Cable Pulling & Laying

Slingco’s Catchblock Gets Network Rail And National Highways Approval

October 19th, 2022

Thorne & Derrick, distributors of a range of Cable Pulling & Laying equipment, are pleased to announce that Slingco’s innovative Catchblock has received formal approval from Network Rail and National Highways (formerly Highways England).

In addition, National Grid has now endorsed the use of the Slingco Catchblock system.

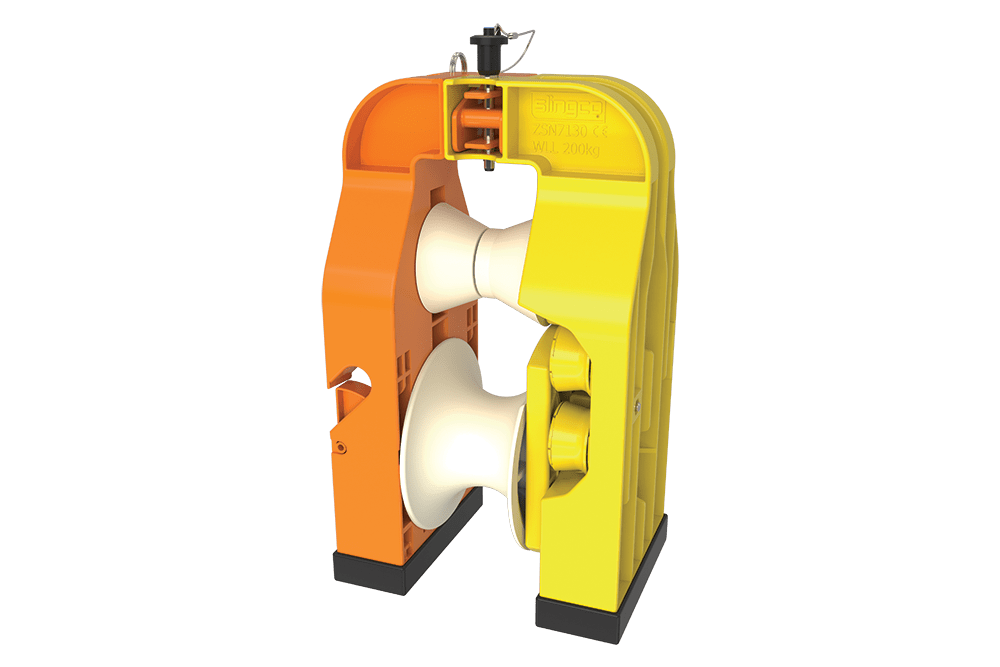

Catchblock

OHL catenary roller system

Catchblock from Slingco is a system for replacing and recovering overhead conductor cable and makes some pretty big claims, including reducing disruption, risks of accidents and costs during replacement of conductor cable.

Nick Dykins, Managing Director, reported: “Our single system has been fully and permanently approved by Network Rail and National Highways.”

“In addition, Network Rail has approved temporary certification for our Catchblock twin system for 12 months. For our utilities contractors this means the seamless replacement of cable with minimal disruption to infrastructure.”

Catchblock is now supplied in two versions – UK and export to meet growing national and international demand for this product.

Catchblock from Slingco is approved by Network Rail and National Highways for OHL Conductor replacement.

Lightweight, robust and easy to deploy, CatchBlock helps to increase efficiency and reduce costs.

REDUCED DISRUPTION

CatchBlock is an innovative OHL catenary roller system. Designed to deploy a twin-rope system, it allows the recovery and redeployment of broken conductors without the need to take possession of road/rail or client/third party property or infrastructure.

REDUCED ACCIDENT RISK

CatchBlock significantly reduces the need for erection and dismantling of scaffolding – cutting down the risk of accidents and harm to site workers.

REDUCED STRINGING COSTS

The reduced need for scaffolding, ease of deployment, and the ability to recover and redeploy, results in a faster, more efficient operation. With fewer hours of effort and less equipment required, Catch Block can deliver substantially reduced costs.

TRUSTED INNOVATION, OUTSTANDING SUPPORT, BESPOKE SOFTWARE

In addition to our complete engineering support service, we offer bespoke software for the CatchBlock system to replace spreadsheet calculations. Intuitive and easy to use, this software needs only limited training to enable site staff to complete regulatory checks. The CatchBlock system has been rigorously trialled and tested.

At no point has there been the need to take out possession orders for property or infrastructure, even with a failed conductor.

CatchBlock has received formal approval from Network Rail and National Highways

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

Safety Hook Extreme | Cable Management for Temporary Electrical Cables

September 27th, 2022

Cable Hooks | Cablesafe | UK Stockists & Suppliers

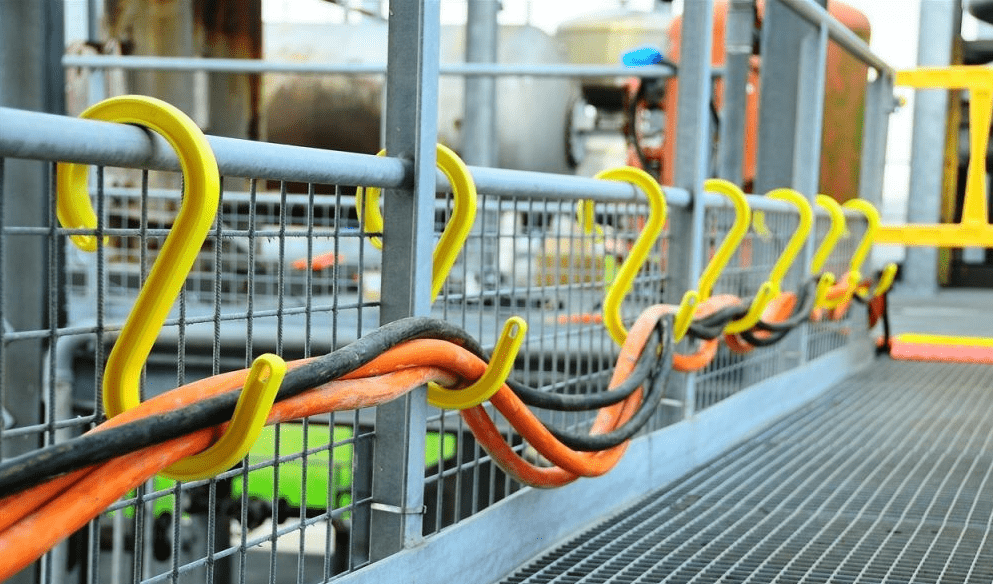

Cable Safety Hook Extreme

Cable Management for Temporary Electrical Cables

CableSafe Safety Hooks are used in cable management while conducting maintenance, turnarounds, construction works and industrial works. The Safety Hook Extreme is used as an electrical safety product to suspend cables and hoses of the work floor.

Multinationals prescribe the use of Safety Hooks in company procedures to adhere to the highest safety practices.

CableSafe Cable Hooks are ‘S’ shaped plastic cable hangers made from GRP (glass reinforced polyester) which are used to support, suspend and retain all types of electrical cables (LV-HV power, control, instrumentation), welding cables, temporary lighting extension cords and hoses in the offshore energy, data centre, marine, petrochemical, mining, rail, chemical and power industries.

Safety Hook Extreme

The Safety Hook Extreme is an advanced specification and high performance version of the standard industrial cable hook manufactured with glass reinforced PBT and is UV stabilized, Flame Retardant (Class: 94V-0, Flame Class Rating 3) and Cold Weather rated.

Safety Hook Extreme

While the Safety Cable Hook is a high quality product, CableSafe engineering team found a way to improve it. That is why we are proud to introduce our new Safety Hook: the Safety Hook Extreme. The development of this Safety Hook Extreme is done in cooperation with a Norwegian oil & gas multinational.

The Safety Hook Extreme is manufactured with glass reinforced PBT and is UV stabilized, Flame Retardant (class: 94V-0, Flame Class Rating 3) and Cold Weather rated.

Safety Hook Exstreme | Prevent Slips Trips Falls Accidents

British Standard

British Standard recently adopted the Requirements for Electrical Installations [BS7671:2018] for the electrical design industry. This standard is developed after the death of two firefighters at Harrow Court, Hertfordshire, in 2005.

The two firefighters got entangled as a result of the collapse of an electrical installation during a fire. The implemented standard states that it requires cables to be adequately supported against their premature collapse in the event of a fire. Installations designs from 2019 onwards have to comply with this new standard. This has implications for personnel involved with design, erection and verification of electrical installations. The Safety Hook Extreme is developed with this standard in mind.

OSHA

The Occupational Safety and Health Administration (OSHA) is an agency of the United States Department of Labor. OSHA claims that fire safety must be everyone’s job at a worksite.

Employers should train workers about fire hazards in the workplace and on what to do in a fire emergency [OSHA Part 1926.150, Subpart F].

During a fire hazard it is of vital importance to suspend cables and hoses of the work floor to prevent slip, trip and fall accidents. That is why we made the Safety Hook Extreme flame retardant.

CPR

In the European Union (EU), the product ‘cable’ was added to the Construction Product Regulation (CPR) in 2017. Thereby, creating an obligation to classify cables according to fire

behaviour in order to be able to market them in Europe for use in buildings [NEN8012:2015]. The EU recognises the danger of fire due to unsafe cables. Cables must be flame retardant,

so should Safety Hooks be.

Different Sizes

The Safety Hook Extreme is available in 4 sizes: 15 inch which holds 265 kg, 12 inch which holds 190 kg, 9 inch which holds 55 kg and 6 inch which holds 40 kg static load. The Safety Hook Extreme colour is yellow, as this is often used in safety equipment.

CableSafe Cable Hooks

Cable Hooks features & Specifications

CableSafe safety hooks are available in four sizes 6, 9, 12 and 15 inches and can carry loads of up to 650g (1.43lbs) – cable hooks are fire retardant, non-conductive and have very high UV resistance ensuring long service lifetime of over 25 years of active use in heavy industries.

A hole in each end of the hook enables the user to secure and fix the cable hook itself by means of a cable tie wrap – cable hooks are suitable for bundled cables.

- CableSafe S-hooks help with cable management & housekeeping

- S-hooks are easy to use, cables & wires are cleared quickly

- Four sizes: 6”, 9”, 12”, and 15” [approximately 15, 23, 30, 38 cm]

- Easily secure loads using a tie-wrap through holes in end of the cable hook

- S-hooks do not conduct electricity or heat

- Durable: over 25 years of active use in heavy industries

- Cable hooks are sold in batches of 25 pieces – minimum order – delivered from stock

- For quantities of 500 pieces or more (per type) it is possible to receive the hooks with the company name engraved in the cable hook or in a special colour. Production time 3 to 4 weeks.

Selection of Cable Hooks

The CableSafe® Safety Hooks are available in 4 sizes

- CableSafe Safety Hooks 15″ (15 inch) diameter

- CableSafe Safety Hooks 12″ (12 inch) diameter

- CableSafe Safety Hooks 9″ (9 inch) diameter

- CableSafe Safety Hooks 6″ (6 inch) diameter

| Cable Hooks | 6″ Hooks | 9″ Hooks | 12″ Hooks | 15″ Hooks |

| Size of Cable Opening (top) | 1 1/8″ | 2.9 cm | 1 3/4” | 4.5 cm | 2 1/8” | 5.4 cm | 2 1/2” | 6.4 cm |

| Size of Cable Opening (bottom) | 1 1/7” | 2.9 cm | 2 3/4” | 7 cm | 3 1/2” | 8.9 cm | 4 1/2” | 11.4 cm |

| Maximum Load | 40 kg | 88 lbs | 55 kg | 121 lbs | 190 kg | 418 lbs | 300 kg | 661 lbs |

| Weight | 55 gram | 0.12 lbs | 105 gram | 0.23 lbs | 350 gram | 0.77 lbs | 650 gram | 1.43 lbs |

| Material | Glass reinforced polyester – injection moulded product | |||

| Available Colours | Yellow | Glow-in-the-dark (Minimum order quantity 25 hooks) White | Black | Blue | Green | Red (Minimum order quantity of 500 hooks) |

|||

CABLE SAFETY HOOKS & EQUIPMENT

OSHA maintains general industry regulations on walking and working surfaces that guard workers against hazards and the risk of injury including clutter, protruding objects and wet conditions. These Health & Safety hazards can harm everyone in a facility, regardless of title or job responsibilities.

Slips, trips, and falls cause nearly 700 fatalities per year and many more injurious accident in the workplace according to the Bureau of Labor Statistics. The CableSafe range of products ensure all cables, wires and hoses are suspended off the ground especially in high traffic work areas such as production floors, machinery spaces and deck level areas where maintenance is being carried out.

CableSafe Safety solutions are critical cable essentials and are well proved construction safety products.

Cable Safety Equipment | Cable Stand | Cable Bridge | Cable Rail | Cable Guard | Dropped Object Prevention Mats

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Cubis Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

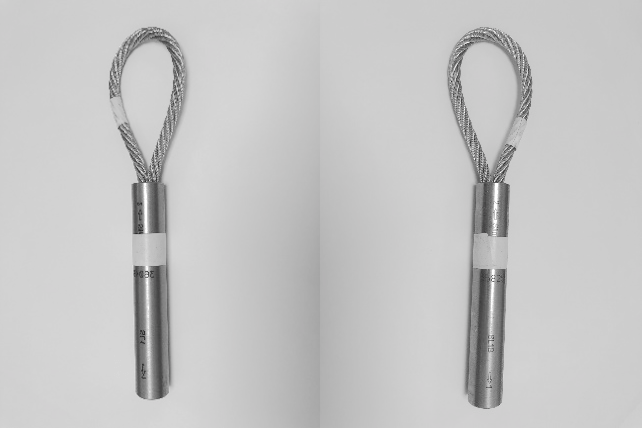

Integrated Fixed-Eye Cable Pulling Socks: The Solution

July 26th, 2022

A custom solution for a global problem: how Slingco integrated fixed-eye cable pulling socks onto existing cables.

Cable Pulling Socks

Thorne & Derrick distribute a complete range of Cable Pulling Products to support the safe installation of LV, MV & HV cables into underground ducts, conduits and trenches. Cable socks and support grips are available for a wide range of applications such as the installation of 33kV & 66kV array cables prior to Jointing & Terminating in windfarm towers, turbines and offshore substations.

THE PROBLEM

Slingco teamed up with one of the world’s leading cable manufacturers to devise a way to integrate a fixed eye pulling loop on to cables manufactured for the global market. During initial consultations with the client, we identified several historical lead time and reliability issues experienced using their existing method and product.

THE SOLUTION

Slingco applied its proven New Product Development process (NPD) to create a solution that provided the client a superior solution. The key to the NPD process is our ability to listen to the client’s needs, understand the challenge and react promptly to provide a viable solution at a competitive price.

The Slingco team of cable management experts identified ways to create a more reliable and less expensive method to install their cables. With Slingco’s manufacturing and supply chain expertise, we were able to shorten the customer’s lead times and stock out issues.

Cable Socks – Pulling Underground Cables & Stringing Overhead Conductors LV MV HV

Fixed eye crimp-on cable socks are easy to install, minimise the length of cable being impacted by the pulling device and are a secure way to pull and manage the cable during the manufacturing and spooling process.

Crimping the pulling eye onto the cable is quick and easy using a Slingco hydraulic crimper, which securely holds the cable during all pulling and cable management processes.

Slingco were able to demonstrate an effective design, manufacture and standardise the product used today, and able to provide an impeccable service via a robust manufacturing supply chain. Our ongoing quality assurance processes ensure the continuous reliability of the product delivered.

Main Improvements:

- Material specification analysed to reduce fatigue / cracking.

- Colour coding for easy identification. Not just pulling eyes but tooling as well to ensure the correct tool is used.

- New tooling and standardised swage diameters introduced to prevent over crimping. Reduce the number of sharp burrs.

- Improved marking of product for easy-to-read identification purposes and easy positioning of the product for swaging.

- Box weights and quantity batch size introduced for ease of lifting and movement.

- Acceptable minimum order quantities and reorder levels introduced.

- Ongoing testing support for new cable designs introduced by client to check compatibility of Slingco fittings.

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

➡ See Also Further Reading

- Cable Laying, Installation & Support Products | MV HV Windfarm

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

- NOF Members Thorne & Derrick and Slingco Ltd Supporting Cables in the Offshore Wind Industry

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct

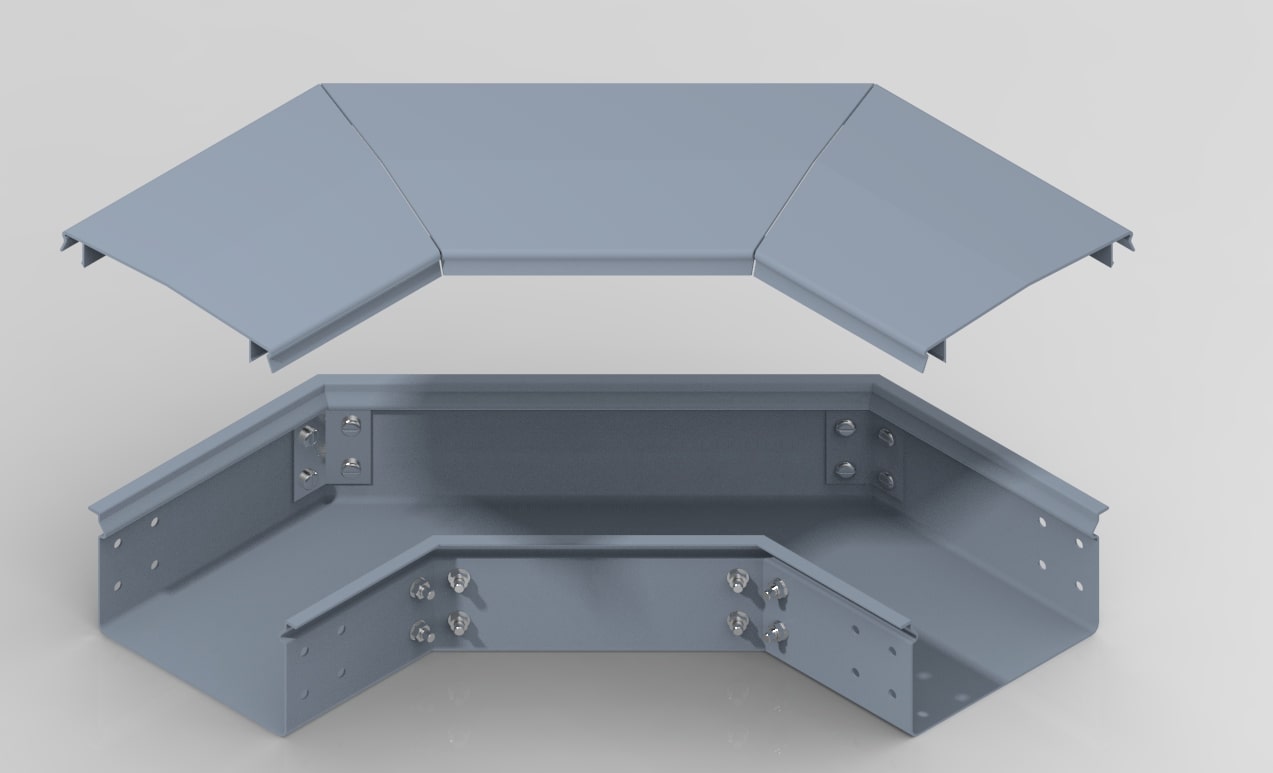

GRP Cable Containment | From LV DC to 25kV Rail Cable Containment

June 28th, 2022

Article Written by Andrew Sillars, Rail Sector Manager, Wibe Group UK Ltd

GRP Cable Containment

Having supported the specification of Glass Reinforced Polymer cable containment since 2005, I have experienced its unique features such as lightweight, long-life durability, no deburring, no earth bonding and many more. All these advantages of GRP Cable Containment support a cheaper, quicker and easier-to-install system that gives a true fit-and-forget solution.

Thorne & Derrick are an approved distributor of the MITA brand, now powered by Wibe Group who are a RISQS approved supplier. Andrew together with Wibe are proud to introduce our extensive cable support offer which includes Glass Reinforced Polymer GRP cable ladders, CABSYS cable trays and elevated cable troughing with accessories.

GRP Elevated Cable Troughing | Containment System for Rail

GRP elevated cable troughing is an especially useful containment system for rail.

Ground Level Troughing (GLT) is often used in signalling and telecoms schemes for the cable connections to lineside equipment such as points, train detection, signals and radio sites. However, in many places, GLT cannot be used due to the ground profile and steep embankments and cuttings. GRP is an ideal alternative for such locations and it is also essential for large current-carrying power cables.

High quality manufacture

Mita GRP is produced by pultrusion technology. This uses a combination of unidirectional and cross-strand glass mat which is resin-impregnated and pulled through a hot die to produce a very solid, structurally sound profile with excellent mechanical rigidity unlike other moulded systems.

Mita GRP does not contract or expand with heat causing the troughing route to distort. It is produced with a high quality of manufacture and modified by the use of additives to the resin, and with protection from ultra-violet light.

This year, with the launch of the new GRP GMAXR 6m troughing range, which allows a 6m post span, Mita GRP becomes a full offer with its 3m or 6m lengths to meet the needs of every application in the most cost-effective way.

Features and benefits

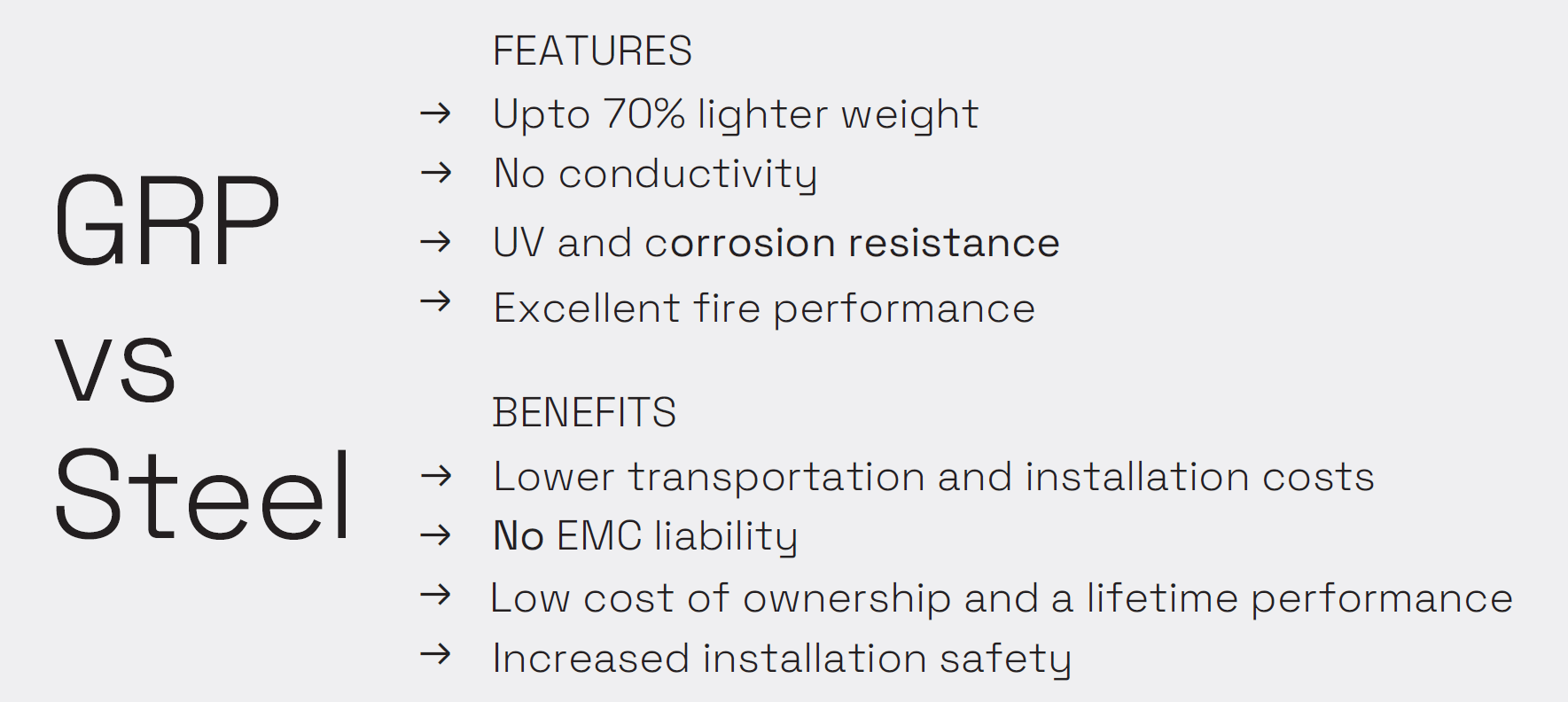

Mita GRP is 70% lighter than steel; it is also corrosion resistant. It does not conduct heat and has excellent durability against adverse weather conditions. The product offers excellent UV stability resulting in a cost-effective long-term solution.

The Mita GRP is provided in a wide range of trays, troughing and ladders which can support any type of cable – especially power and fibre cables which require a gentle bending radius. Unlike some competitors’ systems, Mita elevated troughing is provided with GRP support posts to increase its durability. The troughing lids clip securely in place, providing cable theft protection. Further security can easily be added by installing stainless steel bands around the elevated route.

Working with GRP

Another particularly useful feature of the MitaR GRP system is that it is integrated with the Bentley Raceway and Cable Management Building Information Modelling (BIM) tool.This provides a complete layout, routing and material estimating function in a single, integrated system. It can be applied from the initial concept design through to detailed design and construction.

A user can create an accurate 3D model of the cable troughing route, making it easy to ensure that adequate space and clearances are available in confined locations, and for the detailed design and material requirements to be quickly and easily produced.

Network Rail approval and other applications

The Mita GRP elevated cable route has been fully approved by Network Rail under Certificate of Acceptance PA05/00442 issued in 2015 for use in locations unsuited to GLT. The Zero Halogen Low Smoke (ZHLS) version has also been approved for use in sub-surface stations, connecting tunnels, and London Underground applications.

It was a concern that sensitive signalling equipment was susceptible to contact by flakes of galvanisation from steel support systems and that DC traction cabling system might create eddy currents within troughing ladders and supports if they were metallic.

Mita GRP troughing was chosen as it is the best candidate with non-magnetic and non-conductive properties.

The cable containment system is not just used in rail, but has also been successfully employed in a wide range of industries including data centres, petro-chemical industries, water treatment, off-shore oil and gas etc.

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

GRP Cable Support Solutions | The Benefits of GRP for Harsh, Hazardous & High Voltage Power Containment

June 28th, 2022

Article Written by David Bryan, UK GRP Account Manager, Wibe Group UK Ltd

GRP Cable Support Solutions

Did you know that there is an alternative option to steel cable support solutions, which is more durable and has less hassle while handling? Through this article, we will explore the features of GRP, its additional and unique benefits in cable support applications and discover the Mita brand.

Thorne & Derrick are an approved distributor of the MITA brand, now powered by Wibe Group, providing competitive prices and fast delivery from stock for the complete range of cable troughs, CABSYS cable trays & GRP cable ladders

What is GRP?

GRP or FRP is the abbreviation for Glass/Fibre Reinforced Polymer, meaning it is a man-made resin based material which makes it a polymer, reinforced with glass. Polymer itself is extremely strong – it is a fibre material and in contrary to how it sounds, it is very durable. It is resistant to most chemicals, stretching and shrinking, resistant to mildew and abrasion as well. When it is reinforced with glass through pultrusion, it becomes a structural polymer resistant to fire and highly corrosive environments. Furthermore, it does not conduct heat. GRP has extra durability to adverse weather conditions and has UV stability which makes it an excellent candidate for outdoor applications, even for wind power substations built in the middle of the sea.

GRP cable support

Cable support is the backbone of any development. Wherever there is a structural development, cable support is there to facilitate electrification, signalling and data.

GRP cable support systems possess unique properties which provide structural strength as much as a stainless steel installation and resist many corrosive environments, particularly where conditions indicate that conventional materials may not provide an economic service life.

Features of GRP Cable Support Solutions vs Steel

Supporting Applications With A long Standing Brand

Mita GRP, designed and manufactured in the UK, is now powered by Wibe Group. Thorne & Derrick supply and distribute the complete GRP cable support system range specifically designed for harsh and corrosive environments, ensuring a sustainable installation through its lifetime. Serving industries of transportation, onshore and offshore power, water and waste management, chemicals, pharmaceuticals and many more, Mita GRP stands for “peace of mind” with its “fit and forget” solutions for generations to come.

Working with GRP

Another particularly useful feature of Mita GRP cable support solutions and systems is its ability to be integrated with the Bentley Raceway and Cable Management Building Information Modelling (BIM) tool. This provides a complete layout, routing and material estimating function in a single, integrated system. It can be applied from the initial concept design through to detailed design and construction. A user can create an accurate 3D model of the cable troughing route, making it easy to ensure that adequate space and clearances are available in confined locations, and for the detailed design and material requirements to be quickly and easily produced.

In conclusion, the Mita GRP cable trough system is a non-hazardous, inert product. It is lightweight and can be manually handled without difficulty, unlike concrete and steel. In contrast to steel, GRP does not have to be deburred or given edge treatment before fitting, saving time and further reducing labour costs. During installation, any cutting, drilling, bonding and jointing can be easily undertaken and will not give rise to a hazardous situation, with any dust kept to a minimum.

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.