Cable Pulling & Laying

Cubis Systems Network Rail PADS Approved Access Chambers & Cable Protection

August 17th, 2020

Access Chambers & Cable Protection

Cubis Access Chambers & Cable Protection

Network Rail PADS Approved

The Cubis Systems Network Rail PADS approved access chamber and cable protection products ULTIMA access chambers and MULTIduct™ cable protection were specified by Amey Consulting on a recent Midland Mainline upgrade at Kettering Electrical Stabling.

Reduction in track possession and installation times were key factors in the products being selected to deliver the electrical containment and chamber access elements of this light maintenance and stabling facility.

800×800 and 1200×1200 sized ULTIMA Chambers and approximately 700m of 4 Way XL MULTIduct™ were used on this part of the project and installed mainly along the four walkways between the tracks of the sidings.

The versatility of the modular ULTIMA sections was fully utilized on site, building up the levels of the chambers in segments to get to the correct height. This was found to be a much easier installation process than traditional build options given that the stabling facility was created by excavating down in excess of 2m from ground level to sub track formation.

Space is also at a premium when operating at trackside and the use of MULTIduct™ created significant installation space and time savings over regular circular ducting due to the compact profile.

The Cubis team helped from design phase to final installation advice, to ensure another successful rail project.

Cubis Access Chambers

CUBIS ACCESS CHAMBERS

STAKKAbox™ chambers are significantly faster to install than conventional alternatives, with complete installations typically taking under one hour. This results in reduced costs for the installer and significant time saving. No specialist equipment or plant is required in order to install an access chamber and there is no need for specialist box builders. With flexible installation, Cubis access chambers can be adapted to suit on-site conditions with standard tools to build over existing networks.

Cubis | Access Chambers, Access Covers, Cable Protection & Cable Accessories

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Access Chambers & Cable Ducting | Virtual Lunch Learn with Cubis

August 17th, 2020

Access Chambers & Cable Ducting

Virtual Lunch & Learn with Cubis

Thorne & Derrick, the leading Specialist Distributor of LV HV Jointing, Earthing, Substation & Electrical Eqpt, are distributors for the Cubis range of products. Cubis is the global leader in the design and manufacture of Access Chambers, Access Covers and Cable Protection for infrastructure networks.

With restrictions on travel and the changes in how we work as a result of the current global pandemic, Cubis and Thorne & Derrick will try to continue and diversify our digital offerings to support our clients. With this in mind we are looking at a series of tools to ensure we can still communicate with customers and facilitate meetings/lunch and learns remotely.

In light of this, Cubis has now launched their virtual Lunch & Learn sessions which cover an overview of the following:

- Company Introduction

- Product Knowledge

- BIM & Digital Construction

- Design & Specification Guidance

- Installation Advice

- Case Studies

How to arrange

Contact Thorne & Derrick and request further information.

CUBIS ACCESS CHAMBERS

STAKKAbox™ chambers are significantly faster to install than conventional alternatives, with complete installations typically taking under one hour. This results in reduced costs for the installer and significant time saving. No specialist equipment or plant is required in order to install an access chamber and there is no need for specialist box builders. With flexible installation, Cubis access chambers can be adapted to suit on-site conditions with standard tools to build over existing networks.

Cubis | Access Chambers, Access Covers, Cable Protection & Cable Accessories

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

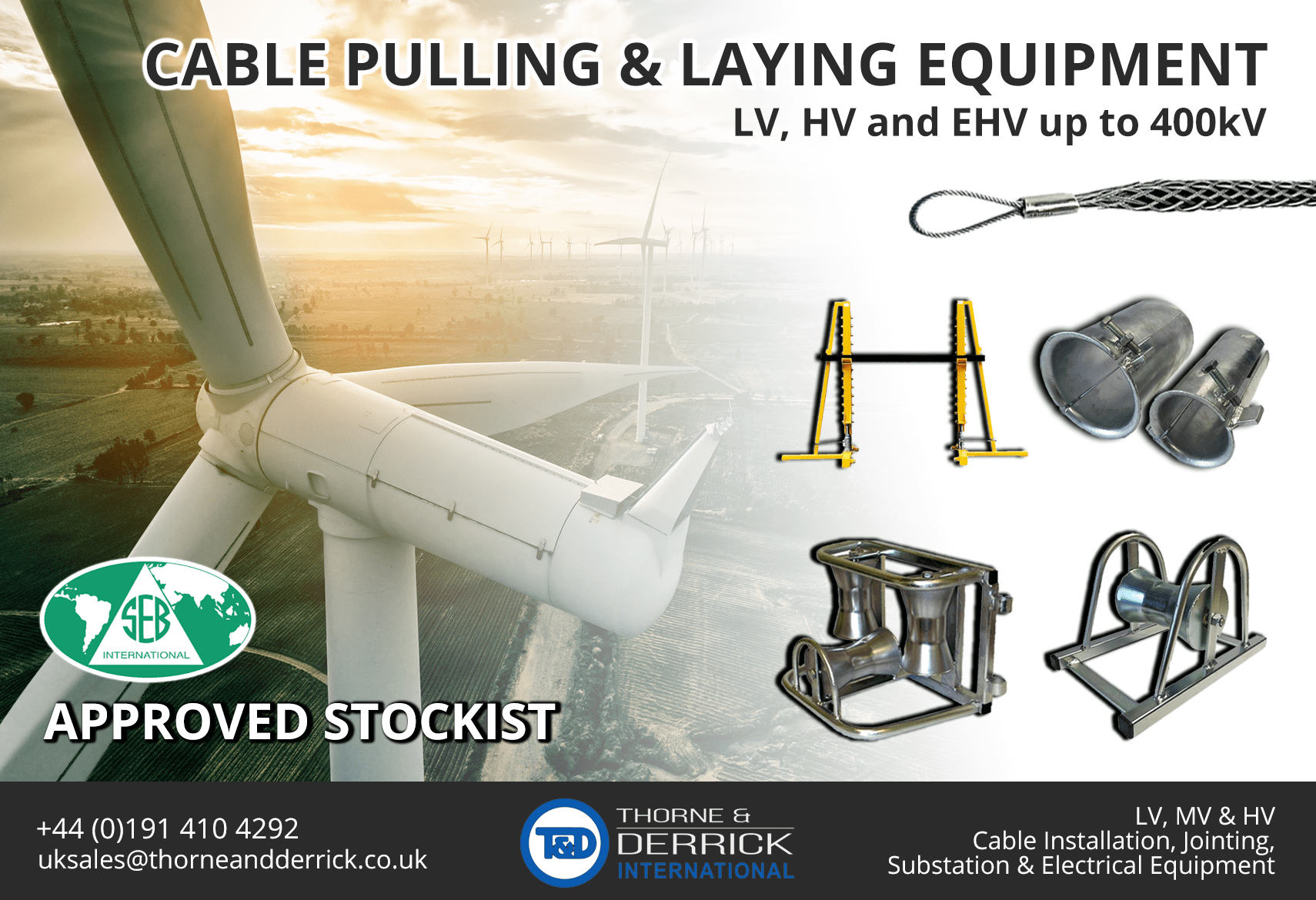

Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

June 3rd, 2020

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

Press Release | 1st July 2021

LV to 400kV

Thorne & Derrick International, based in the UK, are delighted to announce they have entered into an Approved Stockist Agreement with SEB International, the market-leading Cable Laying Equipment manufacturer.

Thorne & Derrick have partnered with SEB to service the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

From today, Thorne & Derrick will provide competitive prices and technical support for the SEB range of exceptional quality, British manufactured Cable Pulling & Laying Equipment – this includes rollers, socks, jacks, winches and trailers to enable cables, umbilicals or pipes to be installed into ducts, trenches and tunnels.

We can provide expert technical advice and pulling system specifications to maximise cable and circuit safety requirements to UK DNO policy standards. Since 1971, SEB International have manufactured both standard range and complex customised cable pulling equipment from the largest product selection found throughout the world.

“Traditionally, our core business has been the supply of High Voltage Jointing & Termination products from stock up to 66kV – as a Specialist Distributor we now have an enhanced commercial strength and added-value service to support projects at the cable laying stage. Whether pulling underground or subsea power cables into trench or duct we can provide reliable and competitive solutions .

Thorne & Derrick and SEB can innovatively overcome the technical and logistical challenges of laying and deploying cables across all sectors – from offshore windfarm to hyper-scale data centre projects, we can help. We have a scheduled sales and marketing campaign to launch and look forward to introducing SEB to existing and new clients,” comments Chris Dodds Sales & Marketing Manager at Thorne & Derrick.

Andrew Hetherington (Commercial Director at SEB International Ltd) adds, “both of our family-owned companies pride themselves on a super-efficient level of customer service, which is unrivalled throughout this industry. Allied to this is the combined technical knowledge and experience that both our businesses possess – this is at the heart of our business success story and we expect this new working partnership to further support the industry and our business goals.”

You can contact Thorne & Derrick to discuss both standard and customised cable handling equipment for the safe installation of underground or subsea power cables: LV, HV and EHV up to 400kV.

Following a post-COVID f2f supply chain meeting at SEB International Ltd – the world leading UK manufacturer of Cable Pulling Equipment – Thorne & Derrick have agreed an Approved Stockist relationship with SEB. Pictured | Andrew Hetherington (MD SEB), Debbie Commins (Sales & Marketing SEB), Chris Dodds (Sales & Marketing Manager T&D) and Jonny Hewitt (Key Account Manager T&D).

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Stokbord Drum | Protection of High Voltage Electricity Cables

April 29th, 2020

Stokbord Drum

Stokbord Drum

Protection of High Voltage Electricity Cables

Representatives from across the utilities sector were shown first-hand how new developments in cable protection have made a significant step forward.

Centriforce, working through their distributor network including Thorne & Derrick, announce a new cable protection product that can help to improve working safety for High Voltage Electricity Cables applications – known as the Stokbord Drum.

The utility sector have been shown first hand how new developments in high voltage cable protection have improved performance, capacity and sustainability

Centriforce, manufacturers of the Stokbord Cable Cover and Stokbord Drum Systems, have developed a revised specification in accordance with The National Grid Standard TS 3.05.07, ENA-TS 12-23 Class 1 and ENA-TS 12-23 Class 2 technical specifications: which takes the thickness from 14mm and 12mm, to 12mm and 10mm.

Simon Carroll, Centriforce CEO, said: “The focus on the day was to demonstrate how Centriforce Stokbord Cable Cover and Stokbord Drum are capable of meeting technical specifications – delivering consistent protection with the benefits of 12mm for The National Grid Standard TS 3.05.07 and ENA-TS 12-23 Class 1 and 10mm for ENA-TS 12-23 Class 2.

“Traditionally, it has been considered industry practice to refer to 14mm protection for The National Grid Standard TS 3.05.07 and ENA-TS 12-23 Class 1, and 12mm for ENA-TS 12-23 Class 2 technical specifications.

“We were involved in those initial specifications, but materials science has moved forward, and the strength and performance of Stokbord now means that the utilities industry can draw on our research and development activity to achieve optimum safety with these new levels.

“This advancement makes a strong economic case for our utilities clients – ensuring that the Stokbord solution continues to be the optimum choice where safety and security count – whilst offering cost savings and sustainability benefits as standard.

“That brings a variety of advantages, including the reduced labour and transportation costs all associated with the introduction of lighter materials.”

Stokbord is a highly versatile impact resistant product that protects underground utilities from damage and at the same time provides a highly visual alert of what lies beneath.

For the utilities sector, it is provided as a cable cover, which is a one metre tile, or in the new drum format – launched last year – which offers a faster and safer solution to installation.

Both systems can used to protect underground utilities, particularly high voltage electricity cables, but can also be used for water and gas pipes, as well as fibre optic cables.

They help to prevent damage to cables buried underground by ensuring that anyone digging in the area at some point in the future, where a cable is laid, hits the Stokbord before they hit the cable – preventing serious injury, as well as a costly and disruptive outage in the electricity system.

Simon added: “For decades, we have been recognised across the industry for our time-proven and trusted methods of keeping underground utilities safe.

“Stokbord is specified around the world for its ability to deliver heavy duty protection for buried utilities, including gas, water, electricity and telecoms.

“It’s built a reputation based on trust. We’ve been the ‘go to’ partner in utilities for more than 40 years, standing out as pioneers in the sector and seen as the experts in knowing what we are doing.

“That expertise and industry knowledge means we are now well-placed to deliver new levels of performance with 12mm and 10mm standards, for 2020 and beyond.”

As part of the event, the visitors to Centriforce were able to witness an on-site impact test by an independent consultant engineer, to see first-hand the impact resistance and specification capabilities at the reduced thicknesses.

Attendees also saw a demonstration of the Stokbord Drum system, where Stokbord supplied on a reel enables it to be rolled across a large area with minimal intervention.

Jonathan Pearce, Head of Sales at Centriforce, said: “The drum system was developed in our work with our customers, who recognised that the amount of time spent in the trench was a rising concern.

“We focused on creating a mechanical rather than manual installation, keeping operatives safer and at the same time significantly speeding up the process.

“It reduces the manual labour involved and creates a lower risk environment as operatives spend less time in the trench.

“With this system and Stokbord Cable Cover, there is now a choice to meet exact project needs.”

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Stokbord Drum Features

- Time saving installation for cable protection at LV MV HV EHV

- Lower risk to operatives and cable installation teams

- High impact resistance – cable protection does not shatter on impact

- Provides clear visual warning with bright colours and bold warning text

- Rot resistant and chemically inert meaning a long service life

- Cable covers conform to internationally recognised standards (e.g. BS 2484)

- Tried and tested by UK Distribution Network Operators and their contractors

Stokbord Drum Cable Protection for Underground Utility Cables

Stokbord® Drum has since been successfully used on a number of large projects across the UK.

Centriforce Tapetile and Stokbord underground cable protection tiles and covers are the market leading, heavy duty utility protection system for protecting underground cable and pipes – this includes low voltage, medium voltage and high voltage power networks working at 11kV and 33kV.

Stokbord Drum Cable Protection for Underground Utility Cables

FURTHER READING

- UKPN Cable Protection Tapes & Covers (LV MV HV)

- ENA-TS 12-23 : Cable Tiles & Cable Covers For Use With LV 11kV 33kV & HV Cables

- Stokbord Drum | Cable Protection for Underground Utility Cables

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

CASE STUDY: ULTIMA Connect At The London Olympics

April 21st, 2020

ULTIMA Connect At The London Olympics

Cubis systems were involved in the major project of the London 2012 Olympics site and stadium redevelopment.

The implementation of Cubis Access Chambers (in particular, the ULTIMA Connect) to assist with the redevelopment project resulted in huge savings in time and cost. The underground infrastructure was developed in time for the Olympics in 2012, and then updated and reconfigured for the future use of the site two years later.

The site has been massively transformed.

Today, East Bank is a new powerhouse for innovation, creativity and learning on Queen Elizabeth Olympic Park. It is a unique collaboration between world-leading universities, arts and culture institution that opens up opportunities for everyone who visits, lives and works in East London. The industrial land has been replaced with landscaped greenery; while the rivers and canals, previously derelict, are now dotted with tour boats and swan-shaped paddle boats.

ULTIMA Connect

London Olympic Stadium Redevelopment

Image by Gill Cooper from Pixabay

STAKKAbox™ ULTIMA Connect Access Chamber provides huge savings in time and cost

Project |

Queen Elizabeth Olympic Park Stadium Renovation |

Client |

London Legacy Development Corporation |

Contractor |

Balfour Beatty & PJ Carey (Groundworks) |

Products used |

STAKKAbox™ ULTIMA Connect |

Cubis supplied large chambers for turning of large high-voltage power cables in the build in time for the 2012 Olympic Games.

The chambers were designed and manufactured using the original ‘cut and bolt’ system to order, the largest being 6m x 3m x 3m (internal dimensions).

Two years after the games finished, the site was being re-configured for future use, which meant upgrading and diverting the buried infrastructure on site. Cubis were asked to supply a solution for two chambers that would be able to be retrofitted over the existing cable banks.

In order to meet the criteria, Cubis supplied the ULTIMA Connect system in flat-pack format for this project. Thanks to the component design, the chambers could be fabricated on site to build around the ducts. This was done by forming two ‘C shape’ chambers around the duct bank until it reached the depth that allowed the chamber to be built normally over the top.

Each installation took less than a day to complete, including the assembly and backfill. This was significantly faster than alternatives, while offering a flexible solution for benching over existing services and creating duct entries.

London Olympic Site Redevelopment with the ULTIMA Connect

The redevelopment of the London Olympic East site now features a new tech cluster of start-ups, corporations, universities, venture capital investors and a huge new data centre. The buildings contain more than a million square feet of redeveloped space that was once home to BT Sport and other broadcasters during and after the London Olympics.

The redevelopment of the site by Laing O’Rourke Group for future use meant the upgrade of more high and low-voltage power supplies on site. Cubis were asked to supply a chamber system solution that could be quickly installed without the need for expensive trades. The use of the STAKKAbox™ ULTIMA Connect offered the customer the flexibility to build on site to bespoke dimensions. The flexibility of the flat-pack connect system was highlighted when the customers’ needs changed at the last minute due to the conditions on site with limited access. The connect system was able to be built and altered onsite for a quick turnaround for the customer and this resulted in the installation of 1 x 5m x 2m x 1.2 deep chamber and 1 x 2m x 2m x 0.9m deep chamber by two operatives in less than 3½ hours.

The significantly faster install time compared to alternatives lead to the order of more chambers by the contractor for further works.

Further Reading: Cubis Access Chambers VS Traditional Access Chambers

Cubis Access Chambers

STAKKAbox™ chambers are significantly faster to install than conventional alternatives, with complete installations typically taking under one hour. This results in reduced costs for the installer and significant time saving. No specialist equipment or plant is required in order to install an access chamber and there is no need for specialist box builders. With flexible installation, cubis access chambers can be adapted to suit on-site conditions with standard tools to build over existing networks.

Cubis – Access Chambers, Access Covers, Cable Protection & Cable Accessories

Thorne & Derrick

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV