Blog

Arc Flash Clothing Saves Lives | Watch Eddies Story

November 23rd, 2020

Saving Lives | Arc Flash Clothing & Protection

Lifesaving Arc Flash Clothing

-

uploaded by Chris Dodds | Sales Marketing Manager at Thorne & Derrick

“If I wasn’t wearing my PPE, it probably would have been a different story.”

This Case Study focuses on the importance of wearing PPE clothing to protect against Arc Flash in the construction and utilities industries when working around buried services – it could save your life, like it did Eddie’s.

A few years ago, an operative was using a jackhammer when he struck a low voltage electrical cable, which led to an Arc Flash incident.

Fortunately, Eddie was wearing suitable arc flash clothing and PPE which ended up saving his life and protecting him from further and more significant injuries.

We were fortunate enough to meet with Eddie Smith, a Team Leader for construction firm, Clancy Docwra, and his colleagues to speak to them about the day, the incident itself and the importance of keeping people safe while at work.

Utilities | Avoiding Danger from Underground Services

Guidance is provided by the HSE HSG47 Document to utilities workers involved in commissioning, planning, managing and carrying out work on or near underground services – this includes all underground pipes, cables and equipment associated with electricity, gas, water (including piped sewage) and telecommunications.

How Arc Flash Clothing

Saves Lives

The video that ProGARM created in partnership with Clancy Docwra is to be used as part of internal training for their operatives and to better educate those working around live electricity, of the realities of the risks involved.

We thought it was too important not to show you, so please watch Eddie’s story below and feel free to share.

Jim Eldred – Operation Manager at Clancy Docwra “I received a phone call mid to late morning from Eddie’s teammate. He informed me that Eddie had had an accident and that he had suffered injuries. I was informed that it was electric and that an ambulance was on route.

For me I was scared, I was pretty worried.”

Eddie’s Jackhammer had hit a live electrical cable.

Stephen Bainbridge – Field Performance Manager at Clancy Docwra “The first thing that runs through your mind is, is Eddie okay? And then you start thinking about his children – because he had a young family and a wife. having children myself, that was my concern for Eddie, is he going to come back from this, is he going to work again? As a team we took it quite badly..”

Eddie Smith “When the Arc Flash hit me – it went so fast. And then everything that happened after seemed to go in slow motion. There were these thoughts running through my head; the first one being obviously my little boy, but also my family and my job, and worry about the physical injuries.

“I had burns all the way up my hands, down my neck, inside my nose, mouth and around my face. But because I wear this PPE it didn’t touch my chest, legs or arms.”

“It’s one of those things you think is never going to happen to me, I know what I’m doing I’ve been doing it years – when it does its a massive shock to you and your family.”

Stephen Bainbridge – Field Performance Manager at Clancy Docwra “We need to get across that it’s not about money, it’s not about how many jobs you get done in a day – it’s about doing that job safely. Mostly. You have to wear this PPE. If you don’t wear it you could be dead with just one cable strike.

Eddie Smith “If I wasn’t wearing my PPE, it probably would have been a different story.”

On seeing the photos, Mark Lant, a Technical Expert at ProGARM said: “Obviously, we’d prefer it if Arc Flash incidents never occurred. However, the fact is they do, and we’re pleased to see our polo shirt performing as effectively in the field as it did in the lab. We wish the operative a speedy recovery from his other injuries.”

The PPE that saved Eddie’s life.

“It’s only when you see ProGARM’s Arc Flash garments in action like this that you realise how vital they are to saving lives in the field. We can perform every test available on our range of protective clothing, but to see real garments in real situations saving real lives is the ultimate proof of our success. When an Arc Flash incident occurs, we know that our protective garments are up to the job.”

Thankfully, Eddie made a full recovery in the end and is now back at work. Make sure that your team can do the same.

Remember, PPE is the last line of defence. Make sure you have safe working procedures in place before undertaking any work near live electricity.

Stay safe and don’t compromise.

Further Arc Flash Reading

- Arc Flash PPE | 7 Top Considerations

- Arc Flash The Basics

- 5 Arc Flash Risks for Solar Industry Personnel

PROGARM | THE ARC FLASH SPECIALISTS

Specialist Distributor & Customer Service

Thorne and Derrick are Approved Specialist Suppliers & Distributors of ProGARM Arc Flash Clothing & PPE providing competitive prices from extensive stocks with excellent customer service levels. We protect LV HV Cable Jointers, SAP’s, Overhead Linesmen, Substation & Electrical Engineers; whether racking and switching Medium Voltage switchgear or fusing Low Voltage feeder pillars – we have the correct clothing and workwear to provide safe protection against all calculated levels of arc flash hazards.

Overview of Arc Flash Clothing | Contact us to discuss your garment and PPE requirements, we can mitigate risk with guidance on safe working practices and by providing appropriate worker clothing that offers advanced Arc Flash Protection that saves lives every day. Whether working on underground cables or overhead lines, here is a selection of workwear clothing – contact us to discuss your requirements;

>> Download Your Guide To Here <<

HV Cable Joints, Terminations & Connectors | Approved Stockists & Distributors | 3M Electrical (Cold Shrink) | Nexans (Euromold JTS MONO) | Pfisterer (CONNEX SEANEX) | 11kV 33kV 66kV Medium & High Voltage Cable Accessories

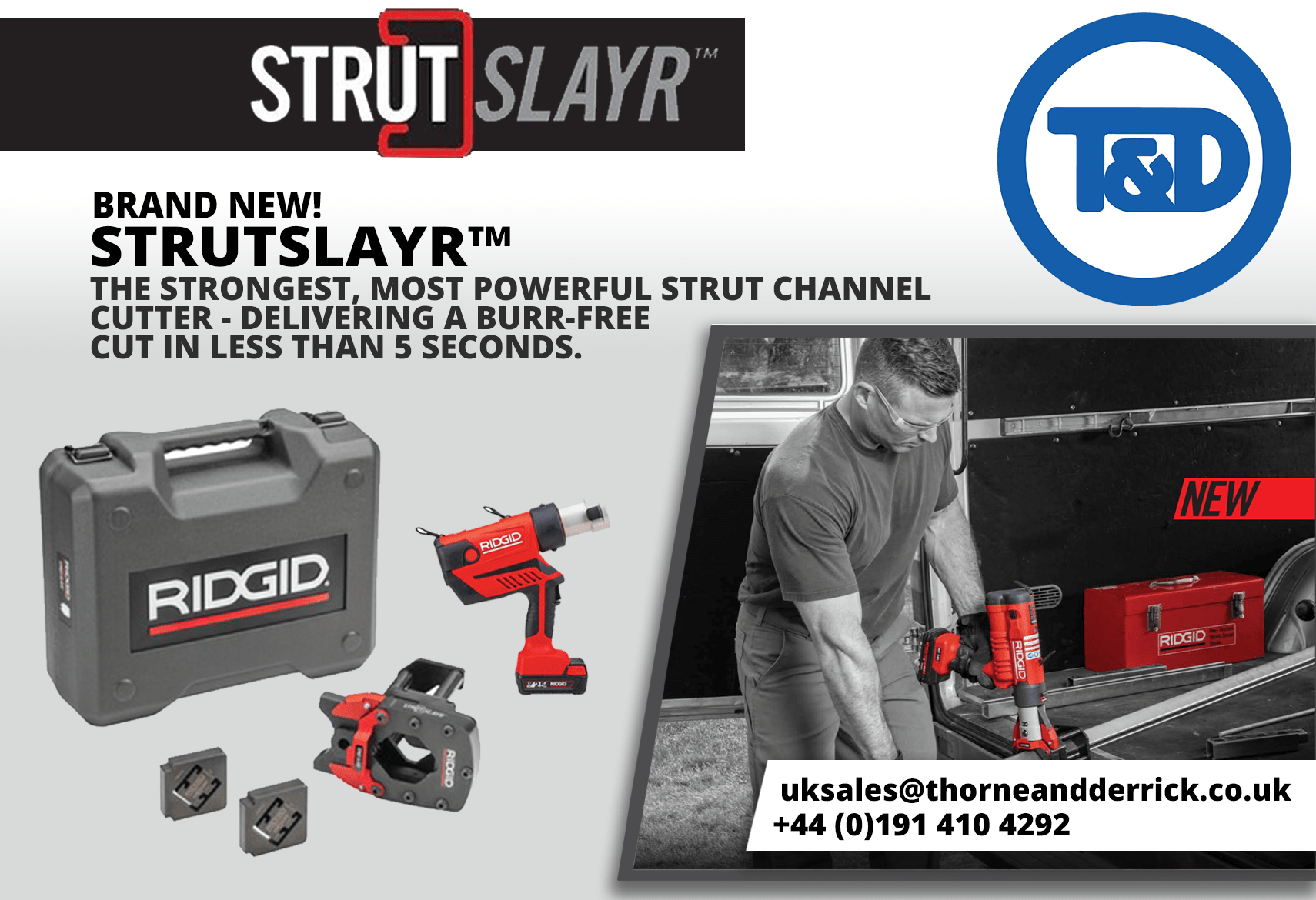

STRUTSLAYR from RIDGID | The Strongest Most Powerful Strut Channel Cutter

November 16th, 2020

STRUTSLAYR | Stocked by Thorne & Derrick

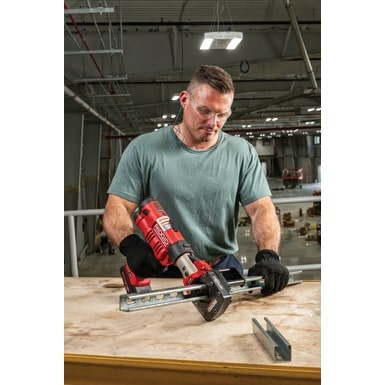

The NEW RIDGID STRUTSLAYR™ strut channel cutter is the latest accessory that makes the world’s most popular press tool even more valuable.

Strut channels are used in a wide variety of applications such as Plumbing, HVAC, Fire Protection, Electrical and Solar for structural support of pipes, ventilation/air-conditioning/sprinkler systems as well as cable trays and solar panels. Before they are installed, each strut channel needs to be cut and deburred; this activity can be a very time-consuming task when it is done with traditional cutting tools like an angle grinder, cold cutting and recip saw.

Introducing StrutSlayr

STRUTSLAYR Strut Shear Head attaches to, and is compatible with, RIDGID 32kN press tools – delivering excellent shop quality with a burr-free cut in less than 5 seconds.

The StrutSlayr offers a shearing operation, where the material gets displaced rather than directly cut. This means that there are no grinding or sawing sparks with this Strut Cutter – just a clear consistent SHEAR cut with a pull of a trigger.

The RIDGID® STRUTSLAYR™ delivers shop quality, burr-free strut channel cuts on the jobsite in 5 seconds or less. Compatible with RIDGID 32kN press tools, the STRUTSLAYR strut cutter offers a clean, consistent cut with a simple pull of a trigger.

*NOTE: Press tools are not included. Not compatible with RIDGID 320-E or CT-400.

STRUTSLAYR Strut Channel Cutter FEATURES

- Fab Shop Quality: Burr-free cuts eliminate the need for extra filing

- Increased Efficiency: Clean, consistent cuts in 5 seconds or less

- Shear Cut: no grinding or sawing sparks

- Portable: Easy to move around the job site and mounts to RIDGID TRISTANDs

- Built-in Measuring Guide: allows accuracy of cut on job site

Choose from the RIDGID STRUTSLAYR™ kit 64053 or 64058 depending on die shear size. Available from stock for fast delivery. |

Request a UK demo of the RIDGID STRUTSLAYR today. |

StrutSlayr Specification

Portability – The StrutSlayr Head weighs only 5.4 kg and is supplied in a sturdy and compact blow-molded case for easy and safe transportation to any jobsite. Cut everywhere, anywhere!

Long-lasting– Approximately 140 cuts can be expected from a single full battery charge with StrutSlayr Head mounted.

Flexibility – StrutSlayr is highly versatile. It can be easily used on a workbench, on a RIDGID TRISTAND, on the ground or even on a platform.

Accuracy – A built-in measuring guide is displayed on the RIDGID StrutSlayr to accurately measure the size of the strut that needs to be cut. The integrated Strut Support prohibits deformation of the Strut channel and provides a straight cut every time. The strut channel cutter offers reduced risk of sparking when compared to grinders and chop saws and still manages to produce a clean, consistent cut.

Size & wall-thickness – StrutSlayr strut cutter features field-replaceable dies and it is supplied with either a 41×41 or 21×41 shearing die, covering the most important two strut channels sizes. StrutSlayr can be used for cutting Strut Channels with wall-thickness up to 2.5 mm. A minimum amount of 2000 cuts can be expected from each new die set. Efficiency never seen before!

Press Tool Compatibility – RIDGID® Standard Series 32kN Press Tools (such as the RIDGID RP 350-B Tool Kit)

*Not for use with RIDGID 320-E and CT-400 Press Tools

For the full technical specification, visit Strut Shear Head

Klauke Orange | World‘s first battery hydraulic crimping and cutting tools with Tri-Insulation Barrier technology to provide jointers, linesmen and electrical engineers with 1000V protection against electrical shocks

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Thorne & Derrick | Stockists & Suppliers | Joints Terminations Connectors up to 66kV

Roxtec Sealing Solutions For Cables & Pipes | Process Industry Whitepapers

November 13th, 2020

Roxtec are global-market leaders in the innovation and manufacture of cable transits and pipe penetration sealing systems to the process and hazardous area industries.

Roxtec solutions seal cables, cable ducts and pipes against water ingress, gas migration and fire hazards into safety critical and sensitive electrical equipment and buildings.

Whitepapers

- Whitepaper: EMP/EMI Protection In Control Rooms/Centres In Critical Infrastructure

- Whitepaper: Roxtec Multi-Cable Transit Devices

- Whitepaper: Modular Integration of Process Equipment Packages for Oil and Gas Facilities

- Whitepaper | Modular Cable Termination Design By Roxtec

Hazardous Areas & Explosive Atmospheres (Gas & Dust) | Ex e and Ex tb Explosion Protection Certified by ATEX & IECEx | Zone 1/21 & Zone 2/22

Process Industry

Typical Applications

Buildings & E-houses

Wall entries

Floor entries

Underground entries

Control rooms

Analyzer shelters

Substations

Remote instrument buildings (RIB)

Field auxiliary rooms (FAR)

Local equipment rooms (LER)

Terminal Boxes, Cabinets & Enclosures

Remote I/O cabinets

Hazardous locations (Ex e)

Ordinary locations

Electric heat tracing systems

Automation and control cabinets

DCS panels

Motor control cabinets

Safety instrumented systems (SIS)

Fire and gas detection control cabinets

Machine monitoring systems

Lighting panels

Thorne & Derrick are distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, – protecting cables and pipes in the process industry sector against water, gas and fire.

CONTACT US WITH YOUR ENQUIRY

Specialist Distributors of Industrial & Hazarodus Area Equipment to provide Power, Heat, Light & Ventilation to the explosive atmospheres and process industries.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery

66/69kV Cable System Performance | Jointer Error Concerns

November 6th, 202066kV

Are you suffering performance issues with your HV Cable Systems?

Our clients have been asking us to provide information on 66/69kV class cable systems.

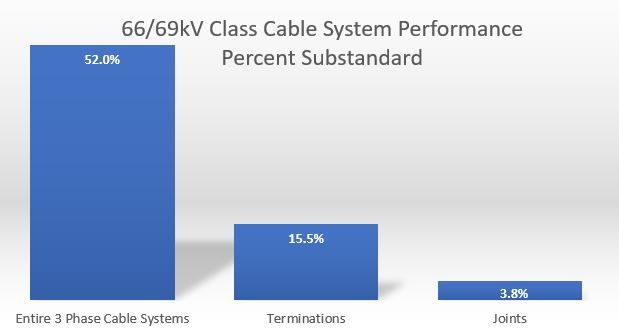

So here is a view from our database of over 200,000 factory comparable (50/60Hz PD with 5pC sensitivity) tests on recently installed 66/69kV cable systems. The data is not pretty.

We have a ways to go to improve performance on these cable systems.

On the basis of a few projects including over 350 cable systems, 52% (from a 3 phase performance stand point) have at least one substandard component.

Terminations are the worst offenders at 15.5% substandard whereas Joints fair a little better at 3.8% substandard.

We have performed dissections on several occasions. The issues? Installation error.

Posted by Ben Lanz | Director, Technology & Test Systems Availability at IMCORP

More from IMCORP

Competency Training

Contact us today to discuss your Jointer Training requirements – client customised Competency Training is provided by Thorne & Derrick International at Nexans UK Centre of Jointer Excellency in the UK.

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Joints Terminations Connectors | Stock Service Support from Thorne & Derrick

Shearbolt Connectors for LV/MV Underground Power Cables: Reliability & Failure Modes

November 5th, 2020Shearbolt Connectors

Thorne & Derrick | Connectors Distributed from Stock | UK & Export Sales

The technology of shearbolt connectors for current transmission has developed quickly – the principle of shearbolt technology was first introduced in the early 1980s when manufacturers sold the first types of low voltage LV bolted connectors. The next step was adopting shearbolt technology for use in low voltage cable applications, where required torque moment was a pre-set parameter machined into the bolt. Based on positive field experience, shearbolt connector technology was adapted for use in medium voltage applications as well. But cable accessories up to 42kV require concentric connector bodies and smooth outer surface, without sheared off bolts standing proud and no sharp edges at the connector and bolts.

![]()

In the 1990s, connector manufacturers introduced different types of multiple shear bolts, allowing a requested torque moment to a particular cable cross-section while ensuring that bolts shear off flat with the outer circumference of the connector body. At the same time, IEC 601238-1 was established to replace former local standards and set higher requirements in terms of contact ageing. The most important advantage of bolted contacts is that one connector type applies for different cross-sections and conductor materials. This created a user-friendly and reliable connector, simplifying allocation of conductor cross-section to connector. Those same principles and connector body design have been adapted and optimized to cover cross-sections of up to 3000sqmm and even for HV/EHV applications.

By Fak Hardt

Head of Product Portfolio & Cable Accessory Development, Pfisterer Holding, Germany

Mr. Hardt is an Electrical Engineering professional.

He has had more than 24 years of experience in manufacturing as R&D-Manager for connectors and fittings with Pfisterer as well as in development of underground power cables and accessories. He has in-depth knowledge of related production processes, quality and environmental management and holds patents for bolted technology and ring connector technology. Pfisterer is a leading independent manufacturer of cable, connectors, insulators and overhead line accessories for sensitive interfaces in energy networks. The Group is headquartered in Winterbach, near Stuttgart in southern Germany.

Pfisterer Sicon | Shearbolt Connectors

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Joints Terminations Connectors | Stock Service Support from Thorne & Derrick