Cable Joints & Terminations HV

McGowan Wraps Up £7.2m Wind Farm Cabling Project for SSEN

December 9th, 2022

Wind Farm Cabling

November marked a major milestone for McGowan Environmental Engineering delivering the largest project they have undertaken to date, at Moy Wind Farm, south of Inverness.

In mid-November, the Aviemore-based civil and environmental engineering contractor successfully installed over 60km of 33kV high voltage underground cable consisting of three circuits in trefoil for Scottish and Southern Electricity Networks (SSEN) Distribution at Moy. Utilising cable ploughing, open-cut methods and Horizontal Directional Drilling, a huge multi-department team effort from McGowans over the last 12 months culminated with the circuits being connected to the national grid in recent days.

SSEN awarded McGowans the Moy cabling contract in October 2021 as part of a £7.2m project to deliver a total of 81km of cabling across Inverness and Caithness.

Due to increased wind farm yield from Moy Windfarm and the newly established Burn of Whilk windfarm in Caithness, the projects involved the installation of new 33kV single-circuit and triple-circuit underground cabling, fibre-optic cable, cross-bonding and intermediate earthing across rural and urban areas.

Speaking about wrapping up the vital £7.2m projects, Darren Hendry, Managing Director of McGowan Environmental Engineering, said:

“We are all delighted at Mcgowan Environmental Engineering to have recently completed the combined Moy and Burn of Whilk cable installation projects. This marks a great milestone for our team within the industry as we look to grow organically within the energy sector through our innovative and people-focused approach.”

Donald L. MacKinnon, Head of Large Capital Delivery (SHEPD) at Scottish and Southern Electricity Networks, commented: “Both Moy and Burn of Whilk projects ran very smoothly considering the distances, terrain and number of landowners involved – this is testament to the hard work and professionalism shown by the project teams at McGowans and SSEN.”

Douglas Munro, Senior Project Manager at McGowan Environmental Engineering, said: “The projects have been a huge success thanks to the combined effort of all parties involved: SSEN, landowners, our supply chain, and the local communities who have been impacted by the works. We are appreciative of our highly skilled site delivery team at McGowans, delivering these projects safely to the highest standard in very challenging conditions.”

Innovative Cabling Technology Deployed

McGowan Project Manager, Steven Mitchell, adds: “Vital to the timely and cost-effective delivery of the project at Moy – with minimal impact on the sensitive landscape – was the deployment of McGowan’s proprietary new cable wrapping technology, Eco Cable Protect. The innovative cable protection, provided both projects with an efficient and effective installation solution, which is set to revolutionise the rural cabling sector.”

Eco Cable Protect allows on-site preparation, production and installation, reducing project delivery times and costs whilst keeping any environmental impact in sensitive landscapes and habitats to a minimum.

Project Spotlight: Burn of Whilk Wind Farm Onshore Cable Installation

Client: SSEN Distribution Location: Caithness, South of Wick (Scotland) Dates: October 2021 – February 2022 Description: to deliver 23.5-kilometers of 33kV cabling through the installation of new single-circuit and triple-circuit underground cabling plus fibre-optic cable – including cross-bonding and intermediate earthing – across rural land. Burn of Whilk Wind Farm: owned and run by Eneco UK and became fully operational in September 2015. The nine-turbine wind farm has a power capacity of 22.5MW and has the ability to generate the equivalent energy needs of 12,500 households per year.

https://www.youtube.com/watch?v=94kiMIbptQs

About McGowan

McGowan Environmental Engineering Ltd was founded in 2009 and is headquartered in Aviemore, within the Cairngorms National Park. We have experienced continued growth and development to become a highly respected contractor, with clients in both the public and private sectors and a proven track-record in delivering civil and environmental engineering projects across the UK & Ireland. Our underlying focus is to deliver quality and value, where we can earn trust and develop longer-term, mutually beneficial working relationships. Every client and project is different, which is why we offer bespoke solutions with a tailored service offering, delivered by a dedicated and skilled project team. We respect our clients and the environment, taking great pride in who we are, what we do and how we do it.

More News

- McGowan selected for Cairngorm conveyor project

- Project Complete: Weir removal & watercourse realignment

- McGowan Presents Eco Cable Protect UK Ltd

Cable Technology News is the leading provider of news and technology information for the cable and wire industry. The website provides opportunities for manufacturers and distributors to feature their products and services via press releases, video, directory listings and advertising. Energy Projects & Technology is part of Cable Technology News, providing news and information on projects, contracts and technology within industry sectors such as power, renewables, subsea and many more.

➡ You can Follow their LinkedIn Company Page here.

Cable Technology News is updated daily with the latest news covering all the main areas of the cable and wire industry and also provides opportunities for manufacturers and distributors to feature their products and services via news, video, profiles and advertising.

Thorne & Derrick | Distributors of MV Medium Voltage Cable Accessories

Next Generation Data Centres Need Medium Voltage UPSs & Fuel Cells

December 8th, 2022

Data Centres

Medium Voltage UPSs & Fuel Cells

Original Article By Danel Turk, ABB Global Data Centre Segment Leader

As data centres grow larger, a move from LV to MV is a natural step. Medium voltage (MV) uninterruptible power supply (UPS) and fuel cell technologies have the potential to protect the availability of and provide power to the grid, while saving energy and carbon emissions.

Why are data centre operators embracing green trends?

Increased environmental legislation, coupled with record-high energy prices, puts European operators under pressure. With energy experiencing a supply crisis at a time of high demand, energy-intensive businesses like data centres are eager to take more control over their energy usage. This will help them meet new legislation, maintain power continuity, and earn income from energy markets.

New UPS and fuel cell technologies can provide both power continuity and power to the grid. The technologies also allow the data centre to integrate renewable energy and even generate income by participating in demand and frequency response schemes. Using low-carbon technologies also help to build your reputation as a sustainable business.

Why is the medium-voltage level beneficial for a UPS system?

Data centre UPS systems traditionally operate alongside servers and HVAC equipment at the low-voltage level. However, data centre facilities are becoming larger and demanding more power to gain economies of scale. As power requirements increase, moving to medium voltage is a natural step for UPS systems.

Aside from offering the two primary benefits of increased reliability and reduced costs, medium-voltage systems provide other benefits too.

Operating at 24kV, medium-voltage equipment is significantly more robust than comparable low-voltage systems. A data centre would also require fewer units to meet its power needs. As individual modules, these units are easier to install, operate, and maintain than multiple low-voltage systems spread around the facility. This reduces downtime because more equipment automatically means more risks.

Since the MV UPS operates at a medium-voltage level at the grid connection point, it’s flexible enough to support any data centre loads.

Medium Voltage MV Data Centres

Thorne & Derrick Stockists for Medium Voltage Cable Accessories | Joints | Terminations | Connectors | Tools

MV Approach

The medium-voltage approach also has energy efficiency advantages as it runs lower currents, reducing electrical losses. The latest systems boast efficiency of up to 98 percent because of power conversion equipment that supports power quality continuously without requiring batteries. Evaluated against a rotary UPS, the higher medium voltage efficiency can save up to 4.2 GWh. This saving equates to 1,245 tonnes of CO2 emissions over a 15-year life for a large site.

Added benefits are achievable by using a scalable and modular MV UPS.

For instance, operators can deploy up to ten ABB HiPerGuard units of 2,250 kVA in parallel to handle 22.5 MVA power. In an N+1 configuration, it’s possible to take one system offline while leaving the others in service for ease of maintenance.

Since the MV UPS operates at a medium-voltage level at the grid connection point, it’s flexible enough to support any data centre loads. This flexibility ensures power continuity for servers to remain stable throughout the center by overcoming short outages and power quality concerns.

In contrast, low-voltage UPS capacity can potentially become stranded when power can’t be reassigned elsewhere. This may require additional capital outlay to ensure full coverage of backup power.

Furthermore, operating at the MV level saves on additional capex, as the UPS units can be installed in an electrical room or substation rather than occupying high-value server room space. Such a location makes it ideal for feeding power back into the grid if necessary.

How can fuel cells play a role?

Many of the largest data centre providers actively pursue strategies to reduce or eliminate reliance on diesel generators. For example, Microsoft has committed to ending diesel use by the end of 2030 and is already trialling fuel cells as an alternative.

In 2020, Google announced a commitment to use large batteries instead of diesel gensets at a new site in Belgium. The appeal of fuel cells lies in their potential to provide local backup power and even inject power into the grid during peak demand periods. Fuel cell technology combines materials and chemical science with automation, and protection and control systems, therefore its application requires specialist knowledge from each field.

Importance of Fuel Cells

Fuel cells can be integrated into power systems, for instance deploying 200kW installations to power electric vehicle charging stations where grid power is unavailable. Furthermore, fuel cells provide emergency backup in microgrids and power for telecoms sites at other remote locations.

As a component of microgrids, fuel cells can be combined with other technologies to meet any off-grid or prosumer need

However, for data centres, further investigation needs to take place at the multi-megawatt level. This requires sophisticated development and testing of the interfaces between fuel cells, energy storage systems, electrical switchgear, and control infrastructure. We need an integrated approach to data centre requirements.

As a component of microgrids, fuel cells can be combined with other technologies to meet any off-grid or prosumer need. The latest offerings are available as modular 1 and 3 MW solutions, which are fast to deliver and deploy.

Fuel Cell Station

How can operators use backup capacity to generate income?

Operators with robust infrastructure can earn additional income and offset their costs by selling their excess power back to the grid during peak demand. This can take place through demand response schemes or using a battery energy storage system to support the integration of renewables like wind and solar.

At the end of the day, the data centres own power needs must remain the top priority. Therefore, operators can use MV UPS systems and fuel cells to support their own servers and HVAC systems in the first instance. Only when these needs have been met can spare capacity be used for grid support.

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, substation battery rooms and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

WEBINAR | Glass Fibre Reinforced (GRP/GFRP) Cable Support Systems (CPD APPROVED)

November 23rd, 2022Cable Support Systems

What is GRP?

GRP/GFRP (Glass-fibre reinforced polymer) cable support and trough systems possess unique properties that enable them to resist highly corrosive environments; particularly where conditions indicate that conventional materials may not provide an economic service life. During this brief but comprehensive webinar/online learning; you will be getting to know more about the type of cable support system designs; GRP as a composite material from the sustainability point of view; how to choose the right cable support; advantages of GRP cable support systems; its applications and many more. This course is designed for beginner and intermediate learners.

Thorne & Derrick are a Preferred Distributor & Supplier of MITA brand Cable Support Systems – contact us for scheme design, specification guidance and competitive delivery of product from UK stocks at reduced lead times.

MITA brand is now powered by Wibe Group. MITA have been supporting customers through their technical journey on choosing the correct product, manufactured from GRP, in cable support applications for almost five decades. MITA are now fully separated operationally from Schneider Electric. They now have a stand alone presence in the UK market with their “Made in UK” products which are fully compliant to the related cable management standards. MITA are marker-leaders in the manufacture of CABSYS cable trays and GRP cable ladders

Euromold Connectors | Voltage Detection & The Capacitive Test Point Source

September 27th, 2022VOLTAGE DETECTION POINT

Euromold Connectors

The connectors manufactured by Euromold are provided with a capacitive test point: the voltage detection point (VD point). This enables a local check to confirm that the product is de-energised prior to disconnection (use a high resistance test device – approx. 250 MΩ).

The capacitive test point consists of a metallic insert, moulded into the insulation and electrically connected to a convenient external terminal.

➡ Thorne & Derrick can support the specification and supply of the correct MV HV connector – heat shrink, cold shrink and push-on joints and terminations are also available, contact us with your requirements or technical queries.

Thorne & Derrick have an International Distribution Agreement with Nexans Power Accessories UK and are their main stockists and suppliers for their range of Heat Shrink Joints & Terminations up to 33kV as well as their Euromold connectors.

Under normal operating circumstances this terminal is earthed by its conductive rubber cap. The cap must be removed prior to testing. When applying the test device, a capacitive potential divider is effectively established.

The components of which are:

- Ctc: between test point and line potential

- Ctg: between test point and earthed conductive screen

- Cm: representing the capacity of the detection apparatus

The voltage available at the test point is directly proportional to the line voltage depending on the capacitance ratio. Although relatively high voltages can be present on the test point after removing the conductive cap, the overall available energy is minimal and any potential would disappear instantaneously if accidentally touched by an operator or other personnel. The current transfer would be a fraction of a micro Ampere and imperceptible to human touch.

Key:

- Key Conductive rubber cap

- Metallic insert (capacitive test point)

- EPDM conductive screen (earth potential)

- EPDM insulation

- EPDM internal screen (line potential)

- Metallic insert (line potential)

Separable Connectors

Euromold 152SR – 158LR 400LR

The Euromold 152SR straight connector with 250A current rating is designed for Interface A and covers voltages from 12kV to 24kV with a maximum conductor size of 95sqmm.

Euromold 152SR straight connectors can be supplied as an elbow connector (158LR) and with surge arresters (156SA) and plug-in type epoxy bushings for oil filled and dry type MV equipment – all suitable for use with Interface A type bushings on SF6 gas-insulated switchgear.

Euromold 152SR-158LR 400LR

The Euromold 480TB tee connector with 630A – 1250A current rating is designed for Interface C and covers voltages from 12kV to 42kV with a maximum conductor size of 300sqmm.

Euromold 480TB plug-in tee connectors can be supplied as a straight connector (450SR) or a coupling connector (800PB, 804PB or 809PB) and with surge arresters (800SA or 300SA) – all suitable for use with Interface C Compact type bushings on SF6 gas-insulated switchgear.

Euromold 909TB 676LRA 750LR-775LR

The Euromold 909TB tee connector with 250A current rating is designed for Interface F and covers voltages from 12kV to 42kV with a maximum conductor size of 1200sqmm.

Euromold 909TB plug-in tee connectors can be supplied as a coupling connector (909PB) and compatible with plug-in type epoxy bushings – all suitable for use with Interface F type bushings on SF6 gas-insulated switchgear.

Nexans Cable Accessories

Nexans manufactured Cable Accessories are in extensive service throughout the UK DNO power grid – the Euromold connectors are approved and are approved by several DNO/IDNO operators dependent on the product, voltage and network.

The JTS Joints and MONO Terminations are increasingly preferred and adopted by NERS Accredited Independent Connection Providers (ICPs) working on 11kV private networks.

Euromold Connectors | Properties & Performance – 40 Years of Market-Leadership

September 27th, 2022

Euromold Connectors

Properties of EPDM & Silicone Rubbers

For approximately 40 years Euromold has been formulating and moulding rubber compounds. The knowledge and skill gained over this extensive period has overcome many obstacles and are a great asset for the future of the brand and the Euromold connectors.

The resultant hydrocarbon-based elastomers have all advantages of general purpose rubbers but its performances excel in electrical strength and resistance to environmental conditions.

The silicone rubbers used by Euromold connectors in its cold-shrinkable and slip-on terminations have been selected for their excellent tracking resistance as well as their unique hydrophobic properties.

Thorne & Derrick have an International Distribution Agreement with Nexans Power Accessories UK and are their main stockists and suppliers for their range of Heat Shrink Joints & Terminations up to 66kV as well as their Euromold connectors.

OZONE/CORONA RESISTANCE

The outstanding resistance to corona is due to the ability of the EPDM rubber to withstand ozone and other chemical compounds formed by discharges and its resistance to heat.

CHEMICAL RESISTANCE

Products made from EPDM rubber resist attacks made by many acids, alkalis, detergents, phosphates, esters, ketones, alcohols and glycols. They give particularly outstanding service in the presence of hot water and high pressure steam. Like all hydrocarbon-based elastomers, EPDM is not resistant to hydrocarbon solvents and oils or chlorinated hydrocarbons.

RADIATION RESISTANCE

EPDM connectors are also installed in nuclear containment areas.

RESISTANCE TO MECHANICAL ABUSE

EPDM rubber has good resistance to compression, cutting, impact, tearing and abrasion over a wide temperature range.

ELECTRICAL PROPERTIES

| Typical Values | EPDM Connectors | Silicone | |

| Insulation | Conductive | Insulation | |

| Dielectric strength (kV/mm) | 33 | – | 24 |

| Dielectric constant | 2.7 to 3.1 | – | 2.6 |

| Dissipation factor (x 10-3) | 2.5 | – | 4 |

| Volume resistivity at 20 °C (Ohm-cm) | 1014 | 50 | 1015 |

OTHER Euromold PROPERTIES

| Typical Values | EPDM Connectors | Silicone | |

| Insulation | Conductive | Insulation | |

| Specific gravity (kg/dm³) | 1.33 | 1.12 | 1.15 |

| Tensile strength (N/mm²) | 4.8 | 11 | 8.5 |

| Shore hardness (Shore A) | 65 | 80 | 47 |

| Elongation (%) | 400 | 450 | 700 |

| Abrasion resistance | good | excellent | poor |

| Heat ageing | good | good | good |

| Temperature range (°C) | -60 to +130 | -60 to +130 | -80 to +200 |

| Resistance to: | |||

| -U.V. | good | good | good |

| -Ozone | excellent | excellent | excellent |

| -Sunlight | outstanding | outstanding | outstanding |

| -Water absorption | very good | very good | excellent |

| -Solvent | poor | poor | poor |

| -Hydrocarbon oil | poor | poor | good |

| -Silicone oil | good | good | poor |

RESISTANCE TO THE ENVIRONMENT

EPDM rubber has properties comparable with the best speciality elastomers in resistance to weather. Accelerated life and salt spray tests suggest excellent properties which have been proven in practice by more than 40 years experience in widely varied applications all over the world. Silicone rubber has outstanding long-term resistance to weather in aggressive environments (industrial, coastal and desert climates).

RESISTANCE TO WATER

Water has little effect on the properties of EPDM hydrocarbon rubber. Even long immersion in hot water results in minimal loss of tensile strength. Tests also show a very low degree of water absorption. Silicone rubbers retain their surface hydrophobicity which is a considerable advantage for outdoor applications.

INTERNATIONAL PROTECTION CLASS

By design, Euromold connectors are protecting live elements of the connection against ingress of dust and water. The protection class per IEC 60529 is IP67.

PROPERTIES OF SILICONE LUBRICANT

The high viscosity silicone grease has been chosen for both its lubrication and dielectric properties. It is used as a lubricant when installing all premoulded rubber accessories on epoxy bushings as well as on the core insulation of dry cables.

Its selection is the result of several years of evaluation by Euromold of many types of silicone grease. Silicone grease displays a high level of long-term lubricating stability avoiding any ageing effects (e.g. the risk of sticking).

It also offers excellent dielectric properties assuring good performance at high voltage interfaces. In addition, the grease contributes in making interfaces watertight. It is completely compatible with all premoulded rubber accessories as well as with polymeric insulated cables.

USES

Use of this grease has proven to be of value in the installation of accessories in series and for operations such as greasing interfaces after disconnection. The installation instructions included in each product package detail clearly the application of the silicone grease.

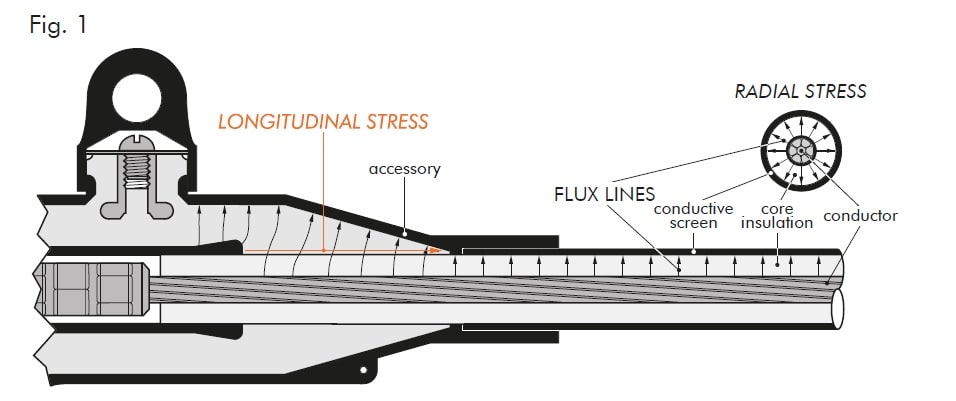

ELECTRICAL STRESS

ELECTRICAL STRESS IN CABLES

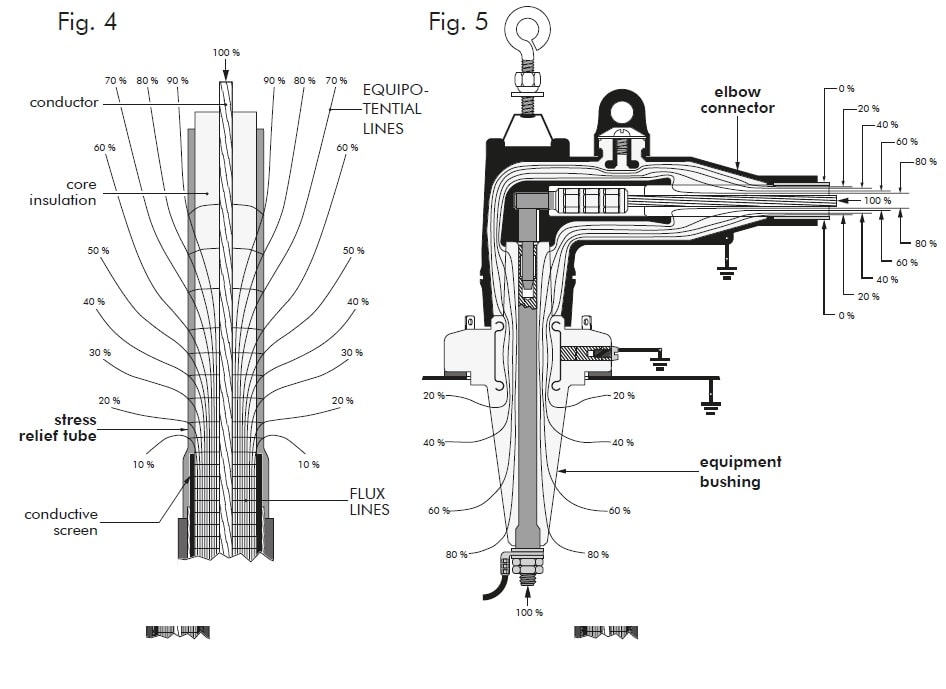

The design and construction of screened power cables is primarily based on two types of electrical stress – a radial stress which can be represented by flux lines and a longitudinal

stress on the surface of the insulation where the screen has been removed. (Fig. 1).

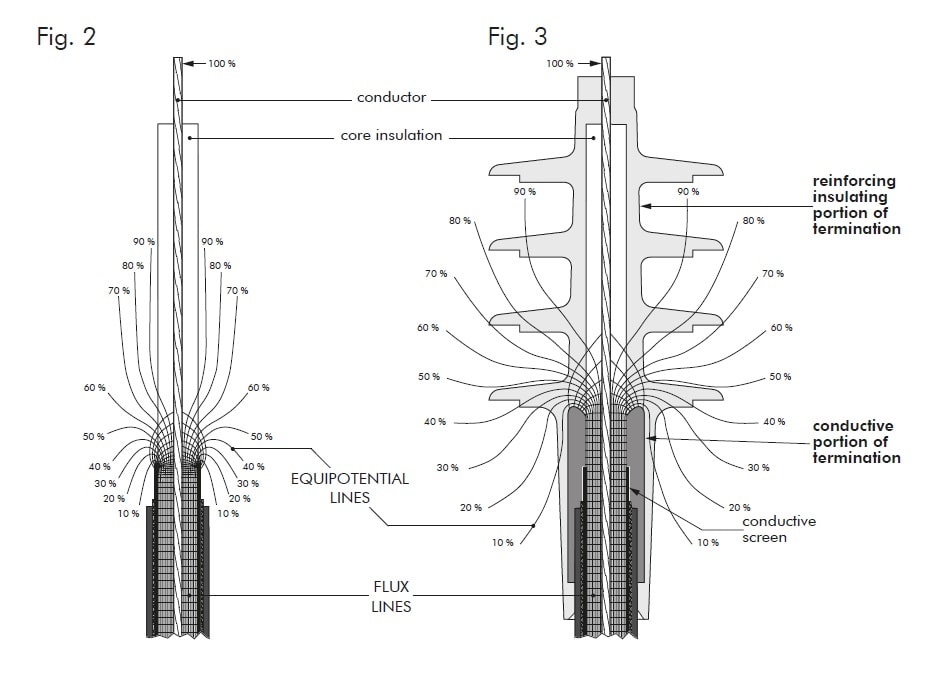

ELECTRICAL STRESS RELIEF

When the semi-conductive screen is cut, the electrical field distribution changes radically. The surrounding air and the dielectric material in the vicinity of the cut screen become overstressed (Fig. 2) and breakdown of the cable will soon occur. To avoid this, we control the equipotential lines by installing a termination with a stress cone (Fig. 3), a termination

with linear stress relief (Fig. 4) or a separable connector (Fig. 5) at the end of the screen.

The terminations will make sure that equipotential lines are sufficiently far apart when they finally emerge into the air and that they will not cause ionization. The separable connector keeps the equipotential lines inside the cable/connector assembly in a controlled way. This stress relief is automatically built into all the accessories by the precision moulding of conductive and/or insulating EPDM/silicone rubber.

Nexans Cable Accessories

Nexans manufactured Cable Accessories are in extensive service throughout the UK DNO power grid – the Euromold connectors are approved and are approved by several DNO/IDNO operators dependent on the product, voltage and network.

The JTS Joints and MONO Terminations are increasingly preferred and adopted by NERS Accredited Independent Connection Providers (ICPs) working on 11kV private networks.