Blog

Advanced Power Services Awarded 3M Qualified Electrical Construction Contractor Accreditation (QECC)

July 4th, 2022

3M QECC

Advanced Power Services is the first company in the UK to be awarded the Qualified Electrical Construction Contractor Accreditation (QECC) from 3M.

Advanced Power Services is the first of a very small number of companies across the UK to be selected by 3M based on qualifications, experience and assessments on skills.

Since 1985, Thorne & Derrick have been Approved Distributors for 3M Electrical Products (LV HV) and whilst the competitive supply of product from stock on short lead times is essential to the contractor it is equally vital that 3M product reputation is preserved through the correct installation of products in accordance with 3M recommendations.

Until now the market has been largely unregulated until the 3M QECC launch. Advanced Power Services are proud to represent 3M in the marketplace and pleased to champion their first adopter of the QECC warranty program.

Advanced Power Services qualified and skilled Jointing Teams have completed in-depth assessments along with theoretical training on each 3M Medium Voltage product family that qualifies for the warranty.

Advanced Power Services qualified and skilled Jointing Teams have completed in-depth assessments along with theoretical training on each 3M Medium Voltage product family that qualifies for the warranty.

Training included Cable Theory, Joint Theory, Termination Theory, 3M Material Science and hands-on training & assessments. In addition to this, 3M will also provide continuous updates and refresher training as per the market requirements.

The QECC Certification enables Advanced Power Services to issue a 20-year product warranty to their clients on each new installation completed by our certified Jointing Teams.

Lee Burrell, Managing Director of Advanced Power Services said;

“I have been working with 3M now for a many years providing feedback on their products and over time we have built up a very good relationship. This new programme we hope will bring confidence to clients that our in-house, experienced jointers installing products on their network are competent, skilled, trained and qualified. This programme will strengthen our clients’ and consumers’ confidence when utilising our services on their networks and investing long term in their assets.”

This will change the landscape for Medium Voltage products.

Who would not want a 20-Year Warranty that provides value for money and peace of mind on their investment?

This will be invaluable for maintenance departments and private networks as any product failure will be covered by the 3M QECC Extended Warranty.

Each 3M Medium Voltage product family that qualifies for the warranty will be recorded in detail so that they can be properly referenced in the unlikely event of a failure to assist in any investigation.

As part of the QECC programme, contractors receive in-depth 3M product and technology training, including theoretical training on 11kV, 22kV, 33kV and 52kV joints, terminations and Separable Connectors.

Advanced Power Services is excited to be able to offer this amazing 20-Year Warranty to all their existing clients and welcomes new relationships with those interested in our cable jointing and testing services.

Choosing a 3M QECC certificated company allows you to have peace of mind that the contractors you’re working with are trained to the highest level and backed by an extended 3M 20-year product warranty.

Advanced Power Services

Advanced Power Services was established as a specialist electrical contractor in July 2010. Our ambition was to create a team of committed cable jointing and testing professionals that fully understands their clients’ needs and are dedicated to delivering exceptional service, safely and within budget.

Advanced Power Services offer Cable Jointing, Terminations, Commissioning and Fault Rectification Services for EHV, 132kV ,275kV, 400kV, HV 66kV and MV, 11kV, 22kV, 25kV, 33kV, 52kV throughout the UK and overseas. Our Jointing and Testing Teams are experienced in working within the Railway Networks, Infrastructure Networks, Renewable Energy, Private Networks, Datacentres and Shipping Industries.

For further details please contact Business Development Manager, Heather Andrews at [email protected] or 07754 855938.

3M Electrical | Scotchlok | ColdShrink | Scotchcast Resin | Scotch Electrical Tapes

Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX and Shrink Polymer Systems.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at MV HV.

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

ATEX | High Voltage Power, Lighting & Heating for Substation Battery Rooms

June 30th, 2022

Image Credit: Eclipse Power Networks

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick, Specialist UK Distributors of LV HV Jointing, Earthing, Substation & Electrical Eqpt up to 66kV, provide expert technical specification, customer support and product supply from stock of an extensive range of Hazardous Area Electrical Equipment – this includes Power, Heating & Lighting products with ATEX Certification for installation in Substation Battery Rooms.

Substation Battery Rooms

What’s The Risk?

Explosive Flammable Gases/Vapours

UK DNO’s detail safe working procedures and rules in their Document Manuals to be followed when working on alkaline or acid substation batteries and storage rooms located within primary network medium/high voltage substations (MV HV).

Lead-acid type batteries release potentially explosive hydrogen gas when charging – this is the primary explosive risk associated with medium/high voltage substations.

ATEX

Consequently, these worksite locations are classified as hazardous area Zones according to the ATEX Directive – a “hazardous area” is defined as an area in which the atmosphere contains, or may contain in sufficient quantities, flammable or explosive gases, dusts or vapours. The Zone designation depends on the level of risk and likelihood of flammable gas, vapour or mist forming during normal operation.

ATEX is an abbreviation of “Atmospheres Explosibles” and is a set of European Union regulations that are designed to ensure the safety of electrical products being used in potentially explosive atmospheres.

Thorne & Derrick, Experts in Equipment for Explosive Atmospheres, provide Zone 1/Zone 2 (Flammable Gas) ATEX Compliant electrical equipment for installation in substations and battery rooms to provide heating, lighting and power distribution.

The Danger Zones

The main Dangers to Persons carrying out work or testing on batteries and chargers are electric shock, explosion or burns arising from the ignition of flammable gas which is emitted by cells during the charging process.

Flammable gas can be ignited by naked flames (eg “hot-working” by cable jointers), cigarettes or by sparks if cell terminals are accidentally earthed or shorted together.

This short-circuiting releases dangerous levels of heat, light and arc energy.

Consequently, electrical equipment installed in MV HV substation battery rooms should be Zone 1 or Zone 2 certified according to ATEX Directive for safe installation in such potentially explosive atmospheres.

♦ Primary Network Substation: a 132kV, 66kV, 33kV or 25kV substation including directly associated 66kV, 33kV, 25kV, 11kV and 6.6kV switchboards at transformer stations (Definition: WPD Engineering Specification EE Spec 25/5).

lIGHT | hEAT | pOWER

How We Can Help?

♦ Lighting – T&D can provide lighting designs to ensure lux levels are achieved in line with regulations, fittings are located correctly and meet certification requirements – we provide a comprehensive hazardous area lighting system design service.

PIR Motion Sensors

♦ Heating – T&D can provide battery room heat loss calculations to ensure the correct heaters are specified and meet ATEX certification requirements to provide adequate comfort heating to the substation.

♦ Power – T&D can specify and supply from stocks Joints & Terminations for the connection and energisation of high voltage power cables to switchgear and transformers up to 66kV.

- Raytec | Light Fittings

- Abtech | Junction Boxes

- Craig & Derricott | Isolators

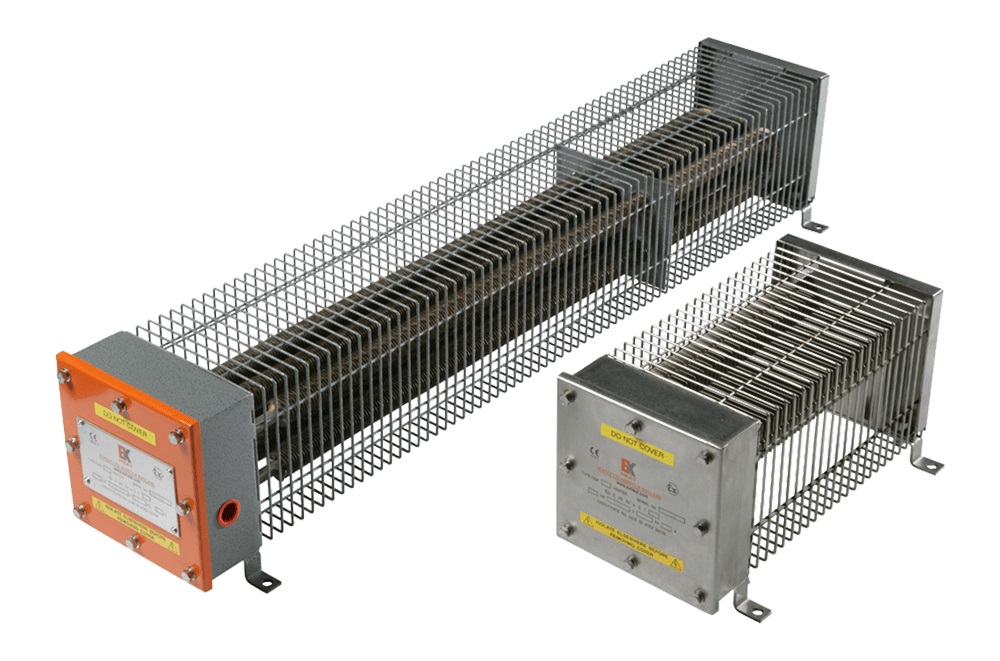

- EXHEAT | Heaters

- Marechal | Plug & Sockets

- Crowcon | Gas Detectors

- Technor | ATEX Enclosures & Control Equipment

- Roxtec | Cable Transits

- Hawke | Cable Glands

The ATEX PIR detector is a movement sensor that detects a moving body heat (infrared) signature and provides an alarm output signal to the alarm/monitoring system accordingly within the substation battery room.

Extensive Stocks | Competitive Prices | HV Joints Terminations Connectors for GIS

Lighting Design & Specification Services

The SPARTAN range of Standard & Emergency ATEX Certified light fittings manufactured by Raytec is designed for lighting hazardous areas which require high performance, high reliability, energy-efficient brilliant “White-Light” illumination using latest LED technology.

Pictured | Stocked by Thorne & Derrick, the SPARTAN WL168 Zone 2 Intelligent Emergency Linear Luminaires improve light levels on this substation battery room site. On this project, the lighting brief was to replace x 4 existing 2x58W fluorescent Zone 2 fittings. The customer originally requested 5ft LED Linear alternatives, but due to SPARTAN’s high lumen output and unique modular design – which would make any ongoing maintenance quick and easy – SPARTAN WL168 provided the ideal solution. Discuss your requirements with us.

The EXHEAT range of FAW heaters provides versatile air warming to battery rooms with 250W to 3kW ratings – the electric heaters are certified for use in hazardous areas where the explosive atmosphere is classified as a Zone 1 or 2 (IIA, IIB, IIC) gas group.

Blogs

- Jointing Cables In Hazardous Areas According To The ATEX Directive

- Sealing Cable Ducts In Hazardous Areas According To ATEX Directive

- The Temporary Hazardous Area Floodlight – Wolf LinkEx WF-300 XL LED Floodlite

- Confined Spaces – Powering, Lighting & Heating Explosive Atmospheres

- 132kV 33kV 11kV DNO Substations – A Guide To Cable Sealing By Roxtec

- Can Arc Flash Clothing Save Utility Workers Lives?

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

GRP Cable Containment | From LV DC to 25kV Rail Cable Containment

June 28th, 2022

Article Written by Andrew Sillars, Rail Sector Manager, Wibe Group UK Ltd

GRP Cable Containment

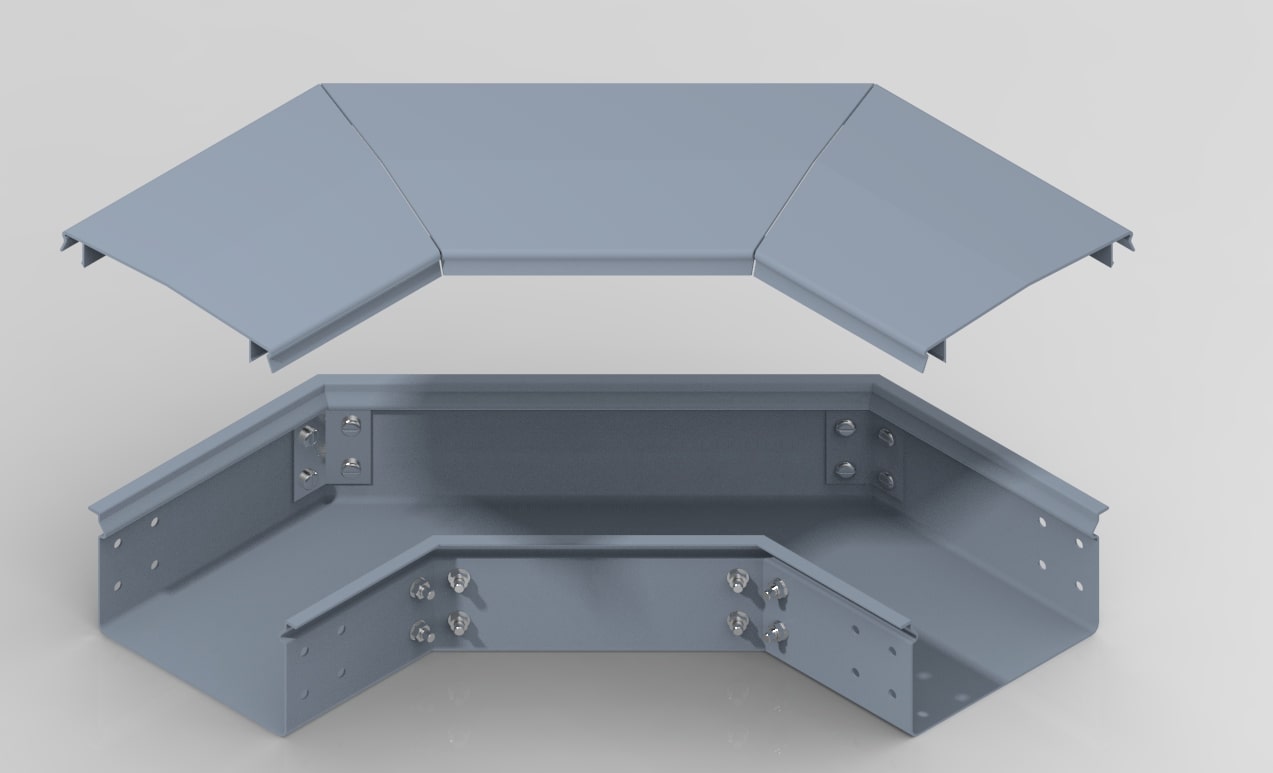

Having supported the specification of Glass Reinforced Polymer cable containment since 2005, I have experienced its unique features such as lightweight, long-life durability, no deburring, no earth bonding and many more. All these advantages of GRP Cable Containment support a cheaper, quicker and easier-to-install system that gives a true fit-and-forget solution.

Thorne & Derrick are an approved distributor of the MITA brand, now powered by Wibe Group who are a RISQS approved supplier. Andrew together with Wibe are proud to introduce our extensive cable support offer which includes Glass Reinforced Polymer GRP cable ladders, CABSYS cable trays and elevated cable troughing with accessories.

GRP Elevated Cable Troughing | Containment System for Rail

GRP elevated cable troughing is an especially useful containment system for rail.

Ground Level Troughing (GLT) is often used in signalling and telecoms schemes for the cable connections to lineside equipment such as points, train detection, signals and radio sites. However, in many places, GLT cannot be used due to the ground profile and steep embankments and cuttings. GRP is an ideal alternative for such locations and it is also essential for large current-carrying power cables.

High quality manufacture

Mita GRP is produced by pultrusion technology. This uses a combination of unidirectional and cross-strand glass mat which is resin-impregnated and pulled through a hot die to produce a very solid, structurally sound profile with excellent mechanical rigidity unlike other moulded systems.

Mita GRP does not contract or expand with heat causing the troughing route to distort. It is produced with a high quality of manufacture and modified by the use of additives to the resin, and with protection from ultra-violet light.

This year, with the launch of the new GRP GMAXR 6m troughing range, which allows a 6m post span, Mita GRP becomes a full offer with its 3m or 6m lengths to meet the needs of every application in the most cost-effective way.

Features and benefits

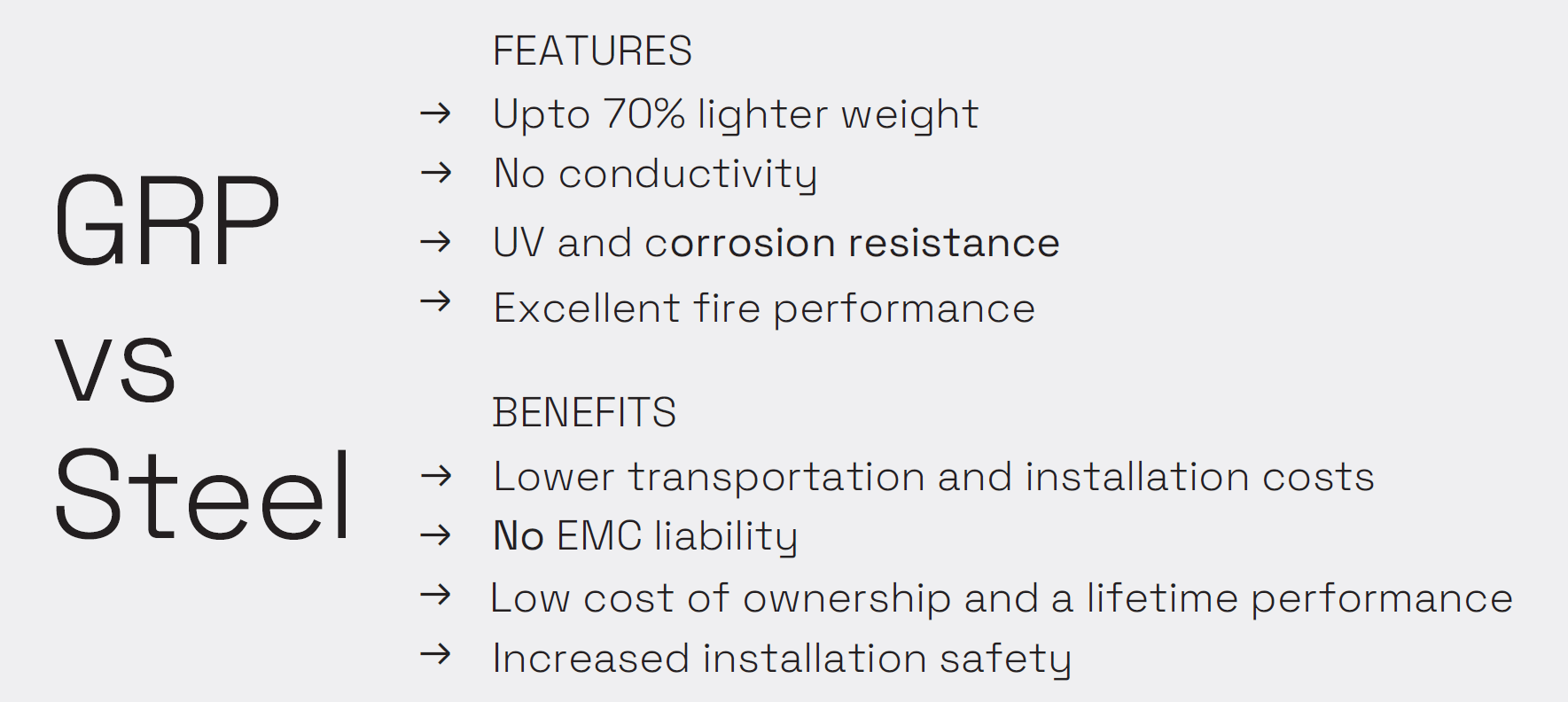

Mita GRP is 70% lighter than steel; it is also corrosion resistant. It does not conduct heat and has excellent durability against adverse weather conditions. The product offers excellent UV stability resulting in a cost-effective long-term solution.

The Mita GRP is provided in a wide range of trays, troughing and ladders which can support any type of cable – especially power and fibre cables which require a gentle bending radius. Unlike some competitors’ systems, Mita elevated troughing is provided with GRP support posts to increase its durability. The troughing lids clip securely in place, providing cable theft protection. Further security can easily be added by installing stainless steel bands around the elevated route.

Working with GRP

Another particularly useful feature of the MitaR GRP system is that it is integrated with the Bentley Raceway and Cable Management Building Information Modelling (BIM) tool.This provides a complete layout, routing and material estimating function in a single, integrated system. It can be applied from the initial concept design through to detailed design and construction.

A user can create an accurate 3D model of the cable troughing route, making it easy to ensure that adequate space and clearances are available in confined locations, and for the detailed design and material requirements to be quickly and easily produced.

Network Rail approval and other applications

The Mita GRP elevated cable route has been fully approved by Network Rail under Certificate of Acceptance PA05/00442 issued in 2015 for use in locations unsuited to GLT. The Zero Halogen Low Smoke (ZHLS) version has also been approved for use in sub-surface stations, connecting tunnels, and London Underground applications.

It was a concern that sensitive signalling equipment was susceptible to contact by flakes of galvanisation from steel support systems and that DC traction cabling system might create eddy currents within troughing ladders and supports if they were metallic.

Mita GRP troughing was chosen as it is the best candidate with non-magnetic and non-conductive properties.

The cable containment system is not just used in rail, but has also been successfully employed in a wide range of industries including data centres, petro-chemical industries, water treatment, off-shore oil and gas etc.

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

GRP Cable Support Solutions | The Benefits of GRP for Harsh, Hazardous & High Voltage Power Containment

June 28th, 2022

Article Written by David Bryan, UK GRP Account Manager, Wibe Group UK Ltd

GRP Cable Support Solutions

Did you know that there is an alternative option to steel cable support solutions, which is more durable and has less hassle while handling? Through this article, we will explore the features of GRP, its additional and unique benefits in cable support applications and discover the Mita brand.

Thorne & Derrick are an approved distributor of the MITA brand, now powered by Wibe Group, providing competitive prices and fast delivery from stock for the complete range of cable troughs, CABSYS cable trays & GRP cable ladders

What is GRP?

GRP or FRP is the abbreviation for Glass/Fibre Reinforced Polymer, meaning it is a man-made resin based material which makes it a polymer, reinforced with glass. Polymer itself is extremely strong – it is a fibre material and in contrary to how it sounds, it is very durable. It is resistant to most chemicals, stretching and shrinking, resistant to mildew and abrasion as well. When it is reinforced with glass through pultrusion, it becomes a structural polymer resistant to fire and highly corrosive environments. Furthermore, it does not conduct heat. GRP has extra durability to adverse weather conditions and has UV stability which makes it an excellent candidate for outdoor applications, even for wind power substations built in the middle of the sea.

GRP cable support

Cable support is the backbone of any development. Wherever there is a structural development, cable support is there to facilitate electrification, signalling and data.

GRP cable support systems possess unique properties which provide structural strength as much as a stainless steel installation and resist many corrosive environments, particularly where conditions indicate that conventional materials may not provide an economic service life.

Features of GRP Cable Support Solutions vs Steel

Supporting Applications With A long Standing Brand

Mita GRP, designed and manufactured in the UK, is now powered by Wibe Group. Thorne & Derrick supply and distribute the complete GRP cable support system range specifically designed for harsh and corrosive environments, ensuring a sustainable installation through its lifetime. Serving industries of transportation, onshore and offshore power, water and waste management, chemicals, pharmaceuticals and many more, Mita GRP stands for “peace of mind” with its “fit and forget” solutions for generations to come.

Working with GRP

Another particularly useful feature of Mita GRP cable support solutions and systems is its ability to be integrated with the Bentley Raceway and Cable Management Building Information Modelling (BIM) tool. This provides a complete layout, routing and material estimating function in a single, integrated system. It can be applied from the initial concept design through to detailed design and construction. A user can create an accurate 3D model of the cable troughing route, making it easy to ensure that adequate space and clearances are available in confined locations, and for the detailed design and material requirements to be quickly and easily produced.

In conclusion, the Mita GRP cable trough system is a non-hazardous, inert product. It is lightweight and can be manually handled without difficulty, unlike concrete and steel. In contrast to steel, GRP does not have to be deburred or given edge treatment before fitting, saving time and further reducing labour costs. During installation, any cutting, drilling, bonding and jointing can be easily undertaken and will not give rise to a hazardous situation, with any dust kept to a minimum.

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

Cut, Strip, Crimp, Punch – Cable Tools for Panel Building & Electrical Contracting

June 28th, 2022

Cut, Strip, Crimp, Punch – All In One Solutions By Klauke

Cable Tools

Cut, Strip, Crimp, Punch

Panel Building & Electrical Contracting

Anyone who works in building electrical panels, knows that customers might have different requirements, so flexibility and being able to respond and adapt fast is a critical success factor. When Klauke develop new cabling tools, versatility is one of the most important drivers. Designing the best quality tools that solve the problem at hand in that fastest and most efficient way is in Klauke’s DNA.

Below is the best range of cable cutting and crimping tools manufactured by Klauke. They are renowned for high-quality, electrical connection tools for cable crimping, cutting and punching that can be used in panel building installations.

Klauke now offer efficiency and safety for control panel building as part of an all-inclusive worry-free package. Whether it’s cutting, stripping, crimping or punching: our power package has just the tool you need!

| Klauke EK 50 ML Micro| Electromechanical Crimping Tool 0.14-50sqmm

|

For Full Klauke Specification – EK 50 ML

|

For Full Klauke Specification – EK 30 ID ML |

Klauke EK 30 ID ML | Battery-powered Hydraulic Press Tool 6-120sqmm

|

| Klauke EK WF 120 ML | Battery-powered Hydraulic Press Tool for Cable End-sleeves 6-120sqmm

|

For Full Klauke Specification – EK WF 120 ML

|

For Full Klauke Specification – ESM 50 IS |

Klauke ESM 50 IS VDE | Standard Battery-powered Hydraulic Cutting Tool

|

| Klauke EK 30 ID ML | Battery-powered Hydraulic Press Tool 6-120sqmm

|

For Full Klauke Specification – EK 30 ID ML |

For Full Klauke Specification – EKM 60 ID

|

Klauke EKM 60 ID | Battery-powered Hydraulic Press Tool 10-240sqmm

|

| Klauke EKM 60/22 | Battery-powered Hydraulic Press Tool 6-300sqmm

|

For Full Klauke Specification – EKM 60/22 |

For Full Klauke Specification – EK 35/4 ML |

Klauke EK 35/4 ML | Battery-powered Hydraulic Press Tool 6-150sqmm

|

| Klauke EK 50 ML | Electromechanical Cable Crimping Tool 0.14 – 50sqmm

|

For Full Klauke Specification – EK 50 ML |

Full Klauke Specification ES 32 F ML & ES 32 ML |

Klauke ES 32 F ML / ES 32 ML | Battery-powered Cable Cutting Tool Ø 32mm

|

| Klauke ESM 50 | Battery-powered Hydraulic Cutting Tool Ø 50 mm for Copper and Aluminium Conductors

|

Full Klauke Specification – ESM 50 |

Full Klauke Specification – EKM 60 UNV |

Klauke EKM 60 UNV | Battery-powered Hydraulic Universal Tool 6-300sqmm

|

| Greenlee LS 50 FLEX | Battery-powered Hydraulic Punching Tool

|

Full Greenlee Specification – Greenlee LS 50 FLEX |

Full Greenlee Specification – LS 100 FLEX |

Greenlee LS 100 FLEX | Battery-powered Hydraulic Punching Tool

|

Crimping Cables, Lugs & Tools

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

➡ Associated Brands & Products | Klauke | Cembre | Pfisterer Sicon | Cable Crimping & Cable Cutting Tools

Should you require technical assistance to select the correct cable crimping or cable cutting tools please contact us.

Thorne & Derrick are Specialist Distributors of cable tools to enable the preparation of all LV MV HV cables prior to the installation of Joints, Terminations & Connectors – this includes Klauke, Cembre, Alroc and Boddingtons cable jointing tools for removal of cable sheath, screen and insulation on 11/33kV (MV) and 66kV/132kV (HV) power cables.

View the complete range of Cable Crimping & Cable Cutting Tools