Blog

Hauff-Technik Officially Approved By Scottish & Southern Electricity Networks (SSEN)

June 25th, 2020

Hauff-Technik

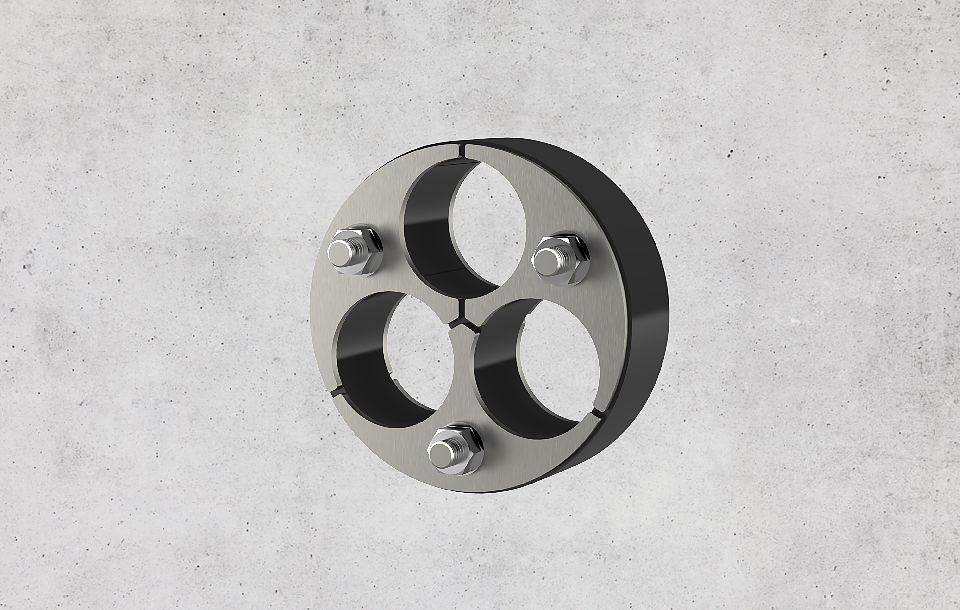

SSEN has fully approved the Hauff-Technik cable and duct sealing solutions for their distribution network. Thanks to their business partner Emtelle, the leading manufacturer of sealing systems, Hauff Technik, have reached another milestone in our UK business.

Both companies are happy with the latest achievement and expect a positive effect at other important utility companies.

Rob Gasken, Product & Sales Engineer at Emtelle, says: “Having worked with Hauff-Technik for a number of years now, supplying their products as part of our full end-to-end ducting network solution, we have no doubt that this will be an enhancement to SSE networks.

We’re proud to be in an existing successful partnership with Hauff-Technik, and to be the named supplier of their mechanical press seals in the SSEN approved product register. Great to see that these superior sealing methods are gaining the official recognition they deserve.”

Jan Holly, Hauff-Techniks Head of Sales UK & Ireland, emphasises „The cooperation with Emtelle has always been full of common interests. The SSE approval is another evidence for what we can achieve with a shared, customer oriented strategy.“

Emtelle cable duct provides underground cable protection to LV-HV cables, including UK DNO approved Class 1 PVC cable duct for 33kV high voltage power cable protection.

Thorne & Derrick

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground and subsea cables, overhead lines, substations and electrical construction at LV, 11kV/33kV up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Specialist Electrical Equipment Distributors for High Voltage Power Systems

Cable Heaters For Straightening 33kV & High Voltage (HV) Cables

June 20th, 2020

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Heating High Voltage Cables

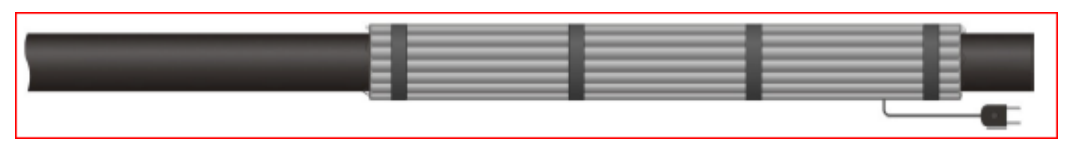

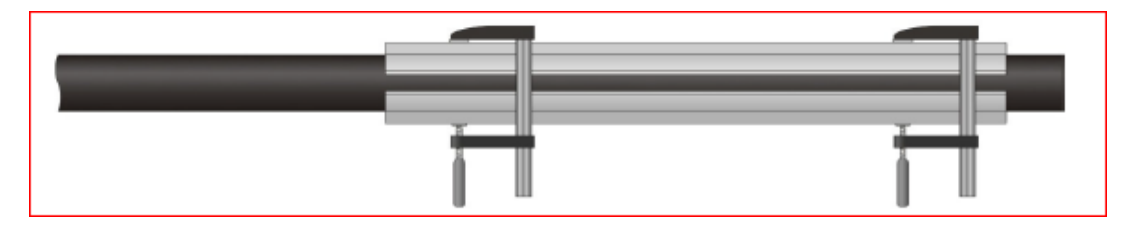

Working closely with HV and EHV cable manufacturers Thorne & Derrick have designed and developed a standard range of cable heating jackets for straightening and relaxation of high voltage cables prior to installing MV HV Joints, Terminations & Connectors – T&D supply a complete HV cable straightening set focusing on safe, exact and consistent heating of high voltage cables with adjustable temperatures up to 100°C.

The unique cable straightener solution with extension pieces gives the HV jointer the most flexible cable heating solution to cover several different cable dimensions with fully homogeneous load density for XLPE insulated cables.

Cable straighteners are used to heat voltage class MV HV cables: 33kV 66kV 132kV 275kV

Cable Heaters Specification

The following table provides technical data to cover the performance and application of cable heater blankets for MV HV cables – please note this is for standard cable straightening applications up to 132kV. T&D working with MV HV cable manufacturers and installers can provide customised cable heating solutions for all types of polymeric (XLPE) type cables.

The cable heaters feature an in built overtemperature switch at 110°C.

| Operating Voltage | 220-240VAC or 110-120VAC |

| Cable Heating Range | Ø70-190 mm or Ø40-69 mm (Outside Diameter) |

| Cable Heating Temp. | 95°C (adjustable setpoint, PID/rampable by time control) |

| Insulation Thickness | 25mm |

| Cables | 5m power supply, 5m cable from controller to cable heating jacket |

| RCD | 30mA, Type A |

| IP Rating | IP44 |

| Cable Heating Voltages | 33kV 66kV 132kV 275kV |

Cable Heaters Selection

The following table includes the standard Cable Heating Jackets – should you require any specification support or technical advice to select the correct cable straightening jackets please do not hesitate to contact us.

| Order Code | Operating Voltage | Cable Diameter | Cable Heater Length |

| CSR 70-115 Cable Heater Blanket up to 190mm Diameter | |||

| Single Set CSR 70-115/1-1500-230 | 220-240VAC | 70-115 | 1500mm |

| Double Set CSR 70-115/2-1500-230 | 220-240VAC | 70-115 | 1500mm |

| Extension CSR EP25-1500-230 | 220-240VAC | – | 1500mm |

| Single Set CSR 70-115/1-2000-230 | 220-240VAC | 70-115 | 2000mm |

| Double Set CSR 70-115/2-2000-230 | 220-240VAC | 70-115 | 2000mm |

| Extension CSR EP25-2000-230 | 220-240VAC | – | 2000mm |

| Single Set CSR 70-115/1-1500-115 | 110-120VAC | 70-115 | 1500mm |

| Double Set CSR 70-115/2-1500-115 | 110-120VAC | 70-115 | 1500mm |

| Extension CSR EP25-1500-115 | 110-120VAC | – | 1500mm |

| CSR 40-69 Cable Heater Blanket up to 69mm Diameter | |||

| Single Set CSR 40-69/1-2000-230 | 220-240VAC | 40-69 | 2000mm |

| Double Set CSR 40-69/2-2000-230 | 220-240VAC | 40-69 | 2000mm |

| Cable Straightening Aluminum Profile | – | – | – |

| CSR SP2000 | – | – | 2000mm |

Pfisterer Heaters

Here is shown the Pfisterer range of cable heating blankets used to pre-heat and straighten medium/high voltage XLPE insulated power cables prior to termination with their pluggable CONNEX range of inner cone terminations.

33kV Cable Heating & Straighteners

The following information is published from the Western Power Distribution company directive CA3C/2 Relating to General Requirements for 33kV Cable Jointing and specifically to the sub-section Heat Straightening of 33kV High Voltage Cables.

With dry designs of medium/high voltage polymeric cable after the removal of the oversheath and metallic sheath, the polymeric XLPE cable has a tendency to bend. This can give rise to problems associated with the fitting of the cable terminations or straight joints. Because of this there is a need for a heat treatment process to be applied to each cable core to relieve the mechanical stresses that are locked into the cable insulation.

With the wet designs of polymeric cable the polymeric cable has a tendency to bend, even after being set into their final position. This can give rise to problems associated with the fitting of the cable terminations or straight joints. Because of this there is a need for the heat treatment process to be applied to the core to relieve the mechanical stress that is locked into the cable insulation

Apply the tube, fitted with the heater tape and thermocouple, over the cable end and onto the PVC packing. Ensure that the thermocouple is not directly under the heater tape. Wrap the complete assembly with a thermal blanket.

Heating 33kV Cables Figures 1

Switch on the controller and bring the temperature of the cable up to 90°C, once the cable has reached the required temperature the heating time is determined by the cable size.

Given below: –

4 hours for conductor sizes up to and including 500sqmm

6 hours for conductor cross sections above 630sqmm and up to 1600sqmm

After the requisite time, switch off. Remove the cable heating blanket, heater tube complete with heater tape, thermocouple and PVC packing. Wearing appropriate gloves carefully straighten the cable into the correct position by hand.

Heating 33kV Cables Figures 2

Clamp the cable into position on a V shaped angle irons or channel irons and allow the cable to cool for a minimum of two hours, insuring the angle iron or channel irons stay in the correct position during the cooling process.

132kV

Jointers depend on 132kV cable heating jackets and blankets to straighten EHV power cables prior to installing Pfisterer CONNEX type inner cone cable terminations into high voltage gas insulated switchgear and susbtations.

How Else Can We Help?

➡ Drum Heating & Cable Straightening Jackets For 132kV Extra High Voltage Cable Terminations

Joints, Terminations & Connectors for HV High Voltage Cables

Thorne & Derrick are stockists of market-leading manufacturers of Cold Shrink, cold applied, heat shrink and EPDM type joints, terminations and connectors up to 66kV.

MV HV cable heaters are designed to provide consistent surface heating to the cables of XLPE insulated type – when cables are pulled from the coiled state on a cable drum they have a tendency to naturally attempt to recoil. The heating process provides linearity of 33kV/66kV/132kV cables to enable optimum installation of cable joints, terminations or connectors in Cold Shrink, heat shrink or EPDM type rubber technology.

Minimising Effects Of Electromagnetic Interference On High Voltage Cables In Electric Vehicles

June 17th, 2020High Voltage Cables In Electric Vehicles

Electromagnetic Interference

BAND-IT began serving the automotive high voltage cable market in 2007 and has supplied millions of clamping solutions to many of the largest and most well-known cable harness manufacturers in the Hybrid and Electric Vehicle Industry.

Vehicle manufacturers use a quick connector and wire mesh shield to minimize the effects of Electromagnetic Interference on high voltage cables in electric vehicles.

With previous solutions, the wire mesh could bunch or gather in one area creating an inconsistent installation. The reduced diameter clamp from BAND-IT can minimize the effects and provide a tight fit with a single stock commodity unit.

With 3 decades of EMI/RFI Shield termination dominance in the Miltary and Aero industry, BAND-IT is consistently selected for the shielding of high voltage cable in automobiles.

The BAND-IT Edge

- Consistent clamp force around the entire circumference of the part

- One BAND-IT clamp can meet many sizes and variation – reducing SKUs

- BAND-IT installation tools minimize variation and provide consistent installation of clamping application

BAND-IY Product Features

- Tamper resistant

- High clamping force securely locks the shielding to the connector

- Designed for high-volume installation

- Robust strength and resistance to vibration, thermocycling, and corrosion

Further Reading

- Cable Clamps: The BAND-IT BAND-FAST Range – IEC61914 Tested

- Solar Farms Replace Nylon Cable Ties With Metal Cable Ties

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

The LV HV Cable Accessory Specialists

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the renewable energy sector – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

Lead Cable Jointing – Where Craftmanship Becomes Artistry

June 11th, 2020-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

Andy O’ Malley is a world-class EHV Jointer with a skill set encompassing both traditional and modern cable splicing and jointing techniques. Andy is a rare breed – expertly Competent and comfortable jointing oil, gas or polymeric cables up to 420kV.

Ticketed by todays market leading manufacturers of EHV polymeric cable accessories such as 3M, JPS, ABB, Elastimold, LS Cables and Pfisterer while acknowledging a debt of gratititude to former BICC and Prysmian (Pirelli) Cable Jointers. A great jointer, a great guy.

“I’m nothing without my great crew and on transmission I owe everything to those whom have trained me – they know who they are. I have had a great team mate, thank you James Nicklin,” Andy comments.

In the following Blog, Andy demonstrates expert lead cable jointing skills.

Tools Of The Trade

“Tools Of The Trade”

Top left: propane/gas torch (underneath plumbing/wiping pad). Andy makes his own pads (from a roll of moleskin).

Double burner (left side: oil tape pot, right hand side: hot pour compound bucket).

Bottom left to right: hammer, hack knife, small hack knife, lead scraper, small paper knife, knife (made by Andy), pipe to set cable cores, ladles, sweating pot and lowering hook (above ladles).

The tube next to the orange gas line is used to help set paper cores on larger sized cables.

1. Lead Sleeve Ready To Prepare

2. One End Scraped & Protected From Oxidizing Using Styrene

3. One End Dressed

4. Sleeve Prepared For Placement Onto Cable

Before & After Lead Cable Jointing

1. Before Y Splice/Breach Joint To Be Broken Down

2. Straight Splice/Joint Complete

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

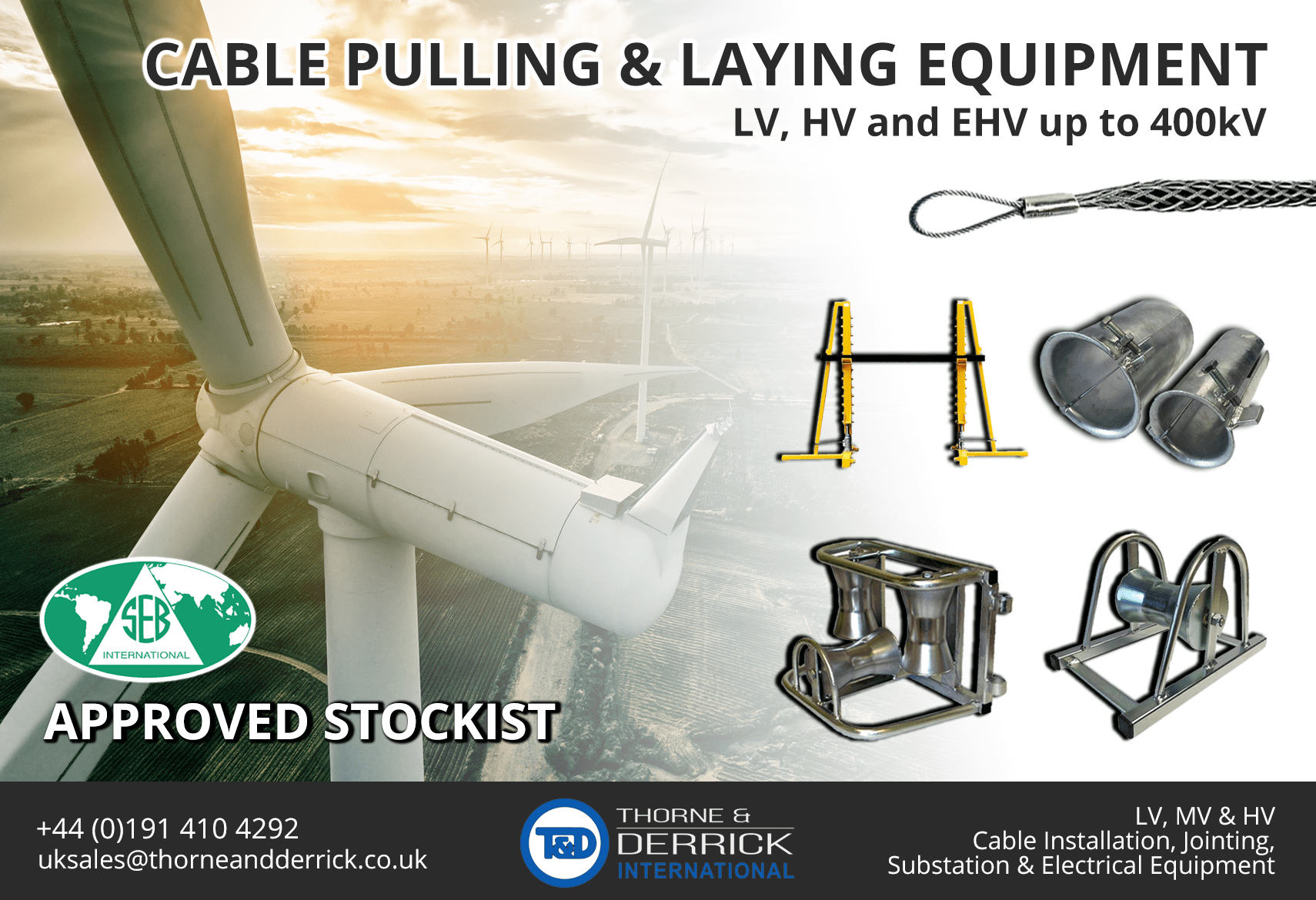

Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

June 3rd, 2020

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

Press Release | 1st July 2021

LV to 400kV

Thorne & Derrick International, based in the UK, are delighted to announce they have entered into an Approved Stockist Agreement with SEB International, the market-leading Cable Laying Equipment manufacturer.

Thorne & Derrick have partnered with SEB to service the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

From today, Thorne & Derrick will provide competitive prices and technical support for the SEB range of exceptional quality, British manufactured Cable Pulling & Laying Equipment – this includes rollers, socks, jacks, winches and trailers to enable cables, umbilicals or pipes to be installed into ducts, trenches and tunnels.

We can provide expert technical advice and pulling system specifications to maximise cable and circuit safety requirements to UK DNO policy standards. Since 1971, SEB International have manufactured both standard range and complex customised cable pulling equipment from the largest product selection found throughout the world.

“Traditionally, our core business has been the supply of High Voltage Jointing & Termination products from stock up to 66kV – as a Specialist Distributor we now have an enhanced commercial strength and added-value service to support projects at the cable laying stage. Whether pulling underground or subsea power cables into trench or duct we can provide reliable and competitive solutions .

Thorne & Derrick and SEB can innovatively overcome the technical and logistical challenges of laying and deploying cables across all sectors – from offshore windfarm to hyper-scale data centre projects, we can help. We have a scheduled sales and marketing campaign to launch and look forward to introducing SEB to existing and new clients,” comments Chris Dodds Sales & Marketing Manager at Thorne & Derrick.

Andrew Hetherington (Commercial Director at SEB International Ltd) adds, “both of our family-owned companies pride themselves on a super-efficient level of customer service, which is unrivalled throughout this industry. Allied to this is the combined technical knowledge and experience that both our businesses possess – this is at the heart of our business success story and we expect this new working partnership to further support the industry and our business goals.”

You can contact Thorne & Derrick to discuss both standard and customised cable handling equipment for the safe installation of underground or subsea power cables: LV, HV and EHV up to 400kV.

Following a post-COVID f2f supply chain meeting at SEB International Ltd – the world leading UK manufacturer of Cable Pulling Equipment – Thorne & Derrick have agreed an Approved Stockist relationship with SEB. Pictured | Andrew Hetherington (MD SEB), Debbie Commins (Sales & Marketing SEB), Chris Dodds (Sales & Marketing Manager T&D) and Jonny Hewitt (Key Account Manager T&D).

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations