Cable Joints & Terminations LV - Cold Shrink, Heat Shrink & Resin

Cable joints are essential components used to safely connect, extend or repair electrical cables across power, control and industrial installations. At Thorne & Derrick International, we supply a comprehensive range of LV joints designed for reliable, long-term performance in demanding environments, supporting applications across utilities, renewables, infrastructure, manufacturing and heavy industry.

Read more…

Our low voltage jointing solutions are suitable for 0.6/1kV cable systems, providing secure electrical continuity, mechanical protection and environmental sealing for both indoor and outdoor installations. Whether used for new installations, network extensions or maintenance and repair work, correctly specified joints are critical to maintaining system safety, integrity and compliance.

We offer a wide selection of straight through and branch joints, covering the most commonly used jointing methods, including heat shrink, cold shrink and resin joints. These solutions are compatible with a wide range of cable constructions, including armoured and unarmoured power cables, control cables and industrial wiring systems.

Our joint kits are supplied by trusted manufacturers and engineered to accommodate different conductor sizes, insulation types and installation conditions. Each solution is designed to provide dependable insulation, strain relief and environmental resistance, helping to protect against moisture ingress, mechanical stress and electrical failure.

With decades of experience as Thorne & Derrick International, supplying cable accessories and electrical equipment to global energy and industrial markets, we combine product availability with deep technical understanding. Our team supports customers in selecting the correct jointing solution based on voltage rating, cable type, installation method and environmental conditions, ensuring safe and compliant installations.

Browse our range of Cable joints below to find reliable jointing kits for your application, backed by expert support, fast delivery and proven performance in critical electrical systems.

Need technical guidance or a quotation?

Talk to one of our experts today — we’ll help you get it right the first time.

Cable Joints

Thorne & Derrick supply 3M, Prysmian, Filoform and SPS low voltage joints suitable for connecting and jointing single and multi-core/pair power, control and instrumentation cables up to 600/1000V (3.3kV) in industrial and hazardous area locations – specialist applications include fire resistant, low smoke zero halogen, hydrocarbon resistant and utility joints.

Jointing kits are available for both unarmoured and armoured type cables including:

- STA | Steel Tape Armour (Multi-core)

- SWA | Steel Wire Armour (Multi-core)

- AWA | Aluminium Wire Armour (Single-core)

Joints are available from stock in several technologies to suit the low voltage (LV) installation application and cable type to be repaired or jointed:

i) Cold Shrink

ii) Heat Shrink

iii) Resin

Joints | LV Low Voltage Cables | Power Pilot Control Jointing Kits Using 3M Scotchcast

Straight Through & Branch Joints

Cable joints are typically supplied as straight through joints, used to connect two cable lengths end-to-end, or branch joints, used to create a spur or additional connection from an existing cable run. Selecting the correct joint type is essential to maintaining electrical integrity, mechanical strength and compliance with installation standards.

Our range of joints includes solutions suitable for both configurations, supporting common power distribution, control and industrial wiring applications.

Jointing Cables Effectively To Eliminate Failure

Careful consideration must be given to the specification of the cable to be jointed, the installation application and environmental factors to prevent the risk of future failure when specifying LV joints.

XLPE, EPR and PILC insulated cables with wire armour or braid and lead sheath cover can be jointed effectively and  safely in straight, branch, transition, mains and service arrangement – joints are suitable for direct burial in underground trench, seawater immersion offshore, location on cable tray (vertical/horizontal) and underground rail tunnels where zero halogen specification is required.

safely in straight, branch, transition, mains and service arrangement – joints are suitable for direct burial in underground trench, seawater immersion offshore, location on cable tray (vertical/horizontal) and underground rail tunnels where zero halogen specification is required.

Hazardous area cable joints are available from stock for both onshore and offshore cables in the oil, gas and petrochemical industry – suitable for Zone 1 and Zone 2 explosive atmospheres where exposure to corrosive and flammable gases, vapours or mists would cause the degradation and premature failure of standard joints.

Pictured opposite is a heat shrink joint failure caused by the jointer not providing adequate connection of the earth continuity across a jointed shipwiring braided type cable. Consequently, hydrocarbons contaminated the cable via a pathway along the wire armours and eroded the cable sheath.

LV Cable Joints

Cold shrink, heat shrink and resin type joints suit the operating requirements for the jointing of LV cables in industrial, marine and offshore, oil and gas, substation and utilities, rail and electrical construction sectors where high quality and performance joints ensure the continued distribution of power supply to critical circuits.

Contact Thorne & Derrick to discuss your application – we can provide expert technical support and specification advice to ensure the correct supply of electrical LV joints to suit your requirement.

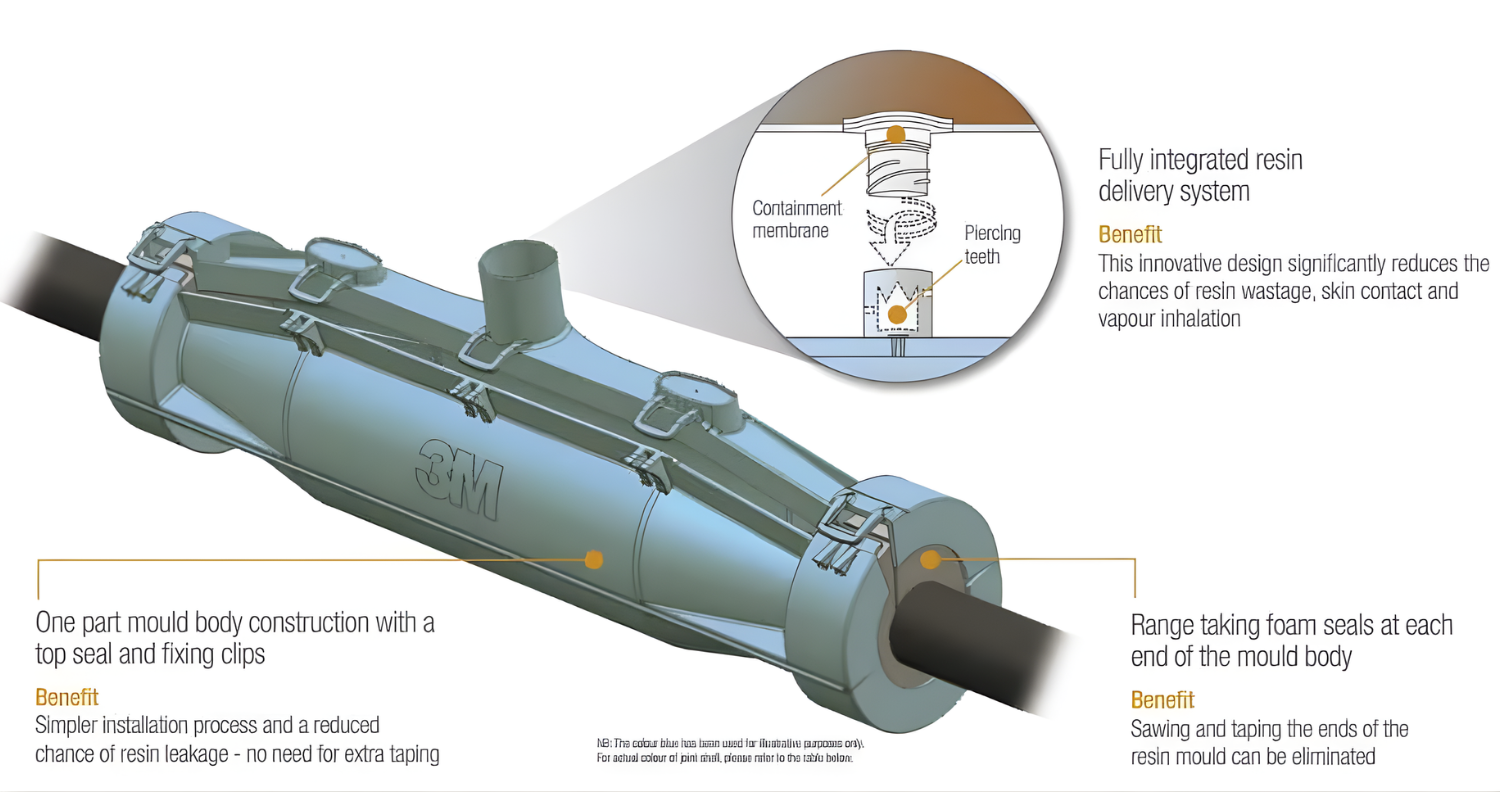

Resin Cable Joints – 3M Scotchcast Resin Joints Features & Benefits

3M LVI-1 Scotchcast Power Cable Joint Selection Table

Straight Joint XLPE to XLPE Cables

| 3M Joint Kit – LVI | Cable Conductor Cross Sectional Area (mm²) | Max Cable OD (mm) | |||

| Single Core | 2 Core | 3 Core | 4 Core | ||

| 3M LVI-1/2-C | N/A | 1.5 – 6 | 1.5 – 6 | 1.5 – 6 | 25 |

| 3M LVI-1/3-C | N/A | 10 – 25 | 10 | 10 | 32 |

| 3M LVI-1/3 | 50 – 70 | N/A | N/A | N/A | 32 |

| 3M LVI-1/4 | 95 – 150 | 35 | 16 – 25 | 16 – 25 | 36 |

| 3M LVI-1/5 | 185 – 240 | 50 – 70 | 35 – 50 | 35 – 50 | 45 |

| 3M LVI-1/6 | 300 – 630 | 95 – 150 | 70 – 95 | 70 | 54 |

| 3M LVI-1/7 | 800 – 1000 | 185 – 240 | 120 – 185 | 95 – 150 | 64 |

| 3M LVI-1/8 | N/A | 300 – 400 | 240 – 400 | 185 – 300 | 90 |

Specialist Cable Joints

Specialist Joints

To meet the performance and specification requirements for planned maintenance, project installations and fault repair work, T&D can deliver from stock joints to suit:

- Fire Resistant & FP Fire Performance Cables – Fire Alarm, Emergency Lighting & Power BS7846

- Low Smoke Zero Halogen Cables – LSZH, LSF, OHLS & ZHLS

- Flexible & Trailing Cables – Protolon, Panzerflex & Mining

- Utility Cables – Waveform, Mains & Service

- Marine & Offshore Cables – BFOU RFOU IEC NEK606 (Mud Resistant)

- Medium & High Voltage MV HV

Training Video

Cold Shrink Cable Joints (3M LC Range)

3M LC range of joints uses Cold Shrink technology for repairing, splicing and jointing polymeric (XLPE EPR) cables eliminating resin handling or exposure to naked flames associated with heat-shrink joints.

Cold Shrink tubes are quick, easy and safe to install providing a reliable joint and environmental seal resistant to acid, alkalis, ozone and UV light.

With smooth profile, minimal space displacement and lightweight design the joints are suitable for installation in cable congested and confined areas, such as cable trays.

Zero Halogen Heat Shrink Joints

Zero Halogen Heat Shrink Joints

In this training video excerpt the Jointer Trainer is shown using a gas torch to heat shrink tubes onto the cable cores and conductors of a rail power cable to complete a zero halogen cable joint. The joints utilise specialist zero halogen tubing with a low emission of toxic and corrosive gases approved by London Underground and Network Rail to establish joints in subsurface applications, such as tunnels.

The XLPE cable insulation has been stripped from the cable conductors and the cores cropped using ratchet cable cutters. Connectors have been installed using hydraulic crimping tools – note the connector heat shrink insulation tubes are positioned centrally over the compression ferrules within the joint, where confined space is a limiting factor the cable connectors can be staggered to provide a more smooth profile joint to reduce footprint of the jointing kit.

3M Network Rail Cold Shrink Joints for Track Feeder Cables

3M Network Rail Cold Shrink Joints for Track Feeder Cables

3M Cold Shrink Network Rail joints are used for the jointing and cable terminating of track feeder cables. 3M Cold Shrink joints require no hot-work permit or special tools for installation.

Track feeder joints are approved for jointing Network Rail NR/PS/ELP/21101, BS6360 and BS6899 specification single core copper and aluminium cables, 650/750 DC supply.

CSP sheathed track feeder cables provide power supply from the substation to the rail track side.

3M Cold Shrink Cable Sealing Tubes are specified for rail cable sealing, insulation and protection and are approved by Network Rail for live rail terminations and inline joints for DC track feeder cable applications.

3M Cold Shrink provides a permanent radial seal, expanding and contracting with the rail cable under load conditions. 3M Cold Shrink Tubes are made from EPDM rubber, expanded onto a removable supporting plastic core.

As the core is unwound, the 3M Cold Shrink insulating sleeve shrinks to form a tight seal around the cable terminal or splice.

3M LA11 and 3M LO42 form part of the 3M Electrical range of EPDM Cold Shrink tube ranges with LUL TfL Approval – for fire resistance and conformance to S1085 Standard the tube should be covered and over-protected using 3M STFF product.

| Joint/Termination Application | Joint Kit | Min Diameter | Max Diameter | Cold Shrink Length |

| 500/630/1000mm² 3rd Rail Terminations | LO41 | 24.4 | 98.2 | 228mm |

| 161/1240mm² Inline Joints or Terminations | LO42 | 15.2 | 61 | 191mm |

| 500/630/800/1000 Inline Joint | LA11 | 38.1 | 114 | 457mm |

To assist with the installation of Joints visit our online 3M Joints & Termination Video Library | Jointer Training Available

Cable Joints – Frequently Asked Questions

Q: What are cable joints used for?

A: Joints are used to connect, extend or repair electrical cables, maintaining electrical continuity, mechanical strength and insulation. They are commonly used in power distribution, industrial systems and infrastructure installations.

Q: What is the difference between heat shrink and cold shrink cable joints?

A: Heat shrink joints require the application of heat to shrink insulation materials tightly around the cable, forming a sealed joint. Cold shrink joints are supplied pre-expanded and contract without heat, making them suitable for flame-free or confined installations.

Q: Are these cable joints suitable for armoured cables?

A: Yes, many LV joints are designed for use with both armoured and unarmoured power cables. Always ensure the joint is correctly specified for the cable construction and size.

Q: What voltage are LV cable joints rated for?

A: Low voltage joints are typically rated for 0.6/1kV applications and are used in standard low voltage power and control cable systems.

Q: Can cable joints be used outdoors or underground?

A: Yes. Certain joints, such as resin and heat shrink joints, are suitable for outdoor, buried or harsh environments where protection against moisture and mechanical stress is required.