Blog

June 14th, 2018

Cembre RHU131-C Crimping Presshead

Cembre RHU131-C

Thorne & Derrick International are Main UK Stockists and Suppliers of Cembre tools including crimping and cutting types for all constructions of LV MV HV cable including medium/high voltage 11kV/33kV power cables.

The following short article provides useful instructions about how to crimp aluminium conductor cables using Cembre model RHU131-C presshead – with built in safety valve the tool with by-pass the oil supply when maximum pressure has been reached.

The following excerpts are taken from the Operating Manual of Cembre RHU131-C hydraulic presshead crimping tool – however this information applies to the following tool model variants Cembre RHU131.

Cembre RHU131-C hydraulic crimping head is suitable for installing the same range of cable lugs, crimp connectors and terminals as Cembre HT 131-UC

For competitive prices, stock availability and technical advice about the Cembre RHU131-C tool please do not hesitate to contact us.

Crimping Aluminium Cables

Hydraulic Crimping Presshead Accessories

Pre-Rounding Conductor (For Sectoral Cables)

Ensure all aluminium conductors are thoroughly cleaned using approved and suitable cable cleaning wipes prior to crimping.

From the table select the Cembre adaptors and pre-rounding dies for the appropriate conductor size.

Insert the upper adaptor Cembre AU130- and lower adaptor AC130–P into the head as per below.

Insert the pre-rounding die (94) into the AC130–P adaptor.

Position the conductor into the pre-rounding die (95) and locate the pre-rounding die (95) in the adaptor AU130.

Ensure that the pre-rounding die is correctly located in the adaptor with its upper slot in line with the internal adaptor pins.

Operate the hydraulic foot pump until the dies are fully closed, such as Cembre PO7000.

Release the hydraulic pressure and remove the compacted round conductor.

Die Insertion

Connector Cable Crimping

Remove the pre-rounding dies and the adaptor AC130–P from the presshead.

From the table select the containing die and indentor recommended for the conductor size.

Insert the indentor into the ram (09).

Insert conductor into the connector.

Locate the connector into the containing Cembre die then locate the containing die in the adaptor.

Commence indent crimping from the barrel end for both splices and terminals following the sequence shown below:

- For every operation ensure the die is correctly located in the adaptor with its upper slots in line with the internal adaptor pins

- Each indenting operation is completed when indentor and die are fully closed; it is recommended to continue pumping until the maximum pressure valve is activated and a “click” is heard

Adaptor Fitting & Removal

- Insert the upper adaptor AU130 (98) into the U-fork head (14) until secured by the locators (15).To remove the adaptor from the U-fork head, push the adaptor from the locators and slide out

- To insert the adaptor AC130–P(91), press the die release pin (12).

Insert the adaptor into the seat of the ram (09), until secured by the retaining pin (11). To facilitate this operation, an advancement of 3÷4 mm (0.11 – 0.16 in.) of the ram (09) is suggested. To remove the adaptor, press the die release pin (12) and slide the adaptor from the ram (09).

Crimping Dies, Indentors, Pre-Rounding Dies – Fitting & Removal

- The containing die (96) and upper pre-rounding die (95): are located in the adaptor AU130-… (98) by grooves in the upper face.

- The lower pre-rounding die (94): is inserted or removed from the adaptor AC130-P (91) by pulling the release button (92).

- The indentor PS130…/E (93): is inserted into the seat on the ram (09)

Guide To The Selection Of Cable Crimping Accessories

| Conductor Section Aluminium (sqmm) |

Upper Adaptor |

Lower Adaptor |

Pre-rounding Die |

Indentor Die |

Containing Die |

| Short |

Long |

Universal |

|

|

|

|

|

|

|

|

|

| 10-16 |

AU 130-150 |

AC 130-P |

– |

PS130-35/E |

MV 35 |

MVM 35 |

– |

MUA 35 |

| 25 |

UP 130-5 |

| 35 |

UP 130-35 |

| 50 |

UP 130-50 |

PS 130-95/E |

MV 95 |

MVM 95 |

MVC 95 |

MUA 95 |

| 70 |

UP 130-70 |

| 95 |

UP 130-95 |

| 120 |

UP 130-120 |

PS 130-150/E |

MV 150 |

MVM 150 |

MVC 150 |

MUA 150 |

| 150 |

UP 130-150 |

| 185 |

AU 130-240 |

UP 130-185 |

PS 130-240/E |

MV 240 |

MVM 240 |

MVC 240 |

MUA 240 |

| 240 |

UP 130-240 |

| 300* |

UP 130-300 |

MUA 300-34 |

*Outside diameter of connector 34mm

Cutting & Crimping Tools

Cable Crimping & Cutting Tools

This post is from a series of articles written to provide advice and guidance on the care and servicing of Cembre cable cutting and crimping tools.

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Cold Shrink

June 13th, 2018

Cembre ECW-H3D Presshead Die Sets

Cembre ECW-H3D

Thorne & Derrick International are Main UK Stockists and Suppliers of Cembre tools including crimping and cutting types for all constructions of LV MV HV cable including medium/high voltage 11kV/33kV power cables.

The following short article provides useful instructions about how to correctly select and position dies in the Cembre presshead model ECW-H3D – the tool is used primarily to joint and terminate lugs or connectors on LV MV HV cables including 11kV/33kV medium/high voltage electrical systems with a range of 500-630sqmm conductors.

The following excerpts are taken from the Operating Manual of Cembre ECW-H3D hydraulic presshead crimping tool.

Cembre ECW-H3D comes complete with complete with male quick automatic coupler for connection to a hydraulic pump with a working pressure of 10,000 psi max.

For competitive prices, stock availability and technical advice about the Cembre ECW-H3D tool please do not hesitate to contact us.

Cembre ECW-H3D

Selecting & Positioning Die Sets

Fig 1 Die Assembly & Positioning

Die Assembly (Fig 1)

- Dedicated Dies

- Select the appropriate die set for the connector to be crimped using ECW-H3D tool

- Extract the die retaining pin (09) from the tool head

- Insert the lower die (26b) and align the groove (30) in the die, with the guide pins (15) in the crimp tool presshead

- Insert the upper die (26a) into the tool head

- Insert the die retaining pin (09) in the head and through the upper die. Ensure the spring loaded pin (10) is fully released

- Semi-circular Dies

- Select the appropriate die set for the connector to be crimped using ECW-H3D tool

- Extract the die retaining pin (09) from the tool head

- Insert the lower half of adapter Cembre AU230-130D (31b) and align the groove (30) in the adapter, with the guide pins (15) in the head

- Insert the upper half of the adapter Cembre AU230-130D (31a) into the head

- Insert the die retaining pin (09) into the head and through the adapter. Ensure the spring loaded pin (10) is fully released

- Press pin (35) on lower part of adapter, AU230-130D and insert one half of the die set until secured by locking pin (34)

- Press pin (32) on upper half of adapter, AU230-130D and insert the other half of the die set until secured by locking pin (33)

♦ Warning: Before carrying out further operations make sure the die-stop pin is completely inserted; a partial insertion may cause damage to the head.

Dies Positioning

- Insert the conductor into the connector.

- Locate the connector between the dies at the desired crimp position. – Operate the pump until the dies touch the connector barrel

♦ Warning: Make sure that dies are exactly positioned on the area to be crimped; otherwise re-open dies and reposition the connector.

Cutting & Crimping Tools

Cable Crimping & Cutting Tools

This post is from a series of articles written to provide advice and guidance on the care and servicing of Cembre cable cutting and crimping tools.

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Cold Shrink

June 13th, 2018

Cembre TC055 Cutting Head

Cembre TC055

Thorne & Derrick International are Main UK Stockists and Suppliers of Cembre tools including crimping and cutting types for all constructions of LV MV HV cable including medium/high voltage 11kV/33kV power cables.

The following short article provides useful instructions about how to replace the cable cutting tool blades of the Cembre TC055 – this cutter has an application range suitable for cutting copper and aluminium cables having a maximum diameter of 55mm.

Note: TC055 cutting head features the same cutting capability as the Cembre HT-TC055 cable cutting tool.

The following excerpts are taken from the Operating Manual of Cembre TC055.

Cembre TC055 is a hydraulic cutting head tool developing a maximum pressure of 10,000 psi for cable and conductor cutting of LV MV HV cables.

For competitive prices, stock availability and technical advice about the Cembre HT-TC055 tool please do not hesitate to contact us.

Cable Cutting Blade Replacement

Cembre TC055

Fig 2 & Fig 3 Cembre TC055 Blade Replacement

The following instructions should be read in conjunction with the image above.

After extended use the blades of the Cembre TC055 may lose their cutting edge.

Replace the blades as follows:

Lower Cable Cutting Blade

Remove locking pin (4) and open the cutting tool head.

Operate the pump to advance the lower cutter blade (24) until split pins (22 and 23) are visible on the ram (18).

Remove split pins (22 and 23) using a drift and remove the lower cutter blade.

Insert the new blade and secure with spring pins.

♦ Warning: Before closing the cutting tool head release the oil pressure and retract the lower cutter blade otherwise the blade may hit the lower blade edge and damage it.

Upper Cable Cutting Blade

With the lower cutter blade fully retracted, the tool head closed and the locking pin (4) fully secured, hold the tool on the blade spacer (1) or (26) in a bench vice (Fig 3).

With a 6mm wrench, unscrew 4 screws (28), remove the two holding plates (29) and the upper cutter blade (25) noting the position of the cutting edge bevel.

Insert the new cutting blade, noting the position of the cutting edge bevel.

Fit the 2 holding plates (29) and secure with 4 screws (28) with relevant washer (30).

Cutting & Crimping Tools

Cable Crimping & Cutting Tools

This post is from a series of articles written to provide advice and guidance on the care and servicing of Cembre cable cutting and crimping tools.

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Cold Shrink

June 13th, 2018

Cembre PO7000 Hydraulic Foot Pump

Thorne & Derrick International are Main UK Stockists and Suppliers of Cembre tools including crimping and cutting types for all constructions of LV MV HV cable including medium/high voltage 11kV/33kV power cables.

The following short article provides useful instructions about how to correctly maintain the flexible hose in the Cembre hydraulic PO7000 hydraulic pump – supplied with 10 foot long high pressure flexible hose complete with an automatic, female, quick-coupler suitable for connection to a Cembre hydraulic crimping or cutting head.

The following excerpts are taken from the Operating Manual of Cembre PO700.

Cembre PO700 is a foot operated double speed hydraulic pump developing a maximum pressure of 10,000 psi for installing cable crimps, lugs and connectors.

Maintenance Of Flexible Hose

Cembre PO7000 Pump stored in plastic case VAL-P21.

The flexible hose is designed for high-pressure operation and should not be tightly bent, knotted, kinked or squashed.

♦ Warning: Take care when storing the pump in the plastic case, the hose should be coiled in wide loops.

High pressure flexible hoses are subject to a natural ageing process which can result in a reduction in performance potentially affecting safety of the operator and functionality of the hydraulic pump. In order to ensure safe use of the PO7000, Cembre recommends replacing the hose within 10 years from the date printed on the tool fittings. Pumps in the PO7000 range are supplied with a standard or non-conductive hose.

♦ Warning: Before using the pump always check the integrity of the flexible hose and the quick couplers making sure there are no abrasions, cuts, deformations or swellings.

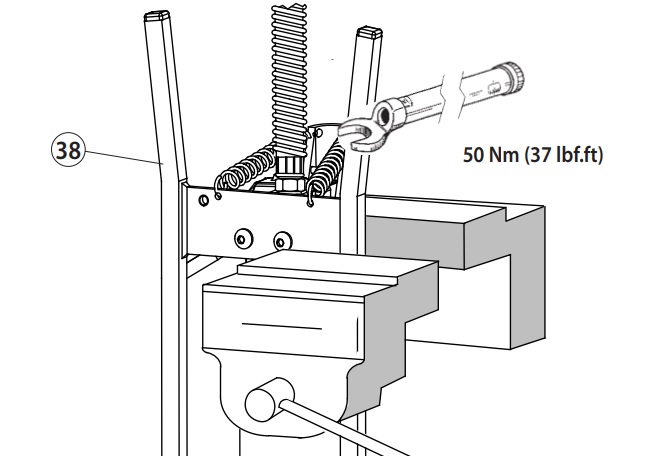

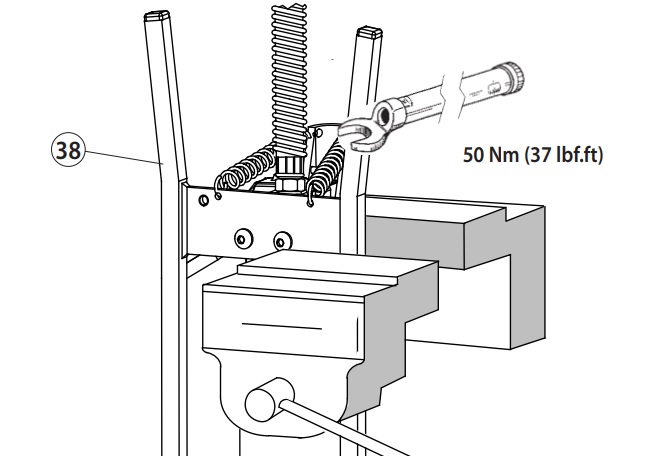

Fig 8 Hydraulic Pump Position For Replacement Of High Pressure Hose

Replacement Of The Pressure Hose

- Hold the pump base (38) in a vice, keeping the hose above the level of the vice

- Using a 19 mm fl at spanner, unscrew the hose from the pump body, while holding the coiled hose

- Carefully clean the thread of the pump body to remove any residual sealing materials

- Restore the gasket (tefl on tape) on the (male) thread of the new hose

- Connect the new hose, tightening the relevant nut to the correct torque ratio: 50 Nm (37 lbf.ft)

- Eliminate air in the hose as follows: unlock the pedal from the latch

- Depress the ball of the female quick coupler fitted to the end of the hose and pump slowly several times, until the oil flows

- Check the oil level and top up as described in operating manual

Cutting & Crimping Tools

Cable Crimping & Cutting Tools

This post is from a series of articles written to provide advice and guidance on the care and servicing of Cembre cable cutting and crimping tools.

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Cold Shrink

June 13th, 2018

Cembre TC120 Cutting Head

Cembre TC120

Thorne & Derrick International are Main UK Stockists and Suppliers of Cembre tools including crimping and cutting types for all constructions of LV MV HV cable including medium/high voltage 11kV/33kV power cables.

The following short article provides useful instructions about how to correctly clean and store the Cembre model TC120 cutting head – the head is designed for cutting copper, aluminium and telephone cables having a maximum diameter of 120mm.

♦ Warning: Do not attempt to cut steel ropes or steel reinforced cables (ACSR)

For competitive prices, stock availability and technical advice about the Cembre TC120 tool please do not hesitate to contact us.

Cembre TC120

How to Correctly Clean & Store

Cutting Tool Storage

Cembre TC120 provided with a special steel case VAL 120 to safely transport the cutting head and prevent damage

♦ Warning: Oil pressure inside the TC120 cutting head must always be completely released before disconnecting the head from the hose.

♦ Warning: All maintenance operations must be performed with the head disconnected from the hydraulic pump hose.

The Cembre TC120 cutting head is robust and requires very little daily maintenance – ensuring you follow the instructions below will help to maintain the optimum performance of the tool by cleaning and storing correctly:

Accurate Cutting Head Cleaning

Dust, sand and dirt are a danger for any hydraulic device. It is essential that after every use the cable crimping or cutting tool should be wiped with a clean cloth removing all residue paying special attention to pivots and moveable joints

Replacement Of The Automatic Quick Male Coupler

- To replace the automatic coupler from Cembre TC120 proceed as follows:

- Remove the old coupler.

- Carefully clean the thread to remove old sealant.

- Apply teflon tape to the thread.

- Fit the new coupler and tighten to 30 Nm (22 lbf ft)

Steel Carry Case VAL TC120

Storage

When not in use, the Cembre TC120 tool should be stored and transported in the steel case to prevent damage.

The steel case (VAL TC120) has the following dimensions 590x209x84mm (height) and weighs 4.9kg.

Cutting & Crimping Tools

Cable Crimping & Cutting Tools

This post is from a series of articles written to provide advice and guidance on the care and servicing of Cembre cable cutting and crimping tools.

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Cold Shrink