Blog

Arc Flash Protection | A Whitepaper on Clothing & Garment Selection

August 18th, 2020 Helping educate companies and raise awareness amongst operatives about what garments to wear and how to wear them, when at risk of an ARC FLASH

Helping educate companies and raise awareness amongst operatives about what garments to wear and how to wear them, when at risk of an ARC FLASH

-

Author: Hamilton Smith Technical Sales Manager 2020

What is an arc flash / electric arc?

Definition: An arc flash is the light and heat produced as part of an arc fault; a type of electrical explosion or discharge that results from a low impedance connection through air to ground or another voltage phase in an electrical system.

… and in laymans’ terms

- An arc flash occurs when electrical current jumps across an air gap between conductors, like when lightening jumps down to earth

- That large instantaneous discharge of electrical current causes an explosion

– Extremely high levels of energy, heat and light are released in fractions of seconds

– Temperatures can reach up to 35,000ºF (19,000ºC) = 4 times the temperature of the Sun’s surface!

– A blast and pressure wave that can damage eardrums and even strip away garments

➡ Ultra Slow Motion Arc Flash 480V

Where & when does an arc flash occur?

Where?

- Industrial electrical environments – Factories, manufacturing plants, electrical maintenance even including areas such as electric vehicle maintenance and manufacture

- Power generation -Traditional environments but also including renewables such as wind turbine maintenance

- Utilities – Anyone breaking ground in electrical, gas and water, even operatives installing street lights

- Rail sector – Electrification and maintenance

- Petrochemicals – Protecting plant workers and even tanker drivers in the same way as for arc flash against flash fire

When?

- Whilst undertaking installation, maintenance or repairs, but also when breaking ground, undertaking excavations and construction

Why does an arc flash occur?

- Tools or equipment inadvertently touch live conductors or are dropped

- Faults or mistakes in isolating equipment

- Equipment failure due to faulty parts, poor installation, or even normal wear + tear

- Dust, corrosion or other impurities on conductor surfaces

- Cable strikes when breaking ground 8 to 10 cable strikes are reported daily in the UK

Arc flash vs Operative … only one winner!

- Skin burns right to 3 rd degree from direct heat exposure

- Damage to eyesight caused by heat and the high intensity flash which includes UV light

- Hearing loss and physical damage as the blast can greatly exceed the sound of a jet engine

- Significant injury risks from flying debris such as equipment, shrapnel wounds and molten metal

- Loss of memory or permanent impairment of brain function from concussion

- Burns from hot liquids in oil cooled or insulated equipment

- Other physical injuries from being blown off ladders, into walls etc

It’s no exaggeration when we say the implications and injuries can be life threatening, they’re certainly life changing.

Employee protection what can be done?

Employers have a duty to protect their employees against injury and other hazards.

There is a hierarchy of steps to safeguard workers:

- Reduce the exposure of operatives to risk

- Define and enforce safe working practices to reduce risk – they can undertake an AF study

- Provide appropriate level sot PPE – AF assessments or studies can help to predict potential exposure and suggest the level of protection.

PPE is designed to reduce the risk of life changing or life threatening 2nd or 3rd degree burns. Arc flash clothing and PPE is the last line of defence when risks cannot be totally eliminated.

Arc Flash Protection standards

IEC 61482 2 : 2018 Protective Clothing Against the Thermal Hazards of Electric Arc

Arc flash testing information – there are two test methods:

BS EN IEC 61482-1 1:2019 | Method 1: Determination of the arc rating (ELIM, ATPV and/or EBT) of clothing materials and of protective clothing using an open arc (Open Arc Test).

- ATPV = Arc Thermal Performance Value

the value of incident energy at which the heat transfer through the test specimen is enough to reach the Stoll criteria with 50% probability of 2nd degree burn e.g. if a product that achieves 8cal/cm² ATPV, is hit with 8cal arc exposure then there is 50% probability of 2nd degree burns. - EBT = Breakopen Threshold Energy

the value of incident energy at which breakopen occurs with 50% probability of 2nd degree burn e.g. a product that achieves 8cal/cm² EBT, if hit with 8cal arc exposure then there is 50% probability of 2nd degree burn and with breakopen of material. - ELIM = Incident Energy Limit

a numerical value of incident energy attributed to a product, below which there is no data point with the amount of heat transmitted through the product reaching the Stoll criteria or with the product exhibiting breakopen e.g. a product that achieves 8cal/cm² ELIM, if hit with 8cal arc exposure then there is 0% probability of 2nd degree burn.

IEC 61482 2 : 2018 Protective Clothing Against the Thermal Hazards of Electric Arc

Arc flash testing information – there are two test methods:

BS EN 61482-1 2:2014 | Method 2: Determination of arc protection class of material and clothing by using a constrained and directed arc (Box Test)

- APC 1 (Class 1):

• test current 4kA (+/-5%)

– voltage 400 volts a.c. (+/-5%)

– arc duration 500 ms (+/-5%)

– frequency either 50hz (+/- 0.1hz) or 60hz (+/- 0.12hz) - APC 2 (Class 2):

– test current 7kA (+/-5%)

– voltage 400 volts a.c. (+/-5%)

– arc duration 500 ms (+/-5%)

– frequency either 50hz (+/ 0.1hz) or 60hz (+/ 0.12hz)

Fibres, Fabrics & Creating Protective Garments

Arc Flash Lineman Coverall ProGARM 6458

Treated vs Inherent

- At ProGARM we believe fundamentally that inherent FR fabrics offer the best solution

- Traditionally treated fabrics have been stiff, uncomfortable, lacked breathability and even smelly!

- Protection from treatments reduces every time a garment is washed

- Inherent means that characteristically the fibre will not burn – Inherent fibres create inherent yarns which are knitted or woven into inherent fabrics instant extinguishing

Our fabrics are called VXS+.

Arc Flash Clothing systems

Examples of garments that are often combined into a PPE system

Protection in layers where 1 + 1 = 3

Make sure they are the right layers though

- We’ve developed a total range of garments from underwear and thermal base layers to 47cal waterproofs

- Many H&S Managers and operatives are not aware that wearing the wrong fabrics, even under AF protective garments, can compromise the AF garments and result in injury

What makes a great garment?

Let’s take a look at some of the features that protect and save lives.

Arc flash garment features to be aware of:

Take a look at the garment design features that show the attention to detail.

- Triple stitched seams

- Inherent fabric & instant extinguishing

- FR threads

- ThermSAFE components tested to continue to function after an incident

- Wrist tabs and neck fastening

- Reflective tape

- SafetyICON marking

- Internal labelling inc batch numbers for traceability

- Stretch panels

- Napoleon pockets for harnesses

- Garments available from S to 4XL

- Women’s garments

Let’s sum up

Education is one of our core missions – we’re here to help.

ProGARM’s Mission

- Educate and inform to save lives

- Constantly develop and innovate

- Deliver an exceptional customer experience

- Never compromise. Lives depend on it

We’re here to help you find the right solution for your operatives who are at risk of an electric arc to make sure they come home safely.

Polo Shirts | Jackets | Coveralls | Trousers | Gloves | Sweatshirts | Helmets

Overview of Arc Flash Clothing | Contact us to discuss your garment and PPE requirements, we can mitigate risk with guidance on safe working practices and by providing appropriate worker clothing that offers advanced Arc Flash Protection that saves lives every day. Whether working on underground cables or overhead lines, here is a selection of workwear clothing – contact us to discuss your requirements;

>> Download Your Guide To Here <<

Further Reading

- Arc Flash Clothing – PPE To Protect Highways, Street Lighting & Utility Contractors

- Arc Gloves | New Arc Flash Dexterity Gloves from Protection Specialists ProGARM

- New Arc Flash Coveralls from Protection Specialists ProGARM

- Latest Arc Flash Legislation & Regulation Explained By ProGarm

- Arc Flash PPE | 7 Top Considerations

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

HV Cable Joints, Terminations & Connectors | Approved Stockists & Distributors | 3M Electrical (Cold Shrink) | Nexans (Euromold JTS MONO) | Pfisterer (CONNEX SEANEX) | 11kV 33kV 66kV Medium & High Voltage Cable Accessories

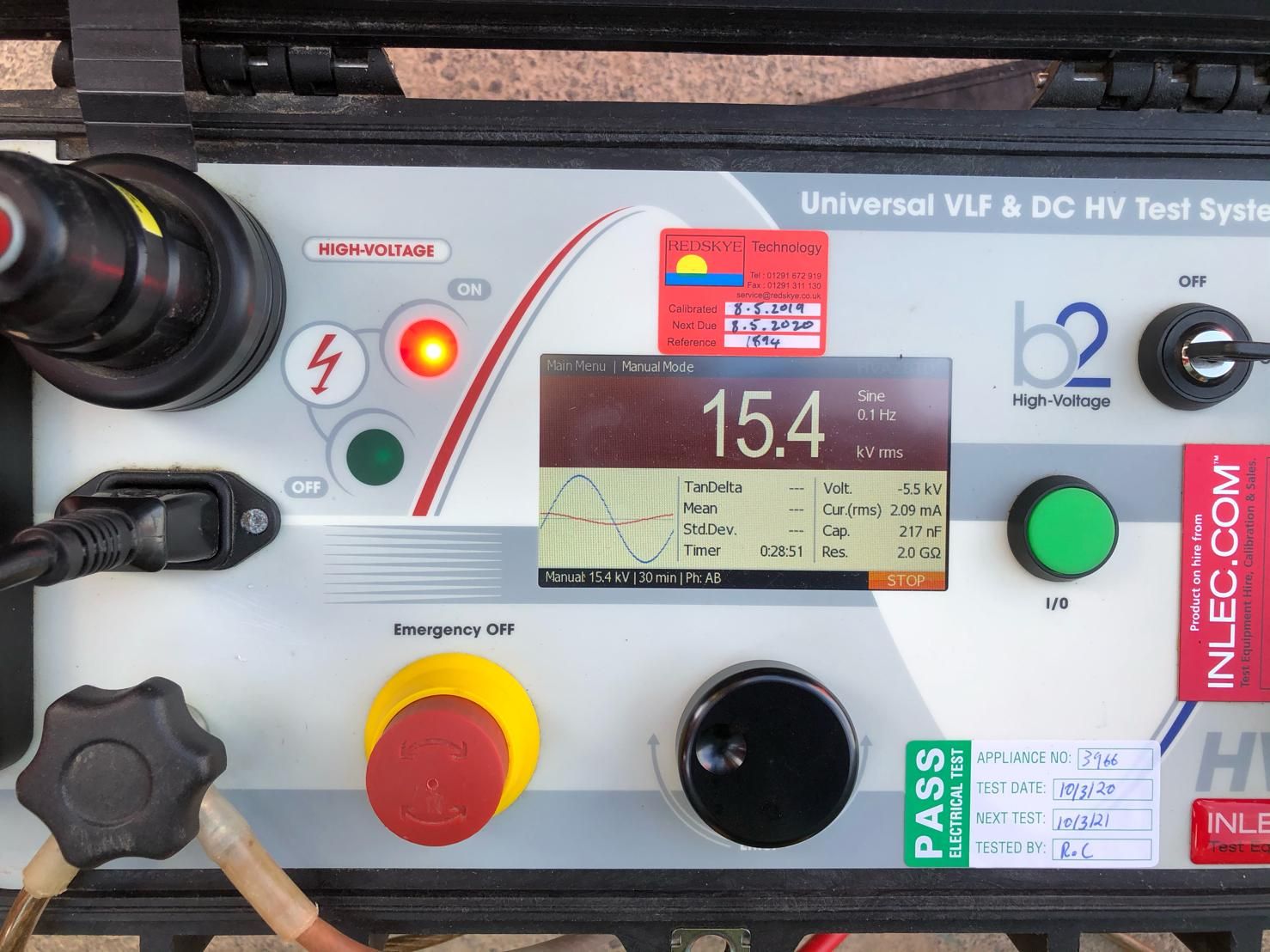

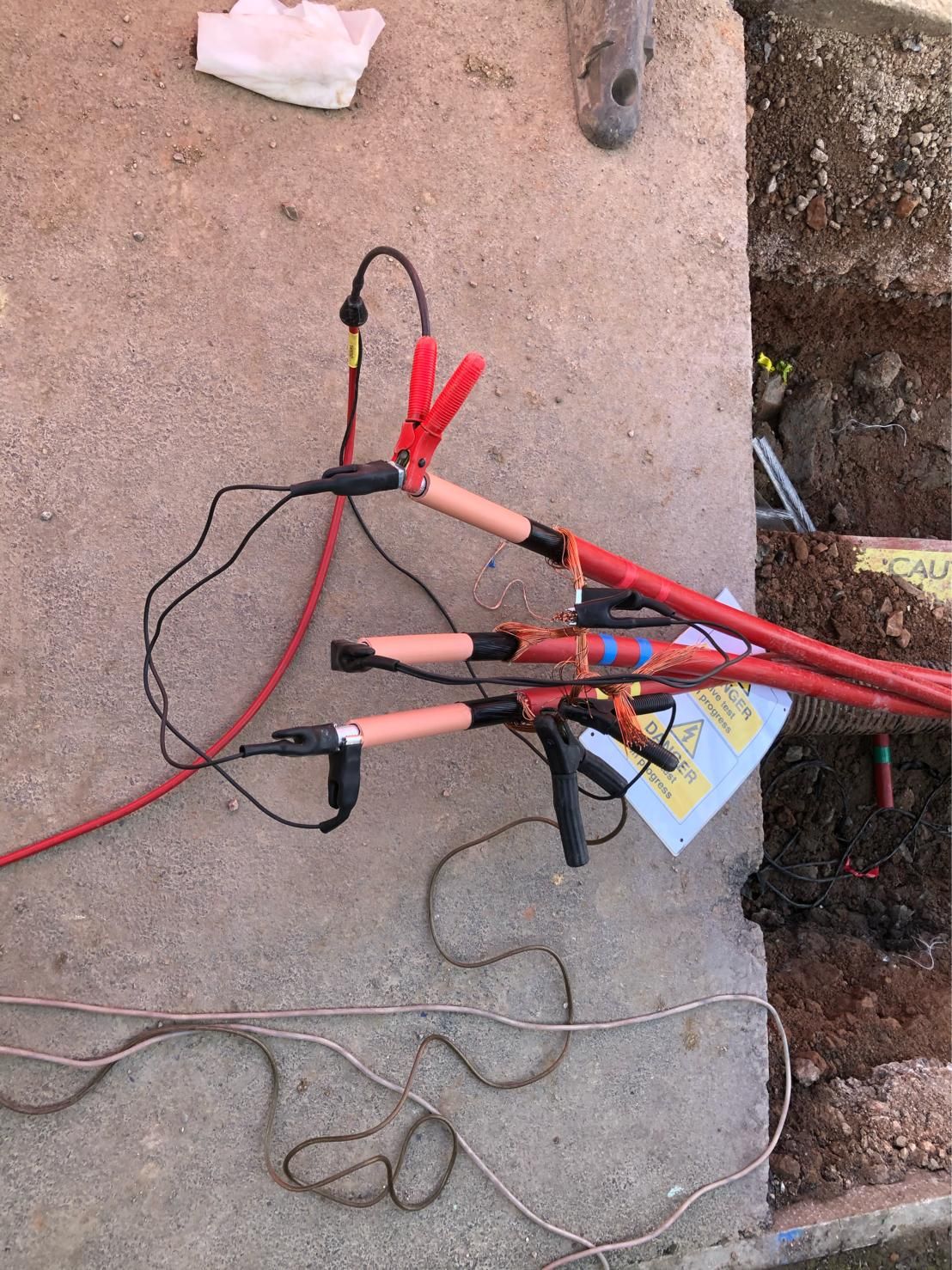

HV VLF Testing 11kV IDNO Connection

August 18th, 2020Pictured: HV High Voltage VLF Testing 11kV IDNO Connection

Images Courtesy of: Andy Dresser GCGI IEng MIET – Director at ASD Power Services Ltd

HV VLF Testing

Some HV VLF testing being carried out for a customer pre-connection of a new substation as part of a IDNO connection. ASD Power Services Ltd offer a wide range of work from VLF testing and sheath testing to SAP works.

asd power services ltd

ASD Power Services Ltd, established July 2016, are based in Newbury, Berkshire and offer the following services:

- (SAP) Senior Authorised Person (11KV)

- Auditing of Electrical Distribution Networks both LV and HV

- Maintenance inspections on electrical installations, including none intrusive IR Inspections

Director Andy Dresser is a Senior Authorised Person (SAP) and has over 25 years of experience in the Electricity Distribution business including network design, project management, auditing, people management, operational engineering, network construction, control engineering and procedure development.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

LV Service & Mains Straight and Branch Cable Jointing

August 18th, 2020Images : James Weston – Cable Jointer at Linbrooke Services Ltd

- LV service to mains cable jointing

- Service cable jointing up to 35sqmm 3 Phase, including connections to waveform and PILC cables

- LV switching and fuse operation on all LV service equipment

- Insulated cut-outs renewal and changing

Single Service Cable Jointed Off .1 PILC Cable – Low Voltage

3 Phase Service Breech Cable Joint Off 5 Core .3 Cable

3 Phase Service Breech Cable Joint Off 5 Core .3 Cable

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Securing Fire Resistant Sleeves On Critical Hoses & Wires In Jet Engines With BAND-IT JS Clamp

August 18th, 2020

Stainless Steel Clamps

BAND-IT JS clamp

Securing Fire Resistant Sleeves On Critical Hoses & Wires In Jet Engines

Fighter jet engines operate in extremes: high altitude, cold air, and hot engines.

While rare, if a fire was to break out in the engine, fiberglass sleeving protects the critical hose and electrical systems to give the pilot a chance to extinguish the fire, land, or eject.

The BAND-IT JS clamp was selected to secure the sleeving in place because of its proven ability to handle extreme heat, extreme cold, and the vibration of the aircraft. The result is a consistent tension on the hose clamp and a sleeve that doesn’t loosen or slip during flight.

The BAND-IT Edge

- Minimal expansion/contraction from thermal changes

- High strength to weight ratio

- Consistent installation tools and smooth edge ensure the sleeve is tightly secured without damaging the sleeving

- Available in multiple alloys, including Alloy 625

Stainless Steel Clamp Product Features

- Stainless steel clamps have a higher melting temperature and longer life than plastic ties

- JS Clamps have a low buckle profile to prevent catching or damage to other components

Thorne & Derrick stock, supply and distribute the most extensive range of BAND-IT products to enable clamp, cleat, support, and identify cables, pipes and hoses.

➡ See also: Cable Cleats | Cable Clamps | Cable Ties | Cable Hangers | Cable Labels | Cable Tags

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Electrical Vehicle Charging | Charging Ahead by Lucy Zodion

August 18th, 2020By David Hall, Head of Sales at Lucy Zodion

EV Charging | Lucy Zodion Feeder Pillars

The government has the unenviable task of managing one of the world’s most significant, and important, transitions to occur in industry for a very long time. Perhaps the most important to happen in motoring, ever.

The government’s Road to Zero strategy aims to be net-zero by 2050. The sale of new conventional petrol and diesel cars will also be phased out by 2040 (and now brought forward to 2035) to support this ambitious goal.

The Department for Transport said its £400m public-private Charging Infrastructure Investment Fund will see thousands more charge points installed around the country. The UK currently has approximately 11,000 public charging locations providing 30,000 EV connectors. Whilst that is quite impressive, it is still a cause for concern.

One factor that impacts on our industry enormously is the lack of charging infrastructure available. While charge point numbers are increasing, the UK is still some way short of what it needs, and this feeds into consumer EV ‘range anxiety’, in turn dampening demand.

Home & Workplace Charging

It is claimed 90% of people who charge their electric car do so at home. The government has set out ambitions for all new homes in the UK to be built with the provision of EV charge points, a world first. But while charging at home is ideal for those who have access to a drive and a charge point, for those without, charging immediately becomes more challenging.

The BBC recently reported on this apparent gap in charging infrastructure, where it identifies real life cases of users struggling to charge thier new electric vehicle due to lack of off-road parking. Read the article here.

The article states: “A recent report from Capital Economics suggested that fleshing out the UK’s electric vehicles (EV) charging network will cost £45.9bn between now and 2050. There are even fears that the electricity grid won’t be able to cope as thousands more EVs get plugged in by their new owners.”

Nevertheless, as Lighting Journal highlighted in the autumn, on-street EV charging is gradually becoming more available, with a range of funding streams available for local authorities and others to tap into (‘Plug in and play?’, November/December 2019, vol 84, no 10). All this, in turn, puts street lighting and streetlamps firmly in the spotlight when it comes to EV charging.

Why Street Lighting? It is existing infrastructure, ubiquitous and common throughout most urban spaces. As streetlights are constantly powered, it makes sense to utilise existing street furniture, especially when adding further street clutter is not suitable or desired.

Nevertheless, as Lighting Journal highlighted in the autumn, on-street EV charging is gradually becoming more available, with a range of funding streams available for local authorities and others to tap into (‘Plug in and Play?’, November/December 2019, vol 84, no 10). All this, in turn, puts street lighting and streetlamps firmly in the spotlight when it comes to EV charging.

Retrofitting EV charging facilities into streetlights can often be cheaper than installing new on-street charge points, which often include expensive ‘new connection’ costs.

Saying that, existing streetlights have their own costs and complications, particularly around connections and earthing requirements. However, manufacturers such as ubitricity have made good headway in tackling this area.

As Allan Howard outlined in Lighting Journal in January (‘It’s not just a case of “here’s a vertical tube, let’s go and drill a hole in it”,’ vol 85 no 1), in order to make streetlights multi-purpose assets in this way, providing both illumination and charging facilities, the electrical infrastructure within the lighting column itself must be adapted, and done so by an approved electrician.

Although streetlights are already connected to a DNO electricity supply there are a number of considerations and requirements, particularly on earthing systems (conversion to a TT earthing system). The correct type of protection must be used and locality of nearby assets must be considered to reduce the potential of electric shock (touching distance).

At Lucy Zodion, we strongly recommend using the latest edition of the IET Code of Practice for Electrical Vehicle Charging Equipment Installation (BS7671+ A3) as your guide for installations. Work with your DNO and appoint an approved contractor to help ensure that your street lighting infrastructure is compatible and in line with industry standards.

In the event when a secondary isolator is not present, ensure you install a product such as (to use our own examples) a Trojan Midi (3-way) or Trojan Maxi (4-way), manufactured to current British and industry standards and tested to IEC/EN 60947-3 and the fuse carrier to IEC/ EN60269-1.

This will provide a reliable protection. Use any service department to help manage variations, gland plates, locking options and so on, where possible, giving individual protection for both the EV charging equipment, feeder pillars and the luminaire.

Public Realm Charging Points

One thing is certain, to implement a holistic EV charging infrastructure, a mix of charging types is required, not just slow (home) and fast (7kW on-street). Public realm charging points are becoming increasingly crucial as adoption rates for electric vehicles surge. People will need to charge their cars as they go about their daily lives. Whether at schools, shopping, train stations, or airports (and the list goes on), EV charging needs to be commonplace and readily accessible, not just when at work or home. The need for convenience is paramount.

These public realm chargers will need to have faster charging times – between four hours and 30 minutes – falling into the ‘rapid’ and ‘super charging’ category. With this, of course, comes a different set of requirements. These are associated with larger power capacity, the need for new connections, either from DNO supply or perhaps even a package sub station if a large installation.

And the requirements will vary in different areas of the country, as each DNO will have its own approved products and working practices. Luckily for us at Lucy Zodion our street lighting cut-outs are widely approved across all DNO networks. Additionally, our sister company Lucy Electric has been working with DNOs for decades, supplying heavy duty cut-outs, CTCOs and package sub stations.

Given all this, we recommend five things to consider when installing a new connection for an EV charge point.

1. Plan properly – Anticipate that the process will take longer than expected and, given the increasing demand for new connections, timescales will only get longer.

2. Follow the process – Check with your DNO when ordering a new connection that you are using the right process. Many have fallen foul by not checking first, resulting in an installation that will not get approved.

3. Install quality products –Installing high-quality products will reduce potential issues that may arise in the future. Ensure all your products comply to the appropriate regulations and are tested regularly.

4. Consider oversizing – Consider oversizing your supply and include some spare capacity in your EV connection and supply pillar. By making your system scalable, you can add to the number of charge points or upgrade the rating of your charge points in the future, when technology supersedes current equipment.

5. Maintain regularly – In order to keep your equipment in good working order test and inspect regularly. It is pointless having stranded assets that aren’t serving customers and/or earning revenues.

This article was originally published in the March 2020 edition of the Lighting Journal, available here.

Lucy Zodion | Fortress Feeder Pillars | Pre-Wired Feeder Pillars | Street Lighting Cut-Outs | DNO Cut-Outs | Electrical Power Distribution Enclosures

Further Reading

➡ More Lucy Zodion blogs:

Cut Outs & Isolators – Lucy Zodion Explain The Differences

Feeder Pillars From Lucy Zodion – LV Electrical Power Distribution

Optional Extras For Use With Lucy Zodion Fortress Feeder Pillars

Waveform Cable Termination – 3 Core 300sqmm Cable Onto A 2 Ganged Metered Way In Lucy Cabinet

Galvanised & Stainless Steel | GRP | Pre-Wired | Underground Retractable Feeder Pilars

Read our Blog with Lucy Zodion: Cut-Outs & Isolators – What’s the Difference?

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist