DIN 48083 – The Standard for Cable Lugs & Crimping Tools

Published 29 Aug 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

DIN 48083

The following information is provided courtesy of Nexans Euromold to ensure the safe and reliable termination of LV MV HV cables using cable crimping lugs prior to installing any proprietary brands of cable termination – the information is relevant to Cold Shrink, heat shrink, slip-on and EPDM rubber screened separable connectors.

brands of cable termination – the information is relevant to Cold Shrink, heat shrink, slip-on and EPDM rubber screened separable connectors.

The standardised hexagonal crimp allows cable lugs and electrical connectors according to DIN 46235 to be crimped with certified crimping die sets and tools according to DIN 48083 Part 4.

Crimping Cables & Cable Lugs

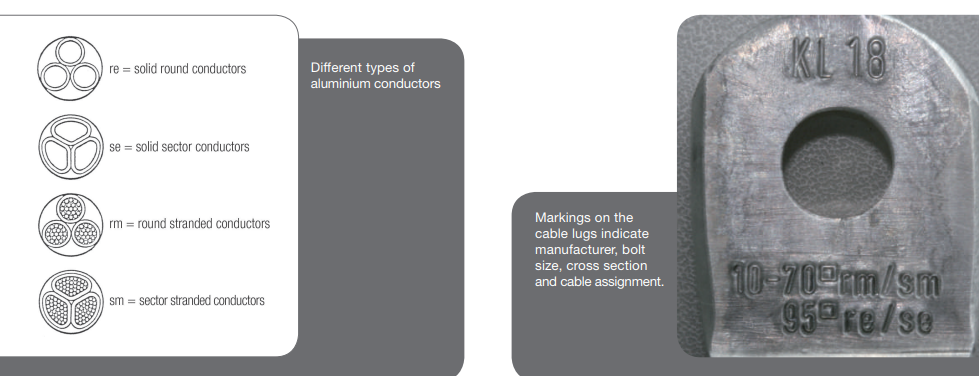

Crimp lugs, compression connections and tubular cable lugs manufactured from copper or aluminium require precise matching of crimp cable lugs, conductor type and crimping tool size.

DIN standard crimping requires adherence of conductor, selected crimp cable lugs and compression die sets to provide optimum results when terminating cable lugs to DIN standards at LV MV HV.

The hexagon crimp or compression is designed for a cable conductor temperature up to 90°C, according to IEC.

DIN Standard 48083

DIN Standard 48083 is a hexagonal crimping profile and to conform to DIN standard where the correctly designated die sets must be used to compression/crimp the lugs or connectors.

All crimp cable lugs are stamped with cross section specification, manufacturer’s logo as well as die set code number, corresponding roughly to the outer diameter of the sleeve.

Select the crimp tool die corresponding to this code.

The hexagon crimps or compressions are carried out by means of mechanical,hydraulic or battery operated crimping tools according to the standard DIN 48083. “Cu” (Copper) marked dies have to be used for copper or steel compression cable lugs.

Designated “Al” (Aluminium) dies are used for aluminium or aluminium alloy compression cable lugs. In the case of hydraulic tools differentiation regarding the conductor materials is not necessary – if in doubt call Thorne & Derrick in connection with any of your cable crimping, lug or tool queries and requirements.

Installing Cable Lugs

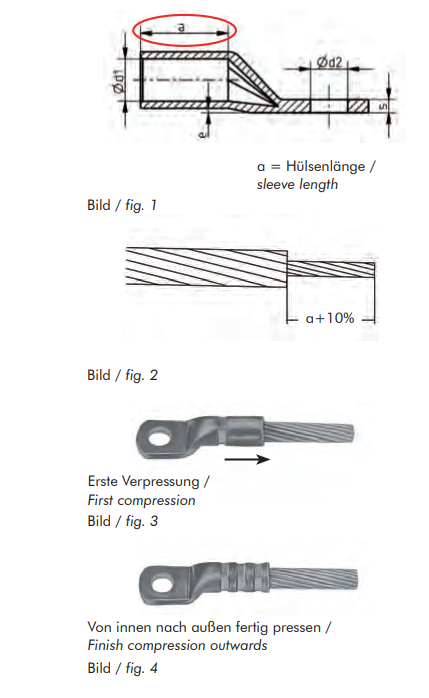

1. Strip cable conductor to sleeve length a+10% (fig. 1, 2)

2. Remove all tapes/yarn or similar conductor filling materials before mounting the cable lug

3. Remove dirt and oxide layers from the cable conductor using a metal brush

4. Insert conductor into compression sleeve up to the stop/inspection hole of the cable lug

5. Before compression verify the die code with the crimp mark number on the cable lug

6. Start crimping using correct tool from the palm side to the barrel end (fig. 3, 4)

7. The number and position of the compression points is indicated by marking lines. Attention: All markings must be compressed by the crimping tool

8. Final Check: The extension length of the sleeve is about 5 % by correct compression with correct conductor – cable lug – die – combination

9. Remove excess grease using cable cleaning wipes

Thorne & Derrick distribute for Cembre and recommend the use of their hydraulic and battery operated crimping tools in order to crimp cables in accordance with DIN Standard 48083 – contact us for technical support, quotations and delivery from stock.

More Reading ➡

Crimping Tools & Die Sets For Aluminium Crimp Connectors – DIN Standard

Cable Lugs & Crimping Tools

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist