Blog

Ellis Patents Cable Cleats for Major Power Plant Project

May 27th, 2025

21.5.2025

HOLDING POWER by Ellis Patents | 30,000+ Vulcan Cleats and Flexistraps shipped out today under the blazing Yorkshire sun. The cable cleats will provide short-circuit restraint to both 11kV and 33kV Medium Voltage Cable Networks.

This WIN demonstrates the high-value of collaborative, proactive and strategized Manufacturer-Distributor relationships; we look forward to co-creating a Case Study to highlight how together we have worked to secure this achievement and satisfy clients specification and technical application requirements.

The consignment is now to be delivered to SEB International Ltd, the UK’s leading manufacturer of Cable Pulling & Laying Equipment, and consolidated for shipment with a CD500S Cable Drum Trailer (Payload 20,000kgs | Max Drum Width 2400mm), TW5000 Cable Pulling Winch and CP700 Cable Pushing Unit to power-up an accelerated cable laying process.

The £750K project value to Thorne & Derrick demonstrates our ability to manage and deliver upon UK and international major projects from our robust world-class supply-chain.

The High Voltage 132kV Cables will be connected to Grid using GIS Dry-Type Terminations from Nexans while all Medium Voltage 33/11kV switchgear and transformer Connectors are completed using market-leading Euromold and Connex brands from Nexans Power Accessories and Pfisterer.

All Cleats & Cable Accessories supplied by Thorne & Derrick – the purchase contract was managed by Gary Amos (Thorne & Derrick Sales Engineer).

Ellis Patents | HOLDING POWER

Pictured | Carl Cox (Thorne & Derrick Sales Engineer | Rail) with Noman Shabir (Ellis Patents National Sales Manager). The Ellis Patents ranges of PADS Approved Cable Cleats & Tunnel Hangers provide advanced material performance for substation, trackside and tunnel applications; this includes the short-circuit restraint and support of LV MV HV power cables. Please do not hesitate to contact Thorne & Derrick should you require further info, Lunch n Learn, CPD or Joint Visit to discuss your next cable cleat project requirements.

Ellis Patents Emperor Cable Cleats | Single & Trefoil | cable cleats designed, developed, tested and manufactured by Ellis from the Emperor range in accordance with IEC 61914 suitable for single, trefoil and Quad cable configurations

Ellis Patents Centaur Cable Saddles | the Ellis Centaur cable cleat has been designed, developed, tested and manufactured in accordance with IEC 61914 (Cable Cleats for Electrical Installations). The cable saddles are designed to support High Voltage Power Cables with diameters from 100mm to 162mm. Centaur consists of an extruded and pressed aluminium saddle and a hinged aluminium over strap.

Ellis Patents Aluminium Cable Cleats | the Ellis 2A two hole cable clamps have been designed, developed, tested and manufactured in accordance with IEC 61914 (Cable Cleats for Electrical Installations). The cable clamps are available in a range of sizes with range taking ability to suit single cables – the clamp can be epoxy coated for use in harsh environments, such as sea air conditions.

Ellis Patents Vulcan Cable Cleats | the Vulcan cleats are available in a range of sizes with range taking ability to suit single and trefoil cable formations (also available in Quad formation). The frame of the cleat is manufactured from corrosion-resistant 316L grade stainless steel, the cable is supported by a liner manufactured from a low smoke zero halogen (LSOH) material.

Ellis Patents Colossus Cable Cleats | The Colossus cleat is available in a range of sizes with range taking ability to suit LV MV HV cables in trefoil formation. The frame of the cleat is manufactured from grade 316L stainless steel, and the body of the cable cleat is manufactured from a low smoke and zero halogen (LSOH) material.

Ellis Patents Trident Cable Cleats | cable cleat is available in a range of sizes with range taking ability to suit LV MV HV cables in trefoil formation. The cleat is manufactured as standard in LSF which is PFAS and halogen free, flame retardant and suitable for outdoor applications.

Further Reading

- Ellis Patents Extend Vulcan+ Cable Cleat Range To Accommodate Smaller Cables

- Polymer Cable Cleats | Holding Power with Ellis Patents

- Cable Cleats | A Device For Short Circuit Protection | CPD Course By Ellis Patents

Cold Shrink Glands for MV HV Cables

May 21st, 2025How to Install SPS 180 & SPS 193 Cold Shrink Cable Glands

To suit 3 Core SWA Armoured XLPE Cables, 3.6kV (3.3kV) to 36kV (33kV)

Reference Numbers: SPS 180(CS) and SPS 193(CS)

In this Post, we present a step-by-step installation guide for the SPS 180(CS) and SPS 193(CS) Cold Shrink ‘Bolt-On’ Type Cable Glands. These “top-hat” glands are designed to connect and gland 3-core armoured XLPE cables from 3.6kV to 36kV, providing a reliable and easy-to-install solution for Cold Shrink termination and are distributed by Thorne & Derrick.

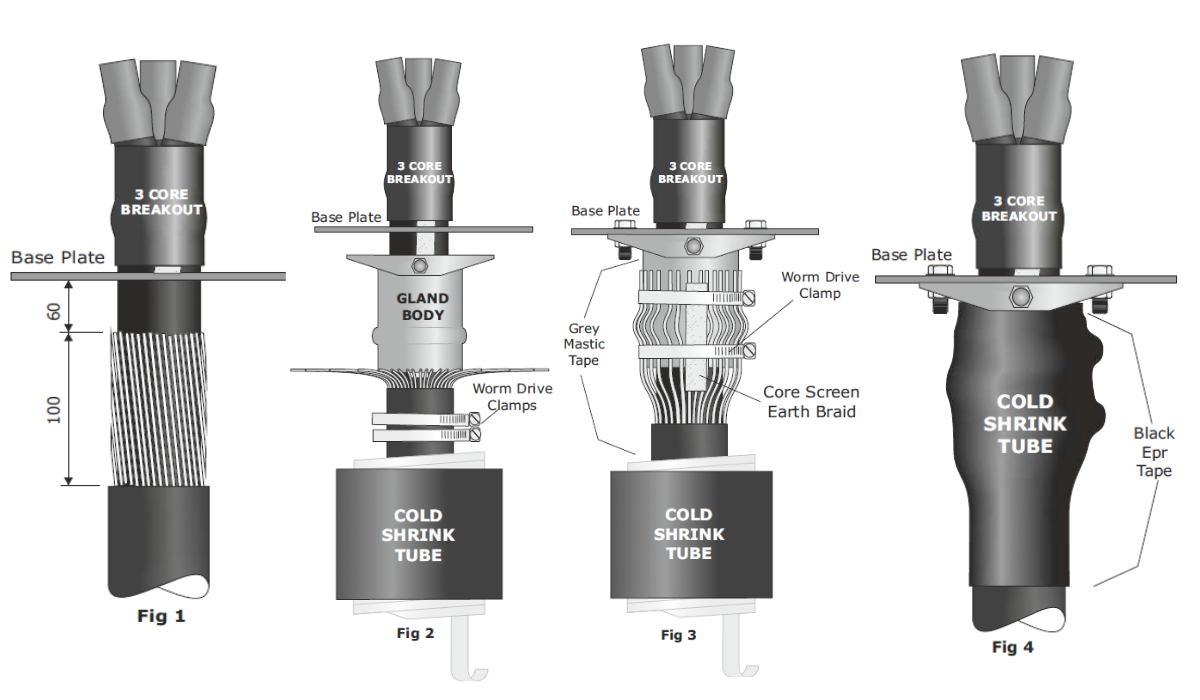

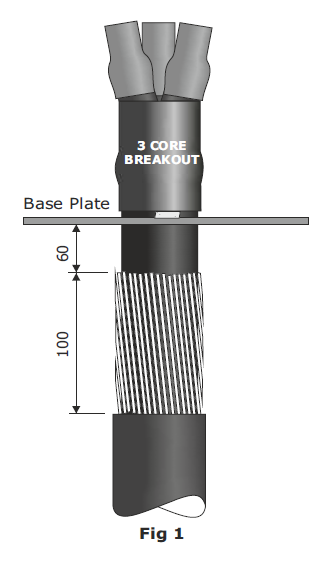

Note:- Fig 1 shows one possible cable gland configuration, in some situations it may be necessary to position the 3 leg heat shrink boot body below the gland plate to gain space within the cable box. If cable is non armoured, additional strain may be put on the heat shrink tube to ensure cable is supported by cable cleats to provide additional strain relief.

Step-by-Step Installation Guide

1. Cable Preparation

-

Before opening up the armour wires, ensure the cold shrink tubes and the two worm drive clamps are in position.

2. Armour Wires

-

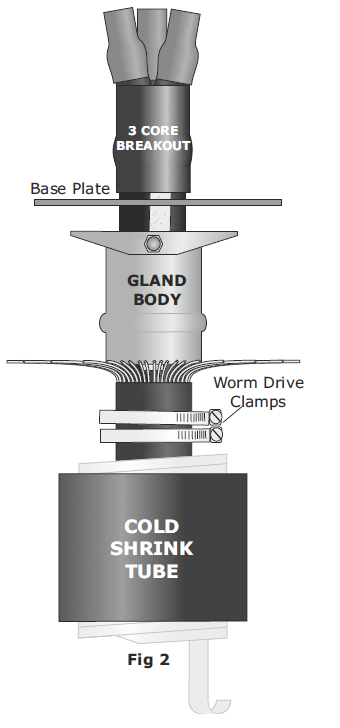

Open up the wire armours as shown in Fig 2.

3. Cable Gland Body

-

Slide the metal cable gland body over the cable.

Note: The cable gland body itself can, in most cases, be positioned after completing the cable termination.

For Steel Tape Armoured Cable:

Prepare to the same dimensions shown in Fig 1 and follow section 7 (see below).Configuration Tip:

Fig 1 shows one possible configuration. In some cases, you may need to position the 3-leg boot body below the gland plate to gain space within the cable box.Non-Armoured Cable Warning:

Additional strain may be placed on the shrink tube. Ensure the cable is supported by cable cleats to provide strain relief.

4. Final Connections

-

Complete the final connections of the cable termination before bolting the cable gland body in place.

5. Bend Armour Back

-

Bend the armours back over the cable gland body.

6. Clamping

-

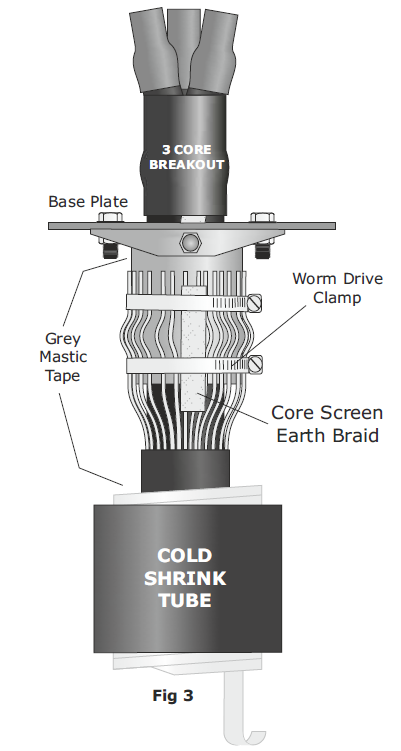

Using the worm drive clamps, connect the cable armours and screen earth braids to the cable gland body as shown in Fig 3. Ensure the cable clamps are tight.

7. Cover Edges

-

Cover any sharp edges and the clamp buckles with PVC tape.

If Steel Tape Armoured:

Unwind the electrical tape below the bottom of the cable gland, re-wrap around the cable gland body, and secure with worm drive clamps.

8. Moisture Seal

-

To provide a moisture seal, stretch and apply a turn of grey mastic tape around:

-

The top of the metal cable gland body.

-

The outer cable jacket.

-

This ensures that the cold shrink tube will recover properly onto the tape.

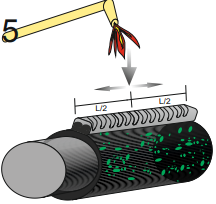

9. Apply Cold Shrink

-

Position the cold shrink tube.

-

Begin pulling the plastic spiral carefully.

-

Do not pull the spiral straight.

-

Wrap it around the cable to avoid snagging.

-

10. Secure Ends

-

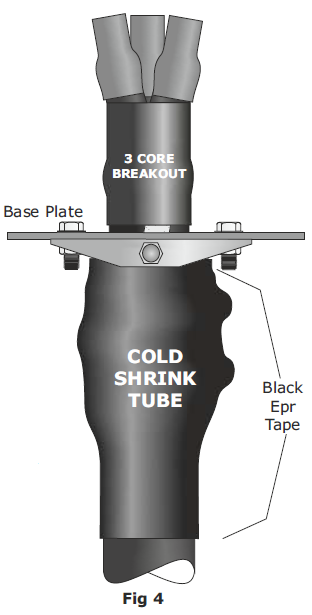

Once fitted, apply the provided black EPR tape at both the top and bottom of the tube.

Figures for Reference

-

Fig 1: Base plate and initial configuration

-

Fig 2: Wire armour open-up

-

Fig 3: Clamp setup with screen earth braid

-

Fig 4: Final assembly with cold shrink and sealing tapes

Cable Glands Distributed from Stock by Thorne & Derrick | the 501/453 range of Universal Cable Glands manufactured by Hawke are suitable for the mechanical retention, glanding and termination of LV MV HV Power Cables with steel wire armour, steel wire braid or steel tape armour.

Shrink Polymer Systems heatshrink cable joints and terminations suit all types of MV-HV electrical cables (single or multi-core) with or without armour or lead sheaths – zero halogen and fire resistant cable joints are also available.

Duct Sealing Solutions with Filoform

May 20th, 2025How Do I Select a Duct Sealing Solution?

At Thorne & Derrick, we pride ourselves on working with industry leaders to deliver innovative, reliable, and compliant solutions to our customers. In this edition of Ask the Experts, Ian Joynson, Technical Specialist at Filoform, talks all things duct sealing — from common challenges in the field to the importance of long-term protection.

At Thorne & Derrick, we pride ourselves on working with industry leaders to deliver innovative, reliable, and compliant solutions to our customers. In this edition of Ask the Experts, Ian Joynson, Technical Specialist at Filoform, talks all things duct sealing — from common challenges in the field to the importance of long-term protection.

Filoform’s Ian Joynson shares expert guidance on what to consider when selecting the right duct sealing solution:

“Selection should start by understanding the specific application and what the seal needs to achieve. Consider:

➖ Are there cables present, and how many?

➖ Is water ingress an issue? If so, how much?

➖ Is fire protection required?

➖ Does the duct enter a building?

➖ Are gases or chemicals a concern?

The right solution should be chosen during the design phase, where sealing requirements can be aligned with the overall project scope.

Most specifications will demand resistance to water, gas, and sometimes fire or chemicals. Expected seal life is also critical — and any reputable manufacturer should be able to validate this.

Avoid over-engineering the seal design. Ultimately, a duct sealing solution that meets the specific needs of the application is the right solution.”

Thorne & Derrick is trusted distributor of Filoform duct sealing systems, supplying reliable and high-performance solutions to contractors, engineers, and project teams across the UK and internationally. Whether you’re sealing cable ducts in substations, renewable energy sites, or industrial facilities, we provide expert support and fast delivery to help you get the job done right.

Duct sealing and sealing products manufactured by Filoform, including the Filoseal range, are installed to provide gas tight and watertight sealing for cable duct entries – protecting underground cables and substation ducting infrastructure against flood and migration of flammable and toxic gas hazards. Fire resistant version also available – suitable for sealing LV-HV power, telecoms and fibre optic cables.

Filoform manufacture and supply quality products and solutions to connect, seal and protect low, medium and high voltage underground cable networks.

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Filoform duct seals and cable joints.

View the complete range of Filoform products.

FiloSeal+HD Duct Sealing System

From Power to Pavement: Enabling Smarter EV Feeder Pillar Solutions with Lucy Zodion

May 20th, 2025- Special thanks to Matt Page EV Business Development Manager at Lucy Zodion for the kind permission to republish.

BEYOND SPEED: FUTURE PROOFING EV INFRASTRUCTURE

As a trusted distributor of Lucy Zodion EV Feeder Pillars, Thorne & Derrick are proud to support the delivery of safe, robust, and future-ready power distribution solutions for electric vehicle charging networks.

In the article below featured in EV & Renewables Supplement, Matt Page, EV expert at Lucy Zodion, explores the critical factors beyond deployment speed that define a successful EV infrastructure rollout.

Lucy Zodion manufacture a wide range of products suitable to provide Low Voltage Electrical Power Distribution for EV charge points – from distribution network operator (DNO) accredited cut-outs and isolators for on-street chargers, to feeder pillars for electrical vehicle charging.

Lucy Zodion’s EVIS (Electric Vehicle Infrastructure Solutions) range delivers pre-wired EV feeder pillars from 100A to 630A reducing time on site and streamlining installation.

Beyond Speed: How to Future-Proof Your Infrastructure

Discover how strategic planning, scalability, and long-term resilience are key to building a charging network that’s ready for tomorrow.

Conversations around EV infrastructure often focus on speed – how quickly can a charging station be deployed, and how fast it can charge a vehicle. While speed is important, it’s not the only factor that determines success. True future-proofing means designing charging infrastructure that is resilient, scalable and adaptable to changing demands and evolving technology.

Building for growth, not just now

Many charging hubs installed today will need to evolve as EV adoption increases. The latest figures from Zapmap show there are now over 75,000 public charge points in the UK our demand is expected to grow significantly and infrastructure that isn’t designed with scalability in mind will quickly become obsolete.

For example, at InstaVolt’s Camphill Village Trust charging site, the approach to power distribution was designed with long-term scalability in mind. The specialised our Main Supply Pillars powering the site’s 160kW chargers were built to support future expansion while maintaining a minimal footprint. Taking this kind of forward-looking approach can prevent costly redesign later on

Similarly, the Isle of Man’s phased EV rollout demonstrates how strategic planning can ensure charging infrastructure is deployed with future expansion in mind. A well-planned approach to power distribution means sites can scale up as EV adoption increases without requiring extensive retrofits.

Resilience is key

Reliability is just as critical as speed. A charging hub that experiences frequent outages due to inadequate electrical protection or environmental wear will create frustration for drivers and site owners alike. Key resilience-focused features to consider include:

- Earth leakage protection and residual current protection to ensure long-term electrical safety

- Surge protection to guard against power fluctuations

- Anti-condensation heaters and service lighting to protect internal components and improve maintenance access.

Integrating these features from the outset can help prevent operational disruptions, enhancing user confidence and reducing long-term costs.

The M7 Real Estate project delivered by Source EV – a joint venture between SSE Energy Solutions and Total Energy – highlights the benefits of durable, weather-resistant power distribution. In high-usage environments, ensuring electrical protection and ease or maintenance is crucial for long-term success.

Collaboration matters

Future-proofing isn’t just about the technology – it’s about the process. The most effective EV infrastructure projects take a holistic, end-to-end approach, Considering electrical distribution, space constraints and future adaptability from the start.

A strong example of this is the InstaVolt project, where power distribution was designed to allow flexibility for future transformer manufacturers equipment. Taking a collaborative approach with stakeholders ensures infrastructure remains adaptable to evolving industry requirements.

The road ahead

The shift to electric mobility is accelerating and infrastructure needs to keep up – not just with speed, but with smart, future-proofed design. Viewing EV infrastructure as an evolving system rather than a one-off installation can help ensure today’s investments continue to deliver value well into the future.

Incorporating scalable electrical systems, built-in resilience and cross-industry collaboration from the outset can help create charging networks that remain effective as demand and technology evolve. By planning with the long term in mind, we can ensure EV charging infrastructure stays ahead of demand, rather than struggling to catch up.

Compliance and standards

When specifying an EV feeder pillar, you need to make sure it is tested to the following standards:

- BS7671- IET Wiring Regulations – Covers the electrical installation of buildings, including the use of surge protection

- BS7671- IET Code of Practice for Electric Charging

- BS EN 61439 – Low Voltage Switchgear and Control Gear Assembly

Considering these key points will ensure that your EV feeder pillar is designed to deliver efficient and reliable power distribution for electric vehicle charging, contributing to a sustainable and greener future.

Lucy Zodion | Fortress Feeder Pillars | Pre-Wired Feeder Pillars | Street Lighting Cut-Outs | DNO Cut-Outs | Electrical Power Distribution Enclosures

How To Repair Damaged Cables Using Wraparound Cable Repair Kits

May 20th, 2025Installing Filoform cable repair kits

Integrity of the cable is of prime concern in mission-critical infrastructure.

Whether maintenance is being performed in utilities, telecommunications, or industrial power systems, damaged jacket cables significantly degrade operations and safety. Filoform Heat Shrinkable Reinforced Wrap Around Cable Jacket Repair Sleeves offer a tough, field-proven repair solution for on-site repair of cables, offering durability, environmental sealing, and mechanical protection.

Filoform Jacket Repair Sleeve

The Filoform cable repair sleeve is engineered for reliability in hostile environments. This metal-reinforced, heat-shrinkable wraparound sleeve enables fast, permanent cable jacket repair without cable movement or disconnection.

Cable Repair Product Features

- Heat-activated seal with hot melt adhesive

- Metal channel closure for mechanical reinforcement

- Extensive cable diameter compatibility

- Application for indoor and outdoor use when repairing damaged cables

Cable Repair Installation Guide

Important: Use a soft yellow flame (not pencil type). Always direct heat in the direction of shrinking and maintain a sweeping motion to avoid scorching. Begin shrinking from the centre outward. Ensure uniform shrinking and proper adhesive oozing.

Ensure performance perfection with this precise installation procedure:

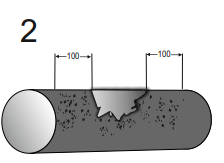

Step 1:

Action: Degrease, clean, and dust the cable surface where the sleeve will be applied.

✅ Use solvents that are compatible with the cable material.

✅ Clean 100 mm on both sides of the damaged section.

Step 2:

Action: Abrade the outer jacket of the cable using abrasive tape or sandpaper.

✅ Roughen 100 mm on each side of the damage for optimal adhesion.

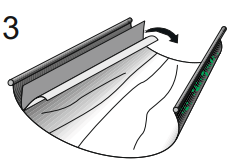

Step 3: Remove the Adhesive Film

Step 3: Remove the Adhesive Film

Action: Peel off the release liner from the adhesive-coated inner surface of the sleeve.

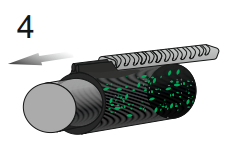

Step 4: Apply the Sleeve and Insert the Metal Channel

Step 4: Apply the Sleeve and Insert the Metal Channel

Action: Wrap the sleeve around the cable and slide the metal channel along the overlap to lock it.

✅ Extend the channel 10 mm beyond both ends of the sleeve.

✅ Confirm that the sleeve fits snugly around the cable.

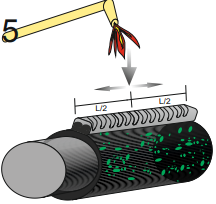

Step 5: Start Heat Shrinking at the Center

Step 5: Start Heat Shrinking at the Center

Action: Begin applying heat at the centre of the sleeve and work outward.

✅ Apply uniform heat all around the sleeve.

✅ Focus extra heat along the metal channel.

✅ If necessary, bend the channel to follow the cable’s contours.

Step 6 Monitor Adhesive Flow

Action: Look for hot melt adhesive uniformly oozing from all edges.

✅ This indicates a secure and sealed installation.

✅ Let the sleeve cool fully before applying any mechanical stress.