3M Cable Joints & Terminations

Medium Voltage Sensored Cable Accessories from 3M Electrical

June 24th, 2022

3M Sensored Cable Accessories for Medium Voltage Grid Automation

An effective solution for monitoring your underground distribution system

3M Sensored MedIUM VOLTAGE

Cable Accessories (SCA)

3M Sensored Cable Accessories (SCA) provide a retrofittable, compact and economical way for Distribution System Operators (DSOs) to gain visibility and data from their distribution grid with voltage and current measurements.

As the need and importance of measurement and data in the underground grid rises, 3M SCA provides a simple path to high accuracy solutions for assessing and improving fault detection, power flow and power quality. The advent of new regulations and integration of renewables into the medium voltage network, make the need for high accuracy measurements critical for assessing the health of your electrical grid and better managing the future of the network’s grid modernisation.

3M helps provide visibility into the medium voltage (MV) electrical infrastructure

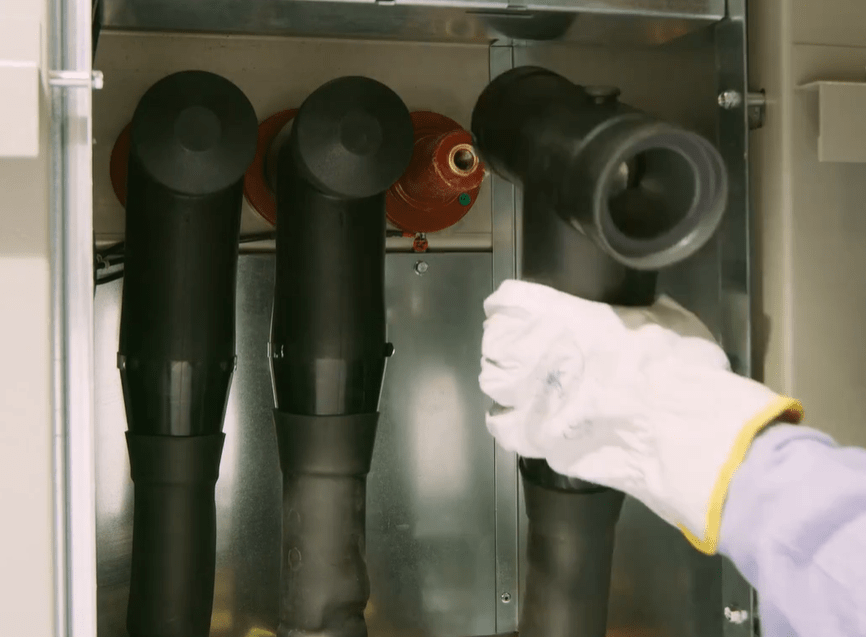

3M Sensored Accessories easily retrofit inside cable compartments, air insulated switches, gas insulated switches or on transformers inside substations. When you upgrade your existing medium voltage substation with our product, you gain high accurate sensing and overall insight into multiple nodes without the need to replace.

Seeing the Whole Picture

Situational awareness is critical in the underground medium voltage distribution grid, as faults in this segment can potentially impact large numbers of customers downstream. This can be compounded by the wide-scale integration of renewables, which places additional demands on aging equipment and compromises network efficiency. Although distribution automation and control solutions have evolved to tackle these issues, acquiring key grid parameter data with high accuracy – and in real time – continues to be a major challenge, especially for underground medium voltage systems.

Now, 3M brings you advanced Sensored Cable Accessories that provide highly accurate voltage and current data, and can be deployed throughout your underground medium voltage system with low capital investment. When coupled with your existing communication infrastructure, 3M™ Sensored Cable Accessories enable real-time monitoring, giving you better visibility throughout your underground MV distribution system.

Accurate information about the state of your MV grid can help protect your customers – and your reputation – against the steep costs of outages, cable repair work and lost productivity. Better information drives better decisions: rapid fault diagnosis, fast and accurate response, and precise load control all depend on grid visibility.

3M™ Sensored Cable Accessories

for MV Grid Automation

3M Sensored Cable Accessories consist of passive sensors that provide highly accurate analog voltage and current waveforms. Your existing power equipment can be retrofitted with these accessories, which are both easy and economical to install.

Installation of the 3M SCA

- A fast, economical solution – Ability to retrofit power equipment allows installation at your chosen locations

- Underground system data – Enables real-time monitoring of your underground system when integrated with your communication infrastructure

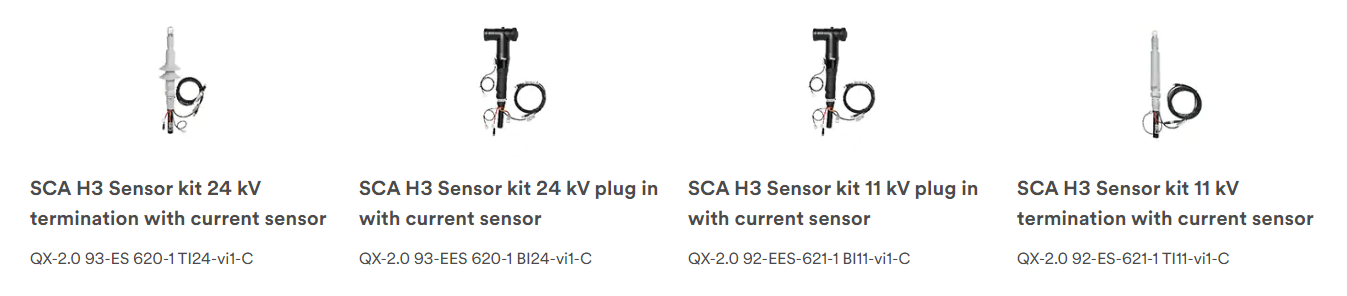

- Highly-accurate readouts – Provides voltage accuracy of ±0.5%* and current accuracy of ±1%*, giving you real-time data that can be used in advanced automation and control applications

- No external power source required – Enables a simpler, faster, more economical installation

- No field calibration – Factory-calibrated sensors provide reliable, accurate data, without need for calibration in the field.

- Constructed with 3M Cold Shrink technology – For a safe, reliable seal that requires no special tools, sealants, adhesives, torches or other heat sources to install

* Refer to the 3M Sensored Termination Datasheet for detailed accuracy information.

A technology breakthrough, designed to give you more

Flexibility – Upgrade your key locations

Depending on geographic location, load profile, regulatory requirements and legacy equipment, your key locations may be different from those of other utilities. 3M Sensored Cable Accessories and interfaces are engineered to give you the flexibility to monitor key parameters at critical points in your network. This retrofit solution can be installed in your existing power equipment with minimal effort, and integrated into your existing communication infrastructure.

Reliability – Consistent performance

3M Sensored Cable Accessories incorporate passive sensors, which do not require an external power source. These sensors are also factory calibrated – with no field recalibration necessary. And 3M’s advanced Cold Shrink technology provides a reliable, long-lasting compressive seal, even in challenging environments. These features help reduce installation time and chance of craft error, while also providing the data needed to manage your grid assets proactively.

Accuracy – Analog waveforms for advanced analytics

Automatic distribution and control systems require highly accurate, real-time information about key grid parameters, such as voltage and current, in order to perform to their full potential. 3M Sensored Cable Accessories provide voltage data accurate to ±0.5%*, and current data accurate to within ±1%*. The bi-directional power flow and intermittent nature of renewable resources makes this data critical to utilities’ efforts to manage efficiency, quickly locate and correct faults, and keep end customers online.

Visibility – Real-time measurements

Currently available distributed intelligence solutions are generally too expensive to meet return on investment requirements if deployed systemwide. As a result, they are concentrated at just a few nodes – giving only a partial picture of the distribution grid. Since medium voltage cable accessories are typically located close to power equipment, 3M Sensored Cable Accessories can be deployed at strategic locations on the feeder, substations and consumption points throughout the grid – allowing wide-scale deployment and coverage.

Smart grid applications for 3M Sensored Cable Accessories

- Volt/VAR Optimization (VVO), including Conservation Voltage Reduction (CVR)

- Fault detection, isolation and restoration (FDIR)

- Asset management

- Load balancing

Voltage and Current Measurement Made Easy

The 3M Sensored Cable Accessory QX-Generation 2.0 enables you to measure critical parameters (voltage, current, phase angle) in an underground medium voltage electrical network. This solution incorporates highly accurate voltage and current measurement integrated into one product which means you get precise measurements without modification of the installed equipment. Additionally, the sensors are passive components thereby not requiring an external power source for sensing.

3M Sensors and Cold Shrink technology ensures easy and fast installation for a wide range of cable cross sections.

Your Trusted Connection

3M, together with Thorne & Derrick, understand the greatest of challenges. Every minute of downtime damages your brand, and power outages can be costly. 3M technology can be trusted to adapt facilities for changing business needs, working with your team to add value to existing infrastructure, reduce operating costs and give a competitive edge.

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

How To Splice A 15kV Cable Using 3M Mining Cable Splice Kit 3103

May 20th, 2021

A series of How-To videos for repairing, jointing and terminating cables using 3M Cold Shrink & Scotchcast products.

This video by 3M Electrical shows how to splice a 15kV SHDC cable using 3M Mining Cable Splice Kit 3103 safely.

3M Mining Cable Splice Kit 3103 may be used for flexible conduit and mining jacket repairs, as well as for cable splicing and jointing mine and portable cable.

3M 3103 cable splices and joints are for use on 3-conductor mine and portable cables, type SHD-GC, MPF-GC and MPF; # 6 AWG-500 kcmil; 5kV, 8kV, 15kV.

3M Mining Cable Splice Kit 3103 Kit Contents

- 2 rolls 3M Scotch 31 heavy duty mining cable tape

- 1 roll 3M Temflex 1700P vinyl electrical tape

- 3 rolls 3M Scotch 24 shielding tape

- 2 rolls 3M Scotch 2228 rubber mastic tape

- 2 CC2 Dry cable cleaning & preparation kits

- 3 rolls 3M Scotch 13 semi electrical conductive tape

- 3 rolls 3M Scotch 130C linerless rubber self-amalgamating tape – 1 ½” x 30 ft

- 3 rolls 3M Scotch 130C linerless rubber self-amalgamating tape – ¾” x 30 ft

Cable Preparation

Position cable end so that the colour rotation matches. Circle cut the cable jacket 12” from each end. Be sure not to damage the cable conductors. Measure 14” from the cable end and fully taper down to the circle cut.

Remove 12” of the cable jacket and cable fillers. Scuff and clean 4” of the cable jacket beyond the top of the taper. Hold back the grounds and ground check conductors and temporarily tape to cable with Temflex 1700P vinyl tape.

Select one conductor and cut at 9”. Match this conductor with the same colour conductor on the opposite end. Take the next conductor at 6”. Remove ¾” of the braid or tape metallic shielding from each conductor plus one half the connector length plus ¼”.

Remove cable semi con to ¼” of the shielding. Remove insulation for one half of the connector length plus ¼”. Pencil the insulation for ¾” and sand it smooth and even with electrical graded abrasive cloth.

Connecting Phase Conductors

Once the cable is prepared, join the power connectors with the proper connectors and cable crimping tool. Be sure the conductors butt up against the centre indents of the connector.

Note that ground wires and ground check will be joined later.

Applying Primary Insulation

Apply two highly stretched half lapped layers of Scotch 13 from the edge of one taper to the other, making sure to completely overlap the exposed semi conductive shield. Next apply highly stretched half lapped layers of Scotch 130C and up onto the tapers.

Build up half lapped layers building onto the existing insulation to 1/8” from the edge of the original cable semi con. The taper should be wrapped equal or greater than the original insulation.

Apply 2 highly stretched half lapped layers of Scotch 13 over the Scotch 130C overlapping the edges of metallic shielding.

Starting 2” up on the exposed metallic shielding wrap 1 half lapped layer of Scotch 24 over semi conductive tape continuing onto the opposite shielding for 2”.

Secure with a half inch square knot and trim the ends. Repeat connecting the phase conductors and applying primary insulation for the remaining phases.

Connecting Ground Connectors

Beforre cutting the ground wires reposition the spliced power conductors so that the conductors are returned to the natural helix of the cable. Lay the ground wires in their natural position in the valley between the two power conductors. Allow the ground to link staggered so as to avoid connection over the power conductor connections.

Join the conductors with the proper connectors and appropriate crimping tool. If present, connect the ground check conductor after trimming it to the proper length and remove one half connector length of the insulation from each lead.

On the ground check, clean the insulation 1” on both sides of the connection and apply one half lapped layer of 3M Temflex 1700P, one half lapped layer of Scotch 130C and one half lapped layer of 1700P over the connector and the clean insulation. Connect the remaining ground wires.

Jacketing The Splice

Bundle the cable assembly and bind it with 3M Temflex 1700P tape. Cover 1700P tape with one half lapped layer of Scotch 2228 and starting half way up the tapers, wrap half lapped layers of Scotch 130C building up and across the splice until the tape is equal to or greater than the original jacket thickness and extends 1” past the top of the jacket tapers.

Start 2” beyond the Scotch 130C tape and wrap one half lapped layer of Scotch 31 tape extending 2” beyond the 130C tape on the opposite end. Always wrap the Scotch 31 tape toward the machine end of the cable.

Start 1“ past the Scotch 31 and apply 3 half lapped layers of 3M Temflex 1700P to each end to temporarily secure the ends of the Scotch 31 tape jacket until the jacket reaches full bond.

Repairing Damaged Cable Jacket

Remove damaged cable jacket and taper the jacket approximately 2”. Scuff and clean 4” of the cable jacket beyond each split end. Bundle the cable assembly and bind with 3M Temflex 1700P tape.

Cover the Temflex 1700P tape with one half lapped layer of Scotch 2228. Wrap half lapped layers of Scotch 130C building up and across the splice until it is equal to or greater than then original jacket thickness and extends 1” beyond the top of the jacket tapers.

Start 2” beyond the Scotch 130C tape and wrap one half lapped layer of Scotch 31 tape extending 2” beyond the 130C tape on the opposite end. Always wrap the Scotch 31 tape toward the machine end of the cable.

Start 1“ past the Scotch 31 and apply 3 half lapped layers of 3M Temflex 1700P to each end to temporarily secure the ends of the Scotch 31 tape jacket until the jacket reaches full bond.

Cold Shrink – invented by 3M over 40 years ago and now the preferred technology for heat-free jointing, terminating, sealing and abandonment of LV HV cables

We hope you find this video informative and educational, contact T&D for technical support, quotations and stock availability for 3M Mining Cable Splice Kit 3103.

➡ Visit 3M Electrical for further information about joints, terminations, tapes and insulation to seal, repair, splice and connect LV MV HV cables.

Cold Shrink | Joint | Terminate | Seal | Repair | Splice | LV MV HV Cables | 3M

- 3M Electrical Products Stocked By Thorne & Derrick International

3M Scotch Super 33+ Vinyl Electrical Tape

May 11th, 2021

3M Scotch Super 33+ Vinyl Electrical Tape

3M Electrical Tapes

Scotch Super 33+ Tapes

When it comes to the your most demanding electrical maintenance and repair jobs where failure and equipment downtime are simply not an option look no further than the 3M Scotch Super 33+ Vinyl Electrical Tape.

The vinyl electrical tape has excellent resistance to abrasion, moisture, alkalies, acids, corrosion and varying weather conditions (including UV exposure) and forms part of the 3M Scotch Electrical Tapes. Scotch Super 33+ can be used in hot or cold temperatures, high humidity or in contact with contaminants and aggressive substances making the tape suitable for inside and outdoor environments.

Highly conformable and super-stretchy and designed to perform continuously in ambient temperatures up to 105 °C

Scotch® Super 33+™ Vinyl Electrical Tape is designed for:

- Primary electrical insulation of electrical connections up to 600V

- Protective cable jacketing and repairs

- Weatherproofing

- Harnessing of wires and cables

Thorne & Derrick – 3M Electrical Stockists & Suppliers | Scotch Tapes | Scotchcast Resins | Cold Shrink Products | UK & Export Sales

3M Scotch Super 33+ can be used in combination with other 3M professional tapes.

| 3M Tapes | Tape Description | 3M Tape Image |

| Scotch Vinyl Colour Coding Electrical Tape 35 | Scotch Vinyl Colour Coding Electrical Tape 35 is the professional grade vinyl electrical tape available in nine fade resistant colours: blue, brown, grey, green, orange, red, violet, white, yellow, and pink. Outstanding electrical and mechanical properties make this tape excellent for use in phase identification, colour coding of motor leads and piping systems, and for marking safety areas. Scotch® Tape 35 applies smoothly and conforms well down to 0 °C. Maximum operation temperature is 105 °C. |

|

| Scotch Rubber Splicing Tape 23 | Scotch® Rubber Splicing Tape 23 is made from Ethylene Propylene Rubber. This product fuses to itself in a short time after application to create a solid piece of rubber with high dielectric properties and is impenetrable by moisture. It’s a great option when working on jobs with voltage up to 69 kV. Split resistant, crack resistant and flag resistant within harsh environments. Rated for 90 °C continuous operating temperature and over- load temperatures of up to 130 °C. Scotch® Rubber Splicing Tape 23 features a liner, making it easy to cut and apply the tape in strips and in messy environments. |

|

| Scotch Rubber Mastic Tape 2228 | This product combines the advantages of rubber and mastic tapes for fast application. Scotch® Rubber Mastic 2228 is a conformable self-fusing rubber electrical tape designed for electrical insulating and moisture sealing applications at 90 °C with an emergency overload rating of 130 °C. It is flexible and conformable over irregular shapes. The thick construction allows quick application build-up and padding, good for cable jacket repair. It is UV resist- ant and has excellent adhesion and sealing characteristics with copper, aluminium and power cable jacket material. |

|

| 3M Scotchfil Electrical Insulation Putty | 3MTM Scotchfil Electrical Insulation Putty is a noncorrosive electrical grade compound in a tape form, easy to mould by hand down to 0 °C. It’s a great solution for smoothing uneven surfaces and eliminating voids until good overall padding is provided. 3MTM Scotchfil Putty is recognized as a splice insulation for electrical conductors at temperatures up to 80 °C when overwrapped with Scotch® Super 33+TM. |  |

➡ Specialist Application 3M Scotch Tapes: Fire Retardant, Fire Resistant, Arc Proofing, Cable Sheath & Jacket Repairing, Bundling & Harnessing Cables.

3M Scotch Electrical tapes are used to cable joint, splice, repair, seal and protect cables against abrasion, fire and corrosion – this includes LV-HV (11kV-33kV cables) – please contact T&D should you require assistance with selecting the correct tape.

The 5 Factors To Assessing Cable Splice Life Expectancy

May 4th, 2021

Cable Splicing

Assessing Life Expectancy

Guest Article | 3M Electrical Canada

Thorne & Derrick Stockists & Distributors for 3M Electrical Since 1985

Scotchcast, Scotch & ColdShrink Joints, Terminations up to 66kV Ex Stock

Cable splice failures are expensive, so just imagine the dire consequences of a power failure leaving over 700,000 customers without power. Many of us in Ontario can still recall the shock of the 2003 Northeast Blackout.

As a consumer of electricity our expectation is that our lights stay on, our fridges stay cold, and our roads stay safe with operating traffic lights. When the lights go out, utilities have the extensive task of finding the source of the electrical or power cable fault, communicating with public and customers, and taking on the cost of repair including labour costs.

How do utilities actively try to prevent electrical failures?

Utilities measure system average interruption duration index (SAIDI) and customer average interruption duration index (CAIFI) as both of these are negatively impacted by underground cable splices and their failures. They are constantly looking for ways to help improve these measurements – and improvement comes down to choosing safe and reliable MV Cable Accessories.

Identifying this need within the utility industry, I created a Whitepaper that evaluates the five critical factors to help determine the overall life expectancy of a cable splice. I did this by leveraging 3M Cold Shrink QS-III’s 23 years of field experience.

➡ Did you know: Some of the 3M Cold Shrink Products installed in the field are still operational after almost 50 years!

The goal of this study is to help provide utilities with research and insights to help improve their SAIDI and CAIFI measurements.

Study highlight: 5 factors to help determine the life expectancy of an electrical Cable splice

- Technology: Reliability of an electrical cable splice hinges on your ability to maintain radial splice pressure on the cables. 3M™ Cold Shrink QS-III is equipped with 3M™ Cold Shrink Technology, which retains radial pressure over the life of the cable splice. As a result, there is no loss of pressure with heat cycling.

- Materials: Elasticity and the capability to apply in cold environments (especially in Canada’s frigid winters) are critical. 3M™ Cold Shrink QS-III’s silicone rubber is an excellent material choice for splicing applications. It acts as a “living seal” – helping provide long-term elasticity (including at negative temperatures) and has great electrical properties required by a robust splice design. Additionally, we use silicone rubber filled with thermally conductive additives to help improve heat dissipating properties of the splice body.

- Design: An electrical cable splice or cable joint must be designed to manage electrical stresses by minimizing them for increased long-term performance. 3M™ Cold Shrink QS-III’s moulded splice body exhibits design features that lower electrical stresses. The features include large electrical geometric stress cones, rounded semi-conductive electrodes with an undercut insulation that lower stresses at cable/splice interface and additional insulation thickness at the end of the inner electrode to compensate for increased stresses in this area.

- Workmanship: Workmanship in splice installation and cable preparation have a great impact in long-term performance. A clear majority of cable failure investigations that I’ve run for our customers pinpoint poor workmanship in cable preparation techniques as the leading root cause for failures. Some of the negative impacts of inconsistent cable preparation and/or cable cleaning that increase electrical stresses can be mitigated by design features such as the rounded semi-conductive electrode with an undercut of insulation that lowers stresses in the area of the splice/cable interface. 3M™ Cold Shrink QS-III is designed to help mitigate these cable preparation errors and the moulded electrical splice body offers ease of installation and high quality.

- Testing Procedures: A product that is designed and tested at levels meeting and exceeding industry standards will have an adequate long-term performance. For 3M™ Cold Shrink QS-III qualification testing, we rate our electrical splices one basic insulation level (BIL) level higher than the corresponding splice classification (ex. 15kV splices meet the BIL requirements of a 25kV splice).

Further Reading

- Cable Terminations | Cold Shrink Terminations MV HV Cables

- 3M Cold Shrink Terminations Connecting Nexans 12kV (MV) Cable Onto Busbar

- 66kV Terminations | NEW Stock Introduction for 3M Cold Shrink Cable Terminations

- 3M Terminations | Surface Tracking on Medium Voltage Cable Terminations by 3M

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Equipment – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

3M Medium Voltage EPDM Separable Connectors Plug In Selection Guide

May 4th, 2021

3M Medium Voltage EPDM Separable Connectors Plug In Selection Guide

Medium Voltage EPDM Separable Connectors

The easy to install range of plug-in separable connectors from 3M are moulded using high quality EPDM and meet the requirements of EN 50180 and EN 50181.

Designed for indoor use and suitable for a wide range of applications the straight, elbow and T-Plug connectors are sold in packs of 3 and come with silicone stress control elements, earthing set, mechanical cable lug for main conductor, mechanical cable lug for wire screen, all assembly materials and assembly instructions.

All medium voltage connector kits are fully type tested to Cenelec HD 629.1 (DIN VDE 0278) and are available for voltage classes 6.6/11(12)kV, 20/22(24)kV, and 19/33(36)kV.

The screened separable connectors are suitable for single core, copper wire screened, un-armoured cables, in a wide range of sizes, for outer cone bushings.

Individual range data sheets are available, with full details of each kit – please contact Thorne & Derrick for more information.

| Voltage | Configuration | Cross Section Area | 3M Order Code |

| 6.6/11(12)kV | Elbow 250A | 35mm² & 50mm² | 92-EE 895-2 35-50 |

| 50mm², 70mm² & 95mm² | 93-EE 895-2 25-95 | ||

| 120mm² & 150mm² | 93-EE 895-2 70-150 | ||

| Elbow 400A | 50mm², 70mm² & 95mm² | 93-EE 895-4 25-70 | |

| 95mm² & 120mm² | 92-EE 895-4 95-120 | ||

| 150mm², 185mm² & 240mm² | 93-EE 895-4 95-240 | ||

| 6.6/11(12)kV | Straight 250A | 35mm² & 50mm² | 92-EE 890-2 35-50 |

| 50mm², 70mm² & 95mm² | 93-EE 890-2 25-95 | ||

| 120mm² & 150mm² | 93-EE 890-2 70-150 | ||

| 6.6/11(12)kV | T 630A Asymmetrical | 50mm², 70mm² & 95mm² | 93-EE 995-6 25-70 |

| 95mm², 120mm² & 150mm² | 92-EE 995-6 95-150 | ||

| 150mm², 185mm² & 240mm² | 93-EE 995-6 95-240 | ||

| T1250A Asymmetrical | 240mm², 300mm² & 400mm² | 93-EE 995-6 240-400 | |

| 500mm² & 630mm² | 93-EE 995-6 400-630 | ||

| T 630A Symmetrical | 50mm², 70mm² & 95mm² | 93-EE 998-6 25-70 | |

| 95mm², 120mm² & 150mm² | 92-EE 998-6 95-150 | ||

| 150mm², 185mm² & 240mm² | 93-EE 998-6 95-240 | ||

| 20/22(24)kV | Elbow 250A | 25mm², 35mm², 50mm², 70mm² & 95mm² | 93-EE 895-2 25-95 |

| 70mm², 95mm², 120mm² & 150mm² | 93-EE 895-2 70-150 | ||

| Elbow 400A | 25mm², 35mm², 50mm² & 70mm² | 93-EE 895-4 25-70 | |

| 95mm², 120mm², 150mm², 185mm² & 240mm² | 93-EE 895-4 95-240 | ||

| 20/22(24)kV | Straight 250A | 25mm², 35mm², 50mm², 70mm² & 95mm² | 93-EE 890-2 25-95 |

| 70mm², 95mm², 120mm² & 150mm² | 93-EE 890-2 70-150 | ||

| 20/22(24)kV | T 630A Asymmetrical | 25mm², 35mm², 50mm² & 70mm² | 93-EE 995-6 25-70 |

| 95mm², 120mm², 150mm², 185mm² & 240mm² | 93-EE 995-6 95-240 | ||

| 240mm², 300mm² & 400mm² | 93-EE 995-6 240-400 | ||

| T 1250A Asymmetrical | 400mm², 500mm² & 630mm² | 93-EE 995-6 400-630 | |

| T 630A Symmetrical | 25mm², 35mm², 50mm² & 70mm² | 93-EE 998-6 25-70 | |

| 95mm², 120mm², 150mm², 185mm² & 240mm² | 93-EE 998-6 95-240 | ||

| 19/33(36)kV | Elbow 400A | 35mm², 50mm², 70mm² & 95mm² | 94-EE 895-4 35-95 |

| 95mm² & 120mm² | 94-EE 895-4 95-120 | ||

| 150mm², 185mm² & 240mm² | 94-EE 895-4 150-240 | ||

| 19/33(36)kV | T 630A Asymmetrical | 35mm², 50mm², 70mm² & 95mm² | 94-EE 995-6 35-95 |

| 95mm², 120mm² & 150mm² | 94-EE 995-6 95-150 | ||

| 150mm², 185mm² & 240mm² | 94-EE 995-6 150-240 | ||

| 240mm², 300mm² & 400mm² | 94-EE 995-6 240-400 | ||

| T 1250A Asymmetrical | 400mm², 500mm² & 630mm² | 94-EE 995-6 400-630 | |

3M Medium Voltage EPDM Separable Connectors

3M HV Inner Cone Plug In Separable Connectors

Technical Specification 6.6/11 (12) kV Cables

3M HV Inner Cone Plug In Separable Connectors are designed for inner cone bushings up to 11/12kV voltages and single core polymeric power cable systems with copper wire screen cables according to EN 50180/50181 for Interface types 1, 2 and 3 when connection to metal enclosed switchgear and transformers is required.

Connector Kits include:

- 1. Pressure ring with lamellated contact

- 2. Cone Clamp

- 3. Pressure Disc

- 4. Silicone Rubber Insulator with integrated stress control element

- 5. Pressure spring with support rings

- 6. Entry gland of silumin with fixing flange

- 7. Insulating wrap

- 8. Earth connection (shown for clarity)

- 9. XLPE Cable (shown for clarity)

- 10. Bushing (shown for clarity)

➡ Go to Cold Shrink Terminations to view MV-HV cable terminations for 6.6kV, 11kV, 33kV and 66/132kV cables. Also – cable accessories including high-fault current rated cable glands, cable cleats and cable jointing tools for jointing and terminating of MV/HV power cables.

Cable Box Terminations & Connectors – Inner Cone & Outer Cone

Cold shrink is typically used for the dry termination of medium/high voltage 11kV-33kV cables into MV-HV air insulated cable boxes.

T&D also distribute MV-HV Connectors for terminating cable into metal-enclosed SF6 insulated medium voltage switchgears (GIS) and liquid immersed transformers.

- Nexans Euromold Separable Connectors – elbow-shaped, straight or T-shaped connectors for outer cone bushings

- Pfisterer CONNEX Plugs – medium voltage cable plugs for inner cone bushing sizes 1, 2 or 3