Blog

Subsea Cable Protection Systems Installed On Offshore Wind Farm | Part 1 of 5

September 16th, 2019Subsea Cable Protection Systems

♦ Republished by Chris Dodds with Kind Permission of Greg Campbell-Smith ((Director Sales and Business Development at First Subsea)

First Subsea is the world’s leading developer of subsea connection technology, supplying, installing and decommissioning.

Subsea power cables on offshore wind farms are typically protected by means of burial.

This is a well proven means of cable protection used in other offshore industries.

However, at either end of offshore wind array cables they transition from burial, up through the water and into the wind turbine foundation. This free spanning section of cable is susceptible to what can be substantial wave and current loads.

These loads introduce movement and bending into the subsea cable which, without cable protection, can lead to over-bending, over-tensioning, fatigue and abrasion damage.

This exposed subsea cable is traditionally ‘protected’ by means of a relatively expensive and complex proprietary Cable Protection System (CPS).

Our 1st Article on Subsea Cable Protection Systems and how they provide real time cost savings offshore.

First Subsea Cable Protection System was recently installed on an Offshore Wind Farm in the Southern North Sea and received commendations from the Developer and Installation Contractor alike.

“The engagement system worked very well, 100% connection, quick and efficient installation times” We will be posting several articles on LinkedIn over the next few weeks detailing how we have made Cable Protection easier, quicker, consistent whilst ensuring the cable is fully protected from fatigue and environment challenges over its lifetime offshore.

➡ If you would like a copy of the report, please contact Chris Dodds [email protected]

- Subsea Cable Protection & Laying Costs | Part 2 of 5

- Subsea Cable Protection Systems – Disconnection & Removal | Part 3 of 5

- Subsea Cable Protection Systems, Damage Prevention & Fixed WTG | Part 4 of 5

- Subsea Cable Protection Systems Design For Installation | Part 5 of 5

LV, MV & HV CABLE JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems – we are highly customer responsive and absolutely committed to providing a world-class service.

We have an International Distribution Agreement with Nexans Power Accessories UK to supply their Heat Shrink and Cold Applied ranges of 11kV/33kV/66kV joints and terminations and Euromold brand of separable connectors.

Since 1985, we have established an international reputation based on Service, Integrity and Trust – contact us.

t: 0191 410 4292 | e: [email protected] | www.powerandcables.com

We provide expert technical support and supply from a multi-million pound stock holding:

- Cable Joints, Terminations & Connectors Earthing & Lightning Protection

- Cable Accessories – Lugs, Glands

- Circuit Protection & Fuses

- Cable Cleats & Clamps Electrical Safety Equipment

- Cable Pulling & Laying Equipment

- Arc Flash Protection & Clothing

- Cable Duct Seals & Transit Systems Surge Arresters & Bushings

Further Reading:

- Arc Flash Clothing & Protection For Safe Windfarm & Wind Turbine Working

- Jointer Training Courses – 11kV 33kV 66kV MV HV Cable Jointer Competency Training

- Sealing Cables In Offshore Substations – A Roxtec CPD

Transformer Switching | Mitigating Inrush Currents During Transformer Energisation

September 16th, 2019

➡ The following article has been prepared by Tim Rastall from Enspec Power

“As a Senior Electrical Engineer specialising in Grid Code Compliance and power quality solutions, I help wind, solar, energy storage and industrial connections comply with required standards and operate in an efficient and cost-effective manner.

At Enspec Power we specialise in the design, manufacture, installation and maintenance of Grid Code Compliance solutions and as such are able offer a bespoke and turnkey solution for any connection.

If you would like to find out more about our innovative solutions or how we could help you, please call me on 07481818740 or email me at [email protected].”

SynchroTeq – Transformer Switching

This report was produced by Enspec Power Ltd, it details the application of the SynchroTeq device for transformer switching. The document outlines the application and theory of controlled transformer switching and then presents two commissioned and operational site examples, one from a UK Solar Farm and another from a Wind Farm in Scotland.

In conclusion, the document demonstrates how the SynchroTeq can mitigate inrush currents during the energisation of transformers and provide site compliance with the P28 limit of 3%.

Introduction

When a transformer is energised it may draw a large transient current from the supply connection point. This large current draw results in a voltage dip. According to the UK standards (Electricity Council’s Engineering Recommendation P28), this voltage dip cannot exceed a specified amplitude and/ or duration. Due to this, it has been common practice to install a Pre-insertion Resistor (PIR), that is placed in the circuit during the transformer energisation to reduce the inrush current and thus voltage dip.

However, a PIR requires an extra circuit breaker, has a significant footprint and can be expensive. The SynchroTeq is a controlled switching device that can provide equal or better inrush mitigation to that of a PIR without the need for an extra breaker or costly install.

This document will cover the theory, installation and performance of the SynchroTeq when applied to transformer switching and will end by presenting two operational SynchroTeq installations.

Transformer Controlled Switching

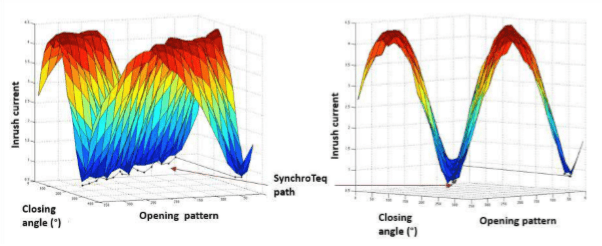

When a transformer is de-energised, the magnetic core will contain a certain amount of residual magnetic flux. This residual flux is dependent on the voltage across the transformer at the time of de-energisation and can intensify saturation leading to high transient inrush current on re-energisation. The possibility or magnitude of saturation and thus inrush current is dependent on the point of re-energisation (angle) in relation to this residual flux. This effect can be seen graphically in Figure 2-1 below.

Figure 2-1 – Inrush Current due to Opening and Subsequent Closing Angle

The above Figure 2-1 shows the inrush current obtained across all possible closing angles for each possible opening angle. As can be seen, there is a best and worst-case closing angle for each opening angle. When switching a standard transformer arrangement there is an equal possibility of hitting a bad point as a good point, and thus a possibility of high inrush current. The SynchroTeq works by monitoring and calculating this residual flux, with knowledge of the residual flux it can calculate the optimum closing angle. This is seen graphically in Figure 2-1 above as ‘SynchroTeq path’.

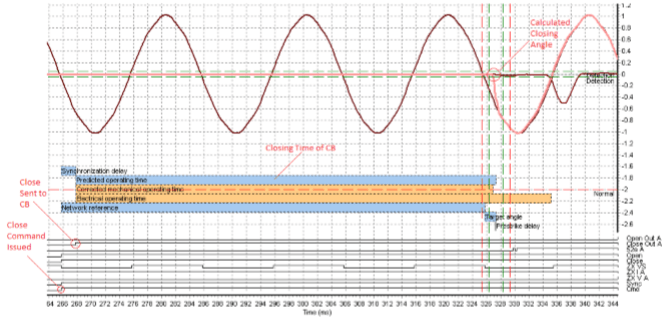

The SynchroTeq then becomes an interface between the open/ close commands (manual, remote or protection) and the Circuit Breaker. Using the calculated residual flux and knowledge of the Circuit Breaker operation time, the SynchroTeq can target this optimum closing angle, thus mitigating high inrush currents. This process can be seen graphically in Figure 2-2 below.

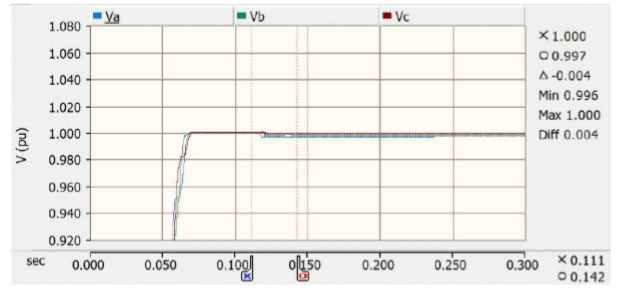

Figure 2-2 – SynchroTeq Controlled Close Operation (Phase A)

The above Figure 2-2 shows a closing operation carried out via the SynchroTeq (Phase A). In this example, the calculated closing angle, based upon the calculated residual flux, is around 220 degrees. Firstly, the close command for the CB is issued to the SynchroTeq, the SynchroTeq then waits until the target angle is the CB closing time ahead (predicted operating time), and then the close command is sent to the CB. The result here is the CB closing at the desired angle with minimum inrush current.

The SynchroTeq can mitigate inrush current using any modern CB. The CB can be a 3-pole gang operated device or a 3-pole individual pole device. When operating via a 3-pole gang operated device, the SynchroTeq cannot close the CB at the optimum point for each phase, in this instance, it calculates the optimum point for all three phases to keep inrush current to a minimum. When operating via an individual pole device inrush current can be completely avoided for unloaded transformers.

SynchroTeq Application

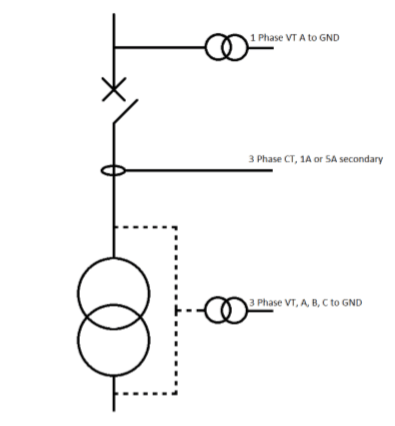

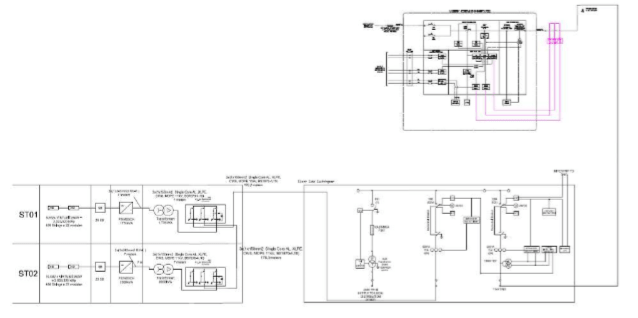

Figure 3-1 – SynchroTeq Signal Requirements

The above Figure 3-1 shows the signal requirements for transformer switching with a SynchroTeq device. The single-phase VT is used for voltage synchronisation, the CT’s are used to measure inrush current and the three-phase VT allows the SynchroTeq to calculate residual flux. The SynchroTeq then forms an interface between the circuit breaker open/ close commands and the circuit breaker itself.

Actual Application and Results

UK Solar Farm

The following results are for a SynchroTeq MVX installed on a UK solar farm.

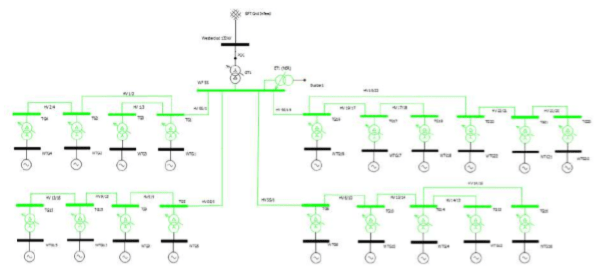

The SynchroTeq was used to control the simultaneous energisation of the sites 2MVA and 1.77MVA 11/04kV transformers. A diagram of the site layout can be seen below in Figure 4-1.

Figure 4-1 – Site SLD

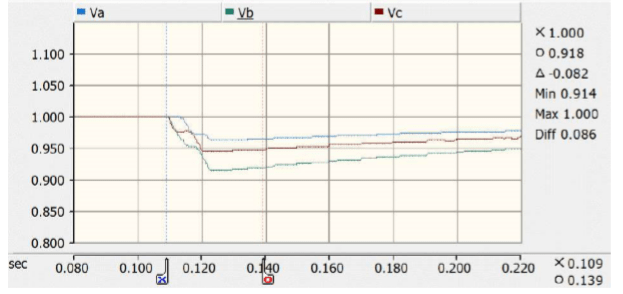

The SynchroTeq MVX was mounted in the client substation and controlled the energisation of the main CB. The initial P28 studies for the site highlighted a 50th percentile voltage dip of 8.2% for the simultaneous energisation of the sites transformers, this can be seen below in Figure 4-2.

Figure 4-2 – PCC Voltage Dip for Whole Site Energisation

The DNO for this site stipulated a maximum voltage dip at the PCC of 6% due to the whole site energisation. The below Figure 4-3 shows the result of the SynchroTeq MVX commissioning:

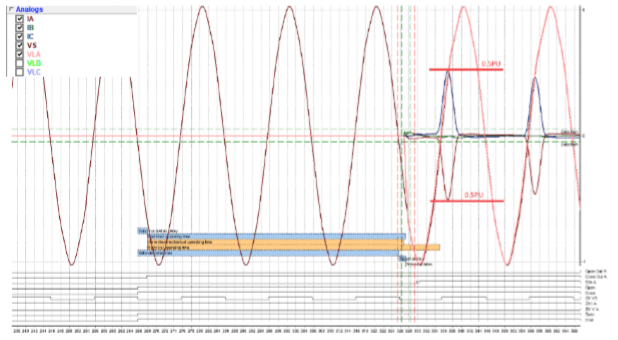

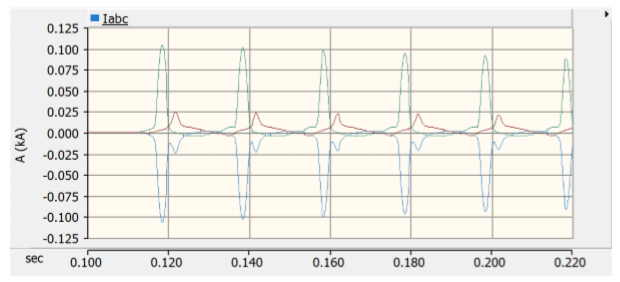

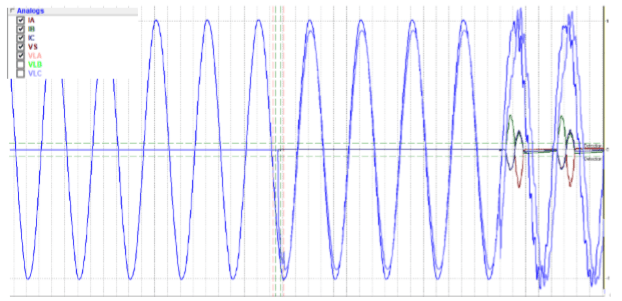

Figure 4-3 – Commissioned SynchroTeq Inrush Current

As can be seen from the above figure the resultant inrush current was 0.51PU (101A).

This resultant inrush current was then used to obtain a new voltage dip using the original P28 simulation model.

Figure 4-4 – SynchroTeq Resultant Inrush Current in P28 Model

Figure 4-5 – Simulated Voltage Dip Based on SynchroTeq Inrush Current

As can be seen from the above figures, simulation of the resultant inrush current led to a PCC voltage dip of 0.4%. As the switching is now controlled by the SynchroTeq this level of inrush current will result from every future energisation, making the site fully P28 compliant.

Scottish Wind Farm

The following results are for a SynchroTeq Plus installed on a Scottish Wind farm. The SynchroTeq was used to control the energisation of the sites 90 MVA 132/33kV transformer. Figure 4-6 below shows the layout of the site.

Figure 4-6 – Site SLD

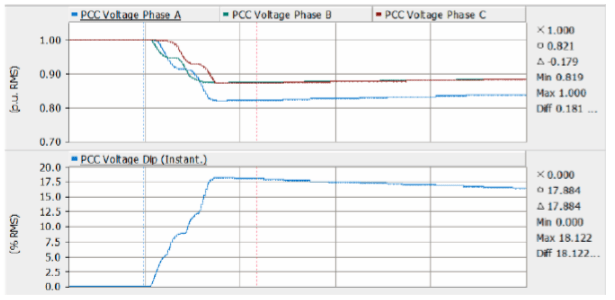

The SynchroTeq Plus was mounted in the 132kV control room and controlled the energisation of the main 132kV CB. The initial P28 studies for the site highlighted a maximum voltage dip of 17.9% for the energisation of the sites transformer, this can be seen below in Figure 4-7.

Figure 4-7 – PCC Voltage Dip for 90MVA Transformer Energisation

The DNO for this site stipulated a maximum voltage dip at the PCC of 6% due to the transformer energisation. The below Figure 4-8 shows the result of the SynchroTeq Plus commissioning.

Figure 4-8 – Commissioned SynchroTeq Inrush Current

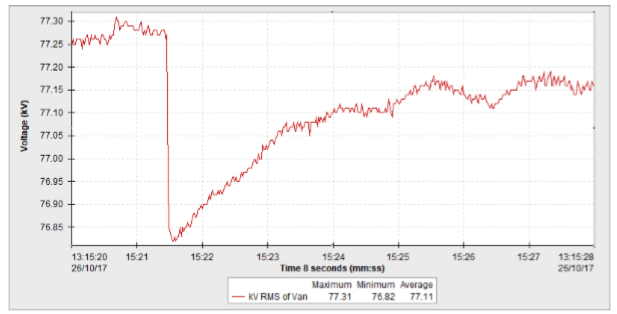

As can be seen from the above figure the resultant inrush current was 0.3PU (118A). A fast-acting voltage recorder was also connected to the 132kV VT and the recording during this switching event can be seen below in Figure 4-9.

Figure 4-9 – Recorded Voltage Dip During SynchroTeq Energisation

As can be seen from the above figures, after commissioning of the SynchroTeq the obtained PCC voltage dip was 0.63%. As the switching is now controlled by the SynchroTeq this level of inrush current will result from every future energisation, making the site fully P28 compliant.

Conclusion

In summary, it has been shown that by using the SynchroTeq device, inrush current caused by transformer energisation can be significantly reduced. Two installed and commissioned cases have been presented that show the potential of the SynchroTeq to ensure P28 compliance when initial system studies predict potential for large voltage dips.

See how Thorne and Derrick support the Wind and Solar industries.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

“You’re Still Just A Cable Splicer!”

September 13th, 2019

This article was wtitten by John Perez of Quanta Underground Power Services

➡ See Part 1 “You’re Just A Cable Splicer!”

I still am and always will be proud to be a “Cable Splicer”, or as I commonly refer to myself; a dirty tattooed underground rat. There are many of us who proudly holds the title of Cable Splicer, and we have been through multiple training programs to achieve our title.

We are an important part of the electric distribution system anywhere multiple cables are installed in manholes, vaults, enclosures, and other types of Confined Spaces.

While I could, and maybe have a few times, go on for days about the importance of a well built underground distribution system installed by good Cable Splicers, we are here to talk about Splicers.

Currently in the U.S.A., not sure about other countries, there is a shortage of Cable Splicers.

Over the last 2 year period, there isn’t a single week that goes by without someone asking me to refer a good Splicer.

Problem is; there are none available at this point. And the be brutally honest, if you are a Splicer and currently can’t find work, there are probably one of two things going on.

1 – You don’t want to travel

2 – Your reputation has preceded you

In recent years there has been a push to recognize the importance of Lineman and the dangerous work they perform. I am happy to see that Lineman and skilled trades are receiving the recognition they deserve.

During all of this wonderful recognition, we must not forget the Cable Splicer who does work which is equally as dangerous under equally difficult conditions.

Cable Splicers and the work we perform should not be considered “less than” simply because we don’t have the title of “Lineman”. I have met, and am friends with, multiple Lineman who would not consider working on cables in Confined Spaces, much the way I would not consider climbing a tower. So, much the same as the Lineman trade, the Cable Splicer trade is in high demand and does not have enough people to fill the needs.

My opinion may be unpopular and maybe even a bit biased, but it is high time for Cable Splicers to begin to receive recognition for the work we perform.

Without the Cable Splicer, the integral and vital underground electric distribution systems that power many large cities would not be maintained and repaired. The knowledge required for rigging, cable splicing, terminating, installing cables, removing cables, changing transformers, switching, reading maps, etc…. is valuable and necessary. There are more tasks that I should list, but that would take up too much time.

I know I already said it, but it bears repeating; Cable Splicers deserve more recognition than they currently are afforded.

Call me crazy if you will, but I believe I am correct.

I vote for National Cable Splicer Day to take place on 7/24/2020.

Further Reading

- PILC Replacement & Cable Longevity

- Cable Splicing At The Lazy Q Ranch

- Cold Shrink Splices & Cable Jointer Training

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing cables, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

“You’re Just A Cable Splicer!”

September 13th, 2019

This article was written by John Perez of Quanta Underground Power Services

➡ See Part 2 “You’re Still Just A Cable Splicer!”

“Your Just A Cable Splicer?!?” was a question that I was once asked by a Lineman, in a very incredulous tone. My first thought was to tell this  person off and to let them know that I was not “only a Cable Splicer” but that I was a very good cable splicer.

person off and to let them know that I was not “only a Cable Splicer” but that I was a very good cable splicer.

But then I realized that what I was going to say would fall on deaf ears. I instead responded, “Yes, I guess that I am just a cable splicer. But the truth is, I know more about cable splicing than you do. Maybe I could teach you a few things.”

I have been a Journeyman Cable Splicer since 1993.

Over the years I have learned that we all have our position that adds value to our trade. Whether you are a Groundman, Apprentice, Lineman, Cable Splicer, Operator, General Foreman, Superintendent, or another Classification everyone has a valuable roll on a crew or within a Company.

Most of us take for granted or talk down to, our Helpers and Groundman, but when we have a crew of all Journeyman, there tends to be a lot of arguing about who will perform clean up tasks. Also, I don’t know of too many Journeyman (of any kind) who wants to go out and dig holes, pole holes, splice pits, transformer vaults, etc…

I have always felt that working together as a crew and teaching those around you, regardless of how many years of experience the other person may have, has always been the best way. None of us know everything about our chosen trade and you should worry about the people who say that they do. You can almost always learn something from someone else, good or bad. Passing on bad work habits or a bad work ethic is really no longer acceptable. This holds especially true, now, for those of us who are Union members. Currently, there is more than one Presidential Candidate who would like to make every State “Right To Work”.

Don’t take for granted our fellow workers within whatever Brotherhood you belong to. Raise the bar of excellence within yourself and I guarantee that your peers will follow, or they will move on. Safety and Quality must always be at the forefront of our work. We should never leave a potential trap for those who may follow us. Besides the person who follows your poor work could be you.

Further Reading

- PILC Replacement & Cable Longevity

- Cable Splicing At The Lazy Q Ranch

- Cold Shrink Splices & Cable Jointer Training

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing cables, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

A Guide To HV Efficiency: Optimising Efficiency With Remote Monitoring (Part 3 of 3)

September 12th, 2019

A Guide To HV Efficiency Optimising Efficiency With Remote Monitoring

HV Efficiency

Optimising Efficiency With Remote Monitoring (Part 3 of 3)

-

uploaded by Chris Dodds - Thorne & Derrick Sales and Marketing Manager

In the first and second installments of the HV efficiency Blog series the advantages of upgrading to a super low loss amorphous core transformer over a traditional CRGO transformer were examined and as in the second blog defined the difference between tapping down HV transformers, and voltage management technologies such as voltage optimisation.

In the third and final part we will analyse the benefits of installing a smart distribution transformer integrated with remote monitoring capabilities when voltage management is not necessary as the voltage profile is not greater than required.

Distribution Transformer With Remote Capabilities

The smart way to transform energy

Technological advancements happen daily worldwide and connectivity is rapidly becoming attractive for all kinds of electrical equipment as there’s a shift in the direction of Industry 4.0.

The reform of distribution transformers has been slow in comparison to other electrical equipment, integrated with internet connectivity and other pairing technologies that increase visibility of asset performance and diagnostics.

Distribution transformers form a pivotal part of the HV infrastructure across the UK so the slow progress was rather unexpected. Normally, a distribution transformer is energised all day every day even when it does not carry a load, this provides the building with an acceptable electrical supply that is safe for use.

Therefore, a fault or breakdown would cause chaos to your operations and can be very hard to predict, especially when out of the normal yearly inspection periods.

Manage your energy effectively

Companies haven’t been able to update their distribution transformers up until recently. Now they are able upgrade to promote connectivity with other energy-saving, smart building control systems for full visibility of their energy use.

At present once the installation of a distribution transformer has occurred it is left as standalone equipment that doesn’t need attention or even repairing. Also it is important to remember that annual manual inspections aren’t necessary as they are not effective at giving continuous insights into the site’s energy use.

However smart distribution transformers with internet connectivity and remote monitoring capabilities, such as Powerstar SO-LO, are now available. It has never been easier to track performance thanks to the remote monitoring capabilities which can give simple to interpret information to users, showing easy to analyse top level statistics regarding state and performance of the distribution transformer.

The range of statistics can consist of grid information, conditional performance, and energy efficiency reports and, from the wide range of crucial data available, companies can use the data to discover further savings and energy efficiency optimisations to deliver the best return on investment.

Smart Transformers LV MV HV 415V – 11kV 33kV Distribution Transformers Powerstar SO-LO

Inevitably problems can a occur with a smart transformers which can cause a shutdown, however with remote monitoring this can be recognised earlier and can avert the building’s electricity supply being affected as an alert or warning is sent when a problem is detected.

The platform, which can be accessed by the relevant individuals from anywhere with a secure internet connection, will also provide reports on oil analysis, voltage, amps, phase to phase metrics, real power, power factor, core temperature, harmonic distortion, system kVA, system kWh, and GPS location for larger facilities.

By carefully checking the above factors, potential problems can be dealt with timely, both reducing downtime of the distribution transformer and the cost ramifications involved with solutions that are out of use.

We hope you enjoyed our 3 part series please see below for parts 1 and 2.

Powerstar, UK manufacturer of leading-edge smart energy solutions, has announced a new partnership with Thorne & Derrick International to help bolster its smart transformers offering for energy conscious businesses, allowing them to improve their existing medium/high voltage (MV HV) infrastructures, maximise efficiencies and reduce electricity consumption and costs with a solution that enables real-time asset monitoring to assess performance and operation.

LV MV HV Transformers

Further Reading

A Guide To HV Efficiency: The Core Of The Problem (1 of 3)

A Guide To HV Efficiency: Distribution Transformers & Voltage Management (2 of 3)

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

The 11kV Specialists

Thorne & Derrick distribute the most extensive range of 11kV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to EHV transmission and distribution voltages.

THORNE & DERRICK today welcomed Lindsay Brownless from @PowerstarVO today – look out for a series of online articles from us about their UK manufactured, online, smart #Transformers with amorphous core and remote monitoring capabilities, 415/11kV.#POWER pic.twitter.com/KfmIZoBuPJ

— Thorne & Derrick (@ThorneanDerrick) January 16, 2019

- Key 11kV Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist