Blog

ARC FLASH AWARENESS DAY 7 JUNE 2024 #AFAD24

April 29th, 2024

Special thanks to David Davenport for the kind permission to help promote #AFAD2024

ARC FLASH AWARENESS DAY

7th June 2024

Arc Flash Awareness Day is a focal point for everyone involved with work where arc flash is a risk. The day has been created to drive awareness of the risks of arc flash incidents, and to share best practice on how to avoid and mitigate those risks.

A wide range of partners have chosen to support Arc Flash Awareness Day and Thorne & Derrick International are delighted to help support the inaugural event.

We’re all committed to spreading the safety message and to making sure that everyone comes home safely.

To join the organisations supporting Arc Flash Awareness Day, get in touch.

UPCOMING EVENTS

Join us for the first-ever Arc Flash Awareness Day (AFAD) this summer to:

⚡ Prevent arc flash injuries

🤕 Promote safer workplaces

💪 Save lives

The day will focus on educating and applying best practices to raise awareness broadly among sectors at risk of arc flash incidents – from board-level executives with a responsibility to keep their people safe, to people on the frontline doing jobs directly at risk.

Join in the conversation online using #AFAD24 #arcflashawarenessday24 and follow:

X (formally Twitter)

Facebook

Instagram

LinkedIn

|

ARC FLASH AWARENESS APRIL 30, 2024 An illustration of Arc Flash occurrences, how, why and what causes them, the life and career-changing injuries, fatalities and the catastrophic damage an Arc Flash creates. The responsibilities of stakeholders and engineers and the devastating legal consequences. Tue, 30 April 12:45-13.15 BST The Health & Safety Event, NEC Birmingham |

|

|

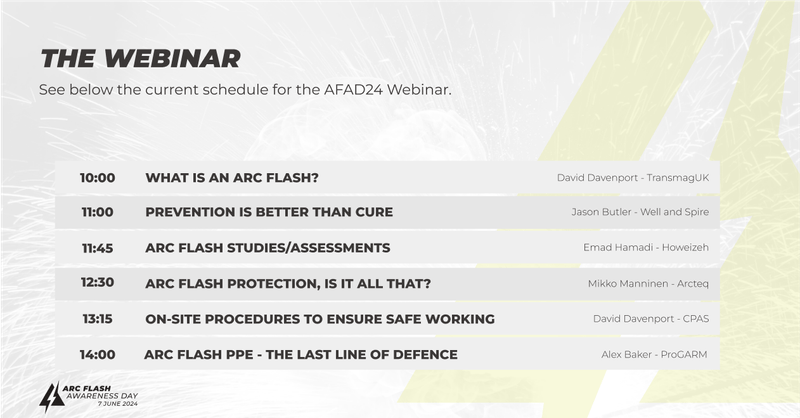

WHAT IS AN ARC FLASH? JUNE 7, 2024 An overview of what an Arc Flash is, how it occurs, indications & what to be aware of; simple measures to prevent. Presented by David Davenport. Fri, 07 Jun 10:00 BST Online |

|

|

|

PREVENTION IS BETTER THAN CURE JUNE 7, 2024 Partial Discharge Monitoring, a simple way of detecting and preventing potential Arc Flash before it occurs. Fri, 07 Jun 11:00 BST Online |

|

|

ARC FLASH STUDIES AND ASSESSMENTS JUNE 7, 2024 Do you know how to undertake an Arc Flash study and assess the risks? Emad Hamadi takes us through this process. Fri, 07 Jun 11:45 BST Online |

|

|

|

ARC FLASH PROTECTION, IS IT ALL THAT? JUNE 7, 2024

The certainty of protecting your workers AND your equipment in the event of an Arc Flash. Fri, 07 Jun 12.30 BST Online |

|

|

ON-SITE PROCEDURES TO ENSURE SAFE WORKING JUNE 7, 2024 It’s important that everyone working in an Arc Flash environment understands the On-site Procedures so that they can work safely and not put themselves or colleagues at risk. Fri, 07 Jun 13.15 BST Online |

|

|

|

ARC RATED PPE – THE LAST LINE OF DEFENCE JUNE 7, 2024

Although we can take steps to reduce the likelihood and severity of an Arc Flash, it cannot never be ruled out. Understand the protection you need in the event of an Arc Flash explosion. Fri, 07 Jun 14:00 BST Online |

Arc Flash Awareness Day Information Pack

The official information pack that contains all the information you need about Arc Flash Awareness Day and how you can get involved.

To keep up to date please sign up to the newsletter HERE.

Protecting Jointers & SAP’s Against Arc Flash Risks | ProGARM 6444 Coveralls

April 22nd, 2024Arc Flash Protection for High Voltage Engineers

Specialist Distributor & Customer Service

Thorne and Derrick are Approved Specialist Suppliers & Distributors of ProGARM Arc Flash Clothing & PPE providing competitive prices from extensive stocks with excellent customer service levels. We protect LV HV Cable Jointers, SAP’s, Overhead Linesmen, Substation & Electrical Engineers; whether racking and switching Medium Voltage switchgear or fusing Low Voltage feeder pillars – we have the correct clothing and workwear to provide safe protection against all calculated levels of arc flash hazards.

Working alongside High Voltage Power Services (SW) Ltd and ProGARM we are committed to providing Jointer & SAP protection against the risk of arc flash incidence.

All clothing can be supplied transferred with company logo, this includes their 6444 Coveralls with Arc Flash Protection (ARC 2) using FR Fabric to provide ultimate worker protection.

The HVPS Team is a well-established, highly accomplished, and competent High Voltage Engineering Team, who between them has over one hundred years of experience in the electrical industry – look them up and Link-In with Paul Birch to discover more.

PROGARM 6444

Arc Flash Protection Coverall

- Flame Resistant fabric and Arc Flash protection

- Mandarin collar // Maximum neck protection

- Kneepad pockets // Wear with kneepads for extra comfort

- Chest pockets with zippers // Secure storage

- Gas monitor loop // Secure fixing point

- SafetyICON™ on arm // Visual EN Standards icon system

- 5cm Flame Resistant Anti Static Reflective Tape // Double-stitched for longer life

- Phone pocket on sleeve with flap // Safe and secure

- Velcro® secured cuff tabs // Close fit around wrist or gloves

- Side access pockets with flaps // With entry inside coverall

- ThermSAFE™ plastic Flame Resistant zippers // CE Certified

- Internal elastic two-point adjustable waistband // Ensures close fit

- Triple stitched side seams // Lifetime quality assurance

- Easy-Stretch™ side panels // Maximum wear comfort

- Action back for improved comfort

- More Information PROGARM 6444 Arc Flash Protection Coverall

ProGARM garments and arc flash clothing protection provides worker comfort and durability to your designs and printed preferences.

The Definitive Guide To Arc Flash

Overview of Arc Flash Clothing | Contact us to discuss your garment and PPE requirements, we can mitigate risk with guidance on safe working practices and by providing appropriate worker clothing that offers advanced Arc Flash Protection that saves lives every day. Whether working on underground cables or overhead lines, here is a selection of workwear clothing – contact us to discuss your requirements;

HV Cable Joints, Terminations & Connectors | Approved Stockists & Distributors | 3M Electrical (Cold Shrink) | Nexans (Euromold JTS MONO) | Pfisterer (CONNEX SEANEX) | 11kV 33kV 66kV Medium & High Voltage Cable Accessories

Specifying An EV Feeder Pillar | What Do You Need To Consider?

April 5th, 2024

- Special thanks to Matt Page EV Business Development Manager at Lucy Zodion for the kind permission to republish.

Specifying a EV Feeder Pillar

What Do You Need To Consider?

The unsung hero of EV infrastructure is not sexy chargers; the unsung hero of great EV infrastructure is the feeder pillar. Used to distribute power safely and efficiently, whilst ensuring charging speed reliability – correctly specifying an EV feeder pillar will provide secure, dependable, and compliant electrical connections, says Matt Page, EV Business Development Manager at Lucy Zodion.

Lucy Zodion manufacture a wide range of products suitable to provide Low Voltage Electrical Power Distribution for EV charge points – from distribution network operator (DNO) accredited cut-outs and isolators for on-street chargers, to feeder pillars for electrical vehicle charging.

Due to the growing demand for Electric Vehicles (EV) around the world and the resulting strain that the charging infrastructure has on our electrical network, a wide range of safe and compliant electrical power and connection solutions are needed.

▶ Thorne & Derrick together with Lucy Zodion are able to offer a range of feeder pillar enclosures and cabinets that are robust, durable and secure providing weatherproof and padlockable vandal resistant protection.

As the electrification revolution continues, robust electrical infrastructure is crucial. Electrical enclosures and cabinets serve as frontline defences, safeguarding components and ensuring system reliability. But how does one specify the correct enclosure amidst various materials and standards?

With decades of experience in electrical connection solutions, Lucy Zodion is here to guide contractors. Here’s an overview of key considerations:

EV Feeder Pillars Considerations

Electrical Supply

The first thing to consider is the electrical supply. Will it be a new point of connection provided by the DNO or ICP, or will it be a private supply routed from a supply elsewhere? If the former, then consideration must be given to the space that the DNO/ICP will need to install its service head/cut-out and any metering requirements.

Earthing

You must decide whether your EV feeder pillar will use Protective Multiple Earthing (PME), O-PEN technology, or TT earthing. The choice depends on various factors, such as existing infrastructure, preservation orders on trees and not forgetting resistance levels that would need to be guaranteed all year round in the event of a TT installation.

TT installations, where an earth rod is installed to provide the earth, are the most common. However, fitting PEN detection technology is a well-recognised alternative where it is impossible to fit an earth rod

or earth mat.

Charge Points

How many EV charge points is the feeder pillar powering and what are their ratings? Outgoing devices include single-phase and three-phase, enabling EV chargers to be powered from 7kW to 150kW.

Current Rating and Load Balancing

What current reading is the incoming supply of 100A, 200A, 400A, and 630A?. Understanding your current rating requirements is essential.

How much power does your feeder pillar need to deliver, and how many charge points (in kilowatts) will it supply? Consider load balancing within charge points to optimise your supply connection and get the most value from your electrical infrastructure.

Residual Circuit Protection

There is a requirement to protect cables supplying the charge points, and to do this, Lucy Zodion installs a 300 mA protection. If the charge points do not have this local protection, the company offers 30 mA protection to cover it.

This is generally seen on the 7-22W charge points, but Lucy Zodion EVIS range offers both solutions to protect your installation requirements.

Futureproofing

Anticipate future needs by allocating space within your feeder pillar for additional equipment or charge points that may be installed later. This proactive approach ensures your infrastructure can adapt to evolving EV demands without costly modifications.

Location & Planning Requirements

Carefully consider the location of your EV feeder pillar. Are there specific planning requirements or access needs for maintenance and testing? Proper planning ensures seamless integration into your site or development.

Aesthetics

In some cases, aesthetics play a vital role. Does your EV feeder pillar need to blend into its surroundings? Standard enclosures are hot-dipped galvanised, but opting for a painted finish can help maintain the integrity of your site or development while ensuring that your infrastructure is functional and visually appealing.

EV Feeder Pillar

Compliance and standards

When specifying an EV feeder pillar, you need to make sure it is tested to the following standards:

- BS7671- IET Wiring Regulations – Covers the electrical installation of buildings, including the use of surge protection

- BS7671- IET Code of Practice for Electric Charging

- BS EN 61439 – Low Voltage Switchgear and Control Gear Assembly

Considering these key points will ensure that your EV feeder pillar is designed to deliver efficient and reliable power distribution for electric vehicle charging, contributing to a sustainable and greener future.

Lucy Zodion | Fortress Feeder Pillars | Pre-Wired Feeder Pillars | Street Lighting Cut-Outs | DNO Cut-Outs | Electrical Power Distribution Enclosures

Cembre CPD | Electrical Connections, BS7609 & Compliant Crimping

April 5th, 2024

Cembre CPD

Thorne & Derrick | Distributed from Stock | Approved Cembre Cable Lugs, Crimp Connectors & Tools Supplier | UK & Export Sales

Electrical Connections, BS7609 & Compliant Crimping

Cembre CPD

Strong R&D, constant innovation in manufacturing technologies, and extensive experience in the field of electrical connectors enable Cembre to swiftly meet the market’s rising demands for high-quality, dependable, long-lasting, and safe products.

Cembre has received accreditation from CPD (Continued Professional Development) to offer certified training on their electrical crimping and compression connectors. Since CPD is a globally renowned independent accrediting body, you can take advantage of their knowledge and experience in the electrical connections industry while also earning CPD credits for your professional advancement.

The course aims to deliver ‘best practice’ crimping methods in accordance with BS7609; for electrical engineers; contractors; and installers. Delegates will learn the importance of material composition; cable preparation and using a ‘matched crimping system’.

▶ Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Cembre cable lugs, connectors, cable cutting and cable crimping tools.

course Content

This training course covers the following:

- Connectors: what they are, how they work, and why they are important for reliable and safe LV MV HV electrical connections.

- BS7609 is the British standard that specifies the requirements and installation methods for un-insulated compression and mechanical connectors for power cables with copper or aluminium conductors.

- Matched system: the system that ensures the highest quality and safety of connections by using electrical connectors, crimping tools, and dies that are designed and tested together.

Participating in Cembre’s CPD-certified training courses offers many benefits, including:

- Certified Excellence: The courses are meticulously crafted and assessed by CPD, ensuring alignment with the highest training standards and guidelines.

- Flexible Learning: Whether you prefer face-to-face interaction or the convenience of online learning, our courses cater to diverse preferences and schedules.

- Certification: Upon completing the training, you will receive a CPD training certificate that that acknowledges your participation and attendance.

Cable lugs are suitable for connection, termination and jointing of 11kV-33kV power cables with copper or aluminium conductors to MV-HV electrical equipment including switchgear, transformers and control panels

Cembre CPD TRAINING cOURSES

CEMBRE training courses are suitable for anyone who works with electrical connections, such as electricians, cable jointers, engineers, technicians, contractors, and inspectors. They are also flexible and convenient, as they can be arranged with local sales engineer at a time and place that suits you.

Contact Thorne & Derrick today to discuss your requirements.

Cembre is a leading European manufacturer of electrical connectors, crimping tools, cutting tools and a variety of accessories for LV (Low Voltage), MV (Medium Voltage) and HV (High Voltage) power systems. Designed for switchgear and control panels, Cembre tools are ideal for installing low and medium voltage connectors.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Cold Shrink

T&D are Specialist Distributors of LV MV HV Cable Installation, Jointing, Substation & Electrical Equipment – we supply companies in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors with products to enable the energisation, operation and maintenance of underground cables and overhead lines.

Reducing RSI Caused by Cable Crimping Using Ratchet Type Tools

April 2nd, 2024

manual ratchet Crimping tools

Reducing RSI In Cable Crimping Applications

Many cable crimping applications throughout the industry are conducted using manual ratchet tools or hand hydraulic tools. Depending on the number of operations conducted each day and the hand force required to close the handles of the crimping tool, Repetitive Strain Injury (RSI) can result.

➡ Thorne & Derrick, are leading suppliers of cable crimp lugs and associated crimping tools for Low, Medium & High Voltage Cables and Power Systems.

The average force required to close the handles of a ratchet crimp tool is 22kg, and with many applications in factories and OEM’s requiring 250+ terminations per day, a significant risk is exposed.

Employee health – Less physical effort due to electrically-driven tools

CABLE CRIMPING & HEALTH & SAFETY

Looking to statistics available on-line, 29% of repetitive strain injuries will result in Carpal Tunnel Syndrome (CTS). This condition is where the Median nerve in the wrist is squashed in the Carpal tunnel, creating chronic pain, pins and needles, and numbness in the fingers and hand of the operator.

In worst cases CTS can only be resolved with surgery, one hand at a time, resulting in employees being unable to work for 6-8 weeks.

Those at risk of CTS are employees where they have a combination of:-

1. Repetitive bending and stretching of the hand

2. High force applications of squeezing or gripping cable cutting or crimping tools

3. Exposure to high vibration (e.g. motor driven saws/ grinders)

Electromechanical Cable Crimping Tools

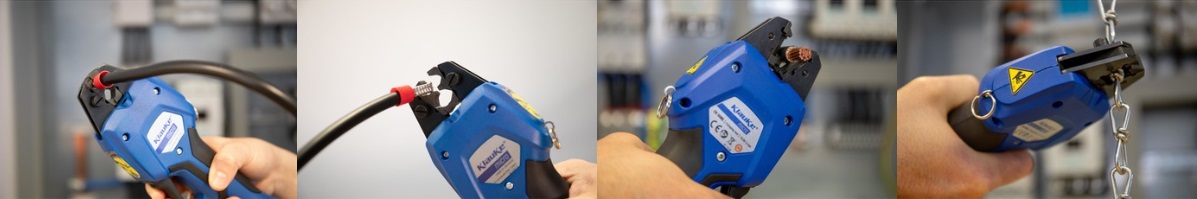

The new alternative to manual ratchet crimping tools for high volume, high force applications, is the Klauke Micro tool. This is an electro-mechanical tool suitable for Pre-insulated connectors (up to 16sqmm), Boot-lace ferrules (up to 50sqmm), and Cu tube lugs (up to 25sqmm). The Micro provides a 90% reduction in hand load experienced by the operator to help keep employees safe and maintain high productivity.

Electromechanical Crimping Tool Operation

Choosing the correct electromechanical crimping tools can help reduce workplace injuries and improve site and worker Health & Safety.

The Micro is less than 1kg, completes in excess of 300 crimps per charge in less than 1.5 secs per crimp. As an intelligent tool, it ensures full closure of the jaws on every crimp and comes with the ability to link to Klauke iPress software, where quality records can be downloaded and stored for improved traceability.

Klauke EK 50 ML 0.14sqmm – 50sqmm Electromechanical Crimping Tool

There are more reported cases of CTS in our industry and with better, safer, more productive tool solutions available today, each employer has a duty of care to provide the most suitable tools to their employees.

Electrical Connections, Lugs & Tools for Crimping, Cutting & Punching | LV MV HV Cables

Insulated Cable Cutters

The Klauke ES32SISML-WSH is a battery powered cable cutting tool with a maximum cutting range of 32mm suitable for use with copper and aluminium conductors up to 300sqmm. The Klauke ES32SISML insulated cable cutter has a slim cutting head for Jointers working in substations, switchgear and trenches with confined spaces – this insulated tool provides advanced worker and electrical protection to utility contractors working live in the vicinity of energised Mains and Service cables up to 1000V.

The insulated tool is typically used by UK DNO’s and their ICP Contractors to core cut 185sqmm, 240sqmm and 300sqmm BS7870 Waveform 600/1000V cables.

Klauke cutting tools are available with 10.8V DeWalt Li-Ion Batteries and are fully insulated to the electrical requirements of IEC 60900.

Cable Innovation Tools & Accessories for Low & High Voltage Power Systems

THORNE & DERRICK are Specialist Distributors of LV HV Cable Jointing, Earthing, Substation & Electrical Eqpt up to 66kV – this includes the most extensive range of Ex Stock Innovation Tooling to facilitate safe and reliable preparation, termination and installation of cables.