Blog

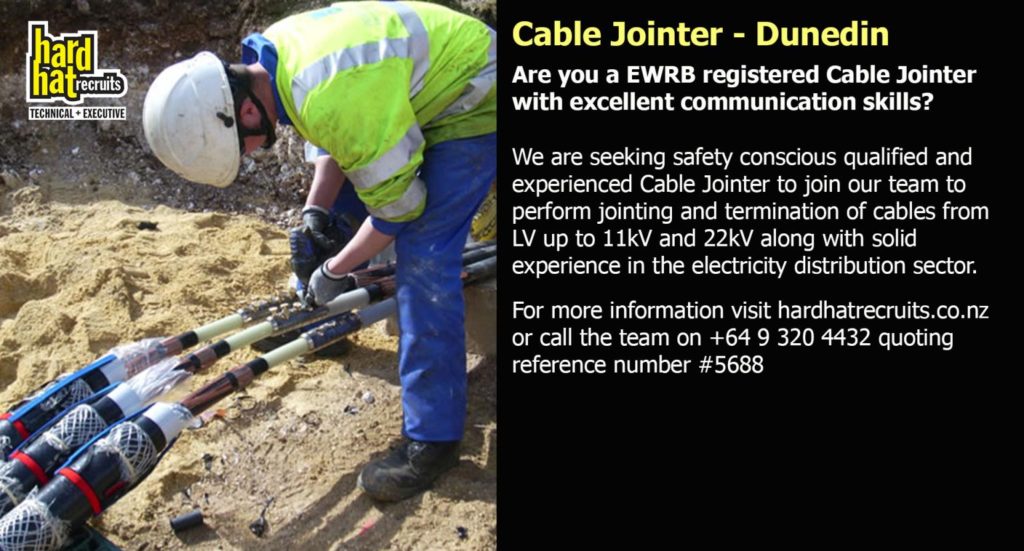

JOB | HV Cable Jointer 11/22kV | Location Dunedin NZ | Apply Here

July 27th, 2020

- Location | Dunedin New Zealand

- A fantastic opportunity to join an industry leader

- Close-knit team

Published one behalf of Red Hat Recruits by Thorne & Derrick International

Martin Walker | Senior Consultant and Account Manager at New Zealand’s market leaders in Power Distribution and Transmission, Fire Detection & Protection.

Our client is seeking an EWRB registered Cable Jointer to join their team in Dunedin, installing cables, terminations and joints.

About the Role

We are seeking safety conscious qualified and experienced Cable Jointer to join our team to perform jointing and termination of cables from LV up to 11kV and 22kV along with solid experience in the electricity distribution sector.

The ideal candidate will have a current EWRB Cable Jointer practising licence and the ability to work in New Zealand.

You will need to have excellent communication skills, be able to cope with the physical demands of the role, work to a high standard and have an excellent safety record as well as a clean NZ driver’s licence.

If you are a team player with a ‘can do and will do’ attitude, please apply today.

Duties

- HV and LV cable jointing and termination

- Compliance, commissioning + test experience of cable jointing up to 22kV

- Adhering to best practice

- Compliance with health, safety, environmental and regulatory requirements

- Excavates and reinstates underground cable installation sites.

- Installs cables, terminations and joints in polymeric and/or paper insulated power cables.

- Installation, replacement and repair of underground distribution assets

Skills & Experience

- NZ Electrical Registration (EWRB) and current practicing licence

- Level 4 Cable Jointer qualification

- HV | LV Cable Jointing experience, 11kV (essential), 22kV (advantage)

- Comfort around working at heights advantageous

- Full Class 1 NZ Drivers licence

- Excellent written and verbal communication skills

- Compliance with health, safety, environmental and regulatory requirements

Apply

If you meet the above criteria, we welcome your application including your CV and cover letter in Word format via Seek.

About Hard Hat Recruits

Hard Hat Recruits is in the hard-hat people business – from recruiting the best construction people through to bringing you highly sought-after engineering professionals and specialist operators.

When it comes to finding the right people in a timely and cost-effective manner, we deliver and that’s no bull.

We are a recruiting company head-quartered in New Zealand, that has in-depth knowledge of both global and local recruitment markets.

For us, it is all or nothing; there is no middle-of-the-road and we are not into compromise.

We seek only the right expertise that will give your project the credibility of which it is worthy.

www.hardhatrecruits.co.nz

Engineering | Construction | Technical | Mining | Water | Social Infrastructure

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

Jointing, Earthing, Substation Electrical & Safety Equipment Distributors

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex

The Purpose Of The Screen & Semi-conductive Layer On MV Cables

July 24th, 2020

The Purpose Of The Screen & Semi-conductive Layer On MV Cables

Republished with the Kind Permission of Sam Soady |

Eccentricity Pty Ltd Director /HV Operator / Cable Jointer

Screen & Semi-conductive Layer

On MV Medium Voltage Cables

Every wondered what the purpose of the screen and semi-conductive layer on MV cables was? Wonder no longer – Eccentricity’s Guest Blog covers it here.

In most modern medium voltage (MV) cables, especially underground, cables are shielded or screened with an earthing conductor. The screen consists of lapped copper tape or metallic foil usually less than 1mm in thickness, which is the interface between the conductor and the insulation (PVC, XLPE).

The main purpose of this conductive screen is to maintain a uniformly divergent electric field and contain the electric field within the cable core. The conductor screen is made from semi-conductive material, which is designed to hold back voltage.

This smooths out the surface irregularities of the conductor by making the voltage on the inside of the insulation the same. This semi-conductive screen material is based on carbon black, which is dispersed within a polymer matrix. The concentration of carbon black needs to be sufficient to ensure adequate and consistent conductivity.

It must also be optimized to provide a smooth interface between the conducting and insulating components of the cable, which is important as it decreases the occurrence of high stress regions on the cable.

The semi-conductive screen also reduces voltage stresses where the conductive components interface with the insulating components.

It accomplishes this when the expansion of the insulating layer is typically 10 times greater than that of the conductor, so that when the cable is at its maximum operating temperature of 90oC a large enough gap is formed to allow electrical discharges to occur.

This then serves to even out the stresses associated with these discharges which would otherwise attack the insulation at specific points along the medium voltage cable.

The screen wires are connected at each extremity of the circuit in solidly grounded systems, dispersing the circulating currents of the MV cable.

When connecting the screen wires, it is important to note whether the installation is using current transformers (CT’s) for the circuit protection. Any currents on the screen wires will be phasor summed in the conductor by the CT. In the case of fault currents, this is often directly out of phase with the conductor current.

As the screen passes through the CT as part of the cable it is then necessary to bring the made-up screen wires back through the CT in the opposite direction prior to grounding. This ensures the screen current is effectively cancelled out to ensure the correct operation of circuit protection devices.

About Eccentricity

Eccentricity is a specialised Brisbane based company with a team of dual trade electricians and cable jointers. Our technicians are fully qualified to work on cables up to 66kV, including XLPE, PILC and EPR cables, backed by over a decade of industry experience.

With a modern and fully compliant fleet of industry vehicles, we are capable of accessing any high risk environment to perform works with a wide range of major MV HV cable jointing projects including, mining, oil, gas, renewable energy, and high voltage transmission networks.

Eccentricity has the capacity for small or large scale projects, providing reliability of power networks wherein client satisfaction is a top priority. We provide a high level of quality with all aspects of both installation and commissioning, ensuring we comply with all relevant regulations and legislative provisions.

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

Jointing, Earthing, Substation Electrical & Safety Equipment Distributors

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex

ENERGYx2020 | Interview With Paul Morrow From Klauke

July 16th, 2020

ENERGYx2020

with Paul Finnegan & Louise Purcell (Energy Network Events)

Exhibiting at ENERGYx2020 in this informative interview Paul Morrow, UK & Ireland Manager for Klauke, part of the Emerson Group and world class manufacturers of cable cutting and crimping tools, discusses electrical safety and the recent launch of the KLAUKE Orange range of fully insulated tools that have set the standard within the global utility industry.

Health & Safety is a main pillar of Energy Network Events and the KLAUKE Orange range is a huge leap forward in the development of battery-powered cabling tools for the cutting and crimping of overhead lines and underground cables.

You can view the complete range of KLAUKE Orange tools here ➡ insulated cable crimping and cutting tools.

Energyxtra Interview

Paul Morrow describes how Klauke was started in 1879 by two brothers in Germany originally making high quality pliers for the watch-making industry employing only 5 people. In 1960 when electrification become more popular Klauke shifted to developing cable lugs.

In 2018 they were acquired by Emerson and along with Greenlee and Rigid, Klauke can now service all the mechanical, electrical and plumbing requirements in the market.

For even more safety, Klauke has now developed the world‘s first battery hydraulic crimping and cutting tools with Tri-Insulation Barrier.

Cable Cutting & Crimping

Insulated Tools & Total Safety

The world‘s first battery hydraulic crimping and

cutting tools with Tri-Insulation Barrier technology that provides users with 1.000V protection against

electrical shocks.

There have been several recent advances in cable cutting and crimping tool technology including data recording, bluetooth remote controls and pressure sensors.

All tools have become more compact making them more efficient for jointing and terminating cables in confined spaces as well as enhancing safety features.

Training, supervision, testing and PPE are all standards but what the KLAUKE Orange implements is another layer of electrical safety into the process.

➡ Download Brochure Klauke Cutting & Crimping Tools

- You frequently work in close proximity of live lines and parts. You cannot take any chances.

- You have ergonomic issues due to use of manual insulated tools. You want to work safe but with faster and more ergonomic tools.

- Cables you perceive as not live, can turn out to be live. You want to be protected at all times.

- Live line cutting is one of your safety critical tasks. You have to use safer tools for more protection.

Tri Insulated Barriers on Klauke Tools

During the interview, Paul stresses the importance of safe working practices including the physical aspect of the tool e.g. the body insulation of the cable crimping or cutting tool. The new Orange Line Tool uses a 3 level or tri-insulation system – the 3 level includes creepage distance, insulation material and oil within the system.

Klauke EKM 60/22 ID ISM VDE battery powered hydraulic crimping tool 6 – 300 mm² |

Klauke EKM 60 ID ISM VDE battery- powered hydraulic crimping tool 10 – 240 mm² |

Klauke ES 20 ISM VDE battery-powered hydraulic cutting tool 20 mm dia. |

Klauke ES 32 ISM VDE battery-powered hydraulic cutting tool 32 mm dia. |

Klauke ES 25 ISM VDE battery powered hydraulic cutting tool 25 mm dia. |

Klauke ESM 35 ISM VDE battery powered hydraulic cutting tool 35 mm dia. |

Klauke ESM 50 ISM VDE battery powered hydraulic cutting tool 50 mm dia (copper + aluminium cables) |

|

➡ View the KLAUKE Orange and to hear the full interview with Paul.

Further Reading

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

- Cable Lugs – Crimping Applications & Standards

- Copper Cable Lugs For Special Applications

- Indent Crimping Of Cables – Benefits & Limitations

- Cable Lugs & Crimping Using The Hexagonal Crimp Method

- DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

- Copper & Aluminium – Crimping CU-AL Cables

- Electrically Driven Crimping Tools For High Volume Applications

About ENERGYx2020

ENERGYx2020 is the best Electricity Industry Event of its kind in Europe for distribution network operators, private network operators, energy transmission, renewable energy, telecommunications, and rail companies. This Net Zero event combines Overhead Lines, Plant and Cables over 2 days on the 24th and 25th of November 2020 at Chester Racecourse.

The event is about the drive to Net Zero and future innovations within the electrical industry, whether that be in the short or long term. It is attended and supported by a wide mix of people working in Electrical Utilities, Network Operators, DNOs, Railway Companies, Transport Specialists, Renewable Companies, Civil Works, Health & Safety, Telecom, Data Centres and Industrial Manufacturers with private networks.

Special thanks to event sponsors Nexans & Lucy Electric.

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Thorne & Derrick | Stockists & Suppliers | Joints Terminations Connectors up to 66kV

PRESS RELEASE: Solar Industry Relaxes Planning Laws For Large Scale Battery Storage

July 15th, 2020

By Solar Trade Association

14th July 2020

The Government has announced it will relax planning legislation to make it easier to construct large batteries to store renewable energy, in a move which will see ministers introduce secondary legislation to remove electricity storage, except pumped hydro, from the Nationally Significant Infrastructure Projects (NSIP) regime in England and Wales. [1]

STA Chief Executive Chris Hewett said: “We welcome the decision to make it easier to deploy flexible large-scale energy storage technologies in the UK, which will help to further decarbonise and improve the resilience of our energy system.”

“The next steps in unlocking the potential of energy storage, and maximising the crucial role it can play in managing growing solar and wind output, are to provide greater access to flexibility markets, including the capacity market, and applying fairer network charging rules.”

“Our aim has to be to fully decarbonise these flexibility markets and minimise all use of fossil fuel generation.”

There is currently in excess of 13.5GW of battery storage projects in the pipeline, with 1.3GW ready to build, 5.7GW with planning permission and a further 6.5GW proposed. [2]

Editors notes:

[1] The Department for Business, Energy and Industrial Strategy – The planning system for electricity storage: follow up consultation: https://www.gov.uk/government/consultations/the-planning-system-for-electricity-storage-follow-up-consultation

[2] Solar Media – UK Battery Storage Project Database Report: https://marketresearch.solarmedia.co.uk/products/uk-battery-storage-project-database-report

For further information or to request an interview, please contact:

- Name: Jack Dobson-Smith

- Title: External Affairs Adviser

- Main line: 0203 637 2946

Background on the Solar Trade Association

The mission of the Solar Trade Association is to empower the UK solar transformation. We are paving the way for solar to deliver the maximum possible share of UK energy by 2030 by enabling a bigger and better solar industry. We represent both solar heat and power plus energy storage, and have a proven track record of winning breakthroughs for all three technologies. Become a member.

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

The LV HV Specialists

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the renewable energy sector – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

BundGuards | Substation & Transformer Oil Spills & Leaks Containment

July 3rd, 2020

BundGuards | Substation & Transformer Oil Spills & Leaks Containment

BundGuards

Substation & Transformer Oil Spills & Leaks Containment

The Andel BundGuard system was first conceived and developed in 1992 as a direct response to the needs of the UK electricity industry and the serious water-removal problems it faced at sub-station sites across the UK.

Since then many thousands of BundGuard units have been installed nationwide, protecting customer assets, site operators and the environment.

To be compliant with current regulations, all above-ground oil storage tanks that contain more than 200 litres of oil, must have secondary containment or a ‘bund’ to contain oil leaks and spills.

Most bunds are exposed to the elements and consequently are likely to collect and fill with rainwater. As a bund fills with water, the containment capacity is reduced and the risk of oil escaping by overtopping the bund wall in the event of tank failure is greatly increased.

It is therefore essential that robust measures are put in place to extract rainwater from exposed bunds.

Andel BundGuard is a cost-effective, self-contained and easy-to-fit automatic pump and alarm unit that is installed within a bund and works continuously and automatically 24 hours, 7 days a week, 365 days a year.

Using advanced circuitry and micro-controller technology, the BundGuard system discriminates between oil and water, keeping oil contained and expelling water from the containment area.

Large oil storage tanks and equipment such as electricity transformers may contain several thousand litres of oil and are also likely to be open to the elements. The bund will gradually collect rainwater and in time, the holding capacity of the bund can be significantly reduced.

As oil floats on water, once the capacity drops below 100% there is a risk of oil overflowing over the bund wall in the event of tank failure.

Thorne & Derrick can supply an extensive range of standard and customised Bundguards for the protection of medium/high voltage substations.

Bundguards

Andel’s BundGuard is a cost-effective, self-contained and easy to fit automatic pump and alarm unit which monitors and works around the clock.

The BundGuard system uses advanced circuitry and micro control technology to keep oil within the container and expel water from the containment area.

The BundGuard has a robust stainless steel pump and sensor unit located within the sump. The control unit activates the pump as required to remove only clean water safe to foul sewer or interceptor depending on the sites circumstances.

Andel’s BundGuard system has a number of failsafe systems in place and a range of visual and relay alarm outputs to ensure safety and allow for communication to remote monitoring systems.

The PPL BundGuard removes the need for regularly emptying the bund by waste contractors thereby reducing costs, the environmental impact and carbon footprint.

Bundguards

Technical Specification

| Control Panel | |

|---|---|

| Power | 110/230 VAC, 440W (Total including pump) |

| Construction | Stainless steel, IP66 |

| Dimensions | 320mm x 260mm x 120mmHeight x Width x Depth |

| Indicators | LEDs: Mains SupplyPump ActiveHigh Water AlarmHigh Oil AlarmPump Disable LCD: Pump Operation Counter |

| Outputs | Mains Fail, High Water, High Oil, Pump Disable rated at;10A at 230VAC (AC1)0.1A at 220VDC (DC1) |

| Fixing | Wall/Surface Mount via External Fixing Lugs |

| Sensor Unit | |

| Power & Voltage | Nominal |

| Construction | Stainless Steel, Immersion Proof |

| Dimensions | 570mm x 180mm x 70mmHeight x Width x Depth |

| Fixing | Free Standing in Base of Sump |

| Pump | |

| Power & Voltage | 230 VAC (110 VAC optional) |

| Construction | Stainless Steel |

| Dimensions | 250mm x 160mmHeight x Width |

| Safety | Thermal Trip; Self Reset |

| Flow Rate | 110 litres per minute at 2-3 metre head |

| Fixing | Part of the sensor unit |

Thorne & Derrick stock and supply the DrainEezy range of transformer bund filters for use with LV MV HV Oil-Filled Transformers providing passive, self-regulating environmental protection and preventing bunds from overflowing during rainfall events; the DrainEezy Bund Filter System is field-ready to fit and retrofittable allowing clean water to drain freely while automatically blocking and retaining insulating oil in the event of a leak or catastrophic transformer failure.

600/1000V | 11kV | 33kV | 66kV Transformer Bund Filters

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories