Blog

NKT Plug In Type Cable Terminations – 33kV XLPE Single Core 630sqmm

October 6th, 2020Image: Andrew Brezovszky | EHV Cable Jointer and Director at Matrix Power Solution Pty Ltd

Pictured: 33kV NKT Plug In Type Cable Terminations – 630sqmm XLPE Cable

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

33kV Cable Jointing Using 3M QS2000 Cold Shrink Joints On Rail Power Cables

October 6th, 2020The following sequence of site photographs detail the installation of 3 x single core 3M QS2000 Cold Shrink Inline Cable Joints onto trackside rail power cable – the 33kV high voltage single core cables are XLPE insulated with a graphite coated sheath and stranded copper conductor (300sqmm).

Key stages of the cable jointing process are detailed including cable spiking, cable preparation and the installation of the Cold Shrink Joints.

Thorne & Derrick are 3M Electrical UK’s largest stockist of their range of Scotchcast and Cold Shrink cable joints, terminations and abandonment kits for industrial and hazardous area installations.

Images Courtesy : Steve Amos (Director & HV/MV Cable Jointer & Supervisor)

Company : Ady-hv limited

“My position within the company is Lead Cable Jointer/Jointing Supervisor. I am responsible for the running of HV cable feeder renewals from substation to substation. My skill set includes : sheath testing, cable fault finding, cable repairs, jointing HV and pilot cables, high voltage cable terminations, pressure testing and lead plumbing.”

“My passion is cable jointing and I will strive to progress to be the best Jointer I can be,” Steve comments.

Blue Sky, Sunny Day – trackside cable identification underway on existing 33kV cables using a Lee Vaughan cable identifier and setting up of the Accles & Shelvoke spiking gun under a sanction for cable testing.

Cables Spiked – 33kV power cable is spiked to ensure worker safety by short circuiting the high voltage power and making the cable “dead”.

Cables Cut – cable jointing position is prepared and cables cut.

Cables Stripped – the cable sheath is cleaned using jointers cable wipes and stripped using appropriate cable jointing tools.

Cable Preparation Perfection – the copper screen wires are peeled back over the cable jacket and taped using PVC tape. Marker applied for semi-con screens.

Cables Stripped – 33kV semi-con screen removed.

More Cable Stripping – 33kV XLPE insulation removed using Alroc stripping tools.

Ready For Jointing – both 33kV cables are expertly prepared and ready to be jointed using 3M QS2000 Cold Shrink.

Cold Shrink Tubes Parked – 3M cable joint components slid onto the 33kV cables before cable can be jointed.

Conductors Jointed – Pfisterer Sicon bolted connectors installed to joint the 300sqmm stranded copper conductors without resort to crimping tools and die sets.

Cold Shrink Joint – once cables are cleaned and grease has been applied then the 3M cable splice body and tapes are installed. Grease is applied onto primary insulation, semi-conductive screen and connectors.

Taping Time – electrical and mastic tapes applied to both sides of the cable joint. Earth Continuity – copper screen sleeve or stocking is then positioned and constant force springs applied.

Almost Done – 3M Cold Shrink outer jacket is then applied and the cable joint is now complete. The cable joint body is shrink down by turning and pulling out the zip core in counter clockwise direction.

Cable Joints Positioned – red and blue phase both complete and in position

Jointing Done For One Day – all three 33kV phases are jointed

Rail Cable Accessories, Electrification

& Installation Equipment

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

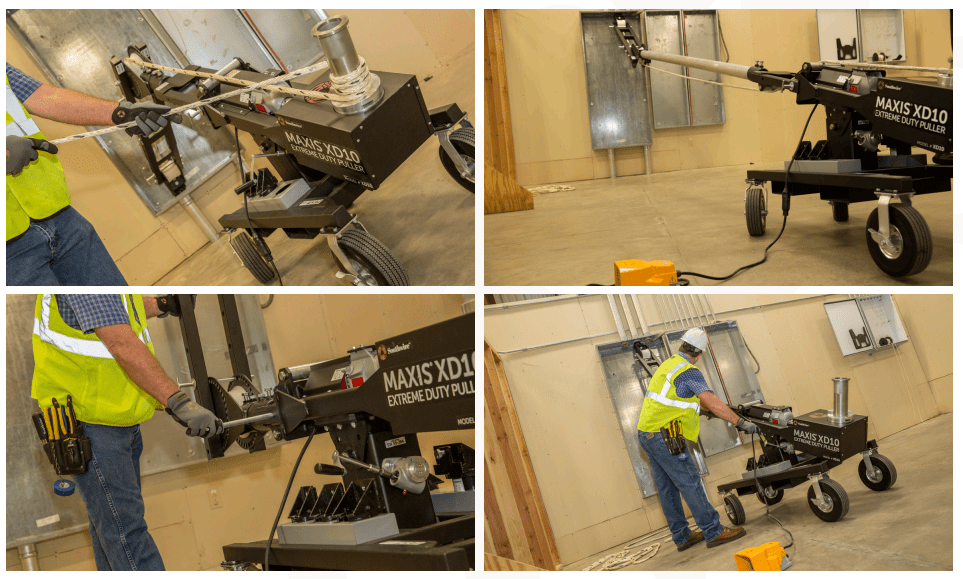

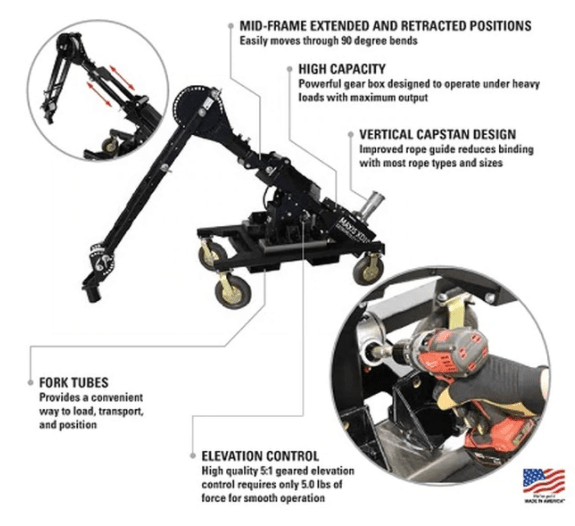

Cable Pulling Machine | Southwire Maxis XD10 EXTREME Duty Cable Puller

October 6th, 2020

Cable Pulling Machines

Southwire Maxis XD10

EXTREME Duty Cable Puller

The Southwire Maxis XD10 EXTREME Duty Cable Puller is a cable pulling machine designed to get the job done, thriving in the most extreme cable pulling conditions – XD10 from Southwire allows you to pull cable faster and safer up to 10,000 lbs.

Designed and manufactured in the USA by Southwire and distributed in the UK by Thorne & Derrick – contact us for further information or to discuss a potential cable pulling or installation application.

Cable Pulling Machine – Southwire Maxis XD10 EXTREME Duty Cable Puller

Southwire Maxis XD10 Cable Puller Features

- 10,000 lbs peak cable pulling force with a continuous pulling rating of 7,000 lbs

- High capacity: powerful gear box operates under heavy loads with maximum output

- Self contained: ready to pull cable with no need for additional parts to use for set up

- Single person set up: quickly adapts from underground cable to overhead pulls

- Smooth elevation: operates with handle or 18V cordless drill to eliminate cable lifting

- Collapsible down to 40″H x 26″W x 70″L for ease of transport and site location

➡ Best in Class rope guide and capstan prevents rope binding, the XD10 is ready to pull with no additional parts.

Southwire Maxis XD10 EXTREME Duty Cable Puller – Technical Specification

| Southwire Model | Cable Puller Description | Height | Width | Length | Weight |

| XD10 | Maxis XD10 EXTREME Duty Cable Puller | 40″ | 26″ | 70″ | 598 lbs |

| XD-10-BD | XD10-BD Maxis XD10 Bolt Down Kit | 18″ | 14″ | 16″ | 35 lbs |

Capacity – Cable Pulling Speed Low

- At 2,000 lbs 11fpm

- At 4,000 lbs 10fpm

- At 6,000 lbs 9fpm

- At 7,000 lb 8fpm

- At 10,000 lbs 7fpm

Cable Pulling Speed High

- At 2,000 lbs 20fpm

- At 4,000 lbs 18fpm

Southwire

Southwire is one of the world’s leading developers, manufacturers and suppliers of building wire and utility cable, as well as the cable tools used in their installation. As such, Southwire is continually improving its cable products, studying how they’re used in the field and assessing the needs of its customers to find new and better ways to solve the problems facing the industry – this includes underground cables and overhead line conductors.

THORNE & DERRICK

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and cable rollers.

DNV GL Approved Cable Accessories, Joints, Terminations & Connectors from Nexans

October 6th, 2020

Thorne & Derrick distribute DNV GL Approved Cable Accessories manufactured by Nexans including elbow connectors and cable terminations for the reliable distribution of medium and high voltage power in the marine and offshore sectors up to 33kV.

This article and download brochure provides information on DNV GL Certification and the Nexans Euromold products qualified according to this classification society.

Products approved by the DNV GL Certificate are accepted for installation on all vessels classified by DNV GL.

For the full list of Nexans products with DNV GL approvals, please refer to the download.

Power Cable Accessories

DNV GL Approved

Nexans is the leading European manufacturer of prefabricated cable accessories for medium voltage (MV) and high voltage (HV) energy distribution. Products include MV-HV Connectors and Joints & Terminations to connect, splice, repair and maintain medium/high voltage cable and power distribution systems.

Bushings | Separable Connectors | Cable Terminations | Cold Applied & Heat Shrink

Cable Accessories

WITH DNV GL APPROVAL

158LR/G |

Interface A

|

Elbow connector

|

152SR/G |

Interface A

|

Straight connector

|

480TB/G |

Interface C

|

Tee connector

|

484TB/G |

Interface C

|

Tee connector

|

489TB/G |

Interface C

|

Tee connector

|

800PB/G |

Interface C

|

Coupling connector

|

804PB/G |

Interface C

|

Coupling connector

|

809PB/G |

Interface C

|

Coupling connector

|

800SA |

Interface C

|

Surge arrester

|

784TB/G |

Interface E

|

Tee connector with ALU rod

|

784TB/G |

Interface E

|

Tee connector with CU rod

|

909TB/G |

Interface F

|

Tee connector

|

909PB/G |

Interface F

|

Coupling connector

|

900SA |

Interface F

|

Surge arrester

|

AIN |

|

Slip-on termination indoor

|

AFN |

|

Slip-on termination outdoor

|

ITK |

|

Cold-shrinkable indoor termination

|

OTK |

|

Cold-shrinkable outdoor termination

|

MONOi |

|

Heat-shrinkable indoor termination

|

MONOe |

|

Heat-shrinkable outdoor termination

|

MONOi3 |

|

Heat-shrinkable indoor termination

|

MONOe3 |

|

Heat-shrinkable outdoor termination

|

1TTE |

|

Heat-shrinkable outdoor termination

|

1GLT4 |

|

Heat-shrinkable straight through joint

|

D-Series |

|

Mechanical Connector

|

NX-FIRE |

|

Fire protection kit

|

A DNV GL Type Approval Certificate states that the design of a product type is in conformity with specified requirements. The Type Approval Certificate confirms compliance with the DNV GL Rules in force at the time of certificate issuance.

To obtain DNV GL approval, DNV GL experts verify the manufacturing processes for compliance with the Classification rules and further relevant standards. During this verification, the manufacturer has to demonstrate and prove the following 4 qualification criterion for DNV GL Certification to be issued:

- They have suitable facilities for manufacturing, testing and inspection;

- The manufacturing is carried out by qualified personnel;

- Constant monitoring of product quality has been established.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage cable systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Cable Glands & Sealing Solutions For Hazardous Areas

October 5th, 2020Triton CDS & RapidEx from CMP

Cable Gland & Sealing Solutions For Hazardous Areas

-

Special thanks to Jade Appleby (Digital Marketing & PR Co-ordinator) and Laurie Wilson (UK & Ireland Sales Manager) at CMP Products Limited | Uploaded by Chris Dodds (Thorne * Derrick International)

Thorne & Derrick, a leading UK based Specialist Distributor of LV HV Jointing, Earthing, Substation & Electrical Eqpt for use in Explosive Atmospheres, are proud to present product innovation from CMP – the world-leading manufacturer of cable glands for the safe termination and sealing of cables in potentially explosive atmospheres.

This Guest Article contributed by CMP describes their cable sealing solutions for hazardous areas featuring their Triton T3CDS cable glands and RapidEx barrier cable glands.

Triton CDS

Right-First-Time Installation

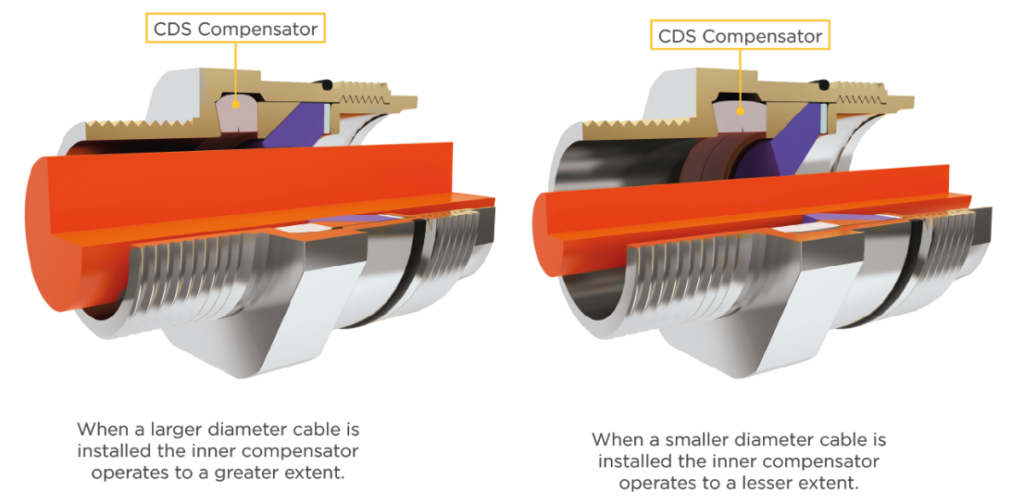

Triton T3CDS cable glands deliver a unique concept in cable sealing techniques incorporating the Compensating Displacement Seal system (CDS).

This concept provides effective sealing on the cable inner sheath utilizing a proven reliable and robust flameproof seal.

The CDS system is activated at the critical cable sealing point, protecting the inner sheath from any excess force. The force is instead transferred and absorbed by the internal compensator in the CDS system, allowing metal-to-metal tightening every time regardless of cable diameter.

Triton CDS Compensator | Triton CDS (T3CDS) | Ex eb, Ex db, Ex nR & Ex ta | The Explosive Atmosphere Cable Gland for all types of Armoured Cables

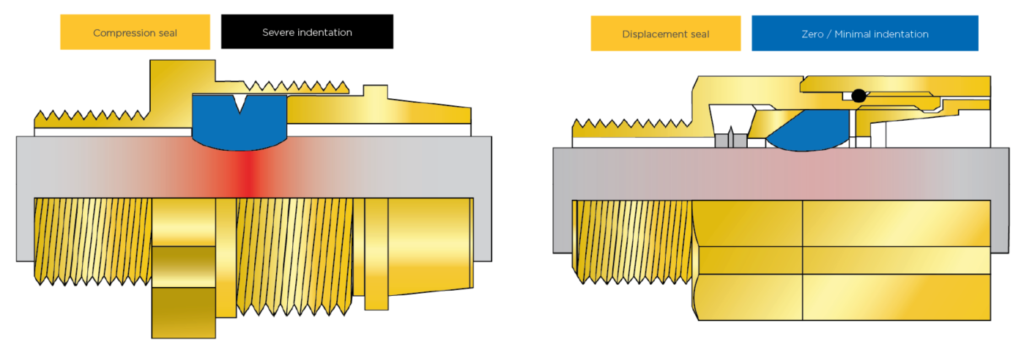

CMP Displacement Seal

The below illustrations demonstrate how CMP’s displacement seal reduces indentation on the cable – the installation is independently controlled by the user during installation of the cable gland to achieve secure flameproof sealing and wire armour termination.

CMP Displacement Seal

Additional Cable Sealing Benefits

- Deluge protection seal, third-party tested to DTS:01

- Full sequential, three step make-off procedure

- Complies with low voltage directive 73/23/EEC

- Uniform hexagon profile

- Options available for VSD and lead sheath cables

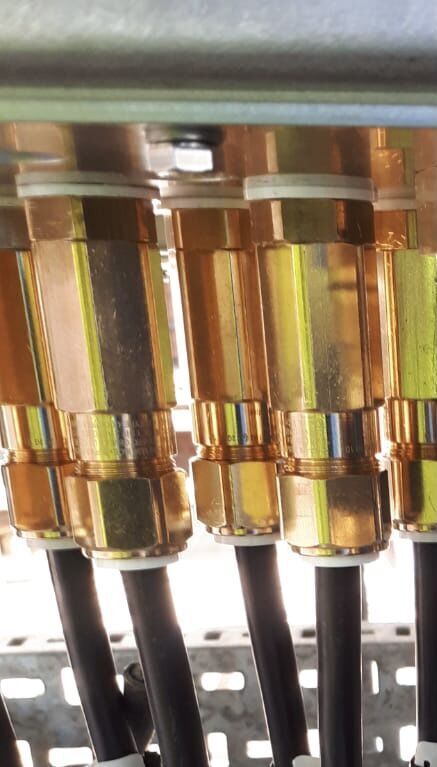

Cable Glands | The T3CDS hazardous area cable gland, manufactured by CMP, supplied in brass as specified by the end customer allows for quick installation and ease of inspection throughout its life on site.

RapidEx – The Original Sealing Solution for Barrier Cable Glands

A barrier gland is a cable gland that provides an effective seal around the individual cores of a cable to maintain the flameproof integrity of Exd Explosion Protected equipment.

Traditional barrier cable glands employing an epoxy-cured clay-based sealing compound, have been used in the industry for many years, to provide effective explosion protection.

However, a certain degree of skill is required with this traditional installation process and the risk of voids increases with the number of cable cores.

Multi-core cable requires the highest degree of competence and a long installation time to ensure a void-free, safe installation.

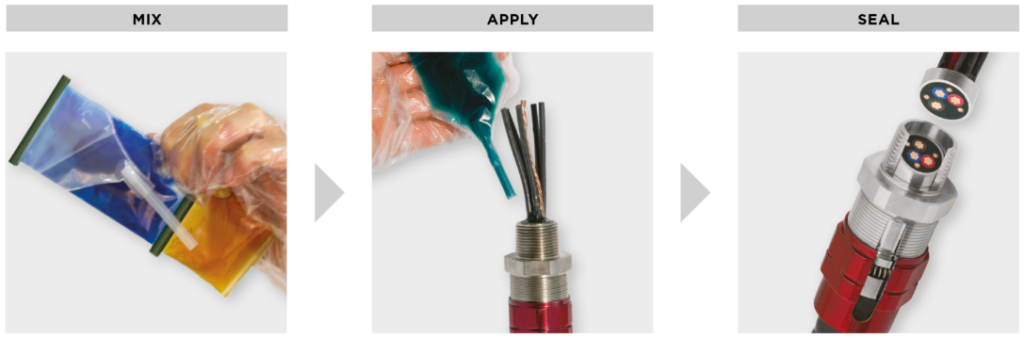

Revolutionary Rapidex | RapidEx is a revolutionary liquid resin sealing solution for barrier cable glands and unions, for use in conjunction with flameproof or explosion-proof enclosures.

In 2012, CMP introduced RapidEx to the market.

RapidEx is a liquid-pour, fast-curing, liquid resin barrier seal that installs in seconds and cures in minutes. The barrier gland has since been installed on a number of major global projects for safe and secure sealing of cables in explosive atmosphere industries including oil, gas and petrochemicals.

Its unique formula begins with a low viscosity liquid that flows into the cable interstices, completely surrounding the cable conductors, and in the process displacing the air from the cable gland’s sealing chamber ensuring the perfect seal.

The viscosity increases and completely cures in less than 40 minutes (at 20°C / 68°F).

- Enhances reliability, reduces risk

- Delivers unprecedented reliability

- Minimises installation time

- Clean and easy to use

CMP RapidEx is certified for use in explosive atmospheres with global certification including approval under ATEX, NEC, CEC and IEC installation codes, and is available with a series of CMP barrier cable glands and unions.

➡ See the full range of CMP RapidEx Barrier Cable Glands for hazardous areas and explosive atmospheres.

NEW Product Launch

717 Stopper Plug

CMP 717 nylon stopper plug range is available for use in industrial applications (717) or explosive atmospheres (717e).

The 717 range of stopper plugs allow customers to ‘blank’ unused cable entries and are manufactured from a unique polymer; providing a combination of strength and durability over the longer term – or simply providing a temporary solution.

Designed to reduce cost and installation time, both the 717 and the 717e feature a universal installation design, comprising a hex-head for spanners, a flat screwdriver and allen key recess. Both products are tested to IP66, IP67, IP68 & IP69(K) without the need of an additional entry thread seal, reducing time as well as cost of installation.

The interface between the stopper plug and its associated enclosure / cable entry does not require additional sealing to achieve ingress protection (IP) ratings higher than IP54.

The minimum protection level is IP54 for explosive gas atmospheres and IP6X for explosive dust atmospheres.

CMP GLANDS

DISTRIBUTORS & SUPPLIERS

Thorne & Derrick provide competitive prices and fast delivery from stocks for the complete range of CMP cable glands for connecting, terminating and sealing all types of LV MV HV cables located in industrial non-hazardous, hazardous area zones and medium/high voltage electrical systems.

As well as cable glands, CMP offer a range of cable cleats that are designed for a variety of industries including the data centre, renewable energy, utility and rail market where high performance and a compact design of cable cleat is critical for the retention of cables in the event of a short circuit fault situation.

UK Leading Dsitributors of Hazardous Area Electrical Equipment | LV MV HV

Experts in Equipment for Explosive Atmospheres

Thorne & Derrick are leaders in the development and distribution of ATEX & IECEx Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, Heating & Lighting Products to your UK and international projects.

NEW BLOG