from.

The two main phrases used in descriptions of arc flash clothing are inherent fabrics and treated fabrics. So, what’s the difference? And why does it matter?

VXS Inherent Fabric | Arc Flash Clothing Fabric

PPE | Treated Flame-Resistant Fabrics

A fabric described as treated will be made from fibres which aren’t flame retardant by their nature, but have either had a chemical applied, or have been through a chemical process, to make them fire resistant by creating a chemical reaction when set alight which then extinguishes the flame.

PPE | Inherent Flame-Resistant Fabrics

Protecting Utility Workers Carrying Out Maintenance, Repair & Operations on Overhead Lines & Underground Cables

If a fabric is inherently flame-resistant (also known as inherently fire-retardant), its ability to protect you from heat and flames comes from the polymer fibres of the fabric which, at normal oxygen levels, don’t ignite.

Pros & Cons of Inherent & Flame-Resistant Fabrics

Most of our ProGARM range of PPE is made using inherent fabrics because this makes it impossible for the flame resistance to degrade over time or be washed out altogether. These garments also don’t shrink when exposed to heat, helping to maintain critical air layers between the fabrics.

The advantage of treated fabrics is that they’re cheaper. However, this passes considerable responsibility to the employer to devise a system for wearers to monitor their garment’s wear and record its laundry cycles so the company knows when to replace the item due to degradation of the protective treatment.

VXS+ 100% INHERENT

ARC FLASH PROTECTION FABRICS

By manufacturing all ProGARM garments with our unique VXS+ inherent fabrics, we ensure they deliver durability, consistent protection and outstanding comfort.

In the past, many Flame Resistant Garments have suffered from reduced protection over time. Through normal washing, treated fibres gradually lose their Flame Resistant properties. With that decreasing level of protection your team members will be at greater risk of injury.

Treating fabrics can also leave them stiff and uncomfortable. Worryingly we hear of operatives deciding to wash treated garments multiple times to make them more comfortable before wearing them. Alternatively, they choose to keep wearing their older garments which have become more comfortable over time. Both of these practices leave your team exposed to a greater risk of injury.

Arc Flash PROTECTION. DURABILITY. COMFORT.

Electrical Safety & Arc Flash PPE

ProGARM ensures this isn’t the case with our unique 100% inherent VXS+ fabrics that offer superb protection for your team, as well as being durable and comfortable to wear.

VXS+ fabrics are manufactured with a combination of yarns which makes the garment inherently Flame Resistant. Compare VXS+ Fabrics with alternative fabrics and the differences are clear. As well as being 100% inherent, VXS+ fabrics make some of the most comfortable Arc Flash protective garments on the market. Through combining yarns in the manufacturing process, we can deliver fabrics that are flexible and comfortable, and from that create garments that are “as comfortable as pyjamas”.

As well as the ultimate protection, you also need garments that are durable. ProGARM garments are have been shown to last up to 70% longer than comparable garments used by our customers. Some non-ProGARM garments can also suffer from shrinkage and their colour fastness isn’t as resilient as it should be, resulting in faded high visibility workwear. VXS+ fabrics have been tested through more than 50 industrial washes to ensure the longevity of the garments. (The European standard only requires demonstrating colour fastness through 5 wash cycles.)

When you equip your team with ProGARM Arc Flash and Flame Resistant garments made from VXS+ Fabrics, you can be assured of durable protection and comfort that delivers protection throughout the life of the garment. That’s why every ProGARM garment is manufactured using VXS+ 100% inherent fabrics to offer the ultimate protection.

ProGARM is Pro-Choice

In developing our products, we’ve researched what’s important to our customers and fully appreciate that the decision between buying inherent or treated arc flash PPE isn’t an easy one when working with budget constraints and trying to keep their workforce safe.

That’s why we’ve been researching and developing treated garments. This gives you a choice without quite such a dilemma about the degree of safety compromise when making price-based decisions.

Our new coverall (available in four colour options) has been designed in a way that offers the cost saving advantages of being made from treated fabric, while also being robust enough to withstand up to 100 washes – lasting much longer than many competitor products, which are only tested up to 50 washes.

Electrical Safety STANDARDS

When it comes down to it, it doesn’t matter whether the fire protection in the fabric is inherent or added afterwards with chemicals. What you should make your decision based on is proof of standards.

We’re proud that all of our PPE clothing (not just our fabrics) meet EU Conformité Européenne (CE) standards and the new United Kingdom Conformity Assessed (UKCA) mark.

Our arc flash garments also hold EN certifications relevant to their intended purpose and/or industry. For example, all our garments conform to a minimum EN ISO 6330: 2012 DOMESTIC for washing, and some go further to meet the industrial washing standard (EN ISO15797: 2004 Industrial).

We go a step further too. Having achieved ISO9001 (Quality Management) and added Article 11B[KC3], all our supply chain partners meet the same standards. For us, there are no compromises on quality.

As well as electrical safety considerations, when developing our garments and fabrics, we always research what’s important to our customers. This helps us maintain our reputation for the best safety, quality and comfort standards.

Our independent testing looks at fading and shrinkage, as well as comfort of electrical PPE. And all our buttons, zips and press studs are made from the same military-grade plastics as NASA uses, so that they won’t melt and will still work if exposed to heat, flames or a high-voltage electric charge.

These decisions result in pioneering safety standards and mean that, when a casualty needs urgent medical attention following an incident, you will be able to unfasten and remove the clothing far more easily.

You’ll find a label on each of our electrical safety workwear products, outlining which European and UKCA certifications it meets[KC5] [LT6], along with garment care guidelines.

If you would like a chat with one of our arc flash experts to discuss your PPE requirements, give us a call on +44 (0)191 410 4292.

Further Reading

- Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

- Arc Flash Risks In The Rail Industry

- Arc Flash Survivor Story – Jason Brozen

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

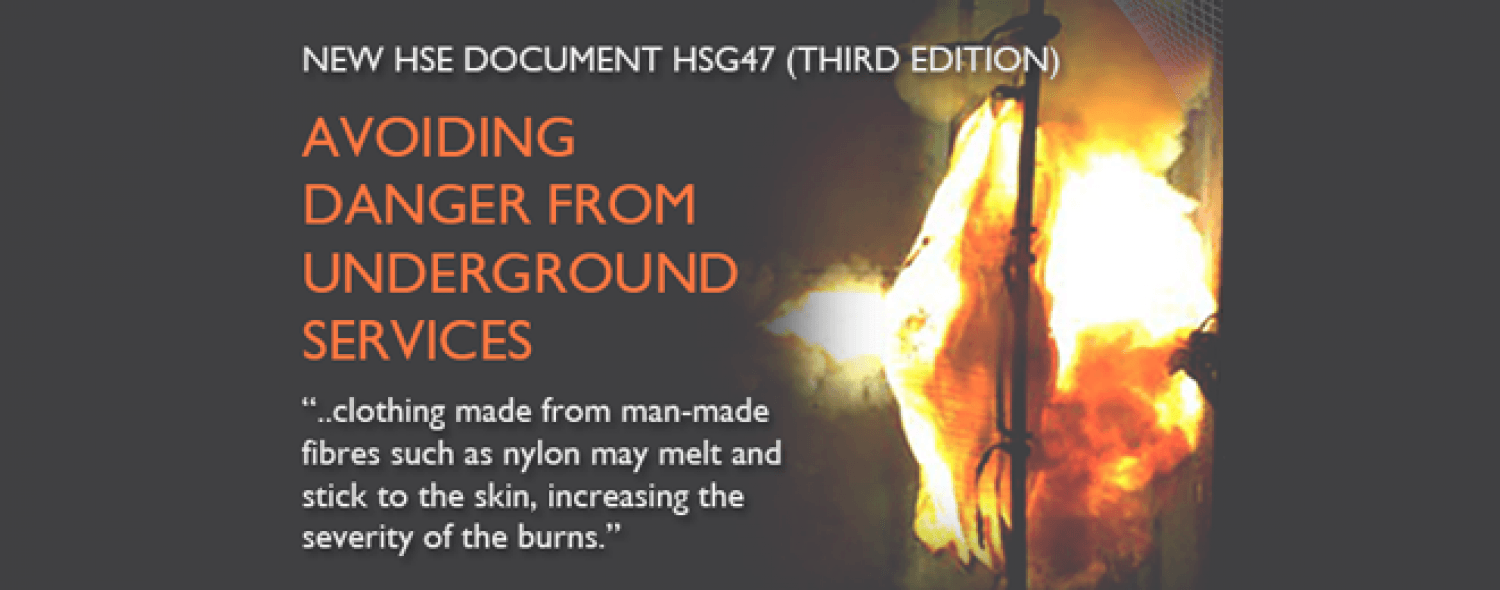

HSG47 | Avoiding Danger From Underground Services | An HSE Document

July 26th, 2021 HSG47 | Avoiding Danger From Underground Services

HSG47 | Avoiding Danger From Underground Services

A Document from Health & Safety Executive

HSE Health & Safety Executive issued the 3rd edition of their guidelines ‘HSG47 Avoiding Danger from Underground Services’ in 2014. Whilst the basic requirements are still the same, this third edition published in February 2014 brings the guidance up to date from the previously published version 14 years previously in 2000.

The document is freely available from the internet by searching on HSG47 2014. Recommendations regarding Protective Clothing against the hazards of Arc Flash Incidents can be found on Page 26 and two extracts are as follows:

“..clothing made from man-made fibres such as nylon may melt and stick to the skin, increasing the severity of the burns.”

“Advice on the suitability and performance of protective clothing should be available from reputable companies specialising in its supply.”

HSG47 (Third Edition) Summary Extract

This guidance is aimed at all those involved in commissioning, planning, managing and carrying out work on or near underground services. It will also be of use to the owners and operators of such services.

It outlines the potential dangers of working near underground services and gives advice on how to reduce any direct risks to people’s health and safety, as well as the indirect risks arising through damage to services.

It explains the three basic elements of a safe system of work during excavation:

- Planning the work

- Locating and identifying buried services

- Safe excavation

This third edition of HSG47 brings the guidance up to date, but the basic requirements remain the same.

(N.B. Extract taken from Page 1 of the document)

Why ProGARM?

Many garments within the ProGARM product range are now certificated to IEC61482 the European Standard for Arc Flash protective clothing and can offer the protection required for your workforce. Garments are tested to either the European Box test method or the US ATPV test method with some garments, including coveralls, offering certification to both test methods.

➡ See also the range of Electrical Safety Equipment

Awareness of Safety Guidance Ahead of Groundworks (HSG47)

Arc Flash Risks During Construction Groundworks

HSG47 is the Health & Safety Executive’s issued guidance aimed at all those involved in commissioning, planning, managing and carrying out work on or near underground services.

It’s comprehensive in covering the three basic elements of safe systems of work through planning, locating & identifying buried services and safe excavation.

Coveralls | Switching Suits | Polo Shirts | Helmets | Gloves | Garments

The most recent third edition, released in 2014, brought guidance up to date, but still outlines the same potential dangers as those flagged in the first release in 1989.

ONLY 22% OF WORKERS AWARE OF HSG47 GUIDANCE

Yet ProGARM’s Arc Flash Survey in 2017 revealed a staggering 78% of respondents were still unaware of what the guidance included when it came to reducing the risks of Arc Flash incidents.

For three whole years of London’s Crossrail project, eight tunnelling machines were working to create the 42 km of new train tunnels.

We can only imagine the extensive degree of research and planning that must have gone into the location and re-siting of London’s complex array of underground services during this phase of the works to avoid such incidents.

But for every high-profile, major infrastructure project like this, with specialist civil engineers working to incredibly precise risk assessments and method statements, there will be hundreds more smaller scale projects taking place where work is not being carried out with the same levels of awareness, diligence or training.

At ProGARM, we may provide a last line of defence against an Arc Flash in the form of specialist PPE, but there’s no substitute for awareness and proactive steps to minimise the risks of them occurring in the first place.

➡ Thorne & Derrick | Specialist Distributors & Stockists of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment to the Rail industry.

Further Reading

- Arc Flash Risks In The Rail Industry

- Arc Flash Survivor Story – Jason Brozen

- The Arc Flash Risk in Electric Metering

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

NEW PRODUCT LAUNCH | RIS-3279-TOM Tested Arc Flash Coveralls (Hi-Vis Orange) | ProGARM 4693

July 26th, 2021ProGARM 4693

RIS-3279-TOM Tested Arc Flash Coveralls

ProGARM’s Mission is to Lead with Innovation

Introducing the new addition to the ProGARM range of Arc Flash Clothing, lightweight and most comfortable high vis orange coveralls – standard style – ProGARM 4693, also available in ladies’ fit style – ProGARM 4694.

These arc flash coveralls feature the newest lightweight 240gms fabric, extremely breathable, designed with intention of achieving lightest and most breathable results.

Features & Benefits of Arc Flash Overalls

- Mandarin collar // Maximum neck protection

- Kneepad pockets // Wear with kneepads for extra comfort

- Chest pockets // Secure storage

- Gas monitor loop // Secure fixing point

- SafetyICON™ on arm // Visual EN Norm icon system

- 5cm FR AS reflective tape // Double stitched for longer life

- Phone Pocket on sleeve with flap // Safe and secure

- Cuff tabs with VELCRO® brand fasteners // Close fit around wrists

- Side access pockets with flaps // With entry inside coverall

- ThermSAFE™ plastic FR zippers // CE Certified

- Internal elastic 2 point adjustable waistband // Ensures close fit

- Double stitched side seams // Lifetime quality assurance

- Easy-Stretch™ side panels // Maximum wear comfort

RIS-3279-TOM Tested Arc Flash Coveralls (Hi-Vis Orange) | ProGARM 4693

Arc Flash Coveralls

Specification

- Sizes: Small Regular leg, Medium Regular leg, Medium Tall leg, Large Regular leg, Large Tall leg, X Large Regular leg, X Large Tall leg, 2X Large Regular leg, 2X Large Tall leg, 3X Large Regular leg, 4X Large Regular leg

- Colour: Hi-Viz Orange

- Open ARC Test: ATPV=6.7 cal/cm², ELIM=6.2 cal/cm², ARC 2

- Box Test: 4KA, Class 1

- LOI: Not Applicable

- Protection Type: Antistatic, ARC Flash, Heat & Flame, Hi-Visibility, Railway

- Fabric: ProGARM VXS+ Inherent Woven Weave 240gsm

- Industry Sector: Industrial Electrical, Petrochemical, Rail, Utilities & Power Generation

- Type: Arc Flash Coveralls

- Collection: Hi-Visibility Orange Collection

ProGARM 4693 EN Standards

- EN 1149-5:2018: Pt. 5:2008 // Pt. 3:2004 // Charge Decay

- EN ISO 11611:2015: Class 1 // A1

- EN ISO 11612:2015: A1 // B1 // C1 // F1

- EN ISO 20471:2013: Class 3

- IEC 61482-2:2020: APC 1 // ELIM=6.2 cal/cm² // ATPV=6.7 cal/cm²

- RIS 3279: Issue 2

ProGARM for the Rail Industry | RIS-3279-TOM

What is RIS-3279-TOM?

RIS-3279-TOM (formerly known as GO-RT 3279) is a high visibility standard that only applies to the rail industry in the UK, as opposed to the EU-Wide nature of other EN standards. The aim is to ensure that rail workers on or near the trackside are sufficiently visible to trains approaching at speed or any other traffic.

High visibility clothing is the fundamental principle behind the UK Rail Industry Standard. This is based on the European Norm EN 20471:2013, and garments must comply to Class 2 High Visibility, the middle of a three class range. The standard states the following: ‘high visibility clothing worn by people on the lineside or on or near the line should conform to a single standard for the colour and luminance of background material and that this standard will accord with the detail contained within BS EN 20471:2013 high visibility clothing – Test methods and requirements (ISO 20471:2013).’

It is stated in the standard that: ‘the colour specific requirements within this standard conform to the range specified within BS EN 20471 clause 5.1.2.’ In order to confine this to a specific orange colour, and to prevent the selection of a colour at the red end of the spectrum, the precise chromaticity co-ordinates for the colour are specified as: Fluorescent orange, X:0.588, Y:0.371. with a luminance factor of at least 0.4. The accepted tolerance in colour is as laid out in EN 20471. However, there is no tolerance for the luminance factor.

Also stipulated in RIS-3279-TOM is the need of retro-reflective materials, with photometric and physical performance aligned with EN 20471.

Mentioned in RIS-3279-TOM is the accepted use of a mini vest where the nature of the work being carried out will not obscure the high visibility clothing, and thus reduce the surface area’ that is visible. The same applies to company logos; these are permitted where they do not compromise the surface area of background colour, and compensation may have to be made for this.

Arc Flash Coveralls

ProGARM 4693

Arc Flash Coveralls, from the ProGARM range of Arc Rated garments and clothing are used to protect against arc flash accidents as the last line of defence. Arc Flash PPE will not prevent incidents, and it is therefore vital that a comprehensive electrical safety plan for maintenance, repair and diagnostic procedures (involving energised LV, MV or HV electrical equipment) is also implemented.

Thorne & Derrick distribute a range of arc flash coveralls to suit a range of requirements. Variations include ladies coveralls, designs for overhead linesmen, orange and yellow hi vis options and a wide range of sizes. Contact Thorne & Derrick with your specific PPE requirements and we will be happy to help.

The ProGARM range of Flame Resistant protective garments are designed for every-day wear and protection – the highly breathable clothing ranges are designed for comfort and safety without compromising the ability of the wearer to work productively, safely and unhampered by cumbersome garments prone to overheating.

Other garments and protection products include Arc Flash Gloves, Arc Clothing, Arc Flash Suits and Arc Flash Helmets & Visors.

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Further Reading

- Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

- Arc Flash Risks In The Rail Industry

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

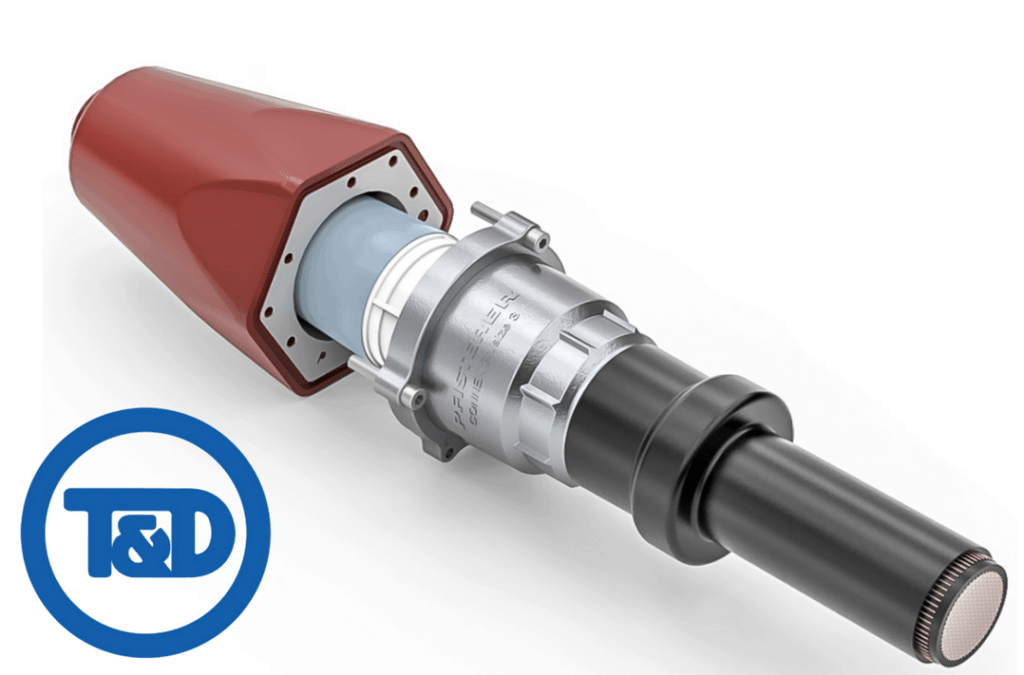

PFISTERER Connex | Separable Connectors Specification Guide for Medium Voltage Electrical Systems

July 23rd, 2021

PFISTERER Connex | Stocked & Distributed in the UK by Thorne & Derrick

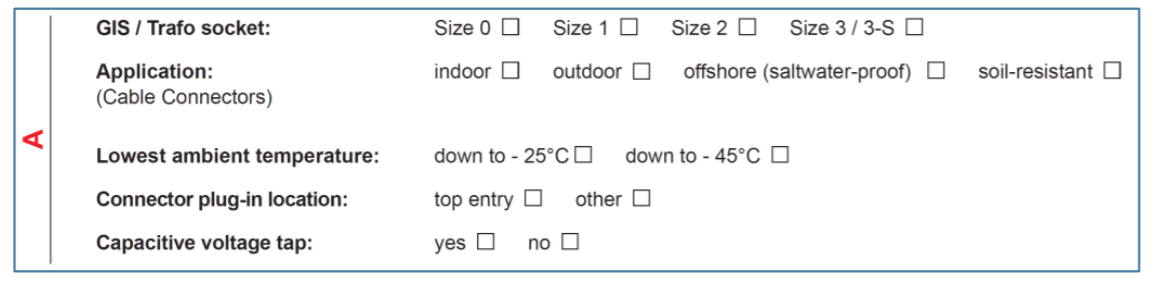

The following guide is designed to help with the specification of PFISTERER CONNEX Separable Connectors size 0 – 3/3-S. You can access the form using the link below.

PFISTERER Connex Separable Connectors

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of LV MV HV Power Products manufactured by Pfisterer – this includes Pfisterer CONNEX MV HV cable plugs and terminations.

The application, cable and MV-CONNEX Separable Connector need to be matched.

Only adapted connectors can achieve the required reliability in the grid.

For cables according to DIN VDE standard, a simplified selection process is possible.

See the beginning of “Section B”.

For cables that have not been produced to comply with DIN VDE, a product configurator is used to determine an individual article number for the required MV-CONNEX Separable Connectors size 0-3/3-S. In order to be able to define the article number, the Specification Form for MV-CONNEX Separable Connectors must be completely filled-in by the project specialists of the customer.

The individual article number consists of a 9-digit number plus an optional variant code. This article number contains all parts for connecting and earthing the individual cable. This article number is marked as Set – which means 3 pieces of the same connector.

Please find instructions below, which will help to correctly fill in the CONNEX Specification form.

The parameters needed can be separated into two groups:

A. Application specific parameters

B. Cable specific parameters

Please complete section ‘A’ and ‘B’.

Section A: Application specific parameters

GIS/Trafo Socket

The cable connector and the socket have to be the same size. The electrical parameters and dimensional measures are defined in the standards EN 50180 and EN 50181.

The following details might help you:

- size 0: lᴺ=250A; Uᵐ=24kV

- size 1: lᴺ=630A; Uᵐ=36kV

- size 2: lᴺ=800A; Uᵐ=42kV

- size 3: lᴺ=1250A; Uᵐ=42kV

- size 3-S: lᴺ=1250A; Uᵐ=52kV

It is important to know the size of the socket of which is installed in the switchgear or the transformer.

Application

Depending on the application some special materials and/or additional components are needed.

For application “offshore” or for application “soil-resistant”, special material for housing and sealing is provided.

The section”offshore” should also be ticked if the application is in a coastal area where there is a saline/corrosive atmosphere. Soil-resistant is used if the cable connector itself is underground.

Lowest Ambient Temperature

The standard ambient temperature range is from +50ºC down to -25ºC. For applications where the ambient temperature goes down to -45ºC a special low temperature grease is needed. The temperature directly around the Separable Cable Connector is relevant.

Please note that for indoor application the decisive factor is the ambient temperature inside the building.

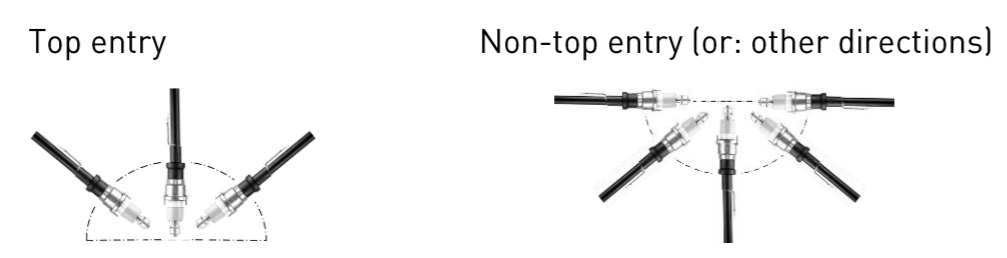

Connector Plug-in Location

Only for single sockets installed from inside of the equipment (not relevant for transformer elbow bushing or cast resin joints).

If the application is “outdor” and if the socket entry is from the top, an additional sealing system has to be applied. This is needed to prevent rain/water from entering the connector.

Therefore, please indicate if the position of installation is “top entry” or “other” (not top entry).

Voltage Tap

The voltage tap serves as an interface for a continuous voltage indicator system (DSA-LRM, DSA-2, DSA-i3). This is used to ensure the absence of voltage in the cable system before working on the cable system. For the indication of voltage, a separate product is needed (not in the scope of supply of the connector). To connect this voltage indicator system, the voltage tap (additional components) has to be included in the connector kit. Please indicate “yes” if needed.

standard is “no”

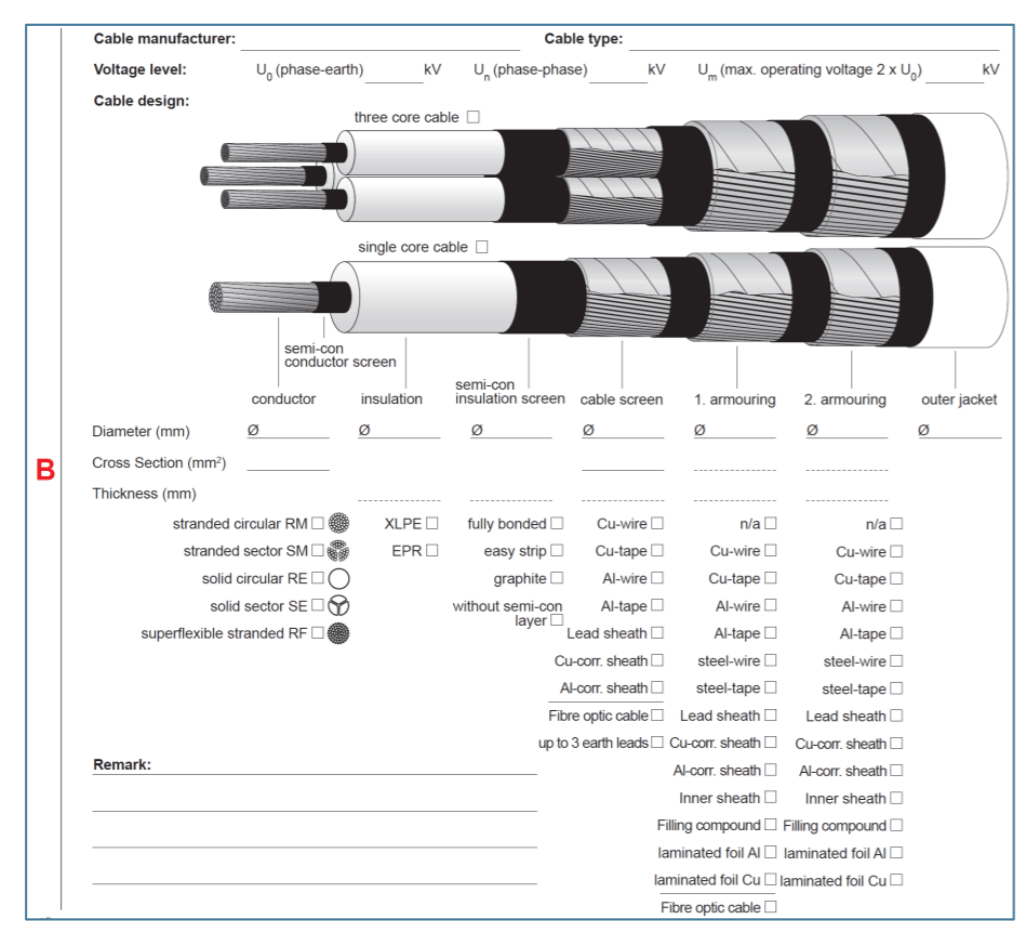

Section B: Cable specific parameters

For cables according to DIN VDE standard, a simplified process is possible. To select the connector, only “cable type”, “cross section”, “voltage level” and “section A” are required.

The simplified process is valid for the following cable types:

| N2XS2Y RM | N2XS(F)2Y RM | N2XS(FL)2Y RM |

| NA2XS2Y RM | NA2XS(F)2Y RM | NA2XS(FL)2y RM |

In case of non-DIN VE cables, please indicate all the cable parameters.

Cable Design

Single core cable or three core cable.

A three core cable only has to be indicated if the accessories for cable break out have to be included in the cable kit. If those accessories are not needed as they are e.g. already supplied in scope of project, single core cable can be selected (please indicate cable screen and armouring only for the single core cable).

Voltage Level

Voltage level of the cable

U⁰ = phase to earth voltage

Uⁿ = nominal voltage; phase to phase voltage

Uᵐ max. operating voltage (2 x U⁰)

Common voltage levels as reference:

| U⁰ (kV) | Uⁿ (kV) | Uᵐ (kV) |

| 3,6 | 6 | 7,2 |

| 3,8 | 6,6 | 7,2 |

| 6 | 10 | 12 |

| 6,6 | 11 | 12 |

| 8,7 | 15 | 17,5 |

| 12 | 20 | 24 |

| 12,7 | 22 | 24 |

| 15 | 20 | 24 |

| 15 | 25 | 30 |

| 18 | 30 | 36 |

| 19 | 33 | 36 |

| 20,8 | 36 | 42 |

| 26 | 42 | 52 |

Conductor Cross Section

Cross Section is only a reference value and does not influence component selection.

Conductor Diameter & Type

The contact system consists of several components. The components are selected according to the conductor type and the diameter of the conductor. The diameter of the bare conductor is relevant (without semi-con conductor screen).

The components have a designed working tolerance in which the can be used. During cable preparation and connector assembly, the conductor diameter has to be within this tolerance, for the contact system components to fit properly.

Conductor types (IEC 60228):

![]() RM: stranded circular (class 2)

RM: stranded circular (class 2)

SM: stranded sector

RE: solid circular (class 1)

SE: solid sector

RF: super-flexible stranded (class 5+6)

The standard is RM stranded circular (class 2).

Insulation Diameter

The insulation diameter defines the correct insulating part of the connector. The diameter of the bare insulation (without semi-con insulation screen) is required.

The insulating parts have a designed working tolerance in which they can be used. During cable preparation and connector assembly the insulation diameter has to be within this tolerance, for the insulating part to fit properly.

Semi-Conductive Insulation Screen

Depending on the semi-conductive screen type and layer thickness, a special assembly method with special components is used.

- Fully Bonded: The semi-con insulation screen is removed with a cable peeling tool. Standard for DIN VDE cables. Standard thickness is ≤ 1mm; in case thickness is ≥ 1mm please indicate the thickness of semi-con layer.

- Easy Strip: The semi-conductive insulation screen can be removed without a cable peeling tool.

- Graphite: The cable has a layer of graphite on the insulation. This could be the case with older cables, but is not common with new cables.

- Without Semi-conductive Layer: if a low voltage cable or a medium voltage cable with only 2 kV voltage level is used the insulation could be without semi-con insulation screen.

The standard is fully bonded, thickness ≤ 1mm.

Cable Screen

Depending on the cable deign the cable core could have one or more metallic layers. If these metallic layers are indicated on the specification form (Cable screen, 1st and 2nd armoring) corresponding accessories to connect and to ground these layers are supplied.

Diameter values are over each metallic layer.

The standard is: cable screen = Cu wire screen, without 1st and without 2nd armouring.

- Wire: made from Cu or Al

- Laminated foil ( ≤ 0,1 mm): made from Cu or Al

- Tape: made from Cu or Al

- Lead Sheath: made from Pb

- Corrugated Sheath: made from Cu or Al

- Wire Mesh: made from Cu

If your cable had another special cable screen, please indicate this on the form, e.g. fibre optics or up to 3 separate earthing leads (3 core cables).

Outer Cable Jacket

Diameter of the complete cable. For cables with very big or very small diameters, a special assembly method with special components is applied.

PFISTERER

The Pfisterer corporate group has been dealing with the interfaces in the flow of electricity ever since it was founded back in 1921.

As a specialist in energy transmission and distribution, Pfisterer offer our customers and business partners a range of sophisticated, future-ready products: For all voltage ranges and wherever reliable, long-lasting systems are needed for powerful energy grids.

As well as the energy sector, they are also active in transport technology and industrial solutions.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Electric Vehicle Charging Supply Feeder Pillars | EV Feeder Pillars

July 23rd, 2021

EV Charging Feeder Pillars

EV Feeder Pillars

EV Charging

Lucy Zodion manufacture a wide range of products suitable to provide Low Voltage Electrical Power Distribution for EV charge points – from distribution network operator (DNO) accredited cut-outs and isolators for on-street chargers, to feeder pillars for electrical vehicle charging.

Meet the increasing demand for accessible EV charging points with power distribution solutions that connect DNO supply with charging outlets. Lucy Zodion’s adaptive and reliable supply solutions consider the charge speeds and times each EV charge point is capable of, from fast to super, to ensure you receive the most suitable and compatible option.

As one of the UK’s leading suppliers of pre-wired power distribution enclosures, Lucy Zodion have developed a standard range of pillars that will support EV charge point requirements that fall into the four categories of main current rating: 100 Amp, 200 Amp, 400 Amp and 630 Amp, providing a link between the DNO and EV charge points. The configuration of all EV feeder pillars in this range can be upgraded once installed to meet future demand requirements.

3-Phase AC Supply | 100 Amp Feeder Pillars

| EV Feeder Pillar Type | Fortress Pillar Size 14 | |||

| Part Number | EV1008007 | EV1003022 | EV1002043 | EV1001050 |

| Rating | 7kW (40A SPN) | 22kW (40A TPN) | 43kW (63A TPN) | 50kW (80A TPN) |

| No. of charge points per feeder pillar | 8 | 3 | 2 | 1 |

| Dimensions H, W, D (mm) | 1300,1250,450 | 1300,1250,450 | 1300,1250,450 | 1300,1250,450 |

| Weight | 250kg | 250kg | 250kg | 250kg |

| Main incomer (MCCB) | ✓ | ✓ | ✓ | ✓ |

| Mild steel: Hop dip galv 3mm | Wedgelocks | Wedgelocks | Wedgelocks | Wedgelocks |

| Lock type | ✓ | ✓ | ✓ | ✓ |

| Anti-condensation heater | ✓ | ✓ | ✓ | ✓ |

100 Amp supply pillar is the smallest feeder pillar within the range and is available in four different configurations. These pillars cover 7kW supplies through to 50kW, with a differing number of connections on each solution.

100 Amp Supply Feeder Pillar

3-Phase AC Supply | 200 Amp Feeder Pillars

| EV Feeder Pillar Type | Fortress Pillar Size 24 | |||

| Part Number | EV1008007 | EV1003022 | EV1002043 | EV1001050 |

| Rating | 7kW (40A SPN) | 22kW (40A TPN) | 43kW (63A TPN) | 50kW (80A TPN) |

| No. of charge points per feeder pillar | 16 | 6 | 4* | 3* |

| Dimensions H, W, D (mm) | 1600,1250,450 | 1600,1250,450 | 1600,1250,450 | 1600,1250,450 |

| Weight | 275kg | 275kg | 275kg | 275kg |

| Main incomer (MCCB) | ✓ | ✓ | ✓ | ✓ |

| Mild steel: Hop dip galv 3mm | Wedgelocks | Wedgelocks | Wedgelocks | Wedgelocks |

| Lock type | ✓ | ✓ | ✓ | ✓ |

| Anti-condensation heater | ✓ | ✓ | ✓ | ✓ |

* Use of load management on chargers required

200 Amp Supply Feeder Pillar

200 Amp supply pillar within our range is available in four different configurations.

These pillars cover 7kW supplies through to 50kW, with a differing number of connections on each solution.

3-Phase AC Supply | 400 Amp Feeder Pillars

| EV Feeder Pillar Type | Fortress Pillar Size 40 | |||

| Part Number | EV4001222 | EV4008043 | EV4005050 | EV4002120 |

| Rating | 22kW (40A TPN) | 43kW (63A TPN) | 50kW (80A TPN) | 120kW (250A TPN) |

| No. of charge points per feeder pillar | 12 | 8* | 5* | 2* |

| Dimensions H, W, D (mm) | 2200/2850/600 | 2200/2850/600 | 2200/2850/600 | 2200/2850/600 |

| Weight | 400kg | 400kg | 400kg | 400kg |

| Main incomer (MCCB) | ✓ | ✓ | ✓ | ✓ |

| Mild steel: Hop dip galv 3mm | Barlock (3 point) | Barlock (3 point) | Barlock (3 point) | Barlock (3 point) |

| Lock type | ✓ | ✓ | ✓ | ✓ |

| Anti-condensation heater | ✓ | ✓ | ✓ | ✓ |

400 Amp supply pillar within our range is available in four different configurations.

These pillars cover 22kW supplies through to 120kW, with a differing number of connections on each solution.

3-Phase AC Supply | 600 Amp Feeder Pillars

| EV Feeder Pillar Type | Fortress Pillar Size 40 | |||

| Part Number | EV6301822 | EV6301043 | EV6307050 | EV6303120 |

| Rating | 22kW (40A TPN) | 43kW (63A TPN) | 50kW (80A TPN) | 120kW (250A TPN) |

| No. of charge points per feeder pillar | 18 | 10 | 7 | 3 |

| Dimensions H, W, D (mm) | 2200/2850/600 | 2200/2850/600 | 2200/2850/600 | 2200/2850/600 |

| Weight | 400kg | 400kg | 400kg | 400kg |

| Main incomer (MCCB) | ✓ | ✓ | ✓ | ✓ |

| Mild steel: Hop dip galv 3mm | Barlock (3 point) | Barlock (3 point) | Barlock (3 point) | Barlock (3 point) |

| Lock type | ✓ | ✓ | ✓ | ✓ |

| Anti-condensation heater | ✓ | ✓ | ✓ | ✓ |

Lucy Zodion | Fortress Feeder Pillars | Pre-Wired Feeder Pillars | Street Lighting Cut-Outs | DNO Cut-Outs | Electrical Power Distribution Enclosures

Further Reading

➡ More Lucy Zodion Blogs:

- Cut Outs & Isolators – Lucy Zodion Explain The Differences

- Feeder Pillars From Lucy Zodion – LV Electrical Power Distribution

- Optional Extras For Use With Lucy Zodion Fortress Feeder Pillars

- Waveform Cable Termination – 3 Core 300sqmm Cable Onto A 2 Ganged Metered Way In Lucy Cabinet

Galvanised & Stainless Steel | GRP | Pre-Wired | Underground Retractable Feeder Pilars

Read our Blog with Lucy Zodion: Cut-Outs & Isolators – What’s the Difference?

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist