Blog

Apprentice Internal Sales Engineer – Business Admin | Customer Service Level 2

March 20th, 2017

Thorne & Derrick is a family owned company, established in 1985. It is a leading specialist distributor of Power and Process Engineering Equipment in the UK and Internationally.

Due to continued growth we have an opportunity for an Apprentice Internal Sales Engineer based at our Chester-le-Street office.

The role is within a fast paced sales environment where you and your colleagues have the responsibility for driving business to business sales in the following sectors: Oil and Gas, Petrochem, Water, Power, Building Services, Rail, Renewable Energy, Hazardous Area Industries.

You will be trained to handle the following key responsibilities:

- Taking inbound calls from customers

- Negotiating to win business and cross selling associated products

- Calculate accurate and competitive sales quotations based on technical information issued by clients

- Follow up quotations in a timely manner

- Making outbound sales calls to pre-identified target accounts

- Liaising with Sale Reps, Customers, Depots and Suppliers

- Processing orders from customers

- Dealing with queries relating to orders

- Creating sales reports

- Updating orders, prices and order confirmations in the Company’s systems

- Updating the Customer Relationship Management software.

- Occasional customer visits

Background, Skills & Qualifications

- Previous work experience gained in a customer services or sales role an advantage

- You must have a desire to build a career in industrial sales and account management

- Strong written and oral communication skills are essential

- Excellent attention to detail is essential

- Strong IT skills that include Microsoft Office (Word, Excel, Email & Web) awareness and experience is essential

- GCSE’s in Maths and English and two A Levels or equivalent

- A clean driving licence and own car would be useful but is not essential

Training period 12 – 18 months including fortnightly college attendance.

25 days holiday

8.30am to 5.00pm – 5 days per week

This is a career opportunity as the position will be made permanent on successful completion of the apprenticeship.

Starting salary £15,500 – Salary will be reviewed after successful completion of the apprenticeship period.

Apply

The apprenticeship will be run through the Northern Skills Group. Please see their website for more information on the Business Admin and Customer Service Level 2 courses.

Northern Skills Group is an expert provider of apprenticeships, employer-led training and retraining and works with over 2000 businesses in the North East and Yorkshire. We provide expert tuition, funding guidance and assistance with apprentice recruitment.

Experts in Apprenticeships and Training from Northern Skills Group on Vimeo.

➡ Please email Mr Richard Derrick [email protected] with your CV and a covering letter explaining more about yourself.

Please visit our website for more information on our business, www.thorneandderrick.com

Thorne & Derrick International

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Prysmian Multicleats – 3 Simple Steps To Cable Cleat Installation

February 27th, 2017Prysmian BICON Multicleats – Cable Cleats

-

by Chris Dodds T&D - estimated reading time 5 minutes

Cleats

T&D are Prysmian cable cleats stockists and distributors committed to supporting the correct installation of all BICON brand products – the following short post outlines the recommended installation procedure for Prysmian Multicleats which are specified to provide short-circuit containment of LV, MV and HV power cables.

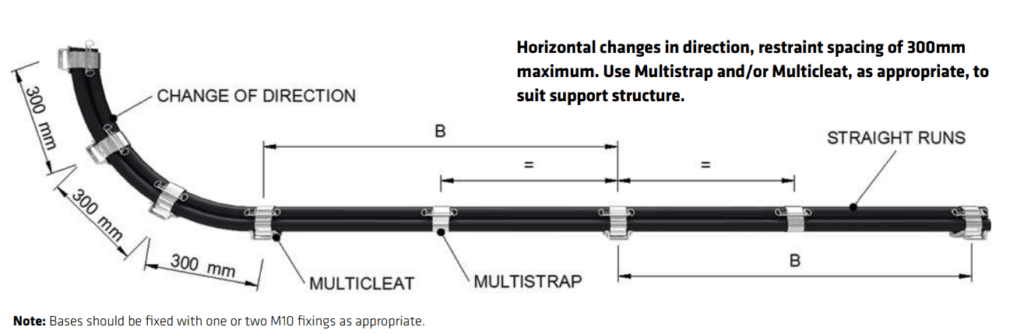

Prysmian Multistrap is a stainless steel cable strap complete with a tensioning clip, securing pin and winding key – can be used for single, bundled or trefoil cleats including 11kV/33kV single core high voltage substation cables.

BICON. A Prysmian brand.

Multistraps are used as an intermediate cable restraint between Multicleats – positioned centrally between a pair of Multicleats to provide additional protection to medium/high voltage power cables in the event of a short-circuit.

The Multicleat cable cleats are commonly used to support and clamp 11kV/33kV power cables in industrial installations, hazardous areas and high voltage substations.

Aluminium cable cleats are also available for cleating cables onto containment in LV-HV substations and electrical building services where corrosion exposure levels are lower.

Multicleats

1. Fasten Prysmian BICON Multicleat base to cable support with M10 fixings. Loop Prysmian Multistrap through cable cleat base and around cables. Standard Duty Multicleats = 2 loops. Heavy Duty Multicleats = 3 loops.

2. Pull slack Prysmian Multistrap into outer loop. Insert split pin from right hand of Multicleat around outer layer of Multistrap about 10mm from end. Push plastic shear torque adaptor fully onto the end of the split pin and attach 13mm socket wrench. To tension the Prysmian Multistrap around the cables, rotating key anti-clockwise with the socket wrench until the adaptor shears.

3. Remove the shear torque adaptor and wrench. Swing the key over and engage in slots in clip.

The Prysmian Multicleat and Multistrap is correctly installed – compatible with most cable containment types including cable ladder and tray systems.

Prysmian BICON Multicleat Installation Steps

For further Multicleat & Multistrap technical specification, selection details and information see the following Slideshare.

To ensure sufficient cable support the Prysmian Multistrap MUST be used at the mid-point between Multicleats on all horizontal or vertical straight cable runs – here the Multicleats are shown cleating single core 33kV cables in trefoil arrangement however the strap-type cable cleats are suitable for single, multiple or bundled cable configurations.

Contact Thorne & Derrick for technical support or specification advice to ensure the correct cable cleat / cable strap arrangement according to the fault rating, installation application and environmental location.

Also from Prysmian ➡ Cable Joints | Cable Glands | Cable Cleats | MV HV Terminations Joints Connectors 11kV 33kV

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Balata Polyester Cable Straps – Balfour Beatty Rail – T&D UK

September 23rd, 2015

Balata Cable Straps To Support Rail Cables (LU & Network Rail Approved)

Project Application : Tunnel Cable Support for Power Cables

Product : Balata Straps

Scope : Supply off 10,000 LU-NYBAL-1 Balata polyester cable straps for the new DC Traction Sub Station & Tunnel Cables in West Ham, London UK.

Client : Balfour Beatty Rail

Country : UK

Sector : Rail

Balata Polyester cable straps are designed as a secure and reliable cable supporting method which is LU London Underground and Network Rail approved – the cable straps are specified to provide surface and sub-surface cable support in overground and underground locations on the UK rail infrastructure; this includes trackside substations, underground tunnels and bridge crossings. The inherently flame retardant cable straps, specified by London Underground (TfL) since 1965, provide superior aging and stable electrical characteristics suitable for installation in damp and dusty locations at both trackside and tunnel locations.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Rail Cable Accessories, Electrification & Installation Equipment

Thorne & Derrick stock and distribute an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

66kV Connectors, Cables & Junctions Boxes – An Interview With Nexans

March 7th, 2014

Nexans Euromold | Medium & High Voltage Cable Connectors

66kV Connectors

Nexans Euromold

An interview with Stefaan Mensaert (Product Line Manager Renewables at Nexans Cables) speaking about 66kV cabling technology in particular 66kV inter-array cables that were recently supplied by Nexans to Blyth Offshore Wind Farm.

What are your major tasks and responsibilities in the company? And what projects are you developing around the 66kV inter array cable technology?

I am continuously monitoring the developments and future needs in the Renewable Energy market segment regarding power connection systems and Nexans has engaged itself to offer a complete solution for the upcoming 66kV cable demand in the offshore wind power market. Besides the 66kV XLPE insulated submarine cable, a complete set of 66kV power cable accessories, based on the outer cone technology have been developed and successfully tested. Being also an active member of the steering committee of the Belgian innovation cluster for offshore energy and Nexans as a global company active in cabling and power accessories, strengthens this position.

What is the major challenge that Nexans, as an experienced cable manufacturer, had to overcome in order to deliver the 66kV XLPE insulated submarine cable and the accessories, junction boxes and connectors?

From the interviews with the main developers in this market it became clear that flexibility of installation, compactness and ease of testing are the major concerns when it comes to connections of the 66kV turbines. Therefore the use of outer cone technology based on an open standardized Interface F Bushing as defined in the standard EN50181 and EN50182 was from the beginning well appreciated and adopted by the different players in the supply chain – this includes both 66kV transformer and switchgear manufacturers. In addition, specific cost effective solutions based on the same outer cone connector system have been worked out to allow easy installation in between inter array and tower cables within a 66kV junction box.

What kind of tests have you executed on your designed junction boxes and high voltage cable connectors to ensure the industry, quality and high performance of your 66kV cabling technology?

All the accessories offered in the 72.kV range from Nexans have gone through an extensive qualification and type testing process according to the IEC60840. For the OEM business, separate additional testing has been performed to meet specific requests, exceeding the values of the IEC60840 – this includes 72.5kV cable joints.

Nexans is to supply the 66kV inter-array cable to the Blyth project in the UK. The industry believes that this new cabling capacity and technology will help to further decrease the cost of wind energy. As an expert in the wind energy industry, what do you think about this statement?

Although initially there was some hesitation to adopt this 66kV voltage level, thanks to the fast reaction of the complete supply chain (cable, switchgear, transformers, etc..) Nexans has proved to be able to deliver the needed building blocks to make the transition to the 66kV level. Developers finally are convinced that this will help reduce the cost significantly of the future wind parks to be developed. Proof of that are the recent announcements of new parks at substantially lower or even zero bid subsidy per MWh.

Blyth Offshore Windfarm

Nexans as developer of junction boxes and connectors. Will you be responsible or take part in the testing of the 66 kVinter-array cabling once is deployed? If so, what kind of test will you be performing to ensure good connection between components and reduce losses?

Not applicable for us as cable accessory supplier – this would be part of cable layer/supplier scope.

Where do you think the future lies for the offshore wind energy 66kV inter-array cabling?

Although it will bring new specific challenges regarding dynamics of the applied cable systems, the ongoing development of floating offshore wind, will require also 66kV to be able to deploy commercial parks in the future. A further optimization of interconnection systems of the 66kV turbines, taking into account more specific maintenance and repair strategy will also become a challenge. To overcome these challenges new initiatives are taken up by different organisations, including Carbon Trust, who was also sponsoring the development of the 66kV from the early stage.

Blyth Offshore Wind farm Project

Gravity-based foundations being constructed on the River Tyne Credit EDF Energy Renewables

The first turbine foundation of an eagerly-anticipated wind farm development off the coast of Blyth made its journey up the River Tyne on the 11th July 2017, a notable milestone for the project.

EDF Energy Renewables is currently building the Blyth Offshore Demonstrator Wind Farm after taking over responsibility for the scheme from Narec (now ORE Catapult) in October 2014.

The project will see five wind turbines with a total generating capacity of 41.5MW installed around 6.5km off the coast of Blyth. Once operational, they will generate enough low carbon electricity to power around 34,000 homes.*

Each foundation was floated into position off the coast of Blyth and submerged onto the seabed, and further ballasted to provide the structures that act as the foundations for the turbines.

The five Gravity Based Foundations for the Blyth Offshore Demonstrator Project are in place and the next phase is underway

All the foundations for the wind farm off the coast of Blyth are now in place. Around 11 kilometres of buried 66kV offshore cables will connect the individual turbines and bring the electricity onshore, where a further 1.5 kilometre of onshore cable will link directly to a new substation built on part of the site of the former Blyth power station.

Further 66kV Reading

- 66kV Cable Joints – A Failure Investigation & Conclusions

- 66kV Cable Jointer Training – A Question Of Competency Not Familiarisation

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Go to our Price List and contact us with your enquiries.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints