Blog

Ellis Patents Centaur Cable Saddles Support London Power Tunnel 400kV Cables

March 15th, 2019

-

uploaded by - Chris Dodds Thorne & Derrick Sales/Marketing Manager

Ellis Patents Centaur Cable Saddles

Ellis Patents, the world’s leading cable manufacturer of cable cleats, has secured a £1.5million order for its Centaur cable saddles and accessories to secure high voltage cables in National Grid’s London Power Tunnels project.

Cable cleats, saddles and J type hangers can be custom manufactured to accommodate extra high voltage (EHV) power cables and steelwork support fixing.

National Grid London Power Tunnel

The project will help ensure Londoners continue to enjoy safe and reliable electricity supplies. When complete there will be over 30km of tunnels carrying high voltage cables between substations in Wimbledon, Hackney, Willesden and St John’s Wood.

Ellis’ Centaur cable saddles, which were developed specifically for use with high voltage cables, were specified by Sϋdkabel, the German manufacturers of the cables being installed in the National Grid tunnels. The order was secured on the back of recent work for National Grid and the fact Ellis Patents was able to prove the suitability and safety of its Centaur product for the project’s specification.

High Voltage Cable Cleats (HV EHV 132kV 275kV 400kV Cables) – Ellis Patents Centaur

Richard Shaw, Managing Director of Ellis, said: “This order has given us dual cause for celebration. Firstly, it’s the largest the company has ever won and secondly it demonstrates why we place so much emphasis on research and development.”

Back in 2008 Ellis launched Centaur; a heavy-duty extruded aluminium saddle cleat that had been designed and developed in-house in response to a serious safety issue surrounding the restraint of high voltage cables up to 400kV with a diameter range of 100 to 160mm.

Ellis Patents Centaur Saddle – Hinged Aluminium Overstrap

“At the time neither the British nor European Standards took into account cleats on cables of this size,” explained Richard. “This meant those specifying for such jobs were very much in the hands of the cable cleat manufacturers, who in most cases simply provided warranties for their cable support products.”

“The problem with this was that none of the products available had been short circuit tested, and so the warranties were based purely on calculations and mechanical tests. As such there was no proof the saddle cleats being used would withstand the most testing elements of the job they’d been bought for.”

Ellis Patent Centaur Cable Saddles – Tunnel Cables

Prior to launch, Ellis put the new product through the most rigorous of testing procedures.

Using cable manufactured by ABB in Sweden, the company shipped the Centaur cable saddles and ABB cable to the Netherlands where they were tested to 163 kA peak and 63 kA RMS for one second, in both 3 phase and phase to phase fault scenarios.

“We invested well over £100,000 in designing, developing, testing and bringing Centaur to market,” added Richard. “At the time this was the largest amount we’d ever invested in one new product, but we did so with confidence that it had the potential to solve a major safety issue and fill a gap in a growing market sector – something that has since been proved wholly correct.”

Ellis Patents Centaur Cable Saddle Specifications

| Part Number | Cable Range Dia. | Length Of Cable Saddle |

| Ellis Patents CS100-112/400 | 100mm – 112mm | 400mm |

| Ellis Patents CS108-122/400 | 108mm – 122mm | 400mm |

| Ellis Patents CS120-132/400 | 120mm – 132mm | 400mm |

| Ellis Patents CS128-142/400 | 128mm – 142mm | 400mm |

| Ellis Patents CS140-152/400 | 140mm – 152mm | 400mm |

| Ellis Patents CS148-162/400 | 148mm – 162mm | 400mm |

| Ellis Patents CS100-112/600 | 100mm – 112mm | 600mm |

| Ellis Patents CS108-122/600 | 108mm – 122mm | 600mm |

| Ellis Patents CS120-132/600 | 120mm – 132mm | 600mm |

| Ellis Patents CS128-142/600 | 128mm – 142mm | 600mm |

| Ellis Patents CS140-152/600 | 140mm – 152mm | 600mm |

| Ellis Patents CS148-162/600 | 148mm – 162mm | 600mm |

| Ellis Patents CS100-112/800 | 100mm – 112mm | 800mm |

| Ellis Patents CS108-122/800 | 108mm – 122mm | 800mm |

| Ellis Patents CS120-132/800 | 120mm – 132mm | 800mm |

| Ellis Patents CS128-142/800 | 128mm – 142mm | 800mm |

| Ellis Patents CS140-152/800 | 140mm – 152mm | 800mm |

| Ellis Patents CS148-162/800 | 148mm – 162mm | 800mm |

Ellis Patents Centaur cable saddles consists of an extruded and pressed aluminium saddle and a hinged aluminium overstrap, which incorporates a Low Smoke Zero Halogen Polymeric liner. The curvature of the cable saddle accommodates the thermal expansion of the cable and the ends of the saddle are flared so that the cable never comes into contact with a sharp edge under any circumstances.

INSTALLING CABLE CLEATS

Installation instructions for single way or trefoil cables using Centaur saddles manufactured by Ellis Patents:

|

|

|

|

| 1. Position the Centaur onto the mounting structure.Tighten the central M16 bolt to the structure using a 24mm socket or spanner set | 2. With care install the cable into the saddle | 3. Attach the strap to the saddle, ensuring that the liner is in place. |

4. Close the strap onto the M12 fixings. Using a 19mm socket or spanner for the head of the set screws and an 18mm socket or spanner for the flange nuts, tighten the strap to an appropriate torque for the cable |

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Transformer Oils – 11kV 33kV 66kV Substation Transformer Oil Refilling, Sampling & Analysis

March 14th, 2019

Substation Transformer Oil Refilling, Sampling & Analysis MV HV

Transformer Oils

♦ MV HV 11kV 33kV 66kV ♦

-

Guest Post by Neil Denbow (Director - Eden Transformer Oil)

The following Guest Article discusses the “end to end service” provided by Eden Transformer Oil and the benefits of their products to maintain transformer oils including MIDEL 7131 and silicon insulating liquids – Eden test, maintain and purify insulating liquids and electrical transformer oils in MV HV transformers and switchgear at 11kV, 33kV and 66kV voltages.

Background

An important and historical site in central London had been refurbished during which five silicone 11kV transformers were replaced with mineral oil filled units.

Due to the room dimensions, materials used and lack of fire prevention equipment the medium voltage substation no longer complied with BS EN 61936-1:2010.

The customer had a choice of further intrusive construction, prolonged power outages and the associated expense of installing fire prevention or whether to upgrade the transformers to a K Class insulating liquid.

The decision was taken to upgrade the existing transformers to MIDEL 7131 and Eden Transformer Oil were contracted to retrofill each transformer in-situ during one weekend day per transformer. Eden Transformer Oil was the first company in the world to be accredited MIDEL Service Partners and has carried out many MIDEL retro-fills on site.

Solution

The mineral oil was removed US specification drums for removal from site to Eden licensed waste oil storage site and over one week day per transformer the units were professionally upgraded to MIDEL 7131.

A professional upgrade requires dedicated MIDEL 7131 equipment, procedures and staff accredited by the manufacturer of MIDEL. The process includes time to allow the removal of excess transformer oil, heating the liquid to 60-80°C, further cycles of purification via vacuum dehydration plant and new gaskets.

Retrofil with MIDEL Transformer Oil

Retrofilling oil-filled MV HV transformers enables the user to enjoy the benefits of MIDEL without having the capital expense of a new transformer, lift and sift, MV HV cable jointing and prolonged productivity outage.

Replacing mineral oil insulating fluid with MIDEL in an existing medium/high voltage transformer means the MV-HV transformer doesn’t need to be removed and the retrofill procedure can be carried out in-situ and on-site.

MIDEL retrofills can be performed by a MIDEL Service Partner who will advise on the ideal MIDEL fluid depending on transformer design and location.

Transformers up to 66kV can be retrofilled with no design change needed.

Benefits of MIDEL 7131 Transformer Oils

Fire Safety

- 100% fire safety record

- High fire point >300˚C

- Classified as K-class transformer oil

- FM Global® approved MV HV transformer fluids for lower insurance premiums (supports Highly Protected Risk status)

- UL® Classified for lower insurance premiums

Environmental Protection

- Readily Biodegradable

- Non-Water Hazardous

- Non-Toxic

- Recoverable and dispersible at sea using standard methods

- Non-Volatile

- Will not evaporate into the environment

Transformer Life Extension

- Use of MIDEL can prolong cellulose lifetime

- This can in turn prolong transformer service

- Wet transformers can also be returned to service

- Suitable for 11kV 33kV 66kV transformer applications

Lower Operating Expense

- MIDEL’s superior moisture tolerance results in lower future maintenance such as purification and / or liquid changes normally associated to mineral oil thereby avoiding maintenance costs and production outages.

- Many insurance companies give improved premiums for MIDEL filled transformers

Improved Overload Resistance

- Based on the IEC 60076-14 curve an MIDEL transformer can run 15˚C hotter with the same lifetime as a mineral oil transformer

- This allows higher normal running temperature

- Temporary overload temperature can also be higher

- MIDEL fluids have a much higher flash point than mineral oil, allows safe running at higher temperatures

Suitable For Transformers In High Risk Areas

- Industrial buildings

- Residential buildings

- Public buildings (schools, hospitals etc.)

- No risk of pool fires

- Reduced clearances to other equipment or buildings (BS EN 61936-1:2010)

Onshore & Offshore Transformers 11kV 33kV 66kV | Medium & High Voltages

MIDEL retrofil checklist

| Yes | No | Do any these apply to your mineral oil transformer? |

| Would a transformer fire in this location endanger lives? | ||

| Is this transformer supplying power to or located close to equipment which is critical for business continuity? | ||

| Is the transformer in a fire-hazardous location? | ||

| Would a leak from this transformer harm the environment? | ||

| Does your company need to demonstrate positive Corporate Social Responsibility? | ||

| Has your insurance company indicated lower insurance premiums by retrofilling this transformer with MIDEL? | ||

| Would delaying the purchase of a replacement transformer be advantageous? | ||

| Do you need to avoid fire suppression system replacement? | ||

| Is this a “wet” transformer that needs recovery? | ||

| Is there a benefit in increasing the rating of this transformer? | ||

| Do you need to reduce the safety zone/space around this transformer, or install an additional transformer in the same substation? |

Eden Transformer Oils

About Us

Eden Transformer Oil Ltd was formed by Alan Denbow and Eddie Gregory in August 1985.

Former employees of Burmah Castrol, they realised that the vast majority of electrical engineers were simply replacing expensive transformer oil without fully appreciating the additional technical benefits of purification to the electrical equipment that Eden could achieve using a more convenient solution at a significantly lower cost.

In more recent years the treatment of transformer oil is the first choice for a cost effective and efficient maintenance program: the increasing cost of new oil, the importance of productivity and equipment downtime, coupled with the environmental benefits of avoiding the transportation of hazardous waste and use of virgin products, are all part of the equation – this applies to medium/high voltage (MV-HV) applications distributing electrical power at 11kV, 33kV and up to 66kV.

As well as providing on-site transformer oil treatment, if needed, Eden can supply and install new or reconditioned insulating liquid and provide all of the on and off-site sampling and analysis to ensure transformers are supervised and maintained according to British Standards (BS EN 60422:2013) and insurance underwriters requirements.

Since August 1985 Eden have been testing and maintaining the insulating liquids in transformers and switchgear in the United Kingdom, Belgium, France and Germany.

Eden provides end-to-end MV HV services and products to maintain transformer oil, MIDEL 7131 and silicon insulating liquid. On their webpage “Why Maintain Oil”, they highlight how Eden can provide a safe, economical and environmentally sound solution to maintaining transformers.

Eden do not just process insulating liquid, but they can also supply new liquids, breathers and consumables used for maintaining transformers.

Whether you are an end user, Electrical Engineering Company, Facilities Manager or Senior Authorised Person, Eden will be able to assist you in the testing and maintenance of your liquid insulated electrical equipment for LV (Low), MV (Medium) and HV (High Voltage) applications up to 66kV.

Transformer Oils | Medium & High Voltage MV HV | 11kV 33kV 66kV

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Ellis Patents No-Bolts Cable Cleats Improve Electrical Safety Of Rail Cable Installations

March 7th, 2019

Ellis Patents No-Bolts Cable Cleats Improve Electrical Safety Of Rail Cable Installations

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cable Cleats For Rail Cables

Thorne & Derrick International, based in the UK, stock and distribute the complete range of cable cleats and cable hangers manufactured by Ellis Patents including No Bolt cleats for short circuit retention and cable protection of LV (Low Voltage), MV (Medium Voltage) and HV (High Voltage) rail cable systems in single-way or trefoil installation.

Ellis Patents are market-leading innovators and manufacturers of cable cleats and clamps for high specification and high performance rail cable management systems including fire-resistant cleats with PADS Network Rail approvals.

Ellis Patents has evolved from being a manufacturer of traditional, standard cable cleats to a market leading innovator; solving installation and safety issues for the likes of Siemens and Balfour Beatty – an example was the development of the Ellis No Bolt cleat in response to a significant health and safety concern for the UK’s rail network owner, Network Rail. Here’s the story as told by Richard Shaw (Managing Director – Ellis Patents UK) in Electrical Engineering magazine in March last year.

For a long time we stressed the importance of correctly specified cable cleats, said Richard.

The key fact being that without correct specification all a cable cleat will do is provide a false sense of security. It would be like fitting seat belts to your car that might work.

Our view today is that the market is well aware of the need for correctly specified cleats.

Instead, our focus is now on what, and how we sell – a change that was first born out of a growing demand for project specific solutions.

I firmly believe that the extent of this drive to become the industry innovator can be encapsulated by just one product – the Ellis No Bolts Cable Cleat, which was developed in response to a major safety concern raised by Network Rail.

The Ellis Patents No Bolts Cleat was designed to a specific remit from Network Rail. Contractors had been injured when working live on cables where metallic components in the cable fixings tore through the cable sheath. Network Rail’s design brief for a new-style fixing specified no metal parts and no tools required for installation and maintenance. The No Bolts Cleat was fast-tracked successfully through the development stages using rapid prototyping technology and achieved its Network Rail PADs approval within a year.

Ellis Patents No Bolts Cable Cleats

The Network Rail problem was to do with outer sheaths of live cables being breached during the installation of cable runs onto existing cleating infrastructure. The nub of the issue was that in order to accommodate new cables and cable cleats, existing cable clamps had to be dismantled, and longer bolts fed through to allow for the stacking of the new cable clamps.

order to accommodate new cables and cable cleats, existing cable clamps had to be dismantled, and longer bolts fed through to allow for the stacking of the new cable clamps.

The existing live cable then had to be placed back into the old cable clamps, and it was during this stage of the process that the long bolts were snagging the cable and allowing current to track into the containment system. This resulted in a number of earth faults and at least one engineer receiving a major electric shock.

Ellis Patents No-Bolts Cable Cleats Installation Guide

Having been alerted of the issue our immediate thought was that the best way to resolve the problem was with a stackable cable cleat product, which would allow additional cable runs to be added without any need to disturb existing live cables, explained Richard. And unlike many other new product ideas, this initial thought was never usurped by a better one.

As the name suggests, the Ellis No Bolts cleat has no bolts. Instead it’s fastened with two keepers that lock into the top clamp and secure it into position within the base clamp – a process that is tool as well as bolt free. The stackable nature of the cable cleats is made possible by a recess in the top moulding, and a twist fit foot on the base moulding, which lock together with a simple quarter turn hand operation.

And the design innovation doesn’t stop with the cable cleat’s mechanics. The chosen manufacturing material by Ellis Patents is a high strength nylon specifically formulated to have sufficient low smoke properties to meet London Underground 1-085 specification.

And because of the non-metallic design, the Ellis cleat is impervious to the bi-metallic corrosion that causes problems in any number of harsh environments.

The crowning glory of the whole process was that the Ellis No Bolts cleat became the first cable cleat to be granted Network Rail’s very own PADs approval.

The Ellis No Bolts cleat, from cable cleat and clamp innovator, Ellis Patents is an all polymeric stackable cable management product that is the first ever cable cleat to be granted PADS approval by Network Rail.

- NETWORK RAIL PADS APPROVED CABLE CLEATS

- PADS 0111/120321 18-22mm Cable Cleat – Ellis NBC18-22

- PADS 0111/120332 20-26mm Cable Cleat – Ellis NBC20-26

- PADS 0111/120323 24-30mm Cable Cleat – Ellis NBC24-30

- PADS 0111/120324 28-34mm Cable Cleat – Ellis NBC28-34

- PADS 0111/120325 32-39mm Cable Cleat – Ellis NBC32-39

- PADS 0111/120133 37-47mm Cable Cleat – Ellis NBC37-47

- PADS 0111/120134 45-55mm Cable Cleat – Ellis NBC45-55

Ellis Patents take enormous pride in their innovative approach to cable cleat product development, and the way we are now seen as market innovators in all of our export markets, added Richard. The Ellis No Bolts cleat really is the perfect example of what we can achieve. Not only does it meet a specific customer requirement, it also tackles and addresses an installation and maintenance issue that affects LV MV HV electrical installations across the world and delivers the best possible commercial solution for such installations.

Since its launch, the Ellis No Bolt cable cleat has been named Innovative Industrial Product of the Year at the Electrical Industry Awards, and Business Innovation of the Year at the York Press Business Awards – the cable cleats are now being specified by rail network owners on a regular basis and was recently specified in the UK for the first time for use in the £800 million Wessex Rail Alliance’s Waterloo and Southwest upgrade project.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Waveform Straight Joint – 3 Core 185sqmm – 95sqmm Cables

March 5th, 2019

- Application: Waveform Straight Joint – 3 Core 185sqmm – 95sqmm Cables

- Cable Type: Wavecon Straight Joint

- Cable Jointer: Damien Davis

- Photo By David Lane Technical Trainer UKPS

Waveform Straight Joint

Thorne & Derrick are Specialist Distributors to the UK Distribution Network Operators and ICP sector providing Waveform Cables, Accessories & Electrical Equipmentfor LV MV & HV Networks – the DNO approved cables are installed for adoptable networks and contestable connections on following DNO’s: Northern Powergrid (NPG), ENW (Electricity North West), Western Power Distribution (WPD), Scottish Power Energy Networks (SPEN), Scottish & Southern Energy (SSE) and United Kingdom Power Networks (UKPN).

Typical common aluminium conductors from stock are 95sqmm, 185sqmm and 300sqmm.

Waveform cables are XLPE insulated and PVC sheathed power cables used for the supply of LV electrical energy 600/1000V – cables are suitable for installations in the open air, in underground and water, indoor and in cable ducts. The concentric conductor is allowed for use as neutral, protective or earthed conductor.

Waveform Straight Joint – 3 Core 185sqmm – 95sqmm Cables

Waveform Cable Accessories

T&D UK distribute an extensive range of low voltage utility waveform power cables including cable joints, cable cleats, cable glands and accessories required to lay and install waveform cables to BS7870.

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Sealing Cable Ducts, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

arrow: Visit Power Blog

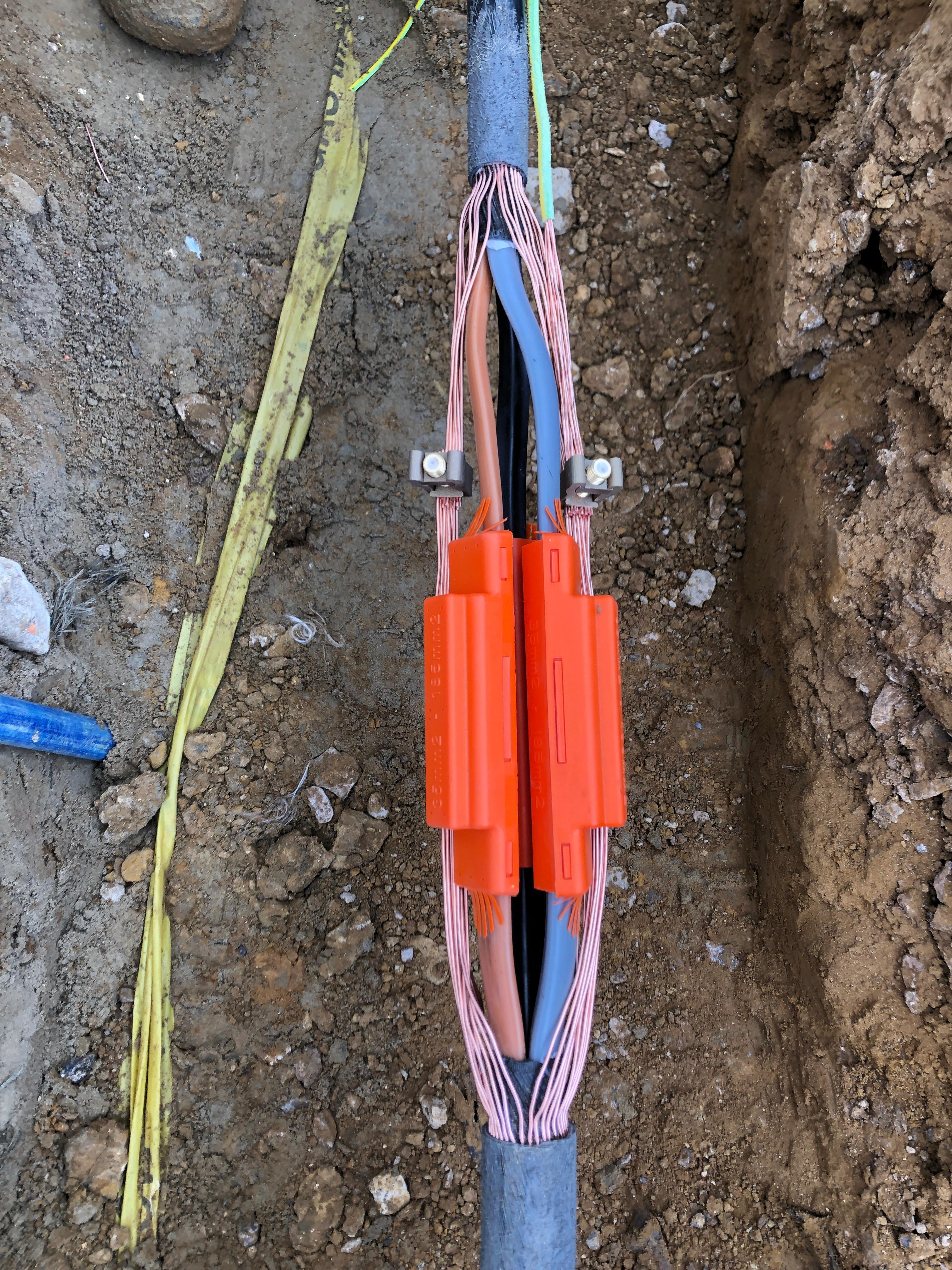

LV Cable Diversion 4 Core PILC to 4 Core Wavecon Straight Joint

March 5th, 2019

- Application: LV Cable Diversion 4 Core PILC to 4 Core Wavecon Straight Joint

- Cable Type: Wavecon Straight Joint

- Cable Jointer: Lee Richards Self Employed Cable Jointer

Jointing Waveform Cables

Here Lee Richards is shown carrying out some LV cable diversions for a private network customer – the installation required 4 x PILC to 4 core Wavecon joints and the cable jointing was assisted by Simon Pearson (Freelance HV SAP Electrical Engineer).

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Sealing Cable Ducts, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

arrow: Visit Power Blog