Blog

Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

January 13th, 2022

Thorne & Derrick International are Specialist Suppliers to the UK and international Offshore Wind Industry of products to provide safe and reliable LV HV Electrical Cable Termination, Jointing, Installation & Power Systems up to 66kV.

We are based in North-East England, recognised as a key strategic location to service the offshore renewables energy market in the UK, from the North Sea to the Nordics – our Exports Division support international offshore wind power projects from USA to China.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Main UK Stockists for: 3M Electrical, PFISTERER Connex, Nexans Power Cable Accessories (Euromold), Alroc, Ellis Patents, ABB, Roxtec, Cembre & CATU Electrical.

Recent Projects

1 Block Island Offshore Wind Farm USA | GE Renewable Energy | Thorne & Derrick, as Approved Vendors to GE Renewable Energy, supplied Earthing, Static Discharging & Electrical Safety Equipment to the substations plus a 33kV Cable Accessories package to power, joint and connect the medium voltage switchgear and transformers.

2 Operational Offshore Wind Farms (12 Locations) | Orsted | Thorne & Derrick, as Approved Vendors to Orsted, supplied both standard and customised heat shrink joints manufactured by Nexans to enable planned maintenance and repair of the ABB, NKT, TFK & Prysmian High Voltage Cables – included land and subsea cable systems operating at 33kV.

3 Multiple Offshore Wind Farm Assets | JDR Cable Systems | Thorne & Derrick, as Approved Vendors to JDR Cable Systems, developed MV Jointers Tool Kits to provide offshore wind technicians with the specialist tools needed to prepare inter array cables up to 33kV prior to the installation of joints, terminations or connectors to the highest standard – included tools to enable the removal of the cable outersheath, insulation (XLPE) and semicon screens.

The Jointers Tool Kits are designed to provide their jointers with the specialist cable tools needed to prepare inter array cables up to 33kV prior to the installation of joints, terminations or connectors to the highest standard.

4 Bespoke & Standard Cable Clamps, Saddles & Cleats | Developed client customised cable support and cleat systems for high voltage cables in the nacelle/tower of WTG’s for a world leading manufacturer of wind turbines currently under NDA.

We are also approved vendors to SSE Renewables, Swire Energy Services (ALL NRG), Vestas Wind Systems A/S, Correll Group, Van Oord, Vattenfall, Boskalis and other leading renewable energy companies throughout the world.

5 Cable Pull-in Equipment | Working with Balfour Beatty plc on the Viking Link project Thorne & Derrick supplied a range of cable drum handling, socks, rollers and lubrication products to enable the safe pulling and trenching of high voltage power cables.

Image Courtesy | Max States Site Engineer at Balfour Beatty plc (Viking Link) – here the EHV 526kV cable is pictured being pulled from a 62 tonne cable drum (1240m circuit) into the cable trench via rollers in July 2021. Viking Link is a 1,400 MW HVDC submarine power cable under construction between the United Kingdom and Denmark.

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

See how T&D support, supply and service the Renewable Energy industry.

Stockists & Suppliers | UK & International Projects

HV Cable Joints, Terminations & Connectors I Blog Library

January 11th, 2022

Main UK Stockists & Distributors of 3M, Nexans & Pfisterer

Resource Centre | Education & Learning

Thorne & Derrick provide competitive prices and fast delivery from extensive UK stocks of a complete range of of LV, MV, HV Cable Joints, Terminations & Connectors to connect, splice, repair and maintain medium/high voltage cable and power distribution systems.

A complete range of Joints, Terminations & Connectors utilising EPDM rubber, heat-shrink and cold applied technologies are available for medium and high voltage power cable networks up to 66kV from 3M, Nexans & Pfisterer.

TOP BLOG PICKS

See our collection of the Top Blogs featuring the complete range of Medium Voltage Power Cable Accessories & Cable Services that Thorne & Derrick can offer:

- 3M Cold Shrink Vs Heat Shrink

- How To Apply 3M Cold Shrink Cable End Caps

- 3M QT-III | Cold Shrink Terminations | Video Demonstration

- Jointer Training Courses 11kV 33kV 66kV

- Nexans Euromold Connectors – Webisodes

- Water Sealing, IP Rating & Temperature Range Of Nexans Euromold Connectors

- Different Insulating Epoxy Plugs & How To Install The Cap On Nexans Euromold Interface C Compact Connectors

- Bevelling The Edge Of The Core Insulation During Installation Of Nexans Euromold Connectors

- Installation & Clamping Of Nexans Euromold Compact Connectors Onto Their Mating Bushings

- Innovation : Heat-Shrinkable Joint with Triple Layer Tube By Nexans

- MV Cable Joints | Nexans NEW PRODUCT Launch

- 66kV Cable Jointer Training – A Question Of Competency Not Familiarisation

- Nexans Euromold Connectors – Webisodes

- Essential Reading – Medium Voltage Cable Accessories Book Published By Nexans

- Sicon | Did You Know That PFISTERER Invented Hexagonal Pressing In The 1950s?

- SICON By PFISTERER | Shearbolt Connectors with Stepless Shear-Off Bolts

- PFISTERER Connex | Separable Connectors MV Specification Guide

- Pfisterer Connex Cable Plugs – Cable Terminations For MV-HV 33kV Cables

- Cable Damage | PFISTERER Universal Repair Kit

- 100 Years of PFISTERER – Connecting Power For The Future

Sector Focus

- Joints & Terminations for Network Rail 25kV Electrification Projects | PADS Approved

- Connecting High Voltages & Energising Data Centres

Featured Jointers

- Richie Rice | LS 220kV Cross Bonded Joint XLPE 2500sqmm Copper

- Richard Mason | 400kV ODSE Terminations | Moray East by GCS & Sudkabel

- Johnothan Bocor | Nexans Slip-on Terminations 33kV | Wind Farm MV Cables

- Andy O’Malley | Terminating 300kV Nexans Transformer Cable Using Pfisterer 6S (245kV)

- Andrew Brezovszky | Masterclass : Pirelli 33kV Fluid Filled Oil Cable Jointing

- Lee Bavington | Angle-DC Project | Cold Shrink Terminations 33kV Cable In DC Inverter

- John Harrison | Array Cables | High Voltage Cable Termination & Testing for Wind Farms

- Michael White | 220kV 2000sqmm Copper Enamelled Cable | Sandblasting by Jointers

Tooling Feature

- Alroc CWB-18-60-MVS – MV Bonded Semicon Removal & Stripping Tool | Video

- Semicon Screen – The Most Critical Point In Any MV Joint, Termination Or Connector

Technology Features

- Cable Testing – Is Resonance Testing The Way Forward For Offshore Wind?

- Severe Defects Missed By Tangent Delta Testing – read how IMCORP”s Factory Grade® Technology can help cable owners pinpoint these problems

- MV Heat Shrink Cable Terminations Can Fail Despite Passing VLF Tests

- Cold Shrink Splices & Cable Jointer Training

➡ For Cable Jointing Tools & Accessories I Alroc I Cembre I Klauke

100 Years of PFISTERER – Connecting Power For The Future

January 11th, 2022

Thorne & Derrick | Distributed from Stock | Approved Supplier

CABLE PLUGS & TERMINATIONS MV HV

100 Years of Pfisterer

Whether rapidly growing megacities, a sustainable energy transition or clean mobility, the challenges for employees at PFISTERER are no less today than they were in the past.

Their task is to find solutions for safe and reliable energy transmission, on both small and large scales, and often unnoticed, in overhead lines and substations, or home power connections and also in trains and wind turbines. PFISTERER products play an essential role in our everyday lives. With its sights always set on solutions for the future, the company celebrated its 100th anniversary in 2021.

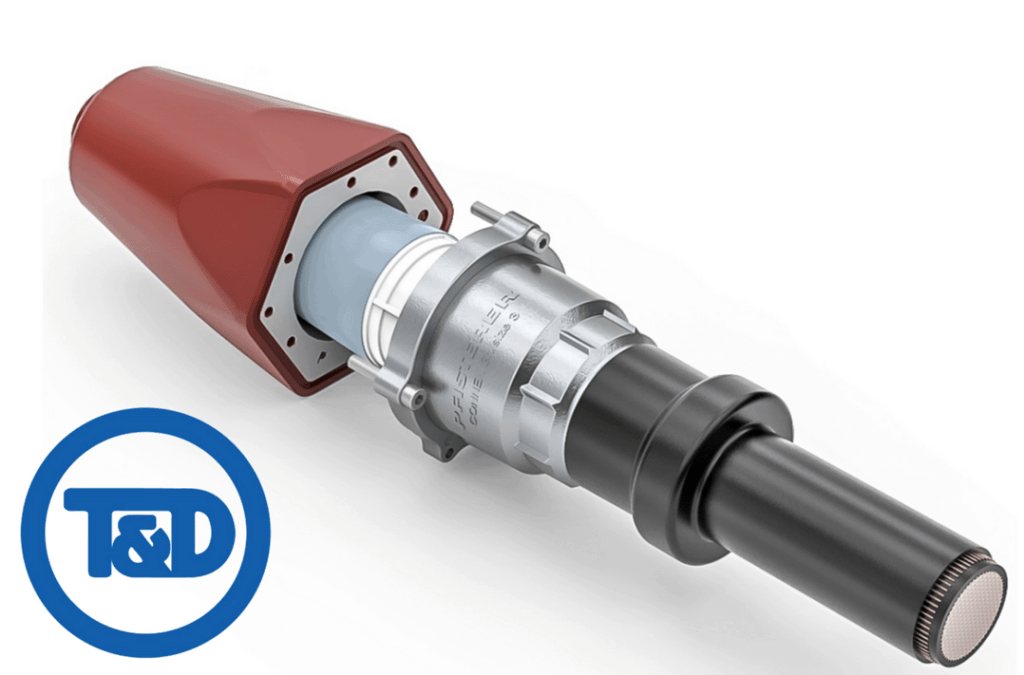

➡ Thorne & Derrick supply the market-leading range of CONNEX type MV HV cable plugs and terminations manufactured by PFISTERER that are suitable for all voltage levels and applications where medium or high voltage power cables must be reliably connected, terminated and distributed within the electricity supply industry.

CONNEX Medium Voltage & High Voltage | Connectors | Bushings | Surge Arresters

Company History

“Karl Pfisterer founded our company in 1921 with the goal of developing a more efficient and safer electrical fitting. His dedication to providing the best solution remains with PFISTERER to this day and encompasses all areas of energy infrastructures – from generation to transmission and also distribution. As a result, we are one of the world’s leading independent manufacturers of cable accessories, insulators and overhead line solutions” says Dr. Konstantin Kurfiss, Executive Board member of PFISTERER.

The family-owned company is an inventor, pioneer and solution provider with unparalleled innovative expertise that has shaped the future of the energy industry for 100 years.

PFISTERER solutions can be found in all types of energy grids, above and below ground.

PFISTERER products are used in rail networks, high-speed trains such as the ICE and TGV and railway safety systems. “Because we are present at countless energy transmission interfaces, our innovations have a huge impact on our partners,” Dr. Kurfiss explains. “That is why we are always thinking about the future and the trends in energy transmission and distribution. We offer solutions today for the challenges of tomorrow”.

The questions the company faces as it looks to the future are more topical than ever; how can we sustainably generate the energy to meet future needs?

How do we strengthen power grids against outages caused by extreme weather in a changing climate whilst bringing energy into harmony with the environment and the needs of fast-growing urban populations?

Pfisterer Sicon

Shearbolt Cable Connectors & Cable Lugs for Medium & High Voltage Cables

Stocked by Thorne & Derrick

Growing urban areas

the challenges of the future

Global energy demand has risen continuously – by more than 160% since the 1970s alone – and continues to rise, with a further 30 percent increase expected by 2040. Over the same period, the number of city-dwellers worldwide will double from 3.6 billion to 6.3 billion.

“To maintain a reliable supply to growing urban areas in the future, more electricity has to be transported into cities – and over ever greater distances: inland from offshore wind farms, and from solar power plants in the South, to industrialised areas in the North. This is made possible for example by our silicone composite insulators – for compact and aesthetic high voltage transmission lines that enjoy high public acceptance” said Stephan Götschel, Executive Board member of PFISTERER Holding AG.

As an offshore pioneer with experience in numerous wind farm projects, PFISTERER also offers the right connection technology for wind turbines, offshore platforms, battery storage facilities and solar power plants. Due to extreme weather associated with climate change, the risk of blackouts is increasing worldwide.

Here, PFISTERER’s unique emergency concepts, help energy suppliers carry out repairs quickly in the event of damage and can also be used as temporary bypass systems for network upgrades, overhauls, maintenance and testing.

Innovation in Termination

SEANEX is a dry pluggable inner cone connection and contact system especially for renewable energy and offshore high voltage power systems up to 72.5kV – based on PFISTERER CONNEX system for voltages of up to 550kV the SEANEX components have been further developed for the offshore installation and lifetime performance certified by DNV GL and compliant with the new offshore standard IEC 63026.

PFISTERER brings the power to the people

above and below ground

PFISTERER has supported the energy industry with overhead line technology, cable systems and components for power distribution since 1921.

Initially for the newly developing local networks, then from 1937 also in the high voltage (HV) sector. The first products were steel components like cable hangers. Later, high voltage overhead line clamps and tension fittings were manufactured at the Gussenstadt plant by PFISTERER, established in 1946.

These successful solutions quickly gained an international reputation. In the 1960s, the expansion of HV transmission networks in Europe was in full swing.

Since then, solutions by PFISTERER have been tried and tested in the construction of overhead lines in extreme Alpine terrain, in the South African desert, in the Gulf region and at the Guri Dam in Venezuela – from 110 V to 1,100 kV. As a pioneer in HV cable connection technology, PFISTERER also offers accessories and solutions for submarine and underground cable systems, including turnkey cable installation. Smart accessories for collecting operating data will play an increasingly important role in the future.

Innovation as a business driver

PFISTERER meets future challenges with the knowledge that comes from one hundred years of experience. This expertise has developed continuously with advances in technology – and technology has advanced thanks to PFISTERER’s expertise.

Numerous innovations and patents continuously drive our growth.

Their success has turned PFISTERER into a globally active company – with a distribution network in 70 countries and 21 locations in Europe, North and South America, Asia and the Middle East. With a workforce of 2100 employees worldwide, state-of-the-art manufacturing processes and a seamless quality management system, all ensure that we will continue to provide the right solutions into the future.

Thorne & Derrick provide competitive prices and fast delivery for the complete range of LV MV HV Power Products manufactured by PFISTERER – this includes the CONNEX MV range of inner-cone cable plugs and terminations up to 33kV.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage cable systems:

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Aclara Sensors | WPD | Transitioning to a Low Carbon Future with Smart Grid Sensors

December 15th, 2021

Transitioning To A Low Carbon Future

Aclara

Case Study: Distributed Generation

Medium & High Voltage Electricity Networks

Western Power Distribution, UK

Western Power Distribution is one of six electricity Distribution Network Operators in the United Kingdom responsible for the Midlands, South Wales, and the South West, delivering

electricity to more than 7.7 million customers over a 55,300 square kilometer service area.

THE LOW-CARBON NETWORK FUND

The company is leading a number of innovative, low carbon projects as part of the Low Carbon Network Fund, introduced by UK energy regulator, the Office of the Gas and Electricity Markets (Ofgem), to prepare for the electricity network of tomorrow – assisting the uptake of low carbon technologies, helping provide affordable and reliable solutions for energy users.

“Our distribution network is the backbone of how we deliver electricity to homes and businesses.” BEN GODFREY – Innovation and Low Carbon Networks Engineer at WPD

IMPROVING RELIABILITY AND OPTIMIZE NETWORK PLANNING

With this deployment, the Aclara grid monitoring platform is providing WPD with real-time visibility into its distribution grid, allowing the network operator to improve reliability and optimize network planning as it eases its transition to a low carbon future.

Distribution Network Operators such as WPD are expecting changes in the way electricity flows around the network as consumers adopt low carbon technologies including electric vehicles and heat pumps.

PROJECT FALCON

One initiative addressing this concern before it becomes reality is the Flexible Approaches to Low Carbon Optimised Networks (FALCON) project, a U.K. regulator-funded program that aims to improve the industry’s understanding of infrastructure needs in a low-carbon environment. WPD is working with innovative smart grid leaders such as Aclara to find the best ways to manage network problems expected to arise from low carbon technologies and generation.

“We selected Aclara’s grid monitoring platform because it provides us with better information for network planning, which will help us improve grid reliability and enable

the transition to a low-carbon future.” BEN GODFREY Innovation and Low Carbon Networks Engineer at WPD

Aclara partnered with Powerline Technologies Limited, a leading U.K. supplier of smart grid equipment, to deliver the Aclara platform to WPD as a part of Project FALCON.

REAL-TIME VISIBILITY WITH ACLARA’S SMART GRID SENSORS

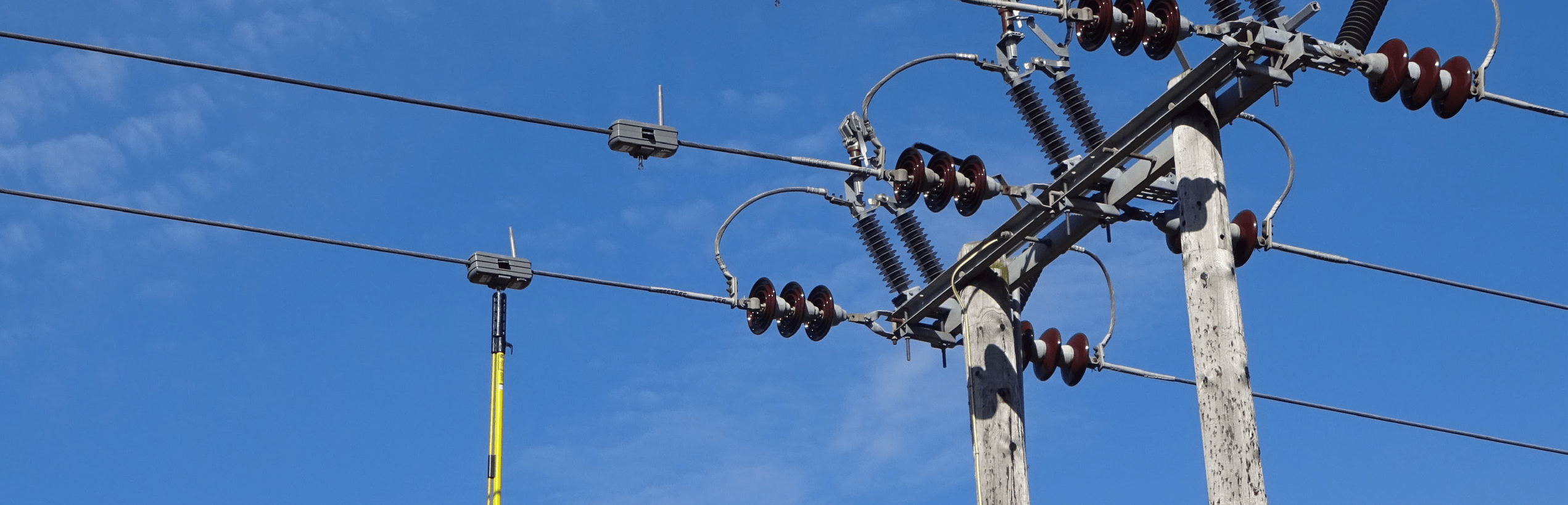

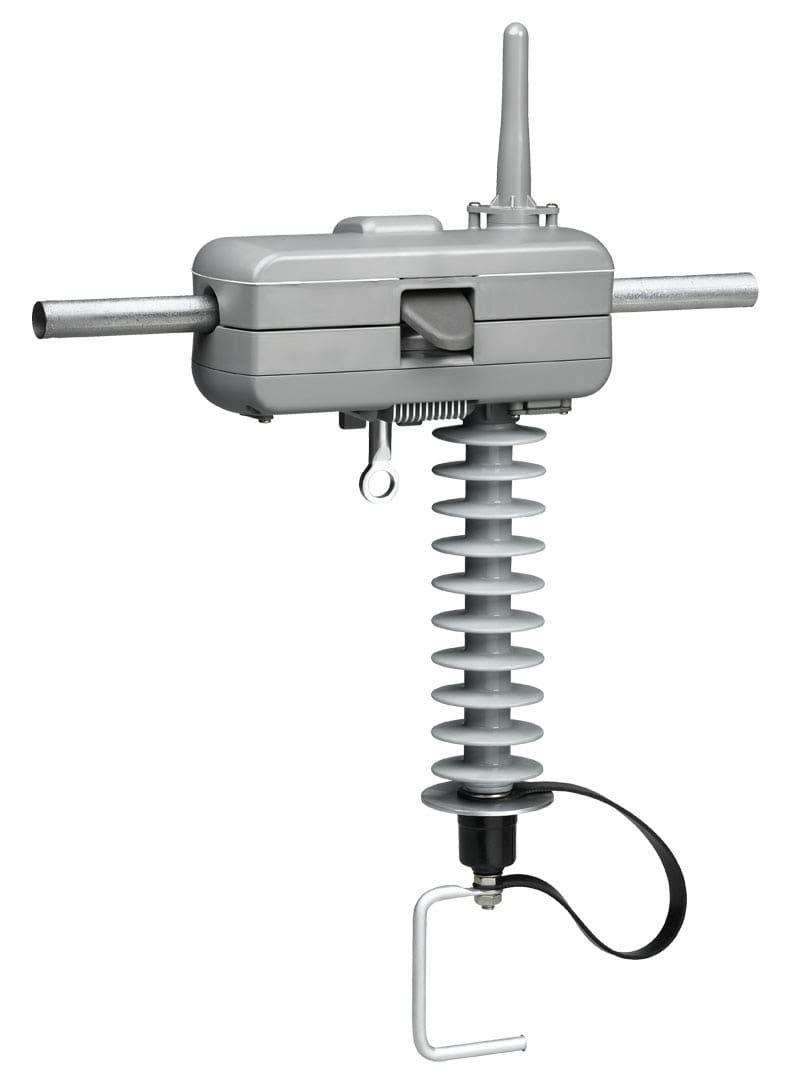

Aclara leads the industry in providing inductively powered, low-current Smart Grid Sensors that give utilities real-time visibility into the distribution grid down to three amps. They are lightweight, easy to install and provide immediate real-time data about grid conditions.

Unlike first-generation fault indicators, Aclara line sensors are combined with predictive analytics software to provide the ideal combination of realtime load and power quality monitoring with outage and fault detection. Within the software, customizable rules alert utilities to inefficient operating conditions that indicate future outages, load imbalances, or technical loss.

These events are linked to map-view displays that make it easy for utilities to pinpoint the locations of problems for quick response and solution. The Aclara platform easily integrates with Data Historians, SCADA, OMS, and DMS systems or can run as its own stand-alone solution hosted by Aclara or within a utility’s own data center.

Aclara

At Aclara, we help utilities manage change, seek new approaches and harness data and new technologies to supply more efficient and reliable services to their customers. We offer a comprehensive suite of solutions comprised of meters and edge devices, advanced metering infrastructure (AMI), software, installation services and provision of labor with a single point of accountability. As an end-to-end, smart infrastructure solutions (SIS) partner we couple innovative technology with data-driven solutions to predict, plan and respond to system conditions across electric, gas or water distribution networks.

Further Reading

Aclara Sensors | UKPN | Detecting Transient Faults on Overhead Networks

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Aclara Sensors | UKPN | Detecting Transient Faults on Overhead Networks

December 15th, 2021

Detecting Transient Faults on Overhead Networks

Aclara

Case Study: Grid Monitoring

Medium & High Voltage Electricity Networks

UK Power Networks, United Kingdom

UK Power Networks is the United Kingdom’s biggest distribution network operator (DNO) and delivers electricity to more than 8 million homes in London, the East and South East of

England. It is transforming itself from a Distribution Network Operator, which simply delivers electricity, to a Distribution System Operator (DSO), which enables a smart, flexible

system that responds to customers’ needs.

The company says its vision for the future proposes significant changes to enable medium voltage electricity networks to enable consumers to use new and emerging technologies.

Transient Fault Outages

BUSINESS CHALLENGE

As part of its effort to continuously improve, UK Power Networks is constantly assessing ways to reduce the number of power outages and their duration. UK Power Networks has more than 46,000 km, or 28,500 miles, of overhead line networks that can occasionally be damaged by high winds, bird strikes or tree contact.

These can result in short power interruptions known as transient fault outages. Transient events typically include short variations of fault current without causing a sustained power outage. Transient events that are cleared automatically by very short interruptions from breakers or reclosers are referred to as momentary fault events.

It can take 6 to 10 hours, on average, to identify the exact location of a transient fault on overhead lines, especially when the outage occurs at night, is in a hard to reach location, or takes place during a storm. Once a fault it located it can then take an additional 1-2 hours to fix it. Reducing the expense and time associated with finding and repairing faults is an important component of reducing customer minutes lost.

Today, the company uses traditional fault passage indicators (FPIs), known as fault current indicators (FCIs) in the United States, to help them identify when faults occur on its overhead electrical system. However, there are several challenges with using FPIs.

While FPI alarms integrate with UK Power Networks’ GE PowerOn™ advanced distribution management system, they lack capabilities to help locate transient faults. They are not effective at detecting momentary line disturbances or developing faults and do not capture fault waveforms.

Due to less sophisticated triggering and classification methods, they may also generate false indications of actual outages or the true location of faults. As a result, operational staff then must be sent out to search for the fault location. This is done through a systematic process of opening the manually operated OHL switches installed along the route, energizing segments and ‘walking the line’ until the fault location is found.

This is a time consuming process.

Reduce Power Interruptions

SOLUTION OVERVIEW

UK Power Networks has recently undertaken a ground breaking project to improve customer service and was looking for new technology to help reduce power interruptions and customer minutes lost on its overhead networks. Funded by the Network Innovation Allowance (NIA), an incentive of the United Kingdom’s Office of Gas and Electricity Markets (Ofgem), part of the project’s objective is to develop algorithms that can predict fault location on overhead circuits and that distinguish false alarms from true outages.

To accomplish its goal, UK Power Networks selected the Aclara Grid Monitoring platform comprised of smart grid sensors and Predictive Grid® analytics software. The power sensors are easily deployed on overhead lines via hot stick, even in remote locations. The data they provide, including voltages, will allow the company to develop a real-time impedance model at the time of a fault, allowing precise location of the faults without having to ‘walk the line’.

“Our goal is to reduce the duration of supply interruptions by directing linesmen to the most likely fault locations. The trial will demonstrate Aclara’s “distance to fault” algorithm to

improve restoration times. ‘We are regularly reviewing Aclara power sensor input as part of UK Power Networks’ overall quality of supply improvement program and hope to make more strides in preventing network failure conditions.” PETER LANG – UK Power Networks’ Project Manager

UK Power Networks has installed over 400 power sensors on 11kV overhead lines on 45 feeders as part of an implementation of the Aclara Grid Monitoring platform in two of its three geographical regions – its East and South East areas.

The Aclara Grid Monitoring platform will continuously monitor load and power quality in places where troublesome overhead circuits have caused many supply interruptions. They are battery-free smart grid sensors capable of monitoring real-time voltage on distribution networks to within 0.5% accuracy.

Power sensors are installed on overhead lines with hot sticks and require no calibration or additional, pole mounted equipment.

These specific line sensors were installed for three reasons:

1 – To allow UK Power Networks to gain better network visibility on its overhead circuits and reduce the time it takes to identify permanent faults that are located on specific spurs or between sectionalised points on the main line.

2 – To reliably detect and resolve developing or transient faults caused by events including branches touching power lines, animal incursions, bird strikes, and defective equipment.

3 – To reduce the length of supply interruptions by directing linesmen to the most likely fault locations.

The Aclara power sensor is a highly integrated and rugged solution that is a fraction of the cost of traditional kits of equipment with equivalent functionality. It introduces additional OpEx savings due to its simple installation and highly reduced maintenance costs compared with similar alternatives.

Precise measurements and events captured by Aclara power sensors, combined with the sophisticated analytics in its sensor management system (SMS) software, including an algorithm that identifies the exact location of faults, provide highly accurate, real-time reporting of fault events. Thus, the Grid Monitoring fault location solution greatly improves restoration times.

Additionally, to build intelligence about what might cause a power failure in the future, Aclara’s SMS software classifies faults and disturbances that do not cause immediate outages. For example, incidents like momentary faults or line disturbances are categorized and can be filtered to show trends across a circuit or during certain times of the year.

This Predictive Grid® analytics capability of the Aclara SMS software lets UK Power Networks identify fault locations quicker, allowing engineers to study fault waveforms to better diagnose the true cause of fault events. It can predict and alert engineers and operators to early signs of developing fault conditions based on frequent patterns of transient conditions.

In addition, Aclara smart grid sensors are easily deployed towards the end of feeders and spurs, in locations where currents may be as low as 3A. This is important because battery-powered FPIs and sensors typically require at least 10A – and some up to 30A – to successfully keep the batteries charged. Therefore, the further you get away from the substation, the harder it is to identify faults because previously there were no solutions for low-current areas.

With the continuous reporting of power conditions, the deployment of Aclara’s smart grid sensors has also proven invaluable to help UK Power Networks gain better insight to the true load profile along its circuits. Better visibility of load and voltage conditions aids planners and network operators for both managing switching operations as well as long term network planning.

Grid Monitoring

BUSINESS JUSTIFICATION

Use of Aclara smart grid sensors allows UK Power Networks to have much better visibility of fault Case Study: Grid Monitoring and disturbance conditions along circuits, leading

to changes in methods in working and business practices at the utility.

The company’s engineers now can go directly to the fault location, eliminating the need to ‘walk the line’ to find it. The deployment of Aclara smart grid sensors also demonstrates that transients or pre-faults can be accurately identified on the network. Analysing waveforms allows operational staff to be proactive in trying to identify the cause, allowing preventative maintenance before faults become permanent and cause network failures.

In addition, Aclara technology will help UK Power Networks meet its goals for reducing the number of power interruptions customers have and the length of the power interruption.

This project provides another key tool to support delivery of a more reliable electricity network. The solution enables UK Power Networks to implement improvements in the cost of network operations, replacing expensive manpower intensive processes.

Aclara

At Aclara, we help utilities manage change, seek new approaches and harness data and new technologies to supply more efficient and reliable services to their customers. We offer a comprehensive suite of solutions comprised of meters and edge devices, advanced metering infrastructure (AMI), software, installation services and provision of labor with a single point of accountability. As an end-to-end, smart infrastructure solutions (SIS) partner we couple innovative technology with data-driven solutions to predict, plan and respond to system conditions across electric, gas or water distribution networks.

Further Reading

Aclara Sensors | WPD | Transitioning to a Low Carbon Future with Smart Grid Sensors

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV