Blog

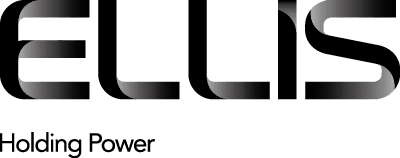

Thorne & Derrick Stocking Agreement for PBwel Rail Earthing Equipment

June 6th, 2022

Thorne & Derrick, the UK Preferred Distributor for P&B Weir Electrical Ltd (PBwel), are now stocking their range of Rail Earthing Equipment with PADS Approval for use on Network Rail high voltage electrification projects. This significant and strategic stock holding is the culmination of discussions and planning to support framework contractors and construction alliances during and beyond the current CP6 plan.

Next Day Delivery

Thorne & Derrick will be able to provide next day delivery from stock at competitive prices for the PBwel range of Operating Poles & Temporary Earthing Kits; the complete range consists of DEP Short Earth Leads, J117 Rail Clamps, Long Blue Interlocked Earths, Short-Circuiting Straps, Rail Bonds, Rail Jumper Bonds, Rail Poles, Voltage Detectors, Rail Socket and Heads, Arboriculture Equipment and Signal Sighting Targets.

“With recent industry announcements by Network Rail about their multi-billion pound Railway Upgrade Plan, which represents the largest rail investment programme since Victorian times, it is important from a business perspective that Thorne & Derrick are placed to support clients requirements from stock. We have been privileged to be suppliers to Network Rail for several decades and this extension to our PADS Approved Rail Products range is aimed to raise levels of customer service and personal safety – the product training provided by Tim Harris including support at our office and in the field has been first-class and we look forward to introducing this news to our customers in the coming weeks.”

“The PBwel Aluflex range of temporary and portable earth leads are manufactured from multi-stranded, commercially pure aluminium with an extruded PVC sheath to preserve the cable – Short Earths, DEP Earths and Jumpers & Bonds are available at any length and with clamp choices for use on 25kV OHL and substation power systems, just contact us with your requirements,” adds Chris Dodds (Sales & Marketing Manager at Thorne & Derrick).

“We had a great discussion about our future commitments and agreed sales targets at the beginning of the year for 2022 – we are now excited to implement our business development plan for the UK rail industry. Working together with Thorne & Derrick we can design new and customised solutions for Portable Earthing and deliver via distribution standard products on an overnight service. Thorne & Derrick will support contractors and end-users via their trained Sales Team with competitive prices and stock availability of product. I will be on hand to support their team with continuous product training, either field based or online, to ensure their technical knowledge is up to date with the latest industry standards,” comments Tim Harris (Technical Sales Engineer at PBwel).

UK rail industry. Working together with Thorne & Derrick we can design new and customised solutions for Portable Earthing and deliver via distribution standard products on an overnight service. Thorne & Derrick will support contractors and end-users via their trained Sales Team with competitive prices and stock availability of product. I will be on hand to support their team with continuous product training, either field based or online, to ensure their technical knowledge is up to date with the latest industry standards,” comments Tim Harris (Technical Sales Engineer at PBwel).

Portable & Temporary Earthing for Rail Electrification | Safe Systems of Working

The PBWel range of PADS Approved Portable Earths handle electrical and drain induced current associated with the inadvertent energisation of 25kV overhead power lines – this provides electrical protection of trackside workers and engineers carrying out maintenance, repair or construction under supervision and inspection of the project HV SAP.

Manufactured from highly conductive, commercially pure, Aluflex aluminium material the system is used during rail track possessions and electrical isolations – the Short Orange DEP (Designated Earth Point) Rail Earth is used in conjunction with operating pole sets, live line indicator and the CATU Dispensing Head MT630C.

Stocked by Thorne & Derrick

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of medium/high voltage power cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Reliable & Compliant Cable Accessories for Substation, Trackside & OHL Power Supply

Contact us for a Quotation for Rail Earthing Equipment

Important Factors You Need To Consider When Working With Cable Cleats

May 24th, 2022Cable Cleats

A cable cleat is designed to ensure that cables are fixed, retained and supported correctly so that in the event of short circuit fault or any other emergency, they will contain the cables without causing damage; enabling the circuit to be restored once the fault has been dealt with.

One of the most important issues to consider when specifying cable cleats is the risk of material corrosion – not just as a result of the installation environment, but also from other metals which the cable cleat may come in to contact with.

Read more about the affects of corrosion in our evidence based specification case blog – Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

All cable cleats distributed by Thorne & Derrick are undergoing testing to conform to the latest IEC 61914:2021 Standards. Certification will be in place before the deadline.

What Else Is Important To Consider When Working With Cable Cleats?

Operating Temperatures

Ellis’s standard ranges of cable cleats are designed for use in ambient temperatures ranging from -50°C to +60°C and with cable conductor temperatures up to 90°C.

Eddy Currents

Ferro-magnetic materials that completely surround single conductors in AC circuits are susceptible to heating from eddy currents.

Generally, eddy current generation at mains frequencies requires a complete electrical and ferro-magnetic circuit around each conductor. However in installations where all three phases are contained within the same cable cleat e.g. three cables in a trefoil cable cleat, the magnetic fields of the phases cancel each other out, which in turn negates the eddy currents and the heating effect.

Despite this, it is preferable to use cable cleats manufactured from non-magnetic materials such as aluminium, injection moulded polymers or stainless steel, which has only very slight magnetic properties.

ALWAYS REMEMBER: When using single cable cleats manufactured from ferro-magnetic materials care should be taken to avoid forming a complete iron loop around the cable.

Multi-core Cables

There is a commonly held belief within the electrical industry that multi-core cables will protect themselves in the event of a short-circuit, meaning their installation does not require fault rated cable cleats.

However, research shows that the forces between the conductors of a multi-core cable in the event of a fault are similar to those between three separate single core cables laid in a trefoil arrangement.

Therefore, when specifying multi-core cables it is advisable that cable manufacturer should be contacted to ascertain the ability of its specific cable to withstand these forces.

It is worth noting that whatever the withstand quoted, in the event of a significant fault an unrestrained multi-core cable will move.

Furthermore, the requirements of most wiring regulations are clear and typically state that:

“Every conductor or cable shall have adequate strength, and be so installed as to withstand the electromagnetic forces that may be caused by any current, including fault current.”

Fire

There are currently no European or IEC standards for fire rated cable clamps, although there are requirements within other standards that can be followed to prevent unsuitable products being specified.

The international standard IEC 61914 requires non-metallic and composite cable cleats to have adequate resistance to flame propagation.

UL94, the standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances, is a plastics flammability standard that classifies plastics according to how they burn in various orientations and thicknesses. Adherence to its V-0 rating for polymers should be demanded by specifiers.

The use of the description LSF (low smoke and fume) is common terminology with regard to polymers, but is misleading as it doesn’t relate to any published standard and so can be interpreted in a wide variety of ways.

Rail Cable Cleats

To ensure complete assurance of performance in a fire, all Ellis plastic products have undergone testing at the Building Research Establishment (BRE) in line with the London Underground 1-085 specification with regard to:

- Smoke emission

- Limited oxygen index

- Toxicity of fumes

The appropriate products are listed in the London Underground Approved Products register. Identification numbers are 360, 361,362, 363, 364, 365 and 1661.

A great deal of focus is placed on fire rated (FP) cables and their performance in fire, but very little attention is given to the cable fixings used to secure these cables. Given that FP cable is typically rated for operation in temperatures ranging from 850°C to 950°C then the use of plastic cable cleats or clamps is clearly inappropriate.

Even aluminium only has a melting point of 660˚C, which means it would fail to support FP cables in a fire.

Cable Cleats | Fire Resistant Cables

To counteract this shortcoming, Ellis manufactures the Phoenix range of clamps for use with FP cables. Independently tested by Exova Warrington fire and BRE, all products in the range are proven to perform to the same level as the FP cables ensuring continuous operation in the event of fire.

UV Resistance

While wholly metal cable cleats are impervious to UV attack, composite and polymer cable cleats can be at risk.

Ellis composite cable cleats such as Emperor, Vulcan and Atlas all have polymer liners, but are designed to be impervious to UV attack because the polymer is shielded by either the cable cleat’s body or the installed cables.

Polymer cable cleats that are likely to be exposed to UV should be supplied in materials containing carbon black or other UV stabilised material.

ALWAYS REMEMBER: All cable cleats supplied by Ellis Patents for applications involving UV are provided in UV resistant materials.

Do Ellis & Thorne & Derrick provide any advice on cable cleat system designs?

As a cable cleat manufacturer, Ellis Patents do not offer advice on the design principles and choices between different types of cable installation. We will however provide expert advice on the suitability of particular cable cleats within any type of installation.

Flexible and Rigid Cable Installations

On most projects a major consideration is the constant movement of the cable due to thermo-mechanical effect. To accommodate this two principal types of installation design exist:

FLEXIBLE SYSTEMS – where the cables are “snaked” either vertically or horizontally. The cable can expand and contract freely between fixing points.

RIGID SYSTEMS – where the cables are rigidly fixed. The longitudinal thermo-mechanical force is withstood by the combination of the stiffness of the cable, the cable cleat reaction force and the rigidity of the support structure.

Cable cleats are designed to withstand the forces exerted by the cable in the ‘axial’ direction, this is relevant to both flexible and rigid systems. It is also important when the cables are installed vertically.

Flat, Trefoil and Quadrafoil Installations

Cable arrangements for three phase installations utilising single conductor cables are typically flat spaced, flat touching or trefoil.

The Wiring Regulations (BS7671) provides current ratings and voltage drop values for all these arrangements. It also contains information on grouping factors and spacing between circuits to achieve thermal independence.

Additionally, IET Guidance Note No. 6 delivers valuable advice on installation arrangements where there are multiple cables per phase.

An additional method for installing single-core cables is to use quadrafoil cable cleats where the neutral is bundled with the three phase conductors. In this arrangement, there is no advice in BS7671 but a report produced by ERA on behalf of Ellis delivered the following guidelines:

Current ratings, given in BS7671, for cables in touching trefoil formation are appropriate for cables in quad bundles

Derating factors, given in BS7671, for cables in touching trefoil formation are appropriate for cables in quad bundles

Voltage drops for circuits in quad formation should be calculated using the values tabulated in BS7671 for cables in flat touching formation

When considering multiple cables per phase, the advice given in Guidance Note No.6 for trefoil groups is applicable to quad bundles

The induced voltage in the neutral conductor of a quad group is minimal and can be ignored.

Quadrofoil Cable Cleats – Ellis Patents Vulcan Quad

How do I prevent thread galling when installing cable cleats?

Stainless steel fasteners have a propensity to “pick-up” when the two threaded surfaces slide against each other. If sufficient speed and pressure is applied to the sliding surfaces then they can weld themselves together – a phenomenon known as thread galling.

All stainless steel fixings will thread gall if there is sufficient friction.

To avoid thread galling, reduce the speed and downward pressure when closing fasteners and use lubrication where appropriate.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

T&D Deliver Their Largest High Voltage Power Cable Cleat Order

May 24th, 2022Press Release | June 30th 2022

Thorne & Derrick, a Specialist Distributor for Ellis Patents, have delivered their largest contract to date to supply cable cleats to provide safety and reliability to high voltage power cable circuits.

The order includes a project total of over 10,000 units of their market-leader cable cleat, The Emperor. The cable cleats will be installed to provide the highest levels of short circuit protection to high voltage power cables. Following several client meetings, Thorne & Derrick were awarded the purchase contract despite market-wide challenges including raw material price volatility and supply chain strains.

This current project award is testament to our ability to utilise the in-house expertise of Ellis Patents to design project specific, bespoke solutions for customers on tight delivery schedules and builds upon recent project successes in the renewable, rail, data-centre and utility substation sectors.

“Emperor was preferred to competitors due to the products established track record and its evidenced compliance to the rigorous IEC 61914: 2015 standard. The ability to demonstrate product performance in similar harsh operating environments with past project references was critical. Ellis Patents have an international reputation to commit and meet customer delivery requirements – trust in the customer-supplier relationship was central to securing the business. We are now working with Ellis on several custom engineered cable clamps and support solutions – the commercial and technical support by Ellis Patents to Thorne & Derrick was outstanding and instrumental in securing this prestigious project order for both our companies,” comments Chris Dodds (Sales & Marketing Manager at Thorne & Derrick.

The Emperor of Cable Cleats

The Emperor is a heavy duty compact stainless steel cable cleat designed, developed, tested and manufactured in accordance with IEC 61914. The cleat is available in an extensive range of sizes with range taking ability to suit cables installed to containment in single or trefoil formation. The frame of the cleat is manufactured from corrosion resistant grade 316L stainless steel, the cable is supported by a liner manufactured form a low smoke zero halogen (LSOH) material. The closure fixings are manufactured from grade A4-70 stainless steel. The Emperor can be fixed to the supporting structure by either two M10 fixings or one M12 fixing. Non standard cleat designs can be supplied upon request.

ES Single Range | 32-150mm diameters with short-circuit test levels to 235kA at 225mm cleat spacings

ER Trefoil Range | 19-128mm diameters with short-circuit test levels to 195kA at 300mm cleat spacings

Cleating 3 Times Faster

Ellis Patents are an outstanding manufacturer innovator of products to drive down life cycle costs, including their Twist-Foot design of cable cleats which is typically 3 times faster to install than using conventional fixings.

Jonny Hewitt from Thorne & Derrick with Noman Shabir from Ellis Patents at the Dogger Bank – Meet The Buyer Event.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

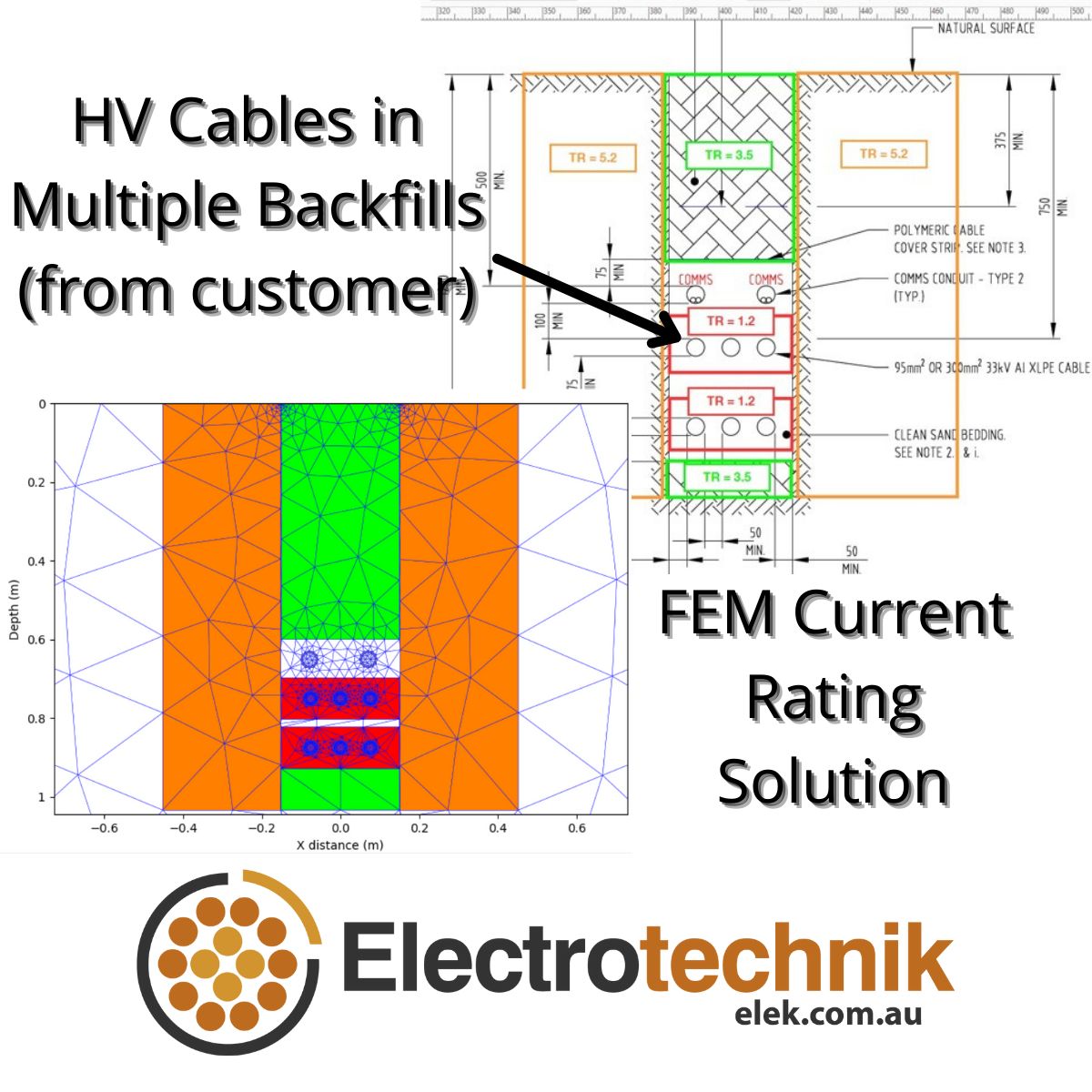

HV Cable Current Ratings For A Challenging Installation

May 23rd, 2022

HV Cables in Multiple Backfills

HV Cable Current Ratings

FEM Current Rating Solution

The customer required HV cable current ratings for an installation involving multiple (6) zones of backfilled soil with Thermal Resistivity (TR) varying between 1.2 – 5.2 K.m/W plus the resistivity of the native soil needed to be considered.

The IEC Standard methods do not cover such a complex installation. The most IEC 60287 can deal with is a single backfill. The native soil thermal resistivity was 1.5 K.m/W which is lower than the backfill areas – the IEC Standard equations are invalid for this condition alone.

The Finite Element Method (FEM) was needed to accurately solving the heat flux distributions for this installation.

How does the FEM model work?

In FEM the space is subdivided into smaller parts known as finite elements using a technique called meshing. These elements take the shape of a tetrahedron or a triangle.

The domain of interest is space discretized and this discretization is implemented by constructing a mesh of the object. The formulation of finite element method results in a system of algebraic equations.

These equations that model the finite elements are then assembled into a larger system of equations that models the entire problem. The solution to the problem is reached by minimizing the mean squared error error function.

For the analysis of HV cables, it is assumed to be in a 2D space. The heat generated by the cable conductors is considered along with the ambient temperature. The FEM model creates the temperature array and a large set of equations are solved.

Another important consideration of the HV cable system which is modelled using FEM is the ground surface and ambient air temperature interface which involves heat convection – this aspect is neglected using the IEC method.

How much difference does FEM make?

The calculated current ratings of HV cables using FEM cannot even be compared with the (approximate) IEC Standard method because the standard method is not valid for this installation.

The current rating for the 11kV single core, 300sqmm copper conductor cables surrounded with 6 zones of soil with different resistivity as well as the native soil resistivity, soil ambient temperature of 25 deg.C. and soil/air interface was as follows:

FEM method = 283 A.

IEC method (uniform soil resistivity 5.2 K.m/W) = 201 A (-29 % underestimate).

IEC method (uniform soil resistivity 1.5 K.m/W) = 366 A (+29 % overestimate)

In conclusion, only using FEM will give an accurate calculation of HV cable current ratings for this complicated installation.

Jayson Patrick – Technical Director, Electrotechnik

![]()

Jayson is the Technical Director at Electrotechnik, a company which develops leading electrical power system design and analysis software and has extensive experience working on large-scale power systems projects in high voltage design, testing/commissioning, and power system analysis roles along with two decades of experience in professional software development.

Jayson has a master’s degree in electrical power engineering and is a professional software developer. He leads a multi-disciplinary team of developers, cloud architects, UI designers, electrical power engineers and PhD researchers. Jayson’s role at Electrotechnik involves developing new software and complex algorithms for electrical power systems design, where he is using a combination of technologies, multiple programming languages and Agile development practices.

Jayson has a passion for UI and UX design and believes in building powerful software which is accurate while being intuitive and easy to use.

Jayson will be delivering a talk at Earthing Conference UK in Birmingham this month.

1:30pm – Day One

Analysis of Earthing Grids in Multilayer Soils at High Frequencies

Jayson Patrick – Technical Director, Electrotechnik

Modelling earthing system behaviour during both power frequency fault conditions and at high frequencies, especially related to lightning phenomena, is of interest to earthing system designers. The behaviour of earthing systems at varying frequencies is quite different and this paper will present details of the algorithm developed and results in the form of a parametric analysis for multiple grids in different soil conditions for high frequencies.

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Register to the SAP Talent Pool for Career Opportunities in the UK & Global Wind Industry

May 19th, 2022

-

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

Thorne & Derrick are privileged to partner with EDS HV Group and support career opportunities within the Wind Industry via their Talent Pool.

Are you an existing Senior Authorised Person (SAP) within the wind industry?

Are you an existing HV High Voltage SAP working in a similar industry looking to make a career move into renewables ?

If so, check out the EDS HV SAP Talent Pool and register your details below today – this is an opportunity to join one of the fastest growing businesses servicing a wide range of clients within the renewable power industry.

SAP Role Vacancies Onshore/Offshore Wind |

|

| Reference | MAY20226602 |

| Expiry date: | 19:04, Wed, 15th Jun 2022 |

| Location: | United Kingdom |

| Salary: | Competitive |

| Benefits: | Competitive |

| Duration: | Various Contracts |

EDS HV Group is a leading authority in the design, installation, operation, maintenance, and repair of high voltage windfarms. Mainly operating in the UK and Europe, EDS has been serving renewables for over a decade and impacting every stage of the wind farm lifecycle.

Due to the growth of EDS they are looking for experienced staff with specific HV SAP experience, with suitable qualifications for a role within the wind industry.

EDS have opportunities across several geographical areas including UK sites, Europe, Taiwan and Japanese sites.

EDS is an innovative and fast-growing organisation with highly skilled teams that enable them to deliver solutions to the most demanding operational and technical challenges faced by their Customers.

EDS HV Group SAP team members will have the following:

- In depth technical knowledge of HV networks particularly the UK, Europe and APAC. Or can demonstrate a high degree of technical competence within their field of experience

- High degree of technical knowledge and analytical skills required to deliver world class HV Network Asset Management performance

- 400/275/132kV SAP, with the requirement to become authorised under the EDS HV Safety rules. Familiarisation training will be provided for the on-call sites

- Wind and Renewables experience transferrable skills from similar industries with HV electrical networks

- Fluency in written and spoken English, ideally with a second language

Essential: An existing SAP (could be 400/275/132 or 66kV), with the requirement to become authorised under the EDS HV Safety rules and customer site safety rules

If you have experience in the above specialism then EDS want to hear from you!!

Complete your application and submit your CV to them now.

Please note this is a Talent Pool, therefore you will only be contacted by EDS when a role becomes available and if your CV is suitable.

If you do see a specific role advertised on the EDS careers site please do apply for that in addition to your CV being in this Talent Pool.

Specialist Distributors of High Voltage Jointing & Electrical Safety Equipment

Thorne & Derrick International are Specialist Suppliers to the UK and international Offshore Wind Industry of products to provide safe and reliable LV HV Electrical Cable Termination, Jointing, Installation & Power Systems up to 66kV.

We are based in North-East England, recognised as a key strategic location to service the offshore renewables energy market in the UK, from the North Sea to the Nordics – our Exports Division support international offshore wind power projects from USA to China.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.