Cable Pulling & Laying

High Voltage Cable Drum Trailers for Utility Projects

July 10th, 2025

High Voltage Cables

Kicking of H2 with another CD500 manufactured by SEB International Ltd to support Utility project cable-pulls at 132/400kV, bound for the Grid – this is our largest Cable Drum Trailer build to date. An outstanding achievement in UK manufacturing excellence and Distributor partnership to lead the powering of global projects.

Customised to client specification to handle HV Cable Drums – should you require assistance with the Pull-in, Cable Termination, Jointing & Energisation of HV Cable Networks please continue to contact our Team. With global electricity demand forecast to double by 2050, Thorne & Derrick are perfectly positioned to meet all your major project constructions and cable fault repair works – our business can now provide technical specifications, competitive pricing and delivery commitments to enable transformer, switchgear and overhead line connections from 600V to 66/132kV polymeric cables up to 2000sqmm.

Further Case Applications

- Cable Drum Trailer Manufactured for Major High Voltage Power Project

- Cable Drum Handling | Jack Towers for LV to EHV Cable Lifting & Site Handling

Cable Drum Trailer Manufactured for Major High Voltage Power Project

October 4th, 2024

Pictured : L – R | Richard Derrick (MD T&D), Andy Smith (SEB Technical Sales Engineer), Chris Dodds (Sales & Marketing Manager T&D), Paul Millett (MD SEB), Regan Redpath (Apprentice Sales Engineer T&D), Kieron Clarke (SEB Junior Fitter) & Lee Mellors (Lead Multi Skilled Fitter.

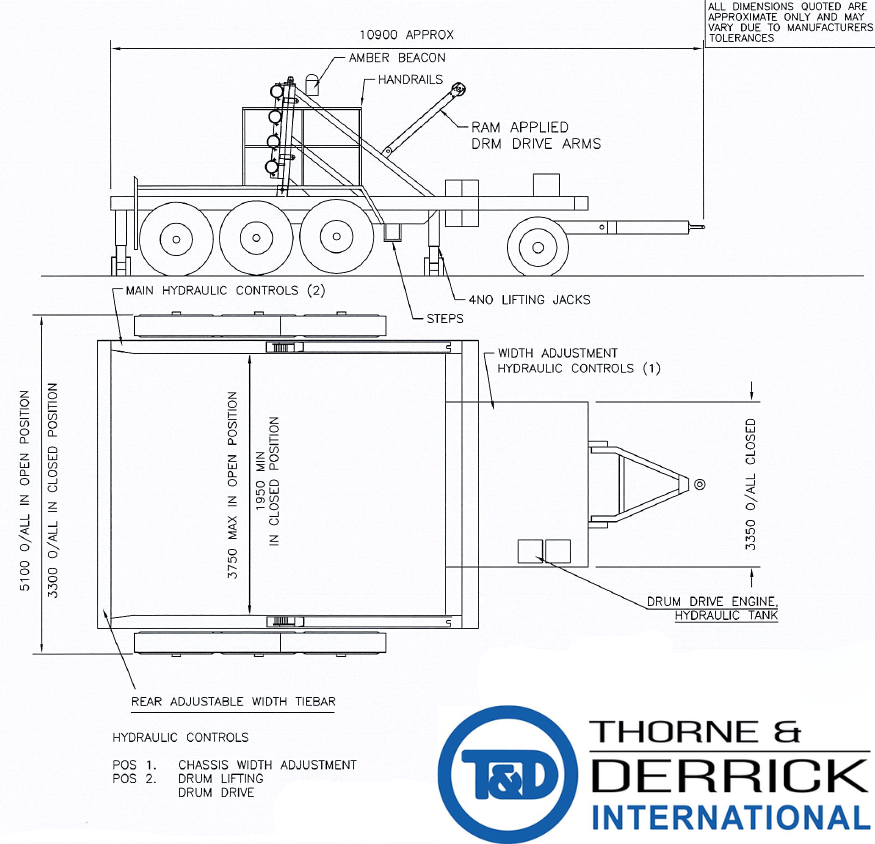

Thorne & Derrick, the leading UK Distributor for the SEB range of cable pulling and laying equipment, recently visited their facility to factory witness test the operation of their largest cable drum trailer manufactured to date – based on the standard CD980S Adjustable & Extendable Cable Drum Trailer the custom-design to a utility client specification provides operational simplicity, maximum power and ultimate reliability built-in. The trailer will safely handle and transport high voltage power cable drums (400kV) with a maximum drum width of 3.6 metres and drum height of 5 metres with a 50 Tonne payload.

Cable Drum Trailer Specification

| Unladen Weight | 15000kgs |

| Gross Weight | 65000kgs |

| Axle Load | 16250kgs |

| Bogie Load | 16250kgs |

| Payload | 50000kgs (MAX) |

| 0/ALL Width Max | 5100mm |

| Max Drum Dia | 5000mm |

| Min Drum Dia | 3300mm |

| Pintle Dia | 152mm 5OT MAX 127mm 5OT MAX |

| Rear Tyres | 14.00×24 |

| Front Tyres | 295×60 |

| Tow Eye | 76mm NATO |

| Brakes | 2 Line Air Brakes |

| Lights | Site Only – LED |

| Speed | 10 km/hr |

| Construction | All Steel |

| Drum Lift | Diesel Engine Powered Hydraulic, Locked Mechanically In Raised Position & Standby Hand Pump |

| Extend/Retract Cassis Width | LWD702 Engine Powered Hydraulic Operation of Jacks & Hydraulic Rams Mounted At Front |

| Paint | Full Gloss |

High Voltage Cable Drum Trailer Diagram

Video Gallery

VIDEO 1 – The cable drum trailer has already been raised off the ground using a diesel engine powered hydraulic system that powers 4no wheeled lifting jacks. The video shows the offside of the cable trailer being hydraulically opened to its full extent.

VIDEO 2 – This video shows the drive rollers turning, these are used to assist in turning the drum of the cable. It also shows the drive rollers which are mounted to a frame being moved forwards, this system applies the rollers to the drum flange, the rollers are then turned.

VIDEO 3 – Once the cable drum trailer has been loaded the pintles (the black tubes) are inserted into the drum. The video shows how the pintles are raised hydraulically, this is done on both sides of the drum trailer which raises the cable drum off the ground.

VIDEO 4 – This shows the nearside of the cable drum trailer being closed. Also, the silver bars across the back are the rear tie bars which are used to hold the rear of the trailer when a high voltage cable drum is installed, they are adjustable to suit any width of cable drum that the trailer can hold.

VIDEO 5 – This shows the diesel engine being started, the operation of the hydraulic control valve that raises the trailer off the ground and the cable drum trailer being lifted up.

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

T&D distribute the complete range of LV-HV Cable Pulling and Laying Equipment including cable rollers, cable socks, drum jacks, drum trailers, cable lubricant, underground cable protection and conduit duct rod.

THORNE & DERRICK are Specialist Distributors of LV HV Cable Jointing, Earthing, Substation & Electrical Eqpt up to 66kV – this includes the most extensive range of Ex Stock Innovation Tooling to facilitate safe and reliable preparation, termination and installation of cables.

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors

Guaranteed Stable Cables Using Vicera Stands for HV Cable Connections

June 2nd, 2023

Vicera Cable Stand Products | Supplied in the UK & Europe by Thorne & Derrick

Approved by & Used by Nexans | NKT | Ensto | Prysmian Group | TE Tyco

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick International

Thorne & Derrick are now Official Distributors for the Vicera range of Cable Jointing Stands – the introduction of this new product range is an excellent extension to our core ranges of Cable Jointing, Pulling Equipment & Preparation Tooling and we look forward to further supporting efficient, easier and more reliable power cable installations.

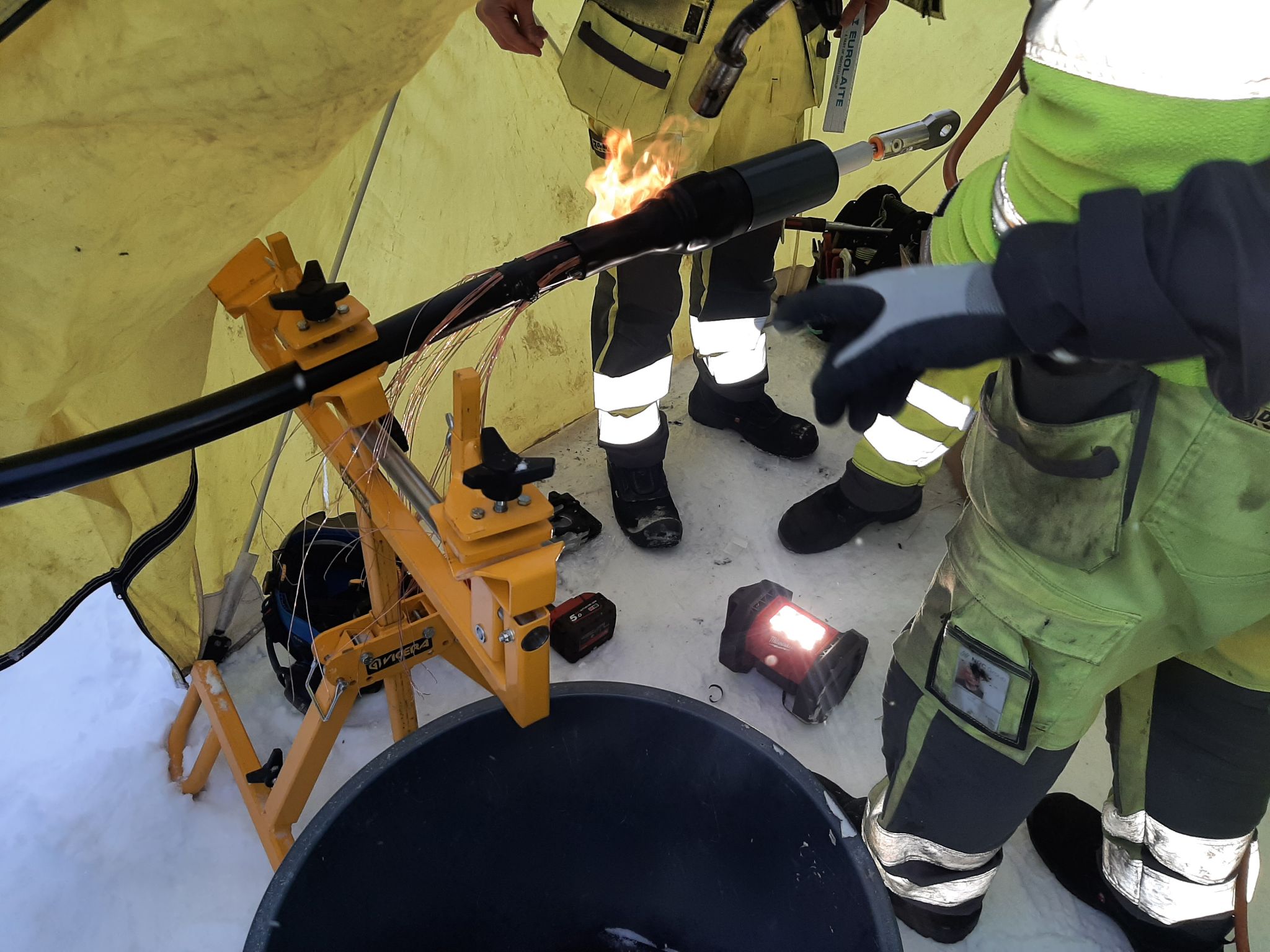

The Vicera range of Cable Stands are for both field or training centre use and provide safe and stable support of Low, Medium & High Voltage Cables – the cable stands are suitable for cable diameters 18-90mm with adjustable height.

The Cable Joint Stands feature stepless lateral and tilt adjustment and high strength clamps to prevent cable slippage or movement while jointing – secure and balanced cables when Jointers are undertaking highly skill-sensitive cable preparation prevents inadvertent damage to cables and future potential O&M reliability.

The cable support stands are rugged and durable for outdoor use in joint bays and trenches in all ground terrain conditions – this includes the support of 11kV/33kV/66kV cables to enable precise cable preparation by the Jointer prior to installation of joints, terminations or connectors on medium/high voltage power cables.

The Jointing Stands are used in the field to enable the completion of pole-top style outdoor terminations and also indoor substation Jointing & Termination installations.

APU2.0 Cable Stand | more info

Provides support and stability for LV HV Cables Ø 18–90mm

- Length: 180mm

Width: 730mm

Height: 720mm

Weight: 17kg - Very wide adjustment options

- Installation height 10” 57” / 25 cm 145 cm

- Sturdy clamps where the cables will stay in place

- Stepless lateral and tilt adjustment in clamps

- Suitable for all cables with an outer diameter of 5/8” 3,5” / 18mm – 90mm

- Suitable for almost any terrain

- Better ergonomics when jointing and terminating cables

- More efficient and easier to achieve best quality

- Risk minimisation during the preparation, jointing and termination of MV HV cables

Image | JK Jointing Ltd

Pictured | Vicera APU2.0 | Here the APU2.0 is shown supporting 33kV BS7870 XLPE Copper Wire Screen single core 1000sqmm cables.

£590.00 + VAT + Delivery

Quantity Discount Available

Product Review

Pictured | Cable stand manufactured by Vicera providing support and stability to medium voltage cables undergoing the termination, connection and installation of Nexans Euromold type P909TB/G screened separable connectors.

💡 Bart Baeyens (Nexans Technical Customer Manager) – “the cable stands provide the necessary stable position to prepare any cable without issues, thanks to the weight and clever design. You can easily adjust height and position resulting on a comfortable position in every situation.”

Pictured | The Vicera APU2.0 Cable Jointing Stand in place at the PFISTERER UK Training facility in the UK. Working alongside PFISTERER we can also assist in the CONNEX & SEANEX Certification of Jointers to support competency of workmanship and safeguard the integrity of medium/high voltage power cable systems across all industries – their UK Jointer Training facility is a global Centre of Excellence for Competency Certification up to 245kV.

Safe & Secure Cables with Vicera

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

We stock Heat shrink, Cold shrink, Push-on and Slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV-66kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing MV HV electricity.

Thorne & Derrick also supply from stock Jointing Tools to enable the Cutting, Crimping & Preparation of all onshore and offshore LV MV HV Cables – this includes the removal of sheath/jacket, screen, insulation and precision engineered procedures of the cable preparation process including chamfering, bevelling, grooving and shaving.

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

Telecoms Cable Winch Supplied to Full Fibre, Gigabit-capable Network Infrastructure

February 28th, 2023

-

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

Customised Cable Winch

Working with client NGE, Thorne & Derrick have supplied a custom engineered Telecoms Cable Winch for the pulling and installation of fibre optic cables to the Liverpool Backhaul project – the cable winch will support the high-speed fiber infrastructure project which will connect all 6 local authority areas in the Liverpool Region, by delivering Gigabit internet connectivity to a diversity of key economic activities.

Thorne & Derrick have supplied the AW1000 is an extremely robust piece of engineered plant, designed specifically to cope with Fibre Optic and light cable pulls, which are becoming a mainstay in today’s economic environment, especially as Fibre Optic is being laid to cope with the increasing demand for broadband internet. The Winch is designed and manufactured by SEB International in the UK, to be simplistic in operation, and consequently the client installation team will find the winch is also straightforward to maintain and service.

The result is a product, which is cost effective, and will provide many years of service. The AW1000 will be an excellent investment and addition to the plant fleet of construction companies responsible for the installation and maintenance of fibre optical cabling systems.

Custom Cable Winch for Offshore Cable Pulling Project

Pictured : More information Customised & Refurbished 5 Tonne Cable Pulling Winch

This refurbished and customised 5 tonne cable winch was customised to enable the pull and installation of medium/high voltage power cables – the winch was delivered within 2 weeks from receipt of client order. The cable winch enabled the installation of cable runs up to 120 metres from the variable frequency drive (VFD) to the compressor junction box which goes from underground cable trench to above ground and onto the cable containment ladder racking system.

The cable winch modification was based on the standard SEB TW5000 version with additional cable tension dynamometer – the dynamometer continuously checks the cable pulling tension to ensure the forces do not exceed the recommended guidelines.

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and rollers.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Installation & Cable Socks For Renewable Energy Sector

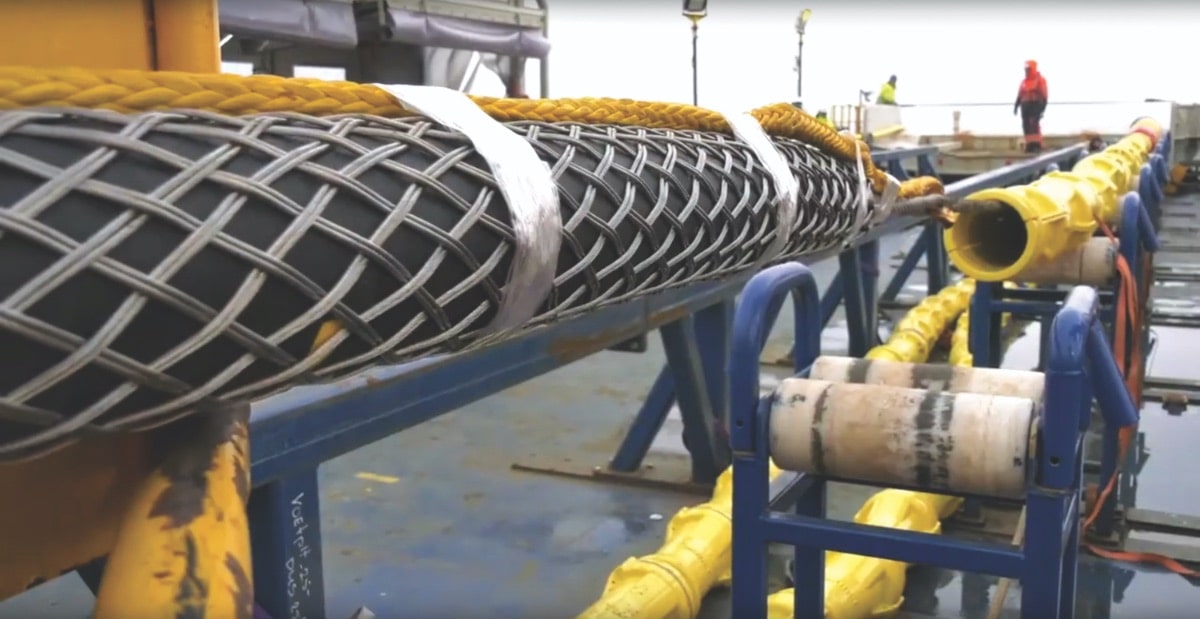

October 19th, 2022

Working with Slingco we have produced engineered and customised solutions using cable grip and support innovation to major cable laying contractors for the connection of wind farm projects globally.

Cable Installation & Cable Socks

Thorne & Derrick together with Slingco offer pulling and supporting to power & subsea cables in the wind sector. Slingco have developed a comprehensive range of cable grips (commonly referred to as cable socks) specifically tailored to the needs of the renewable energy sector.

The marine pulling grips are the for installation of inter-array and export cables for offshore wind farms. There are grips to suit common cable sizes used in offshore applications and have increased break loads.

The cable socks also feature a new ‘two over / two under double weave’ on the lattice which tightens up the angle of deflection over the end of the cable.

Together we can offer an extensive range of marine and hose restraint cable grips for onshore and offshore cable installation, including the support of cables inside wind turbines and general cable management.

SLINGCO MARINE cable socks Features

- Cable range of 90mm to 355mm

- Break load tested and independently witnessed at Lloyds Register

- Manufactured to high quality standards in the UK

- Length standardised from 2.5m to 3.5m

Marine cable socks are designed, manufactured and tested to exacting standards to ensure safe and reliable operation under the most challenging condition

WHY SLINGCO FOR MARINE GRIPS?

- UK manufacturing facility produces between 2,500 to 6,000 grips per month from our new 32,000sqft, state of the art premises

- Options such as Thimble eye, Shoulders, and Anodes are now available on request (manufactured to order), as are stainless steel and aramid, both of which have better corrosion resistance for prolonged subsea lay down durations

- Range of non metallic grips made from high strength aramid fibre, with UV protective coating, ideal for fibre optic offshore applications

- An impeccable track record, with recent projects including: Kincardine, EastAnglia 1 & 2, Borssele 1 & 2, Hornsea 1 & 2, Akita, Triton Knoll, Moray East, St Nazaire, Dolwin 6, Ostwind 2, Formosa 2, Thanet, Walney, Gwynty Mor, Dogger Bank, Park Wind

Every Slingco product is designed, manufactured and tested to exacting standards to ensure safe and reliable operation under the most challenging conditions. From initial product design to technical support and customer service, we are your trusted partner.

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans