Blog

How To Protect LV MV Cables From Electrical Arc Faults & Fire

June 2nd, 2020

3M Scotch 77 Arc Faults & Fire Proofing Tapes

Electrical Arc Faults

Electrical arc fault generated fires can be of up to 2000 Degrees Fahrenheit.

That’s more than twice as hot as the temperature of the surface of Venus and enough heat to melt gold.

Furthermore, this is more than enough to destroy expensive electrical cables.

The resulting catastrophes of an electrical arc fault generated fire means that we have to find a solution to protect cables against these dangerous and damaging fires.

In this Article we show how 3M Scotch® Fire Retardant Electric Arc Proofing Tape 77, can protect low (LV) and medium voltage (MV) electrical cables from electrical arc faults and their resulting fires.

Arc Faults Can Be Catastrophic

Protecting cables From ARC Faults

with 3m scotch 77 tape

Even after a short exposure to a flame, an unprotected cable will catch fire, and continue to burn. Increasing the likely-hood of causing other fires and causing additional major damage. One fire could wreak absolute havoc on cables, or the equipment they are connecting.

Even after a short exposure to a flame, an unprotected cable will catch fire, and continue to burn. Increasing the likely-hood of causing other fires and causing additional major damage. One fire could wreak absolute havoc on cables, or the equipment they are connecting.

Unless of course you can help prevent them from catching fire in the first place. Scotch fire retardant electric arc proofing tape, is designed to protect Low Voltage and Medium Voltage cables and cable accessories from arc faults and the resulting fires.

3M Scotch 77 tape can withstand a 2000 degree torch blast from 3 inches away, for 3 minutes.

That’s 3 minutes longer than an unprotected cable.

3M Scotch 77 Tapes are 0.76mm thick, arc and fireproofing electrical tapes designed to protect all types of electrical cables. This insulating firewall acts as a heat shield and flame barrier, thus protecting the cables joints and accessories.

Scotch 77 tape is burn resistant.

It will also help prevent cable jacket material from melting and dripping flames onto whatever lies beneath it. When the flame is taken away from a cable protected by 77 tape, that’s it, it doesn’t continue burning. It doesn’t cause additional fires and when the tape is removed, the cable underneath does not show any significant damage, and should not need to be replaced.

That kind of trusted protection is why electrical professionals around the globe have taken notice. Used properly, Scotch brand fire retardant electric arc proofing tape 77, can be the difference between a small problem, and an expensive catastrophe.

Stockists & Suppliers of 3M Scotch Electrical Tapes

SCOTCH 77 Tape

- Manufacturer: 3M Electrical

- Brand: Scotch Tapes

- Stock Code: 3M Scotch 77 Tape

- Product Category: Electrical Tapes

- Sub Product Category: Corrosion & Fire Protection Tapes

- 3M Scotch 77 Tape Application: Protects cable from arc and fire until limiting devices can interrupt faulted circuit. Use on high-energy cables that are within 18″ of other high energy cables. Available in black and white the white version is easily visible and easy to inspect

- 3M Scotch 77 Roll Sizes:

- 1-1/2″ x 20′ (38 mm x 6,1 m)

3″ x 20′ (76 mm x 6,1 m)

➡ Also available from Thorne & Derrick are Cold Shrink and Scotchcast – contact us for prices and delivery for the 3M Scotchcast range of cable joints and resins.

Self Amalgamating Tapes | Mastic Tapes | Corrosion & Fire Protection Tapes

Thorne & Derrick

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

LED Lighting for Offshore Wind Farms | The Raytec SPARTAN Lighting Range

June 1st, 2020

LED Lighting for Offshore Wind Farms

LED Lighting

Raytec are world leaders in LED lighting for hazardous area environments – the Raytec SPARTAN range of hazardous area lighting is globally certified Ex LED lighting, approved for all ATEX and IEC Ex Zone 1 and Zone 2 hazardous area environments, including UL /CSA C1D2 (Class 1 Division 2) installations.

In this Application Focus, we explore the lighting requirements for offshore wind farms and identify some of the key features to consider when specifying luminaires for these types of environments.

LED Lighting Requirements

for Offshore Wind Farms

An offshore wind farm can be defined as a cluster of wind turbines constructed in a body of water. The turbines harvest wind energy to generate electricity and benefit from the high wind speeds of their offshore location.

However, the nature of an offshore location provides a challenging environment when specifying lighting. Given the continuous exposure to marine conditions, such as high wind speeds and a saline environment, a high-quality and durable lighting system, capable of withstanding these elements, is critical.

LED Lighting

Offshore Wind Stats

Typical Areas Requiring LED Lighting

Jacket Base Of The Turbine

A turbine sits on a supporting structure called a Jacket Base. The jacket sits above the waterline, as well as being anchored to the seabed, giving the turbine the foundation it needs to withstand the harsh marine environment and dynamic loads.

Lighting, particularly LED lighting, is required to ensure safe working conditions when accessing and departing the turbine, via a crew transfer vessel, where the jacket structure is the main access point. Installing lighting here is also beneficial for routine maintenance and inspection of the area around the ‘splash zone’, where corrosion occurs due to the meeting of the waves and air.

Interior Of The Turbine

Lighting is required inside the turbine for the safety of workers when they perform routine maintenance procedures from within the tower. In many cases ‘Emergency Lighting’, such as the Raytec SPARTAN Intelligent Emergency, is also needed to maintain safety in the event of a power outage.

Access Area Lighting

It is a necessity for heavy-duty industrial lighting to be installed at the crew access point to the turbine, when disembarking the crew transfer vessels. This area sits above the supportive structure and is accessed via a bridge from the crew transfer vessels. Therefore, safety requirements dictate that high-quality industrial lighting is needed to make sure these areas are well lit.

All of these areas require the use of a heavy-duty lighting fitting, such as lighting from the Raytec SPARTAN range, to withstand the challenges of the offshore environment. The remainder of this article will explore the key features to consider when specifying a luminaire for an offshore wind farm.

Specifying Lighting for Offshore Wind Farms

Choosing LED

Firstly, selecting lighting which uses LED technology (rather than conventional lighting, such as high-pressure sodium), should be considered essential when specifying for offshore wind farms.

Lighting Maintenance

Providing it uses effective thermal management, an LED luminaire can offer a lifetime of 100,000 + operating hours, without the need to re-lamp. This results in a significantly longer lifespan and lower life-cycle costs. Reducing the number of maintenance interventions in these remote and offshore locations, where access is difficult and costly, is vital.

Energy Costs

Keeping costs to a minimum is a common goal amongst offshore wind applications. LEDs run more efficiently than conventional lighting; reducing energy costs. The major benefit comes from an LED luminaire’s ability to instantly restrike. Instant restrike allows the lights to be easily switched on and off when they’re not being used. In contrast, due to the warm-up time of a conventional lamp (such as High-Pressure Sodium) they would likely be left switched on 24/7 to avoid costly and impractical delays during maintenance.

Quality of Light

With LED’s capable of providing improved CRI and higher colour temperatures than conventional lighting, light quality is improved which drastically improves working conditions.

Easy Maintenance

Specifying LED lighting can help in reducing the frequency of maintenance required. However, the way a manufacturer has designed the luminaire can have a large impact on how easily maintenance can be carried out of it is required, and how long the site is left without light.

Making Access Easier

For offshore wind farms, where access for maintenance can be difficult, choosing an LED luminaire with a removable power supply unit (PSU), that can be placed separately from the main unit, can help make access easier. For example, Raytec’s SPARTAN High-Power Flood & High-Power Bay luminaires, allow the PSU module to be removed from the main body of the luminaire and be positioned in an easy to access location. This makes access to serviceable parts far easier.

SPARTAN High-Power Bay Lighting

SPARTAN High-Power Flood Lighting

Lighting is required inside the interior of the turbine, stretching from the bottom to the top. Each luminaire can be accessed via a stair or lift system within the turbine column. However, when routine or emergency maintenance is required, having the PSU located at ground level would mean this could be conducted with more efficiency. Having this functionality reduces the time taken to carry out maintenance, and its associated cost. By reducing the time and frequency which maintenance workers spend working at height, health and safety compliance is also positively impacted.

Reducing Downtime

Minimising downtime is crucial to the financial viability of wind farms. If the lighting fails, certain scheduled maintenance procedures can’t take place due to the health and safety risks to the workers.

This could have a detrimental impact on the ‘up-time’ of the turbine itself. So, having a lighting solution that allows maintenance to be quick and easy – bringing the turbine back into service as soon as possible – can be a massive selling point for manufacturers, developers and investors, as this improves the overall financial viability of the site.

LED Lighting For Offshore Wind Farms

Durability

Lighting Withstanding Harsh Environments In Offshore Wind Applications

There are many environmental issues companies need to be aware of when installing hardware for an offshore wind application. These will be discussed in further detail below:

Sea Water (Saline Environments)

A saline environment (exposure to sea water spray and salt water saturated air) can cause a higher risk of corrosion compared to inland applications. Saltwater spray aggressively corrodes the metal. Once evaporated, saltwater can also leave a thin film of salt on the hardware – interfering with the performance of the luminaire by reducing light intensity.

Any luminaire installed in these offshore locations needs to withstand these aggressive conditions. The Raytec SPARTAN range is designed with offshore use in-mind. Made with marine-grade aluminium and stainless-steel fixings, while being ABS approved to marine standards, our luminaires are ideal for any marine application.

Top Tip for Specifying…. Specify a luminaire made from marine grade aluminium or stainless steel as this provides a more robust solution under aggressive environmental conditions. Also look for a luminaire which uses a smaller front gasket, reducing the risk of water ingress into the unit.

High Wind Speeds & Extreme Weather

High wind speeds and other weather conditions such as sleet, hale and heavy rains are a regular occurrence for offshore applications. A luminaire with a high IP rating is essential to prevent water ingress which could damage internal components of the unit.Fixing centres and brackets of luminaires also need to be durable enough to withstand the extra wind forces. If this is not the case, then over time the lighting bracket could wear and snap causing the unit to be lost at sea.

Top Tip for Specifying… Specify a luminaire with an appropriate IP rating, and check exactly which tests the luminaire has been exposed to. SPARTAN lights have been approved to both IP66 and IP67 standards – so they can withstand powerful water jets (IP66) as well as temporary immersion (IP67).

Sun & UV Exposure

Prolonged exposure to the sun, or UV (ultraviolet) rays, is common for offshore locations. In the case of an offshore wind turbine, the turbine is in a vast, open space, with nothing to shadow the turbine. When lighting is installed in external areas, such as the ‘jacket base’, this continuous exposure to UV may cause issues for some luminaires, depending on the materials it’s constructed from. For example, luminaires made from GRP (glass reinforced plastic) can degrade and become brittle when exposed to UV over long periods, causing issues around maintenance and structural integrity of the housing.

Emergency Lighting

Offshore wind sites are high-risk environments and rely on the use of emergency lighting to ensure the safety of maintenance workers on-site at that specific time.

Turbines have a tendency to cut out. This can be down to several reasons, such as the wind speed being too high, water entering the wiring system, a voltage or current surge, or overheating. In these circumstances the turbine is turned off, the fault assessed, repaired, and restarted. This can sometimes be done remotely, but in many cases, it is necessary for people to enter the turbine to manually check the issue. Emergency backup lighting is therefore a necessity to maintain the safety of anyone on site, providing back-up illumination in the event of a power outage. This protects maintenance workers and can be essential in getting the turbine running again. Emergency lighting may also be needed to evacuate people from site if issues are unable to be resolved.

Duration & Output

To ensure an emergency luminaire will provide back-up illumination for the required length of time, it is important to check the emergency duration when specifying. Consideration should also be given to the level of light output the luminaire provides whilst operating in emergency mode. This is usually expressed as a percentage of the luminaire’s output in normal operation, and it is common for output to drop significantly when in emergency mode.

Most of Raytec’s SPARTAN emergency luminaires provide 25% light output for 3 hours as standard but can also offer up to 100% output for a shorter duration if required. The duration and intensity of output are often specific to individual applications, so this flexibility can be an important benefit.

Automated Testing

Some manufacturers are now providing emergency luminaires which increase safety and reliability of emergency systems. Raytec’s SPARTAN Intelligent Emergency luminaires provide a self-testing function which automatically cycles the emergency battery, to maintain its health and to measure its capacity. This ensures the luminaire is operating at its optimum and reduces the requirement for manual intervention. Inspection of emergency luminaires is also made easier, with a tri-colour LED indicator which communicates when the unit is going through a testing procedure and highlighting the health of the luminaire.

HAzardous Area Lighting Considerations

Hazardous Area Lighting Design

Lighting design is an essential part of specifying lighting for an offshore wind application.

With numerous turbines across one site, achieving the correct light levels on-site will improve safety and efficiency across the turbine. For specifiers going through the initial design process, a lighting design will provide peace of mind that the final solution will achieve the required, on-site lighting goal, with no surprises at the point of commissioning.

Thorne & Derrick’s hazardous area lighting design service is completely free of charge, providing you with a visual 3D representation of the final lighting solution, with detailed lux levels and a true indication of lighting performance. Our lighting design experts will guide you through the entire process, ensuring the optimum solution is achieved.

- Nexans OJC Offshore Medium Voltage Junction Cabinets For Wind Power Projects

- Cable Laying, Installation & Support Products | MV HV Windfarm |

- Cable Cleats & Safe Cable Installations for the Wind Energy Industry

- 33kV v 66kV | A Wind Farm Collection Grid Technical Comparison

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Solar Farms Replace Nylon Cable Ties With Metal Cable Ties

May 26th, 2020

Solar Farms Replace Nylon Cable Ties With Metal Cable Ties

BAND-IT Ball-Lok Metal Cable Ties

Essential. Everywhere. Together.

The BAND-IT Ball-Lok range of stainless steel cable ties provide fast and reliable bundling of LV MV HV cables for maximum strength, reliability and clamping of cables.

The corrosion resistant stainless cable steel ties with self-locking design are used to bundle, tie or fasten cables in both onshore and offshore locations including industrial, substation and hazardous area locations with potentially explosive atmospheres.

Several developers and installers of solar farms specify BAND-IT cable ties for a better solution that matches the lifespan of the photovoltaic panels and replaces nylon cable ties with Ball-Lok cable ties as part of their cable management portfolio.

The decision has been by many solar farms to replace the nylon ties with BAND-IT metal cable ties to reduce maintenance and costly failures.

Currently there are over 2,000 solar farms (over 10 MW) planned throughout the United States. The average livespan of a photovoltaic panel is 20 years, which is much longer than the lifespan of a traditional nylon cable tie, especially in extreme heat and UV exposure typically found in high producing solar areas.

BAND-IT Ball-Lok Cable Ties

The BAND-IT Edge

- Ball-Lok cable ties are tested and hold firm in extreme heat

- No UV degradation of stainless steel cable ties

- Simple hand tools minimize installation variation

- ISO 9001 and ISO 14001 Certified manufacturing

BAND-IT Ball-Lok Metal Cable Ties

Product Features

- Cable ties are available coated or uncoated

- Lightweight, high strength to size ratio

- Smooth band edges won’t damage cable sheath

- Installation tool provides consistent tensioning

BAND-IT KE CABLE TIES

BALL LOK STAINLESS STEEL – UNCOATED

The following selection tables shows the complete range of BAND-IT Ball-Lok cable ties – manufactured from type 304 or 316 stainless steel:

| BAND-IT Order Code | Coated / Uncoated | Cable Tie Material | Width | Length | Max Dia Single Wrap | Min Loop Tensile Strength (lbs) | Package Quantity | Package Weight | ||||

| in | mm | in | mm | in | mm | lbs | kg | |||||

| KE1118 | Uncoated | 304 SS | 0.180 | 4.6 | 5.9 | 150 | 1.2 | 30 | 200 | 100 / Bag | 0.4 | 0.2 |

| KE1128 | Uncoated | 304 SS | 0.180 | 4.6 | 7.9 | 201 | 2.0 | 50 | 200 | 100 / Bag | 0.6 | 0.3 |

| KE1138 | Uncoated | 304 SS | 0.180 | 4.6 | 10.2 | 259 | 2.7 | 69 | 200 | 100 / Bag | 0.7 | 0.4 |

| KE1148 | Uncoated | 304 SS | 0.180 | 4.6 | 14.2 | 360 | 4.0 | 102 | 200 | 100 / Bag | 0.9 | 0.5 |

| KE1158 | Uncoated | 304 SS | 0.180 | 4.6 | 20.4 | 520 | 6.0 | 152 | 200 | 100 / Bag | 1.3 | 0.6 |

| KE1168 | Uncoated | 304 SS | 0.180 | 4.6 | 26.8 | 679 | 8.0 | 203 | 200 | 100 / Bag | 1.8 | 0.8 |

| KE1178 | Uncoated | 304 SS | 0.180 | 4.6 | 33.0 | 838 | 10.0 | 254 | 200 | 100 / Bag | 2.1 | 1.0 |

| KE1188 | Uncoated | 304 SS | 0.180 | 4.6 | 42.0 | 1067 | 12.0 | 305 | 200 | 100 / Bag | 2.4 | 1.1 |

| KE0118 | Uncoated | 316 SS | 0.180 | 4.6 | 5.9 | 150 | 1.2 | 30 | 200 | 100 / Bag | 0.4 | 0.2 |

| KE0128 | Uncoated | 316 SS | 0.180 | 4.6 | 7.9 | 201 | 2.0 | 50 | 200 | 100 / Bag | 0.6 | 0.3 |

| KE0138 | Uncoated | 316 SS | 0.180 | 4.6 | 10.2 | 259 | 2.7 | 69 | 200 | 100 / Bag | 0.7 | 0.4 |

| KE0148 | Uncoated | 316 SS | 0.180 | 4.6 | 14.2 | 360 | 4.0 | 102 | 200 | 100 / Bag | 0.9 | 0.5 |

| KE0158 | Uncoated | 316 SS | 0.180 | 4.6 | 20.4 | 520 | 6.0 | 152 | 200 | 100 / Bag | 1.3 | 0.6 |

| KE0168 | Uncoated | 316 SS | 0.180 | 4.6 | 26.8 | 679 | 8.0 | 203 | 200 | 100 / Bag | 1.8 | 0.8 |

| KE0178 | Uncoated | 316 SS | 0.180 | 4.6 | 33.0 | 838 | 10.0 | 254 | 200 | 100 / Bag | 2.1 | 1.0 |

| KE0188 | Uncoated | 316 SS | 0.180 | 4.6 | 42.0 | 1067 | 12.0 | 305 | 200 | 100 / Bag | 2.4 | 1.1 |

| KE1328 | Uncoated | 304 SS | 0.310 | 7.9 | 7.9 | 201 | 2.0 | 50 | 300 | 100 / Bag | 1.0 | 0.5 |

| KE1338 | Uncoated | 304 SS | 0.310 | 7.9 | 10.2 | 259 | 2.7 | 69 | 300 | 100 / Bag | 1.3 | 0.6 |

| KE1348 | Uncoated | 304 SS | 0.310 | 7.9 | 14.2 | 360 | 4.0 | 102 | 300 | 100 / Bag | 1.7 | 0.8 |

| KE1358 | Uncoated | 304 SS | 0.310 | 7.9 | 20.4 | 520 | 6.0 | 152 | 300 | 100 / Bag | 2.2 | 1.1 |

| KE1368 | Uncoated | 304 SS | 0.310 | 7.9 | 26.8 | 679 | 8.0 | 203 | 300 | 100 / Bag | 2.9 | 1.3 |

| KE1378 | Uncoated | 304 SS | 0.310 | 7.9 | 33.0 | 838 | 10.0 | 254 | 300 | 100 / Bag | 3.5 | 1.6 |

| KE1388 | Uncoated | 304 SS | 0.310 | 7.9 | 42.0 | 1067 | 12.0 | 305 | 300 | 100 / Bag | 4.6 | 2.1 |

| KE0328 | Uncoated | 316 SS | 0.310 | 7.9 | 7.9 | 201 | 2.0 | 50 | 300 | 100 / Bag | 1.0 | 0.5 |

| KE0338 | Uncoated | 316 SS | 0.310 | 7.9 | 10.2 | 259 | 2.7 | 69 | 300 | 100 / Bag | 1.3 | 0.6 |

| KE0348 | Uncoated | 316 SS | 0.310 | 7.9 | 14.2 | 360 | 4.0 | 102 | 300 | 100 / Bag | 1.7 | 0.8 |

| KE0358 | Uncoated | 316 SS | 0.310 | 7.9 | 20.4 | 520 | 6.0 | 152 | 300 | 100 / Bag | 2.2 | 1.1 |

| KE0368 | Uncoated | 316 SS | 0.310 | 7.9 | 26.8 | 679 | 8.0 | 203 | 300 | 100 / Bag | 2.9 | 1.3 |

| KE0378 | Uncoated | 316 SS | 0.310 | 7.9 | 33.0 | 838 | 10.0 | 254 | 300 | 100 / Bag | 3.5 | 1.6 |

| KE0388 | Uncoated | 316 SS | 0.310 | 7.9 | 42.0 | 1067 | 12.0 | 305 | 300 | 100 / Bag | 4.6 | 2.1 |

BAND-IT KE CABLE TIES

BALL LOK STAINLESS STEEL – COATED

| BAND-IT Order Code | Coated / Uncoated | Cable Tie Material | Width | Length | Max Dia Single Wrap | Min Loop Tensile Strength (lbs) | Package Quantity | Package Weight | ||||

| in | mm | in | mm | in | mm | lbs | kg | |||||

| KE0218 | Coated | 316 SS | 0.180 | 4.6 | 5.9 | 150 | 1.2 | 30 | 150 | 100 / Bag | 0.5 | 0.2 |

| KE0228 | Coated | 316 SS | 0.180 | 4.6 | 7.9 | 201 | 2.0 | 50 | 150 | 100 / Bag | 0.6 | 0.3 |

| KE0238 | Coated | 316 SS | 0.180 | 4.6 | 10.2 | 259 | 2.7 | 69 | 150 | 100 / Bag | 0.7 | 0.4 |

| KE0248 | Coated | 316 SS | 0.180 | 4.6 | 14.2 | 360 | 4.0 | 102 | 150 | 100 / Bag | 1.0 | 0.5 |

| KE0258 | Coated | 316 SS | 0.180 | 4.6 | 20.4 | 520 | 6.0 | 152 | 150 | 100 / Bag | 1.4 | 0.7 |

| KE0268 | Coated | 316 SS | 0.180 | 4.6 | 26.8 | 679 | 8.0 | 203 | 150 | 100 / Bag | 1.8 | 0.8 |

| KE0278 | Coated | 316 SS | 0.180 | 4.6 | 33.0 | 838 | 10.0 | 254 | 150 | 100 / Bag | 2.3 | 1.1 |

| KE0428 | Coated | 316 SS | 0.310 | 7.9 | 7.9 | 201 | 2.0 | 50 | 175 | 100 / Bag | 1.1 | 0.6 |

| KE0438 | Coated | 316 SS | 0.310 | 7.9 | 10.2 | 259 | 2.7 | 69 | 175 | 100 / Bag | 1.5 | 0.8 |

| KE0448 | Coated | 316 SS | 0.310 | 7.9 | 14.2 | 360 | 4.0 | 102 | 175 | 100 / Bag | 1.8 | 0.8 |

| KE0458 | Coated | 316 SS | 0.310 | 7.9 | 20.4 | 520 | 6.0 | 152 | 175 | 100 / Bag | 2.4 | 1.2 |

| KE0468 | Coated | 316 SS | 0.310 | 7.9 | 26.8 | 679 | 8.0 | 203 | 175 | 100 / Bag | 3.1 | 1.4 |

| KE0478 | Coated | 316 SS | 0.310 | 7.9 | 33.0 | 838 | 10.0 | 254 | 175 | 100 / Bag | 3.8 | 1.2 |

BAND-IT Ball Lok Stainless Steel Cable Ties In Use

BAND-IT Ball Lok Stainless Steel Cable Ties KE Range – Installation Tools

BAND-IT KE cable ties can be installed using BAND-IT K502 Ball-Lok Tool and BAND-IT KE922 Tensioning Tool.

For further information about cable ties for securing LV-HV cables (power, control and instrumentation), visit BAND-IT.

Tie Lok | Ultra-Lok | Ball-Lok | Multi-Lok | Reusable | Band & Buckles | Stainless Steel

Further Reading

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

The LV HV Specialists

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the renewable energy sector – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

High Voltage Substation Earthing Using Copper Earth Tape Conductor

May 20th, 2020

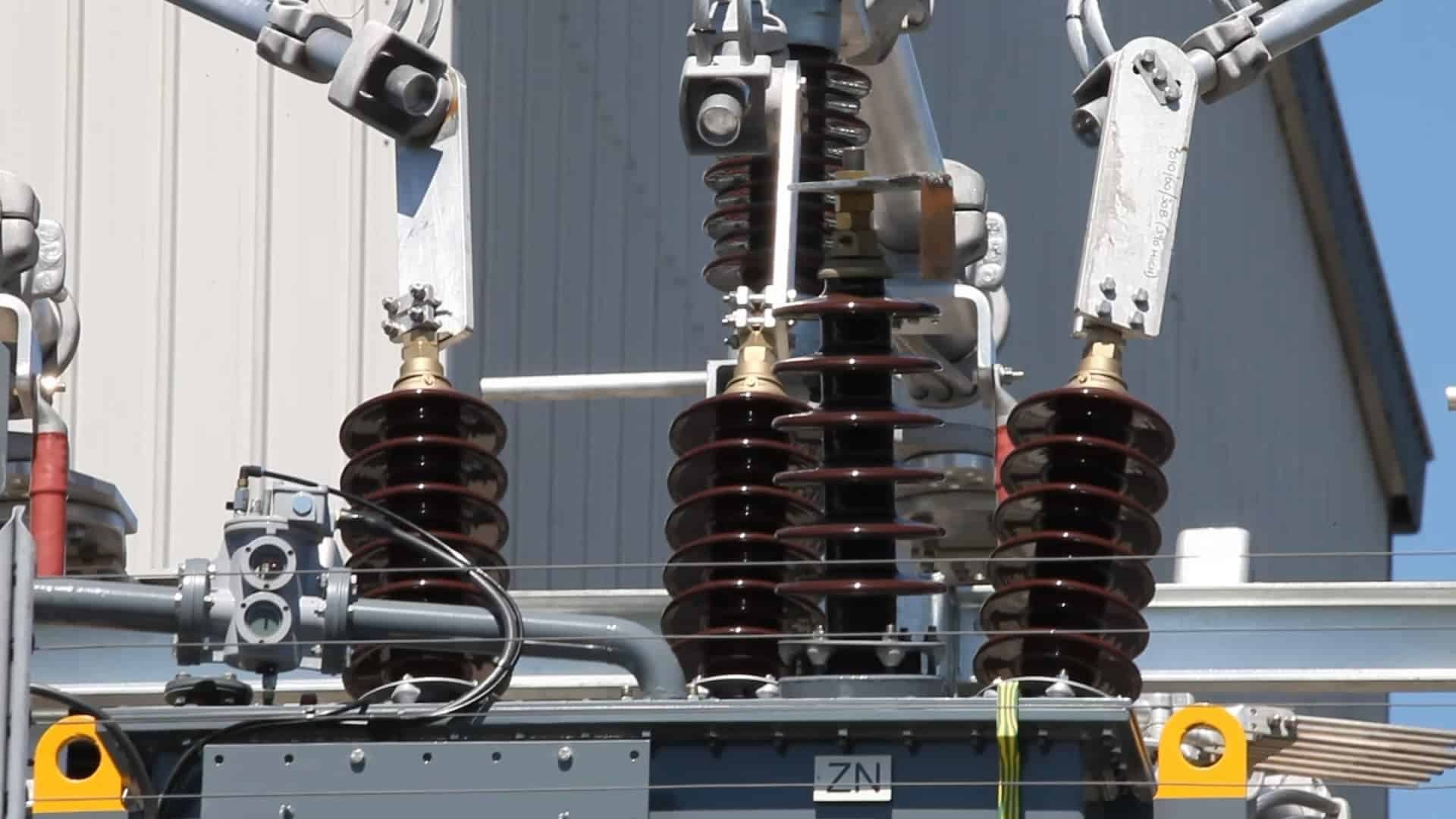

A National Grid substation is a large installation where 275kV and 400kV overhead power lines or underground cables are switched and where electricity is transformed to 132kV for distribution to surrounding areas.

National Grid own HV electricity transmission network in England and Wales operating throughout Great Britain. The transmission network is made up of approximately 7,200 kilometres (4,470 miles) of overhead line, 1,400 kilometres (870 miles) of underground cable and around 330 substations.

Substations contain electrical equipment to transform the voltage to lower or higher voltages, switching equipment to connect and disconnect circuits, and protection equipment to ensure the network operates safely and reliably.

Thorne & Derrick are approved vendors to National Grid and their electricity framework contractors. We can deliver customised copper earth tape for high voltage substation earthing embossed to National Grid specification.

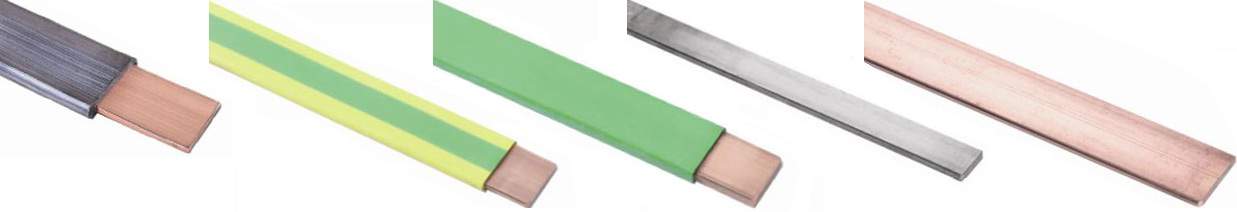

Bare copper earthing tape is an integral component of all high voltage substation earthing and lightning protection systems – bare copper, LSF, PVC and green/yellow insulated copper earth tapes are available.

➡ The Wallis product range includes earth rods (solid copper, copper bond and stainless steel types), earth bars, copper earth mats, earth clamps and copper earth plates.

Earth Tapes – Bare & Covered Copper Tapes

Thorne & Derrick are a leading distributor of Earthing & Lightning Protection Systems to the UK power utility industry – we can imprint or emboss copper earth tapes with all UK DNO ownership requirements.

Willesden National Grid 275kV Substation

National Grid Substation Copper Earth Tape : Copper Earth Tape 75mm x 6mm embossed and stamped Property of National Grid. 1,000 metres palletised for despatch today for earthing 400kV Elstree to St John’s Wood substation maintenance projects.

Copper Earthing & Lightning Protection – National Grid

T&D consolidated for despatch a £75K purchase order for Earthing & Lightning Protection Products – the 26 pallet consignment including galvanised steel and copper earthing tapes, mats, rods, earth bars and clamps is destined for several National Grid infrastructure projects including North London Reinforcement, London Power Tunnels & Nemo Link.

EARTHING GUIDE

Should you require further information or assistance with working on a bill of materials for your earthing requirements, please do not hesitate to contact T&D. Designers of Earthing & Lightning Protection Systems can benefit from downloading our AN Wallis Handbook – an essential resource to ensure compliance with BS EN 62305 the document covers:

- Design of Structural Lightning Protection (BS EN 62305) – Rolling Sphere, Mesh & Protective Angle

- Design of Roof Termination Network

- Copper Tape & Down Conductors – Calculation & Location

- Foundation Copper Earth Rods & Electrodes

Further Reading

Underground Cable Photo Album 1890-1940 – Western Power Distribution (WPD)

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Photo Gallery: Pfisterer 132kV – Switchgear Joints, Terminations & Connex Plugs

May 12th, 2020T&D, a leading distributor and stockist for Pfisterer Connex HV Cable Plugs, are delighted to present a stunning selection of application photographs from the Muncey & Black Peak PV Farms, Melbourn, South Cambridgeshire project.

All images courtesy : Karl McFadden (Business Development Engineer, Renewables & Business Unit PDS at PFISTERER).

Special mention to Richie Rice (EHV Cable Jointer).

Pfisterer Cable Termination : ESS145 Fluid Filled ODSE Terminating 2000sqmm XLPE Single Core Lead Sheathed Cable During DMK Type Test. 132kV.

Pfisterer Cable Joint : MSA145 XKG Single Piece Slip-on Cross Bonding Cable Joint Jointing 2000sqmm XLPE Single Core Lead Sheathed Cable To 300sqmm Concentric Bonding Cable. 132kV.

Pfisterer Cable Termination : ESS145C45 Cable Termination With Cold Fill Compound & Stress Cone Fitted Prior To Hollow Core Being Assembled 132kV.

Pfisterer Cable Termination : ESS145C45 Cable Termination. Semi-con Screen Transition During Jointing.132kV.

Pfisterer Cable Termination : ESS145C45 Cable Termination. Hollow Cores On, Filled & Top Bolts Going Into Place. 132kV.

Pfisterer Cable Termination : EST145 Outdoor EHV Cable Termination (Dry Type). Termination Lifted Onto The Steel Stations. Terminations Were Ground Assembled & Lifted Up For Final Finish. 132kV.

Pfisterer Cable Termination : EST145 Outdoor EHV Cable Termination (Dry Type). Substation. 132kV.

Pfisterer Cable Termination : EST145 Outdoor EHV Cable Termination (Dry Type). Substation. Internal Photo During Termination Installation Prior To Backfilling. Richie Rice assisted install.132kV.

Pfisterer Connex Cable Termination : Size 5S High Voltage GIS Cable Termination Installed To ABB Passmo (Plug & Switch Switchgear) Unit. One Side Completed To 300sqmm Cable (right hand side) & 630sqmm Cable (left hand side). 132kV.

Pfisterer Connex Cable Termination : Size 5S High Voltage GIS Cable Termination Assembled Onto The Cable Prior To Installation. 132kV.

Pfisterer Connex Cable Termination : Size 5S High Voltage GIS Cable Termination Completed Installation. 132kV.

Further Reading