Blog

Portable Earthing Leads – Short Circuiting Kits For HV Substations & Overhead Lines

January 18th, 2018

uploaded by Chris Dodds - reading time 5 minutes

This following procedure from TransGrid supports the Power System Safety Rules and its requirements for Portable Earthing assembled under:

- Making High Voltage Apparatus Safe for Work – Category 5.5; &

- Making Overhead Lines Safe for Work – Categories 6.4, 6.5

The following describes Electrical Safety Equipment manufactured by CATU Electrical which has been approved for portable earthing of high voltage electrical conductors. This procedure also includes methods for checking substation and overhead line earthing equipment along with inspection and maintenance procedures.

Date of Issue: 26 May 2016

Portable Earthing Leads & Systems

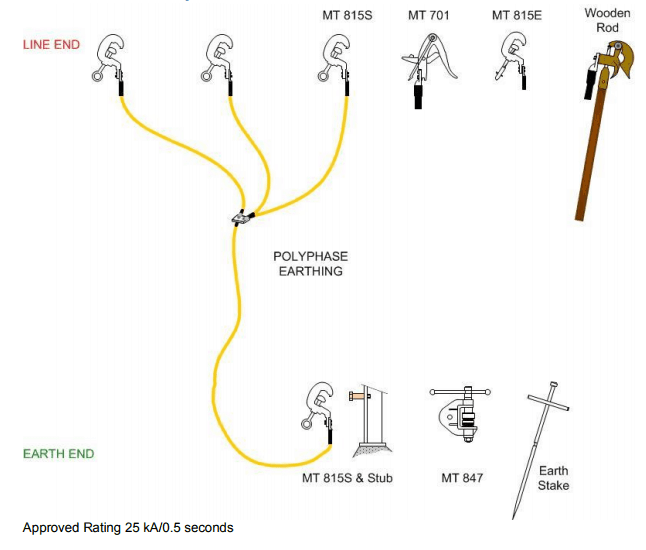

An earthing system is a recognised set of components to perform the function of portable earthing for medium/high voltage cables. The components are assembled into either polyphase earthing systems (usually three phase) or single phase earthing systems.

A portable earthing leads and system comprises of:

1. Line End Clamp or Clamps

2. Portable Earthing Leads

3. Earth End Clamp or Clamps

4. Short Circuiting Point (Trifurcating Plate)

5. Connecting Hardware

6. Insulating Sticks

Portable Earthing Leads & Kits manufactured by CATU Electrical are for short-circuiting of medium/high voltage power cables and conductors including 11kV/33kV and 132kV.

Prior to the issue of an Access Authority, appropriate earths must be applied to High Voltage Equipment. These are referred to as Access Authority earths under the Power System Safety Rules. Where fixed earthing switches are either not available or not suitable for the planned work, portable earths may be used. Such portable earths can be applied to:

- overhead tranmission lines

- substations

- switchboards

- underground cables

The objective of Portable Earthing Equipment is to provide a pathway for unanticipated electrical current to flow safely to earth. The current flowing through the earth causes protection systems to operate, tripping circuit breakers and so removing the source of electrical power supply.

The earthing equipment described in this procedure has been designed and tested for use with standard TransGrid conductors and fittings such as stirrups and stubs.

Electrical Safety

Electrical safety guidance about handling portable earthing equipment in substations or near transmission lines:

1. Always carry earthing equipment below shoulder level

2. Ensure that clamps and leads are kept a safe distance from any high voltage conductor

3. Assemble and inspect earthing equipment on the ground

4. Extend or prepare any earthing equipment such as shot gun sticks on the ground

CATU Electrical – Thorne & Derrick are the largest UK stockist and supplier of MV HV Electrical Safety Equipment for Substations & Overhead Lines

Portable Earths

Applying Portable Earths

Do not allow any part of the earthing system to encroach on safe approach distances.

1. Where practicable keep the portable earthing leads away from the body

2. Apply earth clamps to stirrup (if provided) or a horizontal conductor where possible

3. Avoid earth clamp application to bushing caps and to braids and

4. Position earth clamp so that tension on the earth lead is minimised

Removing Portable Earth Leads

Earthing equipment is to be removed carefully from high voltage conductors to prevent the equipment encroaching on or coming into contact with adjacent live high voltage conductors.

Discharging HV High Voltage Equipment

Where an electrical circuit could potentially discharge through the earthing system, sufficient time must be allowed between the de-energising of the high voltage conductors and the application of the portable earthing system to permit residual charge to be dissipated.

Equipment Experiencing A Fault

Any medium voltage or high voltage portable earthing equipment for overhead line or substation applications that experience a fault or over current shall be withdrawn from service immediately.

Rating

Check that the rating of the earthing equipment is appropriate for the fault level at the location at which it is to be applied. The equipment used for earthing shall have a fault withstand rating greater than that of the location in which it is used.

Information about the expected fault currents and back-up protection times at particular locations is available from System Operations staff.

Where the fault rating of the location exceeds that of the equipment, multiple earthing sets may be used to increase the rating of the earthing system:

1. In switchyards this information will be included on the High Voltage Preparation and Restoration Instruction (HVPRI);

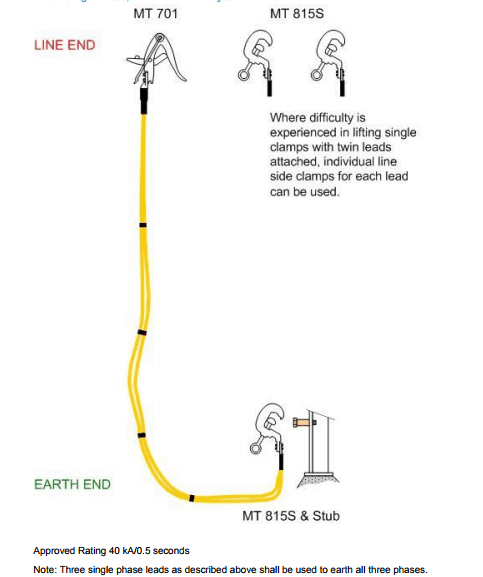

2. On transmission lines where the fault rating of the line exceeds the fault rating of the earthing set, multiple sets of CATU MT815S earth clamps and associated earth end clamps may be used.

Equipment & Connections

Check that the earthing system is complete, i.e. that all earthing components are present.

Check that all bolted connections are tight and that any electrical connection is positive and mechanically sound. Ensure that earthing leads are sufficiently long for the proposed task.

Inspect For Damage

Ensure that the MV-HV earthing leads and equipment is in a serviceable condition. Any portable earthing equipment found to be defective shall be removed from service for repair.

Connect Earths To Earthing End Point

Connection at the earth end point shall be performed prior to any connection to a conductor.

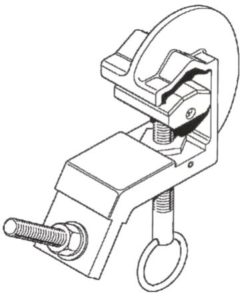

Use Of The CATU MT-815S Clamp

The CATU MT 815S earth clamp is applied to and removed from conductors using a ‘shotgun’ application stick of appropriate length. Once the clamp is placed onto the apparatus to be earthed, the shotgun stick is removed.

Use Of The CATU MT-815E Clamp

The CATU MT 815E earth clamp is applied to and removed from conductors using the attached CATU CM4130-E insulating sticks.

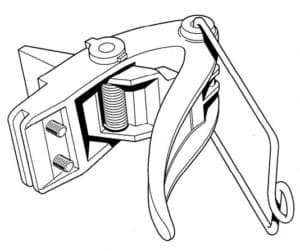

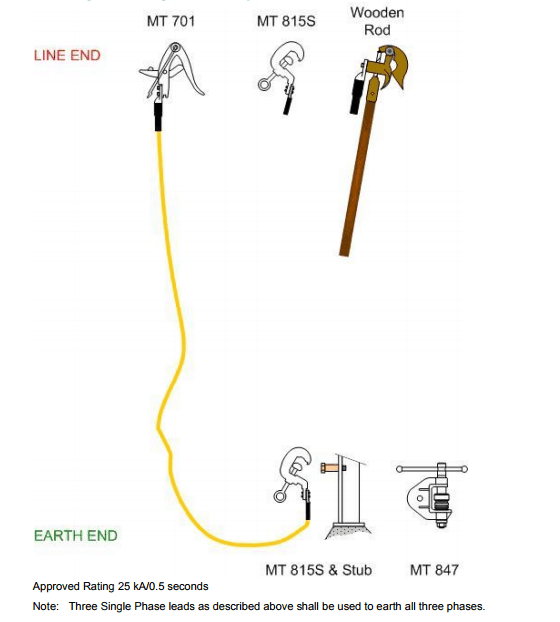

Use Of The CATU MT-701 Clamp

The CATU MT-701 clamp is a V-shaped cast aluminium earth clamp that maintains contact with the conductor via a spring loaded jaw that is preset by a latching mechanism. The clamp is ‘snapped’ onto the conductor by a quick pulling action that triggers the jaw mechanism. The clamp is designed to be applied to and removed from medium/high voltage conductors using haulage and release cords.

Arming The CATU MT-701 Clamp

Lay the clamp on the ground so that the tail of the tongue points vertically upwards.

Holding the earth lead in one hand to stabilise the clamp, use the heel of your shoe to compress the tongue down against the body of the clamp until it latches. Ensure that the clamp is securely latched before handling.

Applying The CATU MT-701 Clamp

1. Pass the haulage cord over the conductor or through the stirrup by the using a sandbag

2. Arm the earth clamp

3. Hoist the clamp to the conductor using the haulage cord; then

4. Latch the clamp to the conductor with a quick pull on the cord

Removing The CATU MT-701 Clamp

1. Take the weight of the CATU clamp and lead on the haulage cord

2. Pull the release cord until the clamp releases from the conductor

3. Lower the earth clamp and lead/s on the haulage cord; and

4. Pull the haulage cord over the conductor or through the stirrup

Portable Earthing For Switchyards

Connection To Earth End Point

Earthing stubs shall be used for all earth end connections within medium/high voltage switchyards and these are generally installed on structures in the area where it is normally necessary to apply portable earths. It is important to ensure that the stub is not corroded and that it is securely mounted on the structure. Only use the CATU MT-815S clamps with earth stubs. At the earth end, the CATU MT-815S clamp can be applied with a CATU insulating stick or the CATU MT-815S application handle.

Portable Earthing Leads For Overhead Lines & Transmission

Connection to Earth End Point on Steel Tower Overhead Lines

For steel tower earthing systems, the tower itself is used as the earth point. CATU MT-847 surface penetrating clamps shall be used on painted or galvanised surfaces. When applying earth end clamps to a steel tower the clamps should be attached to a flat part of the tower structure and screwed up as tightly as practicable by hand.

Connection to Earth End Point On Wood Or Concrete Pole Overhead Lines

Pole earthing systems involves the use of both the pole earth and an independent temporary earth electrode (earth stake). The earth stake is to be positioned approximately 1.3m from the pole and driven 600mm into the ground then bonded to the pole earth using a standard portable earth lead with either CATU MT-815S clamps applied with a shotgun stick or MT-815S application handle

Portable Earthing For Switchgear

In general, indoor medium/high voltage switchgear is provided with manufacturers specific portable earthing systems. However, the dedicated earthing system provided maybe inadequate or non-functioning. The application of portable earthing systems in indoor switchgear situations is usually limited by physical clearances. The choice of MV-HV earthing system used will therefore be determined by the geometry of the switchgear involved and the practicality of applying the available portable earthing equipment within restricted spaces. Any of the earth systems covered in this procedure, when used with earth clamps approved for indoor use, can be implemented in indoor situations.

The Bridge Method is commonly used where the fault rating of the indoor switchgear is less than or equal to the 25 kA 0.5 second rating.

Portable Earthing Using The Bridge Method

Connection To Earth End Point

Earthing stubs shall be used for all earth end connections and these are generally installed on structures in the area where it is normally necessary to apply portable earths. It is important to ensure that the stub is not corroded and that it is securely mounted on the structure. Only use the CATU MT-815S clamps with earth stubs. At the earth end, the CATU MT-815S clamp can be applied with a shotgun stick or the CATU MT-815S application handle.

Use Of The CATU MT815S Clamp On Medium & High Voltage Indoor Switchgear

Clamps can be applied to stirrups and conductors. In certain indoor switchgear situations, an ‘Earth Stub’ may have been installed on the bus bar or conductor to enable the application CATU MT-815S clamps.

Use Of The Pfisterer 360333333 Clamp On Indoor Medium & High Voltage Switchgear

Known as universal angle clamps these are applied to ball stubs using a CATU CM710 E application handle. Once the earth clamp is placed onto the apparatus to be earthed the application handle is removed.

Portable Earth Clamps with Pfisterer 360333333

| Portable Earthing Situations | Line End Clamps | Earth End Clamps | Reference | ||||

| Connection | CATU Clamp | Application | Connection | Clamp | Application | ||

| Conductors In Substations | Earthing Stirrup | MT815S | Shotgun Stick | Earth Stub | Screw Action Clamp MT815S | MT 815S Application Handle | Application of Portable Earthing In MV HV Switchyards |

| Conductor | MT-701 | Haulage & Release Cord, Sandbag, HV Operating Rod | |||||

| Steel Tower Overhead Lines | Conductor | MT815S | Shotgun Stick | Tower Structure | Surface Penetrating Clamp | By Hand | Application of Portable Earthing On Overhead Transmission Lines Connection To Earth End Point On Steel Tower Overhead Lines |

| MT815E | CATU CM-4130-E Application Stick | ||||||

| MT-701 | Haulage & Release Cord, Sandbag, HV Operating Rod | ||||||

| Wood & Concrete Pole Overhead Lines | Conductor | MT815S | Shotgun Stick | Earth Stake | Screw Action Clamp MT815S | MT 815S Application Handle | Application of Portable Earthing On Overhead Transmission Lines Connection To Earth End Point On Wood Or Concrete Pole Overhead Lines |

| MT815E | CATU CM-4130-E Application Stick | ||||||

| MT-701 | Haulage & Release Cord, Sandbag, HV Operating Rod | ||||||

| Indoor Switch Gear | Conductor | MT815S | Shotgun Stick | Earth Stub | Screw Action Clamp MT815S | MT 815S Application Handle | Application Of Portable Earthing On Indoor Switchgear |

| Ball Point | Universal Angle Clamps | CM710E Application Stick | |||||

| Mobile Plant | Earth Stub On Mobile Plant Chassis | MT815S | MT 815S Application Handle | Earth Stub | Screw Action Clamp MT815S | MT 815S Application Handle | Mobile Plant In The Vicinity Of High Voltage Conductors |

| Mobile Plant Chassis Or Boom | Surface Penetrating Clamp | By Hand | Earth Stub | Screw Action Clamp MT815S | MT 815S Application Handle | ||

| Tower Structure | Surface Penetrating Clamp | By Hand | |||||

| Earth Stake | Screw Action Clamp MT815S | MT 815S Application Handle | |||||

| Screw Action Clamp – CATU MT815S |  |

|

| Approved Rating | 40kA/0.5 seconds | |

| Use | Line or Earth end connections for Earthing, Bonding & Bridging | |

| Limitations of Use | Round Conductor up to 44mm in diameter, Flat Conductor from 3mm to 40mm in thickness | |

| Drawing Number | STD-647175 | |

| Stockcode | 3180437 | |

| Associated Equipment | Shotgun Stick or Hand Application Tool | |

| Screw Action Clamp – CATU MT815E |  |

|

| Approved Rating | 25kA/0.5 seconds | |

| Use | Line end connections for transmission line earthing | |

| Limitation of Use | Round Conductor up to 44mm in diameter | |

| Drawing Number | – | |

| Stockcode | – | |

| Associated Equipment | CATU CM-4130-E application stick | |

| Universal Angle Clamp – Pfisterer 360 333 333 |  |

|

| Approved Rating | 40kA/0.5 seconds | |

| Use | Line end connections for Indoor Earthing | |

| Limitations of Use | Haymarket 11kV | |

| Drawing Number | – | |

| Stockcode | Not Stocked | |

| Associated Equipment | CM 710 E application stick | |

| Snap Action Line Clamp – CATU MT-701 |  |

|

| Approved Rating | 40kA/0.5 seconds | |

| Use | Line end earthing connections only | |

| Limitations of Use | Round Conductors 20 to 40mm diameter | |

| Drawing Number | STD-197006 | |

| Stockcode | 986968 ea 986901 complete set with single leads 986893 complete set with twin leads |

|

| CATU CM 710 E Insulating Sticks |  |

|

| Approved Rating | Not applicable | |

| Use | Haymarket 11kV Indoor | |

| Limitations of Use | Must be used only with Pfisterer 360 333 333 | |

| Stockcode | Not stocked | |

| Associated Equipment | Pfisterer 360 333 333 clamp | |

| CATU CM 4130 E Insulating Sticks |  |

|

| Approved Rating | Not applicable | |

| Use | Insulating stick for line end connections for transmission line earthing | |

| Limitations of Use | Must be used only with CATU MT815E clamps | |

| Stockcode | – | |

| Associated Equipment | CATU MT815E clamps | |

Glossary

| Term | Definition |

| Earth Stake | A steel rod driven into the ground to provide an earth point for portable earthing equipment |

| Earth Lead | A yellow flexible cable that connects the conductors of equipment required to be earthed through clamps or other means to the general mass of the earth |

| Bridging | The process of placing a conductor (or bridge) across a break in an electrical circuit (HV conductor, neutral or earthing system) in order to maintain electrical continuity |

| Fault Current | Abnormally high current that flows due to partial or complete failure of insulation at one or more points |

| Earthing System | A group of components that performs a short circuiting or earthing function |

| Earthing Equipment | Any piece of equipment for the purpose of earthing, either individually or combination |

| Line End | That part of an earthing set connected to conductors or other apparatus that may be energised |

| Earth End | That part of an earthing set connected to the general mass of earth directly, or through an “earthed” piece of equipment e.g structure or earth grid |

| Trifurcating Plate | An aluminium plate used to connect the earthing leads and provides a short circuiting point for the phases |

| Screw Action Clamp | A clamp in which the mechanism of attachment to conductors is carried out by a positive screw thread |

| Snap Action Clamp | A clamp by which attachment to the conductors is carried out by a spring operated mechanism |

| Haulage & Release Cord | Associated with snap action clamps, enables the clamp to be hauled up and applied to the conductor to be earthed |

Trifurcated Earthing System

Single Phase, Single Lead Earth System

Single Phase, Twin Lead Earth System

Substation Earthing

Thorne & Derrick International distribute ABB Furse and AN Wallis Earthing & Lightning Protection Systems for the protection and grounding of Medium, High & Extra High Voltage Substations – this includes copper earth tapes, earth rods, copper earthing plates, clamps and ancillary items for 33kV, 66kV, 132kV and 275kV substations. For more information please see substation earthing.

AN Wallis – Copper Earth Tapes | Bars | Clamps | Rods

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substation earthing and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

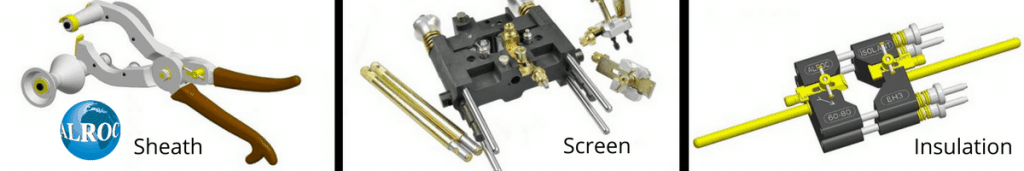

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

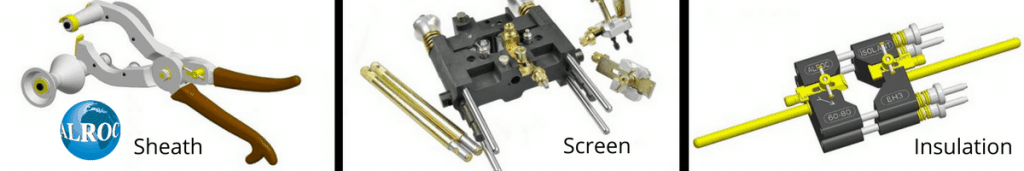

The Alroc range of jointing tools are extensively used to enable the installation of MV HV Joints, Terminations & Connectors including Prysmian, Elastimold, 3M, Pfisterer and Nexans Euromold.

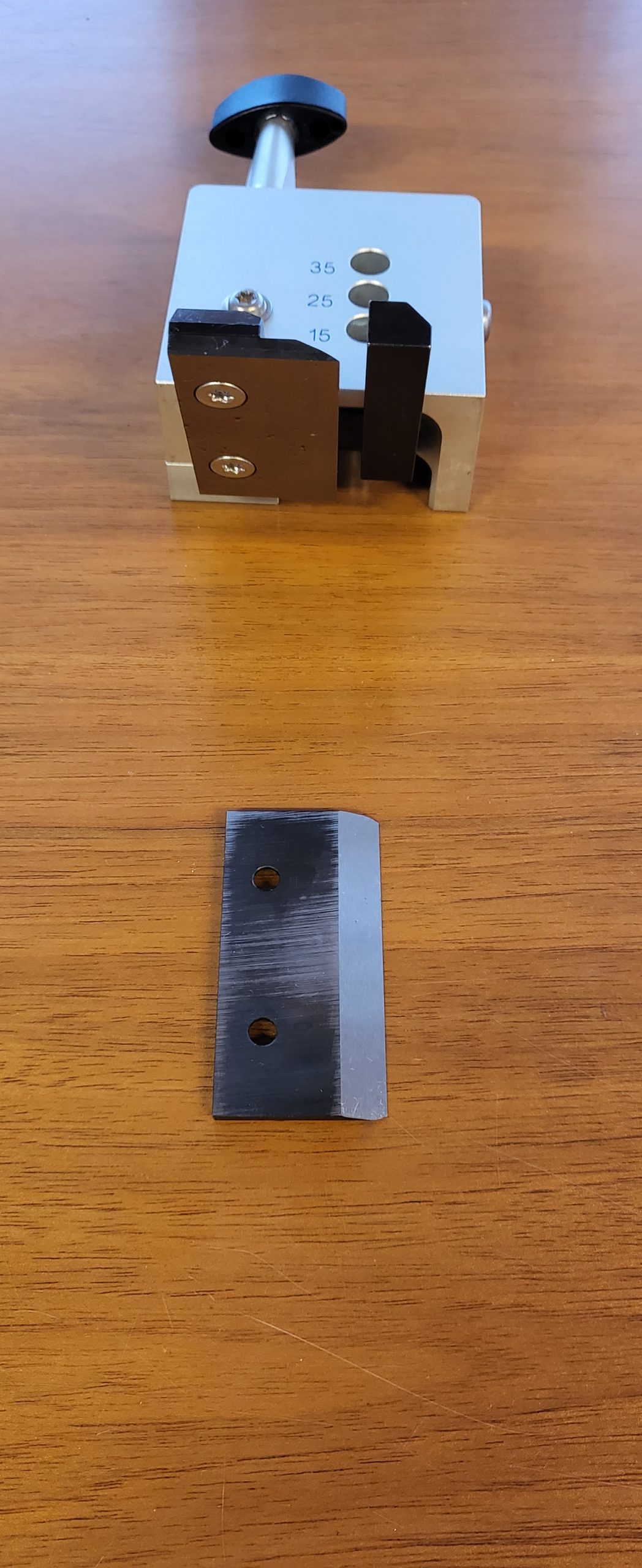

Alroc CAMF4/40-90-BBCF – Multifunction Cable Jointers Tool For Bonded Semiconductor & Insulation

January 18th, 2018

Alroc Cable Jointing Tools | MV HV EHV 11kV 33kV 66kV 132kV

-

uploaded by Chris Dodds - reading time 5 minutes

Alroc

Alroc are market-leading manufacturers of cable jointing tools to ensure the accurate preparation of power cables working at Low, Medium & High Voltage.

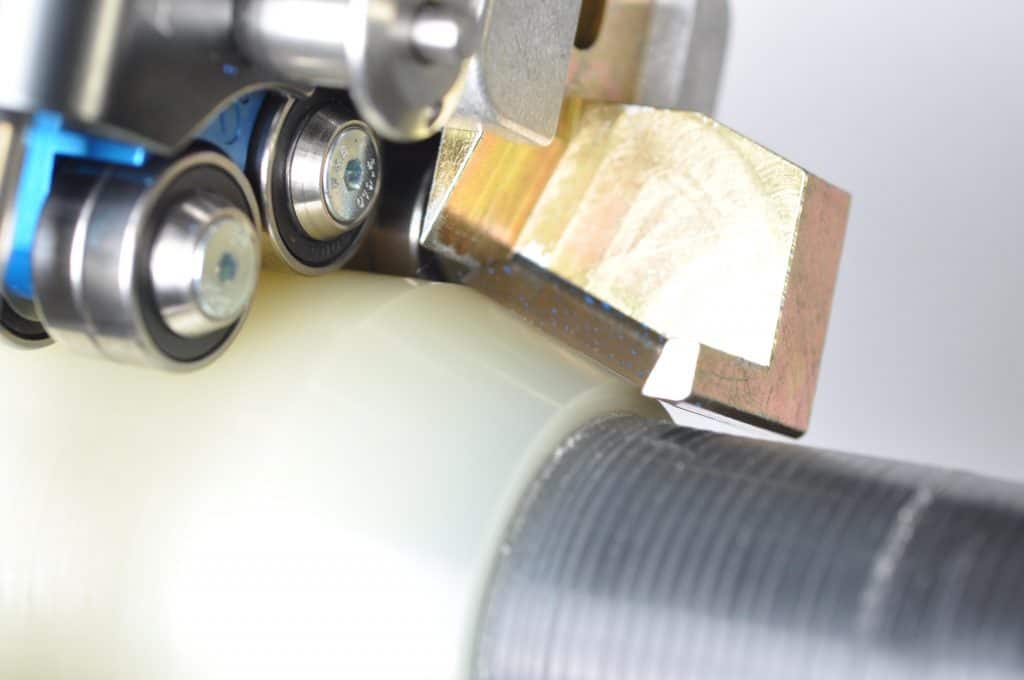

Alroc CAMF4/40-90-BBCF multifunction cable jointing tool is used to remove the outer bonded semi-conductor and the insulation from medium/high voltage power cables.

voltage power cables.

- Diameter ø40-90 mm – ø1.575 – 3.543″

1. Alroc CAMF4/40-90-BBCF enables the MV-HV Cable Jointer to remove the bonded semiconductor

- Bonded semicon thickness capacity 2.5mm / 0.098 in

- Remaining length of the semicon 55mm / 2.165 in

No silicone – the ball bearings in contact with the MV-HV cable enable an easy rotation of the cable preparation and jointing tool.

Low Roughness Over Insulation

Bonded semiconductor removal – very steady (16 ball bearings rolling around the cable), shaping the cable round over the insulation , constant diameter over the insulation, prevent the blade from digging into the insulation, perform a chamfer on transition between the insulation and the semiconductor.

2. Alroc CAMF4/40-90-BBCF enables the MV-HV Cable Jointer to remove the polymeric insulation (XLPE)

- Cable insulation thickness capacity – 35.mm / 1.378 in

Cable Jointing Tool

The tool includes a function for the jointer to simply adjust the outer cable diameter for removal of cable sheath – once the cutting blade is correctly set and positioned the cable jointer rotates the tool around the MV-HV cable in a circular motion. Adjustment of the Alroc tool is simple using the back-iron for clean and consistent cutting of the power cables.

Fine adjustment of the semiconductor shaving depth is possible for precision cable engineering of the semicon cut. Similarly, adjustment of the cable cutting depth using the Alroc CAMF4/40-90-BBCF is possible – the ball bearings can be switched to rotate statically to enable the cable jointer to create a chamfer and groove in the medium/high voltage cable insulation.

The Alroc CAMF4/40-90-BBCF jointing tool performs an excellent semicon cut to ensure the safety and reliability of the cable joint, termination or connectors.

➡ Watch the complete Alroc video here:

Alroc CAMF cable preparation tools can be split for removal by the Jointer – this is a particular benefit for the cable jointer where they solder the cable connector allowing the tool to be easily removed from the HV cable when being used to strip and prepare offshore and submarine cables prior to installing HV joints, terminations or connectors.

The ALROC CAMF440 90 tool features a push/button locking system and also facilitates the Jointer to create a groove in the XLPE insulation (with their blade option) and shave bonded semi-con screens – the tool has 16 wheels rolling against the cable with 4 (or 8) contact points. The unique design of the Alroc tool prevents the cutting blade digging into the XLPE insulation when preparing high voltage power cables with XLPE insulation.

These Jointers Tools are used typically on 132kV high voltage transmission cable circuits, in accordance with EC 60840, to prepare XLPE single core power cables for jointing and termination applications into GIS Switchgear and installation of AIS Cable Sealing Ends.

XLPE Insulation Removal

From High Voltage Cables

Back-iron that enables the cable jointer to tune the pitch of the jointing tool thus making the rotation of the tool easy when removing the insulation from medium/high voltage power cables (MV-HV).

Chamfering Cables

Chamfering – HV High Voltage Cables XLPE Insulation

Grooving Cables

Grooving – HV High Voltage Cables XLPE Insulation

Shaving Cables

Shaving – HV High Voltage Cables XLPE Insulation

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substation earthing and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

The Alroc range of jointing tools are extensively used to enable the installation of MV HV Joints, Terminations & Connectors including Prysmian, Elastimold, 3M, Pfisterer and Nexans Euromold.

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

➡ Visit Power Blog.

Hivotec Tools For 66kV/150kV Cable Jointing, Stripping & Peeling High Voltage Cables

January 17th, 2018

66kV Cables – Jointing Tool Recommendations

-

uploaded by Chris Dodds - reading time 5 minutes Hivotec Tools | Stocked, Supplied & Distributed in UK by Thorne & Derrick

Jointing 66kV cables requires special skills, special tool sets and specialist skilled Jointers – cable preparation by the HV Jointer must be accurate and perfect before the field installation of high voltage joints and terminations.

Whether installing heat shrink, cold shrink, slip-on or separable connectors, joints and terminations the removal of sheath, insulation and semicon screen must be precise and in accordance with the manufacturers jointing instructions.

Jointers preferences vary – they are usually personal and based on familiarity and the type of high voltage cables to be jointed. Leading manufacturers of jointing tools include Alroc, Boddingtons and Ripley a Utility Tool brand.

Some manufacturers, such as Pfisterer, produce their own recommended cable tool sets for use with their range of inner cone plug connector terminations on gas insulated switchgear and substations.

So we invited Chris Barker (HV & EHV Cable Jointer) to comment on his cable tool preferences for use with 66kV high voltage cables – Chris is an international class HV EHV Jointer conversant with XLPE and fluid filled joints and terminations. Competent and certified with Prysmian, ABB, Silec, Nexans, Pfisterer Ixosil, Raychem and 3M at 132kV.

Hivotec CP90 CP130

Screen & Insulation Removal 33kV/66kV Cables

“I wouldn’t say there is a specific cable jointers tool set to hold for 66kV jointing – personally with the range of jointing tools I own I can confidently confront standard 11kV up to extra high voltage 400kV cables,” Chris comments.

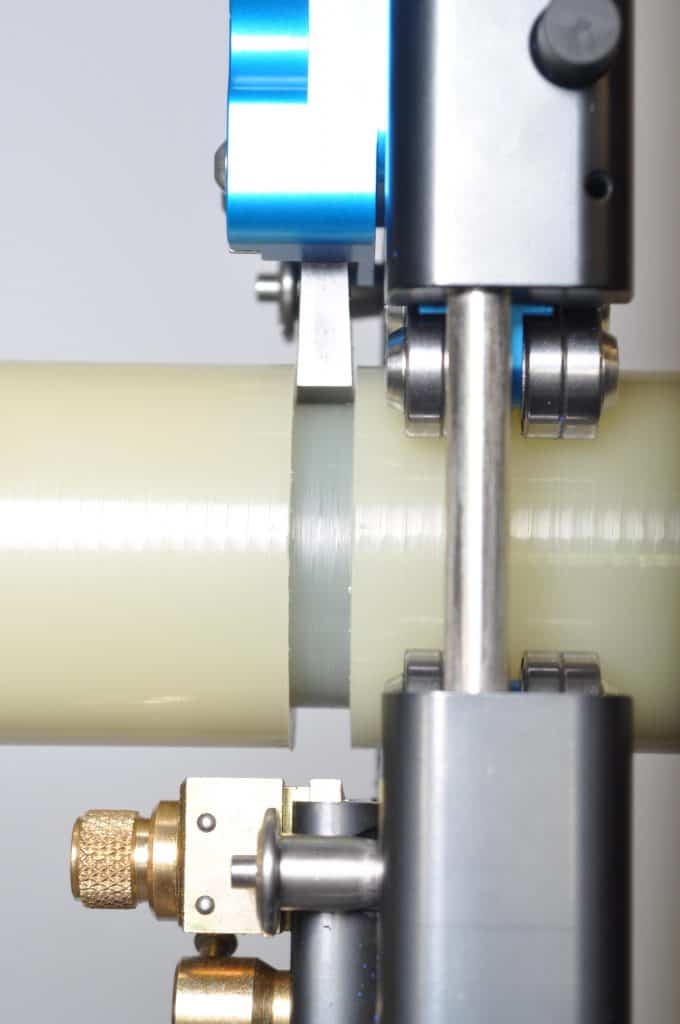

“The Hivotec CP90 semicon peeling and insulation stripping tool with a cable diameter range of 40-90mm can be used to prepare both 33kV medium voltage cables and 66kV high voltage cables with bonded semicon and XLPE polymeric type cable insulation. The Hivotec CP90 provides a perfect transition between the cable insulation and bonded semicon.”

“To remove the PVC cable sheath the PG tools manufactured by Alroc provide clean circumferential and longitudinal cuts to the cable sheath without incurring damage to the cable construction – this tool can also be used to strip lead sheath covering from 33kV/66kV high voltage single core power cables. I would then use a jointers cable knife for tramlining.”

“Hivotec provide a complete range of modular MV HV Jointing Tools for the peeling and stripping of HV cables covering a diameter range from 40-185mm. The Hivotec tools are equipped with guiding rollers eliminating the requirement for greasing of cables,” adds Chris.

The cable peeling depth can be simply adjusted with the fine adjustment screw to provide smooth finish to cable insulation surface without need for additional regrinding or sanding.

- Hivotec CP90 – Peeling and cable stripping tool for a diameter range of 40–90mm (optional drive)

- Hivotec CP130 – Peeling and cable stripping tool for a diameter range of 80–130mm (optional drive)

- Hivotec CP185 – Peeling and cable stripping tool for a diameter range of 130–185mm

- Hivotec Unipower 34R – Gear transmission unit to drive Hivotec CP90 and CP130

The range of HV High Cable Jointing Tools manufactured by Hivotec – specified for the stripping and chamfering of insulation and peeling or removal of bonded semicon screens on high voltage power cables.

hIVOTEC CP90 HV Cable Tools – Main Technical Data

| Range of High Voltage Cable Diameter | mm | 40-90 |

| Weight of Jointing Tool | kg | 4.20 |

| Maximum Semicon Peeling Depth | mm | 2.0 |

| Minimum Length Of Remaining Semicon | mm | 70 |

| Cutting Depth For Insulation | mm | 3…35 |

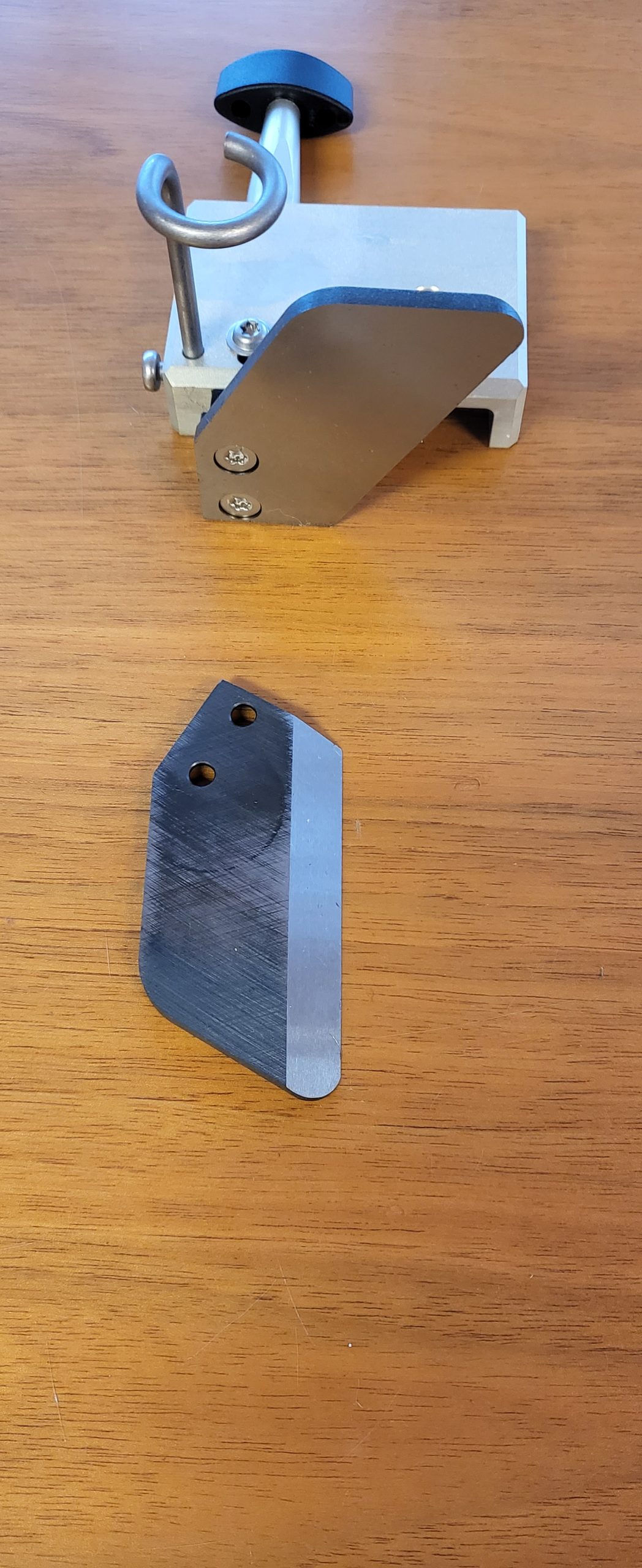

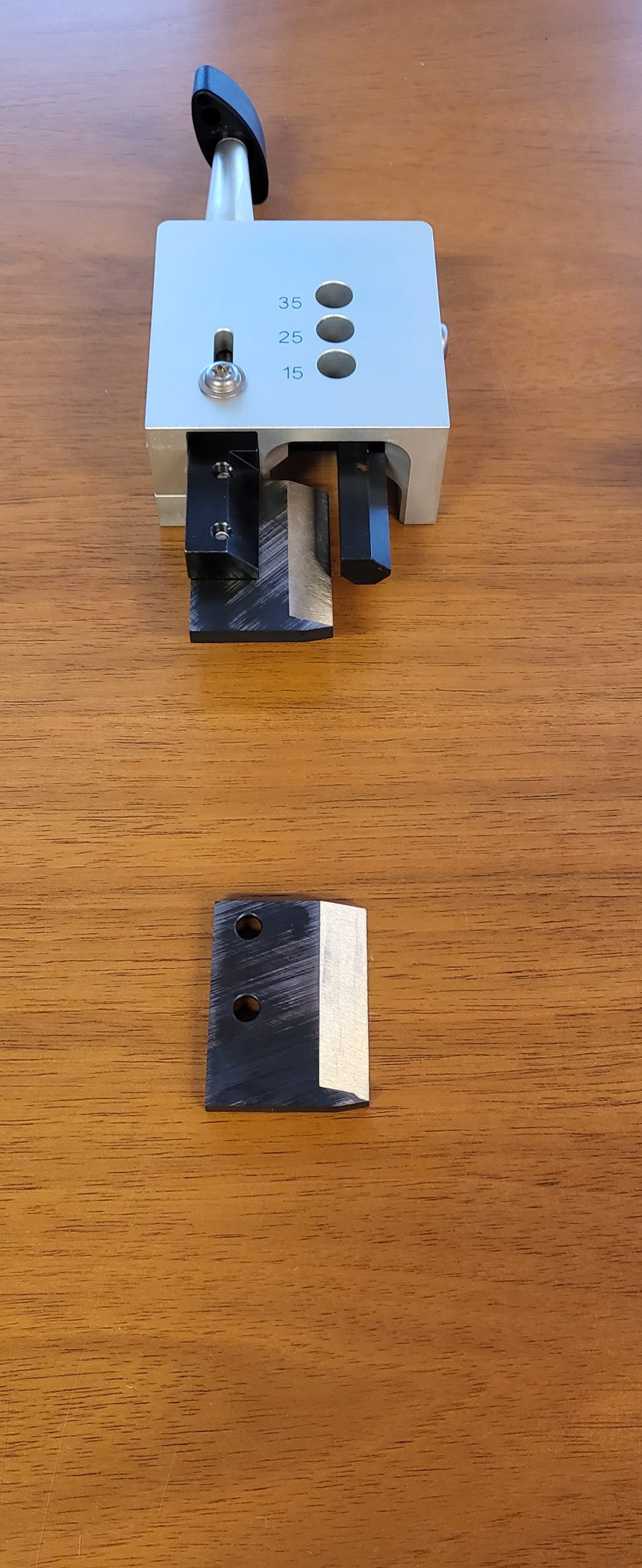

Spare Blades for Use with Hivotec Tools | Peeling, Insulation Stripping & Chamfering

Peeling Blades | FK-CP Cable Stripping Tool – Hivotec Tools

Insulation Stripping Blades | IK-CP Cable Stripping Tool – Hivotec Tools

Chamfering Blades | CK-CP Cable Stripping Tool – Hivotec Tools

150kV Cable Jointing Tools

Hivotec CP130 | Cable Jointing & Peeling Tool – here the high voltage power cable preparation tool is being demonstrated removing XLPE insulation from 150kV cable for an offshore wind farm project.

400kV Cable Jointing Tools

Here the Hivotec CP130 has been used to prepare a perfect EHV cable semicon cut back, high quality cable preparation installations mean minimal future O&M for cable accessories such as joints, terminations and connectors. Note the cleanliness of the cable insulation – all cables whether LV HV EHV should be carefully cleaned using cable cleaning wipes to remove any debris or contaminants from the cable.

Image: Narasingaraj Surappan (EHV Cable Jointer).

400KV Cable | Stripping & Jointing Prysmian EHV Cable Using Hivotec CP130

Thorne & Derrick International

T&D are Specialist Distributors of High Voltage Joints & Terminations to UK and international customers – we guarantee expert technical support across an extensive range of core products to joints, splice, terminate or connect medium and high voltage (MV-HV) cables.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Underground Cable Protection, Earth Tapes, Cable Jointing Tools, Feeder Pillars, Insulating Matting, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Transits, Cable Glands, Arc Flash Clothing/Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

Cable Jointing Tools – Prysmian Cable Jacket Stripping Tools

January 15th, 2018

LV MV HV 11kV 33kV 66kV 132kV Cable Tools for further info see: Cable Jointing Tools

-

uploaded by Chris Dodds - reading time 2 minutes

Jointing & Preparation Tools

Prysmian cable jointing tools include a complete range of cable sheath/jacket strippers specified to strip and remove the cable jackets on concentric neutral cables, flat strap neutrals and PILC cables including the Prysmian AIRGUARD range of Low Voltage & Medium Voltage Power, Instrumentation and Control cables – PG cable jacket and sheath strippers are suitable for low, medium and high voltage cable sheaths.

| Prysmian Order Code | Cable Jacket OD Range Inches (mm) |

| Prysmian PG2-MV-2020 | 0.80-1.40 (20-36mm) |

| Prysmian PG3-MV-1018 | 1.00-2.00 (25-51mm) |

| Prysmian PG3-MV-2833 | 1.00-2.00 (25-51mm) |

| Prysmian PG4-MV-2833 | 1.85-3.00 (47-76mm) |

| Prysmian PG5-MV-3535 | 2.55-3.70 (65-94mm) |

| Prysmian PG6-MV-3535 | 3.14-4.90 (80-124mm) |

Please note – the last number in the Prysmian part number indicates the cable tools blade depth – the first two digits indicate the depth in millimetres of cut for the circumferential cut and the last two digits indicate the depth in millimetres of cut for the longitudinal cut.

Example – Prysmian PG4-MV-2833 contains 4 circumferential blades to cut the cable sheath with a depth of 2.8mm and one longitudinal blade with a cable cutting depth of 3.3mm. Replacement blades are available.

PG Cable Jacket Strippers

♦ Also: Lead Lifting Tools, Cable Sheath Spreaders, Semicon Removal Jointing Tools, XLPE Insulation Removal Tools.

Thorne & Derrick International

T&D are Specialist Distributors of High Voltage Joints & Terminations to UK and international customers – we guarantee expert technical support across an extensive range of core products to joints, splice, terminate or connect medium and high voltage (MV-HV) cables.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Underground Cable Protection, Earth Tapes, Cable Jointing Tools, Feeder Pillars, Insulating Matting, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Transits, Cable Glands, Arc Flash Clothing/Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

Medium Voltage Cable Joints Using Fire Proof Prysmian Cable Joints – 15kV EPR Okonite

January 15th, 2018

- Application: 15kV EPR Okonite Medium Voltage Cable – Primary UD Cables

- Cable Joint Type: Prysmian Cable Joints – Medium & High Voltage

- Cable Jointer: Christopher Fusarelli Splicer at The United Illuminating Company

Joints, Splices & Terminations to suit Okonite Cables LV MV HV | 15kV

-

by Chris Dodds T&D - estimated reading time 5 minutes

MV Joints & Cable Preparation

1. MV Cable Preparation. The medium voltage cables are expertly prepared by the cable jointer/splicer using basic tools such as cable jointing knife, needle nose pliers and a scale ruler – no specialist cable jointing tools were used to complete this MV cable preparation or joint. To achieve this level of precision and accuracy without damaging the cable and jeopardising the medium voltage cable joint requires an exceptional skill level. The 15kV cable manufactured by Okonite is 750 KCMIL with EPR insulation and ready to be connected using Prysmian cable joints. The white tape overlap section between the copper tape screen and semicon screen is used to secure the medium voltage cable shielding in place.

2. Medium Voltage Cable Joints – Fire Proof. The medium voltage cable joint is over-wrapped to provide fire protection and arc proofing. This MV cable joint was for a new medium voltage circuit with several cable chambers so the 15kV cable is actually open on both ends and not grounded – “the phasing is not completed until every medium voltage cable joint or splice is completed except the first and last, and that’s when we phase it,” comments Christopher.

3. Medium Voltage Straight Joints – no tee (or branch) cable joints were installed, “this particular MV circuit isn’t very long and goes from substation to a dozen or so manholes, then the medium voltage cable terminates at a riser. If our circuit has wyes or tees, we still typically phase at the end,” added Christopher. Branch joints can be used to split main feeder cables into two cables that can be directed to other loads.

Cable Pulling – the cable gang pulling 15kV 500MCM medium voltage EPR cable. Here the contractor is preparing to piece out a circuit that runs through the middle of the manhole (cable splicing or jointing chamber).

Prysmian Elaspeed Cable Joints

Prysmian Elaspeed cold shrink cable joints and splices are medium voltage cable accessories extensively specified in North American markets – Elaspeed are not molded cable joints. Elaspeed cable joints feature a core constructed from ethylene propylene rubber (EPR) on a vertical triple extruder which maintains concentricity on medium voltage cables. Cable joints are installed cold-applied without the requirement for heat or open flames associated with heat shrink cable joints.

Watertight Cable Joints

The circumferential pressure of the Prysmian Elaspeed cable jacket in conjunction with the cold flow properties of the mastic supplied with the cable joint kit will prevent water ingress. The Elaspeed MV cable joint has successfully passed external water pressure tests of 45 psi. In addition, the tight interface between the cable and cable joint body can withstand pressures up to 30 psi.

Compact Joints

Prysmian Elaspeed joints mimic the behaviour and performance of MV EPR cables in terms of bending radius in tight manhole situations – cable joints or splices can be bent to the same radius as the cable without impacting upon the performance of the joint. The small and smooth profile of the completed joint occupies less installation space where confined space working does not permit oversized joints.

Medium Voltages

Prysmian Elaspeed joints are available in the following voltage categories: 15kV, 25kV, 28kV, 35kV – the cable joints are available to also connect 3 core conductor armoured cables and aluminium inter-locked armoured MV-105 cables, including TECK Cable. Transition joints are also available to splice 3 or single core conductor paper lead (PILC) cables to 3 or single core conductor EPR / polymeric cables.

Prysmian | Cable Joints | Terminations | Cable Cleats | Connectors Distributor

Thorne & Derrick International

Should you require any assistance with the selection or specification of Prysmian cable joints please do not hesitate to contact us.

T&D distribute the most extensive range of MV & HV Cable Joints & Terminations, Cable Installation Accessories & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substation earthing and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables

➡ Visit Power Blog.