3M Electrical Product Index

Caution Tapes | The 3M 7900 Electronic Marking System

November 1st, 2023

3M | Caution Tapes

Electronic Marking system

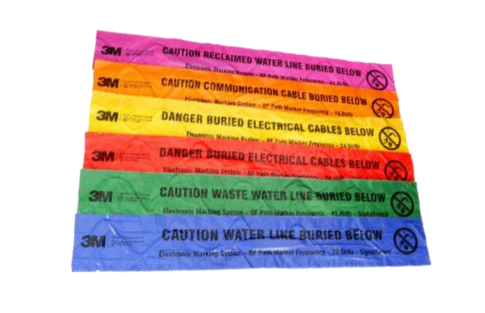

EMS (Electronic Marking System), manufactured by 3M Electrical, is a maintenance free product which is used for marking and locating the route of underground utilities – this includes the range of the following utilities: Wastewater 7904-XT (Green), Gas 7905-XT (Yellow), Recycled Water 7908-XT (Purple), Power 7902-XT (Red), Water 7903-XT (Blue) and Telecommunications 7901-XT (Orange).

Furthermore, the 3M EMS Tape is used to reliably overcome any associated problems and costs relating to the tracer wire and test stations.

Caution marker Tape

The 3M 7900 Marking Tape Series is available in 6 variations for any utility types which can be suitable for open trench applications, including direct buried electrical cables and utility pipework.

The 3M 7900 Caution Marker Tape works independently so if any part of the tape were to be cut or removed, the other markers consistently provide an accurate location whilst not requiring an external power source.

Electronic Caution Cable Tape | 3M

Key Benefits of 3m 7900 ems marker system

- 3M 7900 EMS does not require an external power source or connection to a transmitter

- The EMS System is easy to install and locate using the 3M Dynatel 7000 compatible locator

- Core materials inside allow for early warning for excavators digging nearby

- Work independently

Further Reading

- 3M Scotchcast™ Resins – EU Regulation 2020/1149 Amending REACH Restrictions

- 3M 92 NBA GS Scotchcast Resin Cable Joints (4GS Resin) – Unarmoured Cables

- 3M Dynatel | 1420 Marker Locators for Underground Cables & Utilities

3m scotch electrical tape

Thorne & Derrick distribute the complete range of 3M Scotch Electrical Tapes for the insulation, repair, identification, jointing and terminating of LV, MV & HV cables – specialist fire resistant tapes, arc resistant, semi-conductive and rubber splicing tapes up to 69kV enable the protection of LV-HV cables including 11kV-33kV medium voltages, against abrasion, moisture, alkalis and acids.

3M Scotch Tapes include vinyl electrical insulation, high temperature glass cloth, sealing mastics, rubber self-amalgamating and high voltage tapes to provide track resistance, semi-conductive and sheath repairs to LV, MV & HV cables.

Additionally, 3M Scotch tapes are suitable for end sealing high voltage cables and are highly conformable for irregularly shaped objects. Scotch tapes are stable and durable for years of maintenance-free service.

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of 3M Scotchcast and Cold Shrink cable joints, terminations, resins and Scotch electrical tapes – we stock high voltage cable joints and terminations manufactured by 3M using Cold Shrink for 11kV, 33kV and 66kV cables.

Specialist Distributors to the UK and international industries to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects

3M Scotchlok 314 Prevents Moisture in Stadium Electrical Systems

July 23rd, 2021

Prevent Moisture in Electrical Systems

3M Scotchlok 314

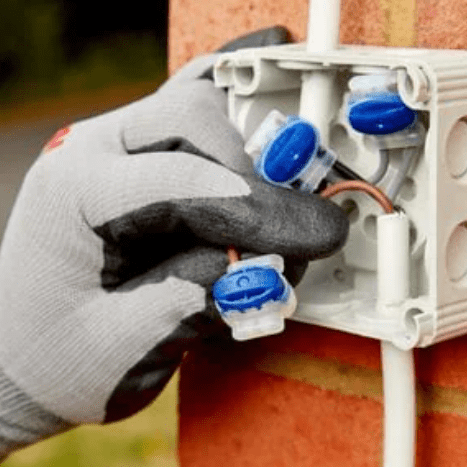

The electrical systems used in stadiums are often exposed to harsh weather conditions such as heavy rain and moisture, creating serious consequences if they fail, with events potentially cancelled or delayed. Problems can occur in hard to reach areas such as floodlights or roof lights, making repair and maintenance difficult and expensive.

Moisture can get into places such as the junction boxes that connect to lighting and other electrical systems, creating poor and unsafe connections. These problems can be solved using 3M Scotchlok 314 Insulation Displacement Connectors (IDC’s), which prevent moisture from getting into electrical installations and causing damage.

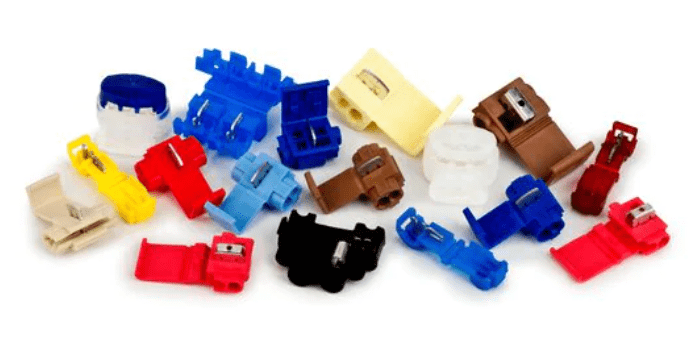

3M Scotchlok Insulation Displacement Connectors

Proven Cable Splicing Technology Designed for your Specific Applications

Scotchlok 314 is an insulation displacement connector used for assembling electrical installations. The wires are inserted into the Scotchlok connector, and when the installation is complete, the connection is secured. This makes it easy and simple to work with, especially in difficult situations.

Due to the connector’s moisture-repellent properties, it’s extremely good for outdoor electrical installations such as exterior lights, signs, sprinkler systems, landscape lighting and other moisture resistant applications at low voltage.

- A “live-spring” joint is made by driving the “U” contact down into the connector

- As the “U” contact is pressed into the connector, it grasps the conductors as it displaces insulation

- The contact grips the conductor(s) and holds with firm, resilient pressure

Scotchlok IDCs incorporate a full wire range capability, an increased port size that accommodates up to 4.82mm insulation sizes, double “U” elements and a solvent-resistant plastic construction.

There are 15 different 3M Scotchlok IDCs to choose from to meet a variety of uses, including fixture, appliance, automotive, marine and control circuit wiring.

3M Scotchlok IDCs have a range of approvals and ratings that meet with industrial standards. To learn more give us a call.

3M Electrical | Scotchlok | ColdShrink | Scotchcast Resin | Scotch Electrical Tapes

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Are You Ready For An SF₆ Phase Out?

June 30th, 2021

3M Novec Insulating Gas

Sustainable SF₆ alternative

The EU commission DG CLIMA has issued a new report on Sulphur Hexafluoride (SF₆) alternatives and potential SF₆ phase out scenarios related to the so-called F-gas regulation (EU Regulation 517/2014). Usage of SF₆ has been banned already in multiple applications with electrical equipment being excluded from these restrictions up to now.

The EU report is assessing the availability of SF₆ alternatives and giving an evaluation for a potential SF₆ phase out 3M Electrical Novec Insulating Gases are the ideal SF₆ alternative as they combine excellent dielectric performance and safety with exceptional environmental properties. Used as part of a gas mixture, Novec Insulating Gases reduce the greenhouse gas potential of more than 99% in on-grid commercial equipment.

3M partners GE, ABB & Hitachi ABB Power Grids are using Novec Insulating Gases as part of their SF₆ free products in multiple medium- and high-voltage application going back to first installations in 2015.

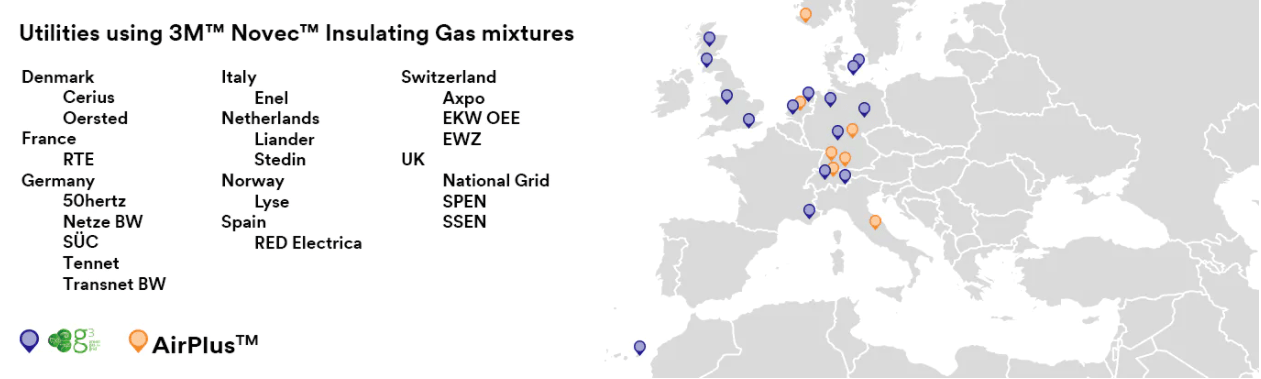

In total, more than 25 installations are already running or are currently being installed in Europe by multiple leading Transmission and Distribution System Operators (TSO’s and DSO’s) which make Novec Insulating Gases a well proven SF6 alternative.

Installations using 3M Novec Insulating Gas

EU Stakeholder Workshop Discussing SF6 Phase Out Scenarios

In a next step the EU Commission (DG CLIMA ) has invited related stakeholder including member states, switchgear OEM’s, utilities and NGO’s to discuss potential SF6 phase out timings. The workshop is based on the 2020 EU report and additional input the commission has received via direct consultation with related stakeholders. It is expected that the commission will issue a proposal for the revised F-gas regulation by the end of 2021 and the regulation will take effect end of 2022/beginning of 2023. It is therefore time to act and to start implementing suitable SF6 alternatives!

Replacing SF6 In Electrical Gas-insulated Switchgear – Impact Analysis for EU 28

In addition, a recent study conducted by the University of Antwerp concluded that the reported SF6 stock and emissions are significantly underestimated. The study also provides an estimate of CO2 eq savings for potential SF6 phase out scenarios using the example of a 145kV Gas Insulated Switchgear (GIS).

3M Novec Insulating Gases

smart, safe, sustainable

Novec Insulating Gases are the ideal SF6 alternative as they combine excellent dielectric performance and safety with exceptional environmental properties. Used as part of a gas mixture, Novec Insulating Gases reduce the greenhouse gas potential by more than 99% in on-grid commercial equipment.

Our partners are using Novec Insulating Gases as part of their SF6 free products in multiple medium- and high-voltage applications going back to first installations in 2015:

GE’s g³ using 3M Novec 4710 Insulating Gas

GE’s g³ Using 3M Novec 4710 Insulating Gas – g3, (pronounced “g” cubed) is GE’s game-changing alternative to SF6 gas, developed for HV electrical transmission equipment and is using 3M Novec 4710. g3 products feature the same ratings and same dimensional footprint as the state-of-the-art SF6 ones, with a drastically reduced environmental impact.

- g³ products operate with no restriction under the same temperature range as SF6 products (down to -30°C).

- GE’s g³ products are type-tested and available for live-tank circuit breakers and gas-insulated substations up to 145 kV, gas-insulated lines (GIL) up to 420 kV and instrument transformers up to 245 kV.

- More than 20 leading utilities have decided to use equipment with g³ incorporating more than 100 bays in total.

AirPlus Using 3M Novec 5110 Insulating Gas – AirPlus, using 3M Novec 5110 as an eco-efficient SF6 alternative, has been developed by ABB. Today, AirPlus is being used in Medium Voltage by ABB AG in MV Primary GIS up to 40.5kV and in MV Secondary GIS and AIS up to 24kV.

- Environmentally sustainable with a GWP of less than 1

- Compact equipment design

- Retains key benefits of established GIS technology

AirPlus using 3M Novec 5110 Insulating Gas

EconiQ by Hitachi ABB Power Grids Using 3M Novec 4710 Insulating Gas – EconiQ is Hitachi ABB Power Grids’ eco-efficient portfolio for sustainability where products, services and solutions are proven to deliver exceptional environmental performance. Since 2010, Hitachi ABB Power Grids has been deploying eco-efficient high-voltage technology with SF6 alternatives. The current EconiQ portfolio covers 145kV GIS and 420kV GIS busducts.

3M Scotch Electrical Tapes

T&D distribute the complete range of 3M Scotch Electrical Tapes for the insulation, repair, identification, jointing and terminating of LV, MV & HV cables – specialist fire resistant tapes, arc resistant, semi-conductive and rubber splicing tapes up to 69kV enable the protection of LV-HV cables including 11kV-33kV medium voltages, against abrasion, moisture, alkalis and acids.

3M Scotch Tapes include vinyl electrical insulation, high temperature glass cloth, sealing mastic, rubber self-amalgamating and high voltage tapes to provide track resistance, semi-conductive and sheath repairs to 11kV-33kV power cables.

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

3M™ Scotchrap™ 50 | Vinyl Corrosion Protection Electrical Tape from 3M

May 4th, 20213M Scotchrap Tape 50

Corrosion Protection

3M Scotchrap Vinyl Corrosion Protection Tape 50 has high-tack adhesive to provide a corrosion- and impact-resistant seal for all-weather protection of metal piping systems above and below ground. The special high tack adhesive is formulated to resist the corrosion of metal piping systems both above and below ground, fittings and joints on all coated pipe and electrical conduit systems.

With excellent UV resistance and a temperature rating of 80°C, Scotchrap Tape 50 provides excellent all-weather corrosion resistance. NOTE: 3M Scotchrap Pipe Primer should be used with all corrosion protection tapes.

Vinyl Corrosion Protection Tape

Benefits

- Excellent UV Resistant

- Tough PVC tape resists corrosion in all weather conditions

- Suitable for fittings and joints on all millcoated pipes and electrical conduit systems above and below ground

- NOTE: 3M Scotchrap Pipe Primer should be used with all corrosion protection tapes

3M Scotchrap Vinyl Tape 50

Technical Specifications

| Adhesion Strength (metric) | 21.9 N/100mm |

| Adhesion to Steel | 20oz/in |

| Adhesive Material | Pressure Sensitive Rubber Adhesive |

| Adhesive Type | Rubber |

| Application/Industry | Commercial Construction, Industrial Construction, Irrigation, Maintenance and Repair Operations, Mining, Residential Construction, Solar, Utility, Wind Power, Commercial Construction, Industrial Construction, Irrigation, Maintenance and Repair Operations, Mining, Residential Construction, Solar, Utility, Wind Power |

| Application Method | Self-adhered |

| Applications | Electrical maintenance |

| Backing Material | Polyvinyl Chloride |

| Backing Thickness (metric) | 0.25mm |

| Chemical Resistant | Yes |

| Division | Electrical Markets Division |

| Electrolytic Corrosion Factor | 0.9 |

| Elongation at Break | 2 |

| Flame Retardant | Yes |

| Installation Temperature Range | -12ºC to +65ºC |

| Manufacturing Origin | USA |

| Material | PVC |

| Maximum Operating Temperature (Celsius) | 80ºC |

| Operating Temperature (Celsius) | Up to 80ºC |

| Operating Temperature Range (Celsius) | -48ºC to 80ºC |

| Overall Length (Metric) | 30.5mm |

| Overall Width (Metric) | 25.4mm |

|

Performance Level

|

Professional Grade |

|

Printed Tape

|

No |

|

Product Colour

|

Black |

|

Product Form

|

Roll |

|

Product Type

|

Corrosion Protection Tapes |

|

RoHS 2011/65/EU Compliant

|

Yes |

|

RoHS EU Comments

|

RoHS 2011/65/EU compliant without exemption |

|

Rolls per Carton

|

1 |

|

Rolls per Case

|

48 |

|

Service Temperature Range

|

-48ºC to 80ºC |

|

Shelf Life

|

5 Years |

|

Shelf Life in Months (from date of manufacture)

|

60 |

|

Storage Environment

|

Room Temperature |

|

Tape Colour

|

Black |

|

Tape Grade

|

Premium |

|

Tape Length (metric)

|

30.5mm |

|

Tape Type

|

Corrosion Protection |

|

Tape Width (metric)

|

25.4mm |

|

Total Tape Thickness without Liner (metric)

|

0.254mm |

|

UV Resistant

|

Yes |

3M Scotch Electrical Tapes

T&D distribute the complete range of 3M Scotch Electrical Tapes for the insulation, repair, identification, jointing and terminating of LV, MV & HV cables – specialist fire resistant tapes, arc resistant, semi-conductive and rubber splicing tapes up to 69kV enable the protection of LV-HV cables including 11kV-33kV medium voltages, against abrasion, moisture, alkalis and acids.

3M Scotch Tapes include vinyl electrical insulation, high temperature glass cloth, sealing mastic, rubber self-amalgamating and high voltage tapes to provide track resistance, semi-conductive and sheath repairs to 11kV-33kV power cables.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Continuous Shearhead Bolt vs. Crimp Compression Technologies By 3M Electrical

May 4th, 2021

3M Electrical

Comparative Study

The power utility industry is risk-averse.

The decision to change a technology is not taken lightly. You need data, you need research, and you need proof that what you’re using is most reliable, so you can have peace of mind when powering entire cities.

Currently in Canada cable crimp compression technology is the more predominate technology for LV MV HV cable connections. However, just because its what’s you’re used to or many companies use it doesn’t mean it’s the most reliable solution of splicing, connecting or terminating cables.

This is why I conducted a cable connection comparison study to compare continuous shearbolt and crimp compression technologies. The goal of this study was to determine which solution offered superior cable connection reliability.

So, utilities could have peace of mind. Here are my study results.

Continuous shear vs. crimp compression.

An easy distinction between continuous shear technologies and crimp compression technologies is that in a continuous shear installation the lug or connector is installed by continuously shearing off the bolts. Where as, with crimp compression technologies you must crimp a connector or lug using a die and special crimping tool.

The study results: how did continuous shearhead bolt technology and crimp compression technology stack up against each other?

My research found that not only does continuous shear technology offer better performance, it also helps enhance the safety and reliability of the network while driving total cost of ownership down in the long run.

This study proved that, despite some benefits, such as offering standardisation improvements, crimp compression technology (CSA hex die system) is not a fool proof solution. A critical shortcoming is that utilities do not have full control in terms of quality or installation because CSA hex die dimensions are proprietary to the die manufacturer.

This can prevent utilities from being able to fully dimensionally check the dies before releasing them for use in the field. This can be problematic because any slight variation in manufacturing tolerances from one crimping tool manufacturer to another, and one die manufacturer to another, as well as small dimensional differences, or variations in material hardness of the connectors and/or lugs, can determine whether it was a successful or failed installation. In short, there’s not enough control, therefore crimp compression technologies like CSA hex die systems are less predictable.

But, with continuous shear technology that shortcoming does not exist.

The winner: continuous shearhead Bolt technology

Our study found various reasons reinforcing continuous shear technology as the more reliable solution. Here are three critical takeaways:

- Enhanced performance: continuous shear technologies, like 3M Mechanical Shearbolt Lugs and Connectors are equipped with scientific design elements, such as the predefined contact points, incorporated elasticity, mitigation of contact aging, and optimisation of contact force – offering superior cable connector performance compared to existing technologies, like crimp compression technologies.

- Operates at lower temperatures: In the comparative heat cycling testing, we found that 3M™ Mechanical Shearbolt Lugs and Connectors operate at lower temperatures. This is important because it means that the connector will thermally age less, so it will last longer compared to aluminium crimp compression connectors under the same test conditions.

- Ease of install: continuous shear technology, like 3M Electrical Mechanical Shearbolt Lugs and Connectors, is easy to install because of its range taking capabilities. It also does not require any additional tools or dies and can accommodate both copper and aluminium conductor types.

Study highlight: The continuous shear technology plays an important role in an aging utility infrastructure that requires substantial upgrades. It also offers new project construction options for a more robust and reliable, electrical network.

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.