Cable Joints & Terminations LV

OSM27-SEF NOJA Power Reclosers Surrounded By Snow

March 11th, 2021

-

Special Thanks To Alex Veselov At Noja Power For The Above Image

My partners in Sweden just shared some great pictures of OSM27-SEF NOJA Power Reclosers surrounded by nice winter nature. Swedish 20kV distribution network has isolated neutral and therefore very low earth fault currents. This is where a special SEF (Sensitive Earth Fault) version of OSM27 can help as it works from as little as 0.2 A fault currents. View the NOJA Power OSM Automatic Circuit Recloser 15kV 27kV 38kV download.

The OSM15, OSM27 and OSM38 automatic circuit reclosers incorporate vacuum interrupters inside solid dielectric insulated poles which are housed within the arc fault venting designed, stainless steel tank. This ensures maximum life and reliability with a fully insulated arrangement inside the long life housing.

NOJA Power

NOJA Power is a world leading manufacturer of Medium Voltage Electrical Equipment.

With more than 64,000 OSM units installed in over 92 countries, our SF6 Free equipment is essential to the future of electricity distribution.

We offer our customers integrated solutions using innovative products combined with unrivalled service and reliability world wide.

We specialise in Medium Voltage Outdoor Switchgear, covering applications such as overhead lines protection, substations, renewable, distributed generation connection & underground cable protection.

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

All international sales enquiries can be serviced and supplied by our Export Power Team.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

DENSOBAND | Sealing Joints In Highway Construction & Maintenance

March 8th, 2021

Highway Joint Sealing

Densoband

Densoband™ is a polymer modified bitumen compound in strip form, used for sealing joints between asphalt to asphalt, concrete and road castings in road construction and bridge expansion joints. It can also be used for airport runway joints and light railway/tram construction to form a flexible seal between the track and the surrounding asphalt.

Containing filler, a flow control additive and a root deterrent, Densoband forms a flexible watertight seal which allows for road movement from cyclic traffic load and thermal changes to prevent cracking and subsequent erosion.

Providing a uniform flexible seal across the joint face, Densoband™ is ideal for base and wearing course joints and prevents deterioration by sealing out water, chemical pollutants, weed seeds and other pollutants/contaminants.

When applying Densoband with a gas torch, a uniform, consistent joint is recommended rather than a randomly poured joint.

➡ See also Denso Mastic Duct Seal | Densoseal 16A Sealing Cable Ducts

Densoband Features

- Used in road, tramway, railway and airport runway repair and construction

- Sealing bridge and flyover expansion joints

- Minimises return maintenance visits

- Uniform flexible seal for base and wearing course joints

- Adheres to asphalt, concrete and ironware

- Withstands road movement from traffic load and thermal changes

- Over 25-years use in the UK

- Densoband fully complies with the Department of Transport Specification for Highway Works, 7th Edition

Instructions For Use

Joint Surface

The joint surface should be sawn for preference to present an even vertical face throughout its length.

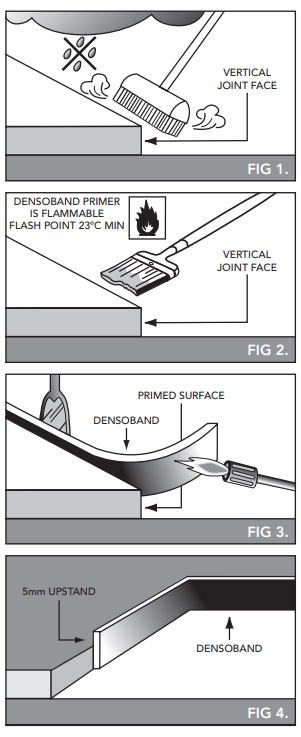

Cleaning (see Fig 1.)

Do not apply Densoband to wet or oil contaminated surfaces.

- Ashpalt, concrete, kerbstone surfaces: Clean with a stiff broom or wire brush to remove all dust, dirt, debris

- Metal surfaces such as road castings: Wire brush to remove all loose rust, dirt, etc.

Priming (see Fig 2.)

Apply Densoband™ Primer to the vertical joint face and allow to dry.

Applying Densoband (see Figs 3 & 4)

- Cut Densoband to length.

- Remove interleaving paper.

- Heat one surface of the Densoband with a gas torch.

- Apply the molten surface to the primed face using the applicator spatula or similar tool to assist adhesion. Densoband should stand 5mm proud of the existing road surface. Trim flush to metal.

- Mitre Densoband into corners of right angle joints.

Compaction

After laying and levelling the new wearing course asphalt, the first pass of the roller should be along the joint edges, compacting the Densoband to form a ‘rivet head’.

Further Reading

Sealing & Waterproofing of Cable Ducts Using Densoseal 16A | Thames Water Project

Denso Mastic Duct Seal | Densoseal 16A Sealing Cable Ducts

Denso Bore-Wrap | Prevent Coating Damage During Pipeline Installations

About Denso

Denso North America Inc. is a subsidiary of Winn & Coales International, a leading manufacturer of anti-corrosion coatings that include Protal liquid epoxies, Denso petrolatum tapes, mastics, primers, bitumen tapes, butyl tapes, hot applied tapes, and a full line of marine pile protection systems. Winn & Coales was originally established as a business in London, England, in 1883, and the first petrolatum tape manufactured in the UK was Denso tape, manufactured under license by Winn & Coales (Denso) Limited.

Denso tape was developed over 80 years ago for the “Long Life Protection” of buried steel pipelines against corrosion. The Denso SeaShield Marine Systems include fiberglass forms, epoxy grouts, underwater epoxies, injectable epoxies, petrolatum tape and wrap systems.

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Ensto Acquires Renley – Boosting Growth In Ireland & The UK

February 8th, 2021

Ensto Acquires Renley

Press Release

Ensto are delighted to inform you that on December 11, 2020, Ensto has acquired the entire share capital of Renley Ltd, an Irish manufacturer of low and medium voltage products and related services for local Distribution System Operators (DSOs). The acquisition is in line with Ensto’s strategy of providing complete solutions for customers and being a leading expert for DSOs.

Renley Ltd is a well‐known supplier for major DSOs in Ireland and the UK. The company, employing approximately 20 professionals in Dunboyne, Ireland, specializes in low and medium voltage distribution panels, mini pillars, fused combination units and cabinets.

In 2019, Renley had a turnover of EUR 5.4 million. Realising Ensto DSO’s growth strategy, the acquisition of Renley will strengthen our market presence in Ireland and the UK, through expanding customer networks and complementing expertise.

Renley has a solid technology in low and medium voltage products with proven expertise, an extensive network of customers and impressive long‐term customer relationships. Its product offering will complement our current product selection, and we are extremely pleased to have the chance to work together with the people at Renley.

Ensto firmly believe that this combination will benefit our customers, partners and personnel, through providing a more comprehensive product range and an even wider selection of distribution panel solutions, while enabling operational synergies for both companies.

Renley will become part of the Ensto DSO business and it will continue its operations under the name Ensto Renley Ltd. Our current Ensto DSO business in Ireland and the UK will be merged with Ensto Renley Ltd as of February 1, 2021, and John Carolan, currently working as Sales Director at Ensto in the UK, will be appointed Managing Director. John, a former Renley employee himself, knows the company and its people very well.

Ensto will keep you informed of any potential changes in our operations. Please do not hesitate to contact us in case you have any questions related to the matter.

Ensto in brief

Ensto designs and provides smart electrical solutions to improve the safety, functionality, reliability and efficiency of smart grids, buildings and transportation. Ensto, an international technology company and a family business, was founded in 1958 and employs ca. 1,400 passionate professionals in Europe, the USA and Asia. In 2019, we generated turnover of 260 million euros.

We believe in a better life with electricity and a more sustainable tomorrow.

➡ Cable Joints & Cable Terminations | Sheath Voltage Limiters | Suspension Clamps | Tension Clamps | Insulated Messenger Wire System | Uninsulated Messenger Wire System | Insulation Piercing Connectors | Busbar Connectors

www.ensto.com

Renley in brief

Renley, founded in 1970, is a family business and a manufacturing company specialising in the development, manufacture and marketing of low and medium voltage products and related services for electricity distribution. Renley employs currently ca. 20 people in Ireland. The company’s turnover was 5.4 million euros in 2019.

www.renley.ie

Thorne & Derrick | Approved Suppliers Distributors

THORNE & DERRICK are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Jointers & Splicers Tents For Irish Rail | Protecting Cables Against Water & Weather Effects

December 8th, 2020-

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

NEWS Thorne & Derrick | LV HV Cable Jointing & Electrical Equipment – following a successful specification and supplier evaluation by the client today we are despatching 22 x Fibre Optic Cable Splicers Tents & Umbrella’s approved for use on Iarnród Éireann (Irish Rail), the operator of the national railway network of Ireland.

PADS Approved | Translucent fibre optic splicing tents with Network Rail approved blue colour skirts suitable for protection against water ingress and weather effects into cables and joints are also available from us.

With 35 years of experience Thorne & Derrick have built our reputation from a proven track record of unquestionable customer service and technical excellence. ➡ See our complete range of Jointers Tents for power and fibre cable jointing and splicing.

Pictured: Sheerspeed Jointing Tent Kit consisting of 180 PZTFOS 1.8m x 1.8m Triangle Tent, 8ft Umbrella, Umbrella Clamp and Carry Bag. The Premium Speed tent range allows natural light into the work area, ideal for jointing and splicing cables in poor weather conditions. Both tent and umbrella are quick and easy to assemble with no loose components, flame retardant and 100% waterproof.

Rail Cable Accessories, Electrification

& Installation Equipment

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

Pot Ending LV SWA PVC Sheathed Service Cables – Engineering Guide UKPN

November 24th, 2020-

uploaded by | Chris Dodds (Sales Marketing Manager at Thorne & Derrick)

PVC Sheath Removal

- Clean the outer PVC sheath of the cable and abrade for 60mm with a rasp, to form moisture seal

- Remove 300mm of the outer PVC sheath

- Refer to the UKPN LV Manual Section 3.5.1 removing the outer PVC Sheath

Steel Wire Armour Opening

- Apply a wire binder around the steel wire armours 25mm from the outer sheath cut at both end of the cable

- Install the service temporary earth bond, consisting of a length insulated braid and two constant force springs, around the steel wires between the sheath removal point and the wire binders

- Using a plastic small wedge and insulated side cutters, cut the individual armour wires around in the centre of the cable joint

- Fold the wires back against the binder at both ends, so they are away from the working area of the cable joint

- PVC tape the cut steel wire armours to the PVC either side of the cable joint

PVC Bedding Removal

- Shroud the exposed armours and the continuity bond connections at both cable ends

- 25mm from the folded back armours, ring round the PVC bedding with a plastic Mini-Hepnyf

- Note: The Mini-Hepnyf needs to be new with a clean sharp edge to ensure that the bedding can be removed without causing damage to the insulation on the cores below

- Remove the bedding between the two bedding removal points, by applying gentle heat to the bedding

- Note: Excessive heat will make the bedding too soft and make it more difficult to remove. Refer to Section 3.5.1 of the LV Jointing Manual

- If the bedding layer is difficult to remove or if it is bonded to the core insulation, then the cable shall be made dead, prior to continuing with the bedding removal process

Core Cutting & Capping

- Refer to Section 3.7.3 of the LV Jointing Manual

- A PILC two or four core heatshrink pot end kit should be utilised depending on the number of cores in the SWA cables

- Once the cores are exposed, test the cores to prove live and neutral

- Insert a plastic cutting wedge between the cores and cut each live core in turn centrally and install a temporary cap

- Finally cut the neutral core and install a temporary cap

- Cut each of the live core(s) 70mm from the bedding and install the heatshrink cap provided in the joint kit, as per Section 4.10.4 of the LV Jointing Manual

- Cut each of the neutral core 70mm from the bedding and install the heatshrink cap provided in the joint kit, as per Section 4.10.4 of the LV Jointing Manual

Completing The Pot End

- Remove the temporary earth continuity bond and any temporary shrouding

- Allow the heat caps to cool, apply two half lap layers of PVC tape over the cores

- Fold the steel wires back over the previously applied PVC tape, trim them to the same length as the phase and neutral cores

- Apply two half lap layers of PVC tape over the wire armours and tinned copper mesh, make sure all sharp edges are covered

- Slide the mastic coated heatshrink tube over to the 60mm of sheath abrasion and shrink into place ensuring a good water seal. As per Section 4.10.4 of the LV Jointing Manual

- Slide the mastic coated large heat shrink cap over the previously shrunk tube and shrink in place, starting at the sealed end, before working towards the open end. To prevent the

cap sliding off hold in place using an insulated wedge

- Allow to cool before fitting the yellow plastic safety bag in place

- Once the pot end has cooled, place the yellow bag over the joint, ensure that the hazard symbol is on the top and fix in place with PVC tape

LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV