Blog

ESB Networks Approved | Cable Joints, Terminations & Electrical Equipment LV HV

November 26th, 2017

ESB Networks

ESB Networks distribute low, medium and high voltage electricity to 2.3 million domestic, commercial and industrial customers in Ireland in a safe and efficient manner every day, every hour and every minute. The LV-HV electricity distribution network includes all distribution stations, overhead electricity lines, poles and underground cables.

ESB through building their Smart Network have significantly increased the electrical network reliability, resulting in a 42% reduction in power outages in 2014.

The total length of the LV-HV overhead lines and underground cables in the Transmission and Distribution systems managed by ESB Networks is 177.500 km.

In 2015 ESB Networks connected with 17,012 new customers making a total of 2,253,000 customer connections to the distribution systems.

Thorne & Derrick are Approved Vendors of ESB Networks Approved Materials List & Assessed Products to enable the cable jointing, termination, distribution and installation of LV, MV (11kV-33kV) & HV cables onto ESB cable network from manufacturers including:

| 3M | CATU Electrical |

| Pfisterer | Nexans Euromold |

| Prysmian | Ellis Patents |

| AN Wallis | Furse |

| Lucy Zodion & Electric | WT Henley |

| Sicame | Cembre |

| Polypipe | Emtelle |

| Tyco TE Connectivity | NKT |

| Roxtec | Alroc |

| Centriforce | MV HV Cables |

➡ Contact us to discuss your requirements for ESB Networks LV, MV & HV Cable Installation, Jointing, Termination, Substation & Electrical Equipment including the following LV-HV Product Categories – our internal ESB commodity code database is constantly updated with new ESB Networks products.

| Cables – LV Waveform 11kV 33kV Triplex | Link Boxes – Underground LV |

| LV Joints – Mains, Straight, Service & Pot End | Cut Outs – House Service & Street Lighting |

| HV Joints – Straight, Branch & Transition | Crimping & Cutting Tools – Cables & Lines |

| HV Terminations – Indoor & Outdoor | Distribution – Service Boards & Feeder Pillars |

| HV Terminations – Separable Connectors | Cable Duct – LV MV HV 11kV 33kV 132kV |

| HV Bushings – 11kV 33kV | Duct Seals – Cable Seals & Transits |

| HV Surge Arresters – 11kV 33kV | Jointing Tools – 11kV 33kV 66kV 132kV |

| EHV Terminations – GIS 132kV Cables | Insulation – Heat Shrink & Cold Shrink |

| Earthing Materials – Copper Tape | Cable Covers – Stokbord & Tapetile |

| Cable Cleats & Clamps – Single & Trefoil | Cable Lugs – Crimp & Mechanical |

ESB cables, joints & terminations 11kv 33kv

Thorne & Derrick distribute DNO approved MV HV Cables including 11kV 33kV – this includes single and 3 core XLPE, EPR and Triplex cables plus suitable cable joints, cable cleats, terminations and connectors in heat shrink, cold shrink, cold applied and plug-in technology.

Cable Pulling & Laying Equipment LV HV

T&D supply Utilities & Approved Contractors with cable pulling products including cable rollers, cable socks and drum lifting jacks to enable the installation of low voltage and high voltage cables intro trench or duct: this includes single core, 3 core and Triplex 11kV/33kV power cables and LV waveform, mains and service cables.

HV Joints Terminations Connectors – 3M Pfisterer Nexans Euromold Elastimold

UK DNO’s

T&D are Specialist Distributors to the UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and High Voltage Jointing Contractors of an extensive range of Cable Joints, Substation, Distribution, Tooling & Installation Equipment approved by the utilities:

- Northern Powergrid – NPG

- Electricity North West – ENW

- NIE – Northern Ireland Electricity Networks

- SPEN – Scottish Power Energy Networks

- SSE – Scottish & Southern Energy Networks

- UKPN – UK Power Networks

- WPD – Western Power Distribution

JOINT ♦ TERMINATE ♦ CONNECT ♦ GLAND ♦ CLEAT ♦ CRIMP ♦ DUCT ♦ SEAL ♦ REPAIR ♦ CABLE ♦ SPLICE ♦ INSULATE

Electricity North West Approved | Cable Joints, Terminations & Electrical Equipment LV HV

November 26th, 2017

Electricity North West ENW

Electricity North West owns, operates and maintains the North West’s electricity distribution network, connecting 2.4 million properties and more than 5 million people in the region to the National Grid.

ENW own one of the original 14 regulated electricity distribution networks in England, Wales and Scotland and are regulated by Ofgem.

The electricity network covers a diverse range of terrain, from isolated farms in rural areas such as Cumbria, to areas of heavy industry and urban populations including Manchester.

Delivering more than 23 terawatt hours of electricity each year to customers in the North West – the equivalent of 2.7 million electric heaters being switched on for a whole year. The LV-HV electrical network consists of around 13,000 km of overhead lines, over 44,000 km of underground cables, almost 86,000 items of LV-HV switchgear and more than 34,000 transformers.

Thorne & Derrick are Approved Vendors of Electricity North West Approved Materials List & Assessed Products to enable the cable jointing, termination, distribution and installation of LV, MV (11kV-33kV) & HV cables onto ENW cable network from manufacturers including:

| 3M | CATU Electrical |

| Pfisterer | Nexans Euromold |

| Prysmian | Ellis Patents |

| AN Wallis | Furse |

| Lucy Zodion & Electric | WT Henley |

| Sicame | Cembre |

| Polypipe | Emtelle |

| Tyco TE Connectivity | NKT |

| Roxtec | Alroc |

| Centriforce | MV HV Cables |

➡ Contact us to discuss your requirements for Electricity North West LV, MV & HV Cable Installation, Jointing, Termination, Substation & Electrical Equipment including the following LV-HV Product Categories – our internal ENW commodity code database is constantly updated with new Electricity North West products.

| Cables – LV Waveform 11kV 33kV Triplex | Link Boxes – Underground LV |

| LV Joints – Mains, Straight, Service & Pot End | Cut Outs – House Service & Street Lighting |

| HV Joints – Straight, Branch & Transition | Crimping & Cutting Tools – Cables & Lines |

| HV Terminations – Indoor & Outdoor | Distribution – Service Boards & Feeder Pillars |

| HV Terminations – Separable Connectors | Cable Duct – LV MV HV 11kV 33kV 132kV |

| HV Bushings – 11kV 33kV | Duct Seals – Cable Seals & Transits |

| HV Surge Arresters – 11kV 33kV | Jointing Tools – 11kV 33kV 66kV 132kV |

| EHV Terminations – GIS 132kV Cables | Insulation – Heat Shrink & Cold Shrink |

| Earthing Materials – Copper Tape | Cable Covers – Stokbord & Tapetile |

| Cable Cleats & Clamps – Single & Trefoil | Cable Lugs – Crimp & Mechanical |

ENW cables, joints & terminations 11kv 33kv

Thorne & Derrick distribute DNO approved MV HV Cables including 11kV 33kV – this includes single and 3 core XLPE, EPR and Triplex cables plus suitable cable joints, cable cleats, terminations and connectors in heat shrink, cold shrink, cold applied and plug-in technology.

Cable Pulling & Laying Equipment LV HV

T&D supply Utilities & Approved Contractors with cable pulling products including cable rollers, cable socks and drum lifting jacks to enable the installation of low voltage and high voltage cables intro trench or duct: this includes single core, 3 core and Triplex 11kV/33kV power cables and LV waveform, mains and service cables.

HV Joints Terminations Connectors – 3M Pfisterer Nexans Euromold Elastimold

UK DNO’s

T&D are Specialist Distributors to the UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and High Voltage Jointing Contractors of an extensive range of Cable Joints, Substation, Distribution, Tooling & Installation Equipment approved by the utilities:

- Northern Powergrid – NPG

- ESB Networks

- NIE – Northern Ireland Electricity Networks

- SPEN – Scottish Power Energy Networks

- SSE – Scottish & Southern Energy Networks

- UKPN – UK Power Networks

- WPD – Western Power Distribution

JOINT ♦ TERMINATE ♦ CONNECT ♦ GLAND ♦ CLEAT ♦ CRIMP ♦ DUCT ♦ SEAL ♦ REPAIR ♦ CABLE ♦ SPLICE ♦ INSULATE

Trefoil Cables – Sealing Ducts & Cleating Trefoil Cables Up To 33kV

November 22nd, 2017by Chris Dodds T&D - estimated reading time 5 minutes

Trefoil Cables

Before we demonstrate an effective duct seal solution for trefoil cables let us first define trefoil and cover the importance of selecting correct cable cleats to prevent short-circuit inflicted damage to power systems and electrical infrastructure.

Cable installations for 3 phase power installations, whether LV or MV (600/1000 Volts to 11kV/33kV) utilise single conductor cables typically in flat or trefoil cables formation – trefoil cable cleats are used to restrain 3 single core cables installed in the “shamrock” style formation, commonly referred to as trefoil.

Where a 3 phase cable system design is based on trefoil cables formation The 17th Edition Wiring Regulations (BS7671) can be consulted to provide current ratings and voltage drop values for the installation.

Trefoil cable formation refers to the installed method for low, medium and high voltage power cables where three single core (phases) distribute the electricity supply rather than a single 3 core cable cable.

Typically, at low voltage (LV) this would be single core XLPE/AWA armoured power BS5467 cables or at medium/high voltage (11kV/33kV) polymeric (XLPE or EPR insulated) single core BS6622 cables.

See more information about Trefoil Cleats

MV HV Single Core – 11kV Single Core Conductor Cables BS6622

Depending upon the short circuit calculation according to IEC 61914 the appropriately fault-rated cable cleats should be used to provide cable restraint depending on whether the LV, MV or HV power cable system generates short, medium or high short circuit levels.

According to the installation application and environmental conditions trefoil cleats are available in a selection of materials including nylon, stainless steel and aluminium.

View the complete range: Ellis Patents Cable Cleats

Clearly cleating cables is essential, as is effective sealing of cable ducts to prevent flood damage to substations and buildings or the spread of potentially flammable gases.

Sealing Trefoil Cables In Substation Ducts

Single core 11kV-33kV cables in “triplex formation” according to British Standard BS7870 require effective sealing of cable duct entries against water, gas and fire on medium/high voltage substations as well as cleating to protect against short circuit situations. Triplex cables are characterised by the appearance of 3 core cables twisted around each other.

MV HV Triplex – 11kV Triplex Cables 3 Core Conductor Cables BS7870

Trefoil cable arrangements entering substation ducts can be difficult to seal using traditional mastic or inflatable cable duct sealing systems, however the FiloSeal+HD duct sealing system effectively seals single, trefoil or multiple cables in duct. The single core cables are carefully separated and supported using the FiloSeal+HD hexagonal tubes – note the central positioning of the hexagonal tubes to establish the required HV cable separation and allow maximum flow of the duct sealant into the trefoil cable formation.

The hexagons separating the pictured 11kV cables must have the smaller hexagonal tubes nested in the large one to create additional strength.

Sealing Cable Ducts With Single, Trefoil & Multiple Cables | LV MV HV 11kV 33kV

Where the cable ducts are located in a designated hazardous area according to the ATEX Directive we can provide expert advice and product recommendations for sealing cables in potentially explosive atmospheres.

Filoform – Water, Gas & Fire Protection | Duct Seals In Industrial & Hazardous Areas

Should you require any advice to enable to selection of duct seals for industrial or hazardous area locations, call us | LV MV HV | 11kV 33kV Cable Joints & Terminations

Thorne & Derrick International

Since 1985 Thorne & Derrick based in the UK have been specialist distributors of LV, MV & HV Cable Installation, Jointing, Substation, Arc Flash Clothing & Electrical Safety Equipment – customers include UK and worldwide contractors, specifiers, traders and end-users involved in cable installations, cable jointing, substation, overhead line and electrical construction at Low, Medium & High Voltages.

We are specialist stockists and distributors of 11kV-33kV Cable Joints, Terminations & Connectors from manufacturers including 3M, Pfisterer, Prysmian and Nexans Euromold in a selection of jointing technologies including heat shrink, cold shrink and push-on.

MV HV | Medium & High Voltage Power Products, Tools, Cables & Electrical Equipment

I’m Now A 4 Day Cable Jointer

November 22nd, 2017

intro by Chris Dodds - Thorne & Derrick International

I woke recently and toyed with the idea of career change. One Costa later I just went for it.

So I Google searched “cable jointer training“.

I booked that 4 day course, turned up, collected my certificate – I am now a Cable Jointer.

With paperwork to prove it.

Easy-peasy.

Next move, carpet bomb LinkedIn recruiters with my new CV, sit back and wait for work.

OK, this is a personal fiction but a common occurrence in the UK jobs market.

There is increasing concern in the electrical industry in general and the Cable Jointing trade specifically about a trend of “fast-track” training courses propelling underskilled manpower into a crowded labour market. Inflicting damage on day rates, earnings and livelihoods.

We’re talking day rate differences of £150 v £500/600.

This is rather bloody serious – the view from the cable trench is that the industry is lawless and time-served experienced craftsmen are the furious victims. Some are fastly loosing faith in their trade, some would say their craft, some even their art. Their pockets are hurting.

There is not a skills desert out there but there is an unwillingness, in part, to recognise the monetary value of their skill, experience and ability.

A curative response is needed to stem the tide – no end of soul-baring spleen venting social media posts will remedy this situation. We’ve lamented the demise of “The Jointer” before – we’ve kicked up stinks and many have smelt the pong if not righted the wrong.

Nevertheless, lets continue the crusade and champion the real-deal Jointer.

Because in 4 days time more cable jointers will be on the job-market for hire.

But can they wipe, glass, strip, chamfer or plumb cable?

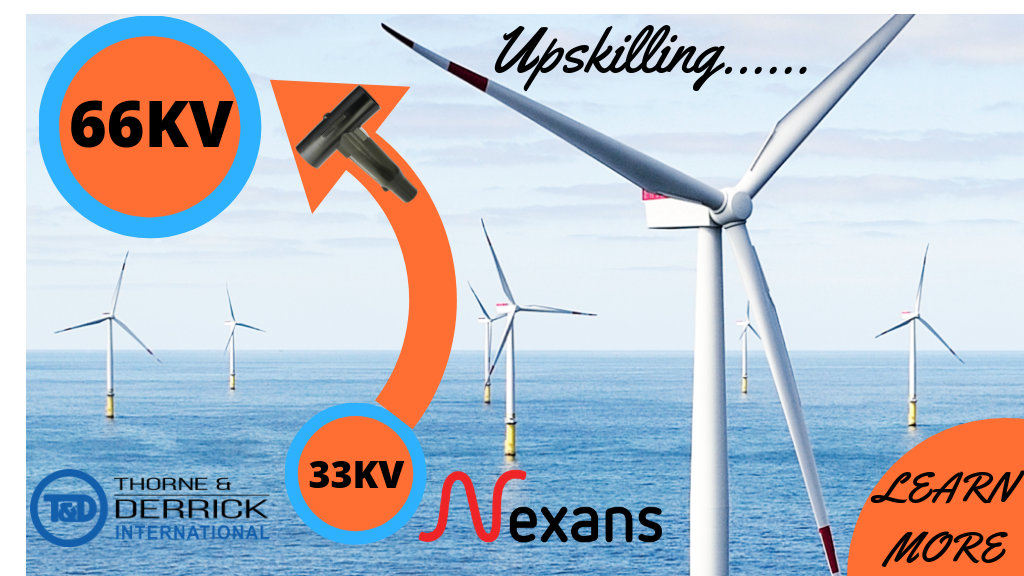

Two Times More Power. Jointers! Empower your CV and skill-set by grasping the 66kV Jointer Training opportunity. Jointers must currently be 33kV Competent and experienced to be ready to undertake the step-up to 66kV from 33kV.

Many cable jointers hold a diversity of accreditations from leading brands such as Nexans Euromold, Brugg, ABB, Pfisterer, Prysmian and 3M – they possess the expertise to joint across an extensive range of medium and high voltage cables (polymeric, gas and oil filled) using cold shrink, heat shrink or push-on HV cable joints, terminations and connectors.

This skill-set is developed over years and contrasts sharply with the generic jointer familiarised with the “specific joint for specific cable” approach of some training centres.

Of course, training is core to career progression without which young, skilled and gifted trainees could never develop – the industry would stagnate to eventual extinction.

Well we’ve blown the trumpet, now we need you – the industry – to rally to the call and let us know your thoughts and opinions. We will feature them on this Post.

The following TweetDeck demonstrates the skills levels and competency of an international class EHV Cable Jointer – Andrew Brezovszky is conversant with the cable jointing techniques required for medium voltage, high voltage and extra high voltage oil filled, gas filled or polymeric cables. 20 years of cable jointing experience with Competency Certificates from leading cable accessory manufacturers including Prysmian, ABB and Pfisterer.

What you might call a real-deal Jointer.

132kV Ericsson Transition Joint – 3 Core Cable Joint XLPE To Oil Filled Cable. Image: Energi Cable Services

Thorne & Derrick International

Since 1985 Thorne & Derrick based in the UK have been specialist distributors of LV, MV & HV Cable Installation, Jointing, Substation, Arc Flash Clothing & Electrical Safety Equipment including voltage detectors, insulating gloves and life saving substation intervention kits.

T&D customers include UK and worldwide contractors, specifiers, traders and end-users involved in cable installations, sealing cable ducts, cable jointing, substation, overhead line and electrical construction at Low, Medium & High Voltages.

We are specialist stockists and distributors of 11kV-33kV Cable Joints, Terminations & Connectors from manufacturers including 3M, Pfisterer, Prysmian and Nexans Euromold in a selection of jointing technologies including heat shrink, cold shrink and push-on.

Cable Innovation Tools & Accessories for Low & High Voltage Power Systems | HV Tools Information

Sealing Cable Ducts In Hazardous Areas According To ATEX Directive

November 21st, 2017

ATEX & Sealing Cable Ducts

by Chris Dodds T&D - estimated reading time 3 minutes

The following short update is written to provide clarification on the requirement to seal cable ducts in hazardous area locations according to the ATEX Directive – ATEX is a EU applicable directive to protect and ensure worker and workplace safety for equipment to be installed in potentially explosive atmospheres.

ATEX Directive relates to equipment which is used in hazardous areas i.e. locations with concentrations of flammable gases and vapours creating a potentially explosive atmosphere.

Specifically ATEX relates to equipment with moving parts posing a potential source of ignition (such as fuel dispensing equipment, gears, motors, pumps, mining equipment, lighting, alarms, plugs, switches, sensors etc).

The comments and conclusions below apply to sealing all types of electrical cables both onshore and offshore – including control, instrumentation and power supplying low, medium and high voltage electricity, typically entering substations at 11kV-33kV.

Hazardous Areas

Equipment is only considered to be within the scope of the ATEX Directive if it is intended (either in whole or in part) to be used in a potentially explosive atmosphere. If a product containing an intended potentially explosive atmosphere, for example a vessel, itself contains equipment as defined in the Directive, then the latter equipment is in effect in a

potentially explosive atmosphere, albeit one which is contained by the vessel, and is therefore subject to the ATEX Directive.

Potential sources of ignition: electric sparks, arcs and flashes, electrostatic discharges, waves, ionising radiation, hot surfaces, flames and hot gases, mechanically generated sparks, chemical flame initiation and compression.

If equipment containing a potentially explosive atmosphere can, due to its construction, operation etc. create a potentially explosive atmosphere itself, which wholly or partially surrounds it, then such equipment is in effect in a potentially explosive atmosphere, and is therefore subject to the Directive.

A third scenario is that there may not only be a surrounding potentially explosive atmosphere but also a process that requires such a mixture to enter and/or be released from the product. The interface between the equipment and the process input/ output will also require consideration. This may, in some cases, lead to equipment having more than one Category, one (or more) for the external atmosphere and another for the process atmosphere.

According to the ATEX Directive download below Section 2 and 3.7 covers the type of equipment that the hazardous area certification covers – the document does not reference products excluded from the Directive.

Conclusion

Duct sealing systems are not covered or categorised according to ATEX – they are effectively “non-sparking” and when installed in accordance with the manufacturers installation instructions do not pose a potential explosion risk. In this instance, a “Statement of Exclusion” applies to cable sealing with respect to the ATEX Directive.

Duct seals are available to prevent water ingress and gas migration into electrical substations, infrastructure and buildings – fire resistant cable seals are available for fire-rated applications. Sealing solutions are available to suit all duct diameters and cable voltages in single, multiple or trefoil cable arrangement.

This information has been provided by SIRA, the leading hazardous area certification body.

Filoform – Water, Gas & Fire Protection Of Cable Ducts In Industrial & Hazardous Areas

Should you require any advice or specification support to enable to selection of cable duct seals for safe, industrial or hazardous area locations, call us | LV MV HV | 11kV 33kV 132kV

Thorne & Derrick International

Since 1985 Thorne & Derrick based in the UK have been specialist distributors of LV, MV & HV Cable Installation, Jointing, Substation, Arc Flash Clothing & Electrical Safety Equipment – customers include UK and worldwide contractors, specifiers, traders and end-users involved in cable installations, sealing cable ducts, cable jointing, substation, overhead line and electrical construction at Low, Medium & High Voltages.

We are specialist stockists and distributors of 11kV-33kV Cable Joints, Terminations & Connectors from manufacturers including 3M, Pfisterer, Prysmian and Nexans Euromold in a selection of jointing technologies including heat shrink, cold shrink and push-on.

➡ Further Reading

ATEX Cable Glands – Glanding Cables In Zone 1 & Zone 2 Hazardous Areas

ATEX Cable Joints – Jointing Cables In Zone 1 & Zone 2 Hazarodus Areas

MV HV | Medium & High Voltage Power Products, Cables & Electrical Equipment