Blog

Cable Sock Damage | How To Ensure Safe & Reliable Cable Sock Performance

May 3rd, 2022

Cable Sock Damage & Maintenance

Cable Sock Inspection & Maintenance

How Can You Tell If They Are Safe To Use?

Inspecting a cable sock is crucially important to ensure safe cable pulling operations, maximum grip strength and grip longevity.

There are a number of variables that can weaken a cable sock that are not immediately obvious on visual inspection. However, there are some important and simple checks that you can do routinely to mitigate product wear, deterioration and potential accidents from happening.

When inspecting a sock, it is critical to know the potential damage and trouble spots. Below is a summary of the types of damage you need to be aware of prior to beginning any pulling project with your cable pulling socks.

Cable Sock Safety

Safety is Thorne & Derrick & Slingco’s primary concern. The products Slingco manufacture are safety critical and therefore they have their own fully certified test facility. This allows them to comprehensively test all socks prior to release from design. They design and manufacture to the highest specifications and test to destruction so you can be confident when using a Slingco product.

If you are in doubt about the serviceability of your cable sock, use a new sock! Thorne & Derrick carry large UK stock of cable socks so lead times are short.

The following are some of the types of damage you should be aware of prior to beginning a cable pulling project with your cable socks. If these are observed, replacement of sock should be considered.

DAMAGED PULLING EYE

The eye of the cable sock is very important. If any damage is found, replace sock immediately. Causes of eye damage include:

• Pulling loads at an angle as opposed to straight line pulling

• Misuse and wear from excessive use

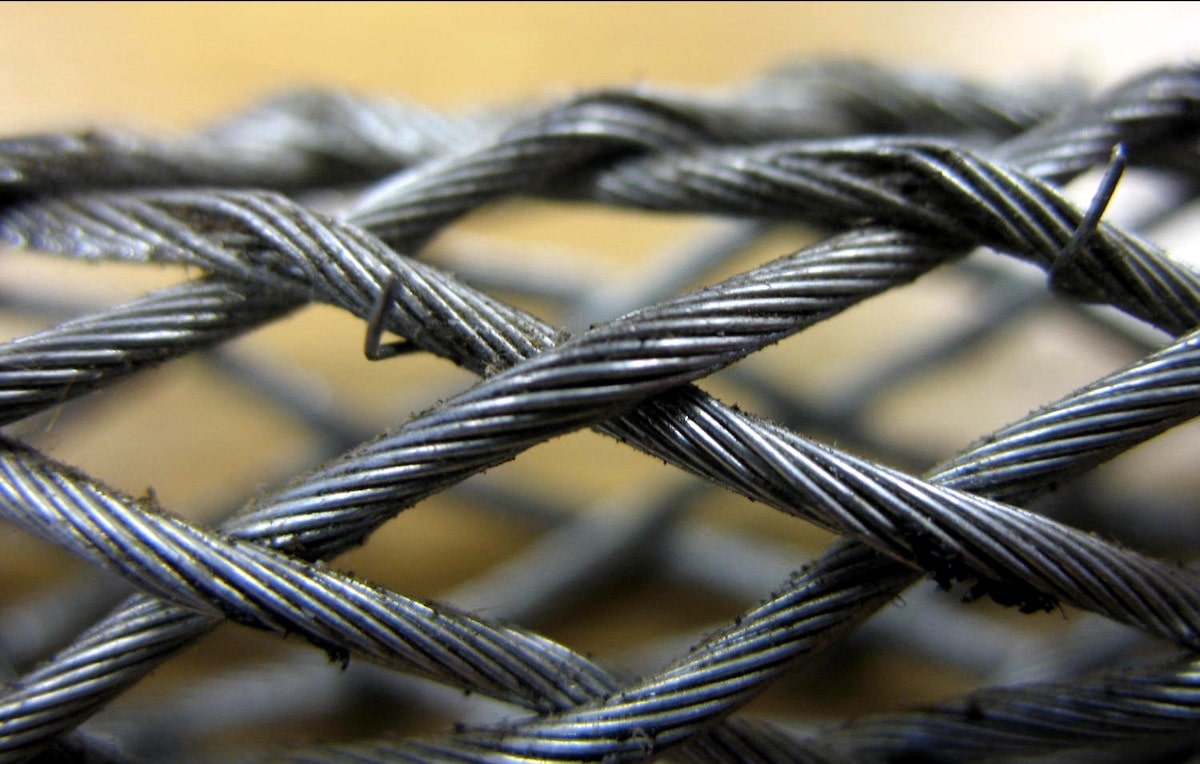

FRAYED WIRES

Frayed wires cause the cable sock to weaken significantly. The more wires damaged, the weaker the sock. Causes of fraying are:

• Excessive abrasion while cable is being pulled

• Becoming stuck or snagging during a pulling operation

Rusted Wire

Rust will weaken the strands of wire that make up the sock. If excessive rust is identified, replace sock. Causes of rust are:

• Socks left in moist conditions or stored damp after water exposure

• Water with high salinity content will cause rusting more rapidly

Bent & Broken Wires

Bent and broken wires have the same effect as fraying and cause the cable sock to weaken significantly. Causes of this type of damage are :

• Excessive abrasion while cable is being pulled

• General wear and tear over time

EFFECTS OF TORSIONAL BUILD UP

The most important factor when using a cable sock to pull wire is to eliminate torsion, or twisting of the cable grip assembly. It is important, when stringing high tension wires for electrical transmission and distribution, to use the proper components to eliminate torsion.

If wires are likely to develop torsion during a pull, line pulling swivels enable the torque to be released, which otherwise could cause damage to the wire or sock.

Advantages of Slingco Swivels include:

- Reduce torsion strain

- Are quality tested and inspected

- Come in bull-nose or rounded style

- Can be matched-up with Slingco’s heavy duty cable socks

Using a cable sock alongside the Slingco swivels to eliminate torsion is crucial

CABLE SOCKS & SUPPORT

ASSESSMENT OF SUITABILITY

There are many factors that must be taken into account when assessing the suitability of a sock for a proposed application, and when trying to calculate the working load limit.

These include:

- Size of cable sock in relation to size/shape of gripped object

- Stability of object(s) when gripped

- Sock surface of object(s)

- Resistive force of object(s)

- Anticipated path of movement, including possible obstructions

- Approximate breaking strength of the cable sock

- Condition of sock

- Suitability and compatibility of any attachments used

- Environment/operating conditions

- Persons at risk

➡ Please note: Slingco socks must be double steel banded securely before being pulled.

CABLE Sock SAFETY INFORMATION

- Ensure that the sock mesh fits the cable correctly

- Ensure that the cable fits up to the mid-point of the protective shoulder

- Clamp the ends of the cable sock when attaching the cable. Slingco recommend between 1.25” and 2.25” from the end of the sock – SECURE CLAMPING MUST BE USED ON SLINGCO SOCKS

- Never modify or attempt to repair any sock

- Ensure proper maintenance of the sock

- Check the condition of the sock, and that it is the correct size for the intended application – do not exceed the rated capacity

- Cable socks that are worn, bent, or otherwise damaged should not be used

- Cable socks are only to be used for temporary installations

- Pulling devices should only be attached via the pulling eye

- Cable socks must only be fitted and used by trained competent person(s)

➡ Slingco cable socks must not be used to their approximate breaking strength. A sensible Safety Factor must always be used. If in doubt contact the manufacturer or distributor that supplied sock.

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Thorne & Derrick distribute a complete range of Cable Pulling Products to support the safe installation of LV, MV & HV cables into underground ducts, conduits and trenches – this includes products to enable safe cable drum handling, lifting and support for cables operating at LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

We service the Power Transmission & Distribution industry in the wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

This includes standard Pulling, Laying & Stringing Products for underground cables, subsea umbilicals and overhead line conductors and also innovations such as Catchblock – a patented overhead line catenary roller system that guarantees that, if a conductor breaks during the stringing process, there will be no need to obtain road or rail possession. This also means reduced need for scaffolding, reduced risk of an accident and an overall more efficient operation.

➡ See Also Further Reading

- Cable Laying, Installation & Support Products | MV HV Windfarm

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

- NOF Members Thorne & Derrick and Slingco Ltd Supporting Cables in the Offshore Wind Industry

Earlier this year, Thorne & Derrick welcomed Phil Day from Slingco Limited, the world-leading manufacturer of cable pulling and support socks, swivels, cable protectors, wire rope assemblies and accessories. Phil provided an Offshore Wind focussed company presentation to our Sales Team (pictured left-to-right Sarah Henderson, Carl Cox, Jonathan Hewitt, Phil Day, Jeff Jhanke, Natalie Lundie and Chris Dodds.

Cable Rollers | Duct Rods | Cable Jacks | Cable Lubricant | Duct Seals | Cable Duct

VOLTS! ARCHIVE | Q1 2022

April 28th, 2022VOLTS is our monthly round-up of industry news, projects, videos, technical tips, training information, promotions, webinars and career opportunities from Thorne & Derrick. Take a moment to Follow Us on LinkedIn to receive future VOLTS.

See the archive below.

Cable Pulling Socks For Array, Export, Umbilical & Subsea Cable Installations

April 26th, 2022

Cable Pulling Socks

For Array, Export, Umbilical & Subsea Cable Installations

After 12 months of extensive research and development, Slingco are delighted to launch their new range of cable socks. Bringing you peace of mind with high-volume project capacity, quick availability, full testing details, and forty years experience.

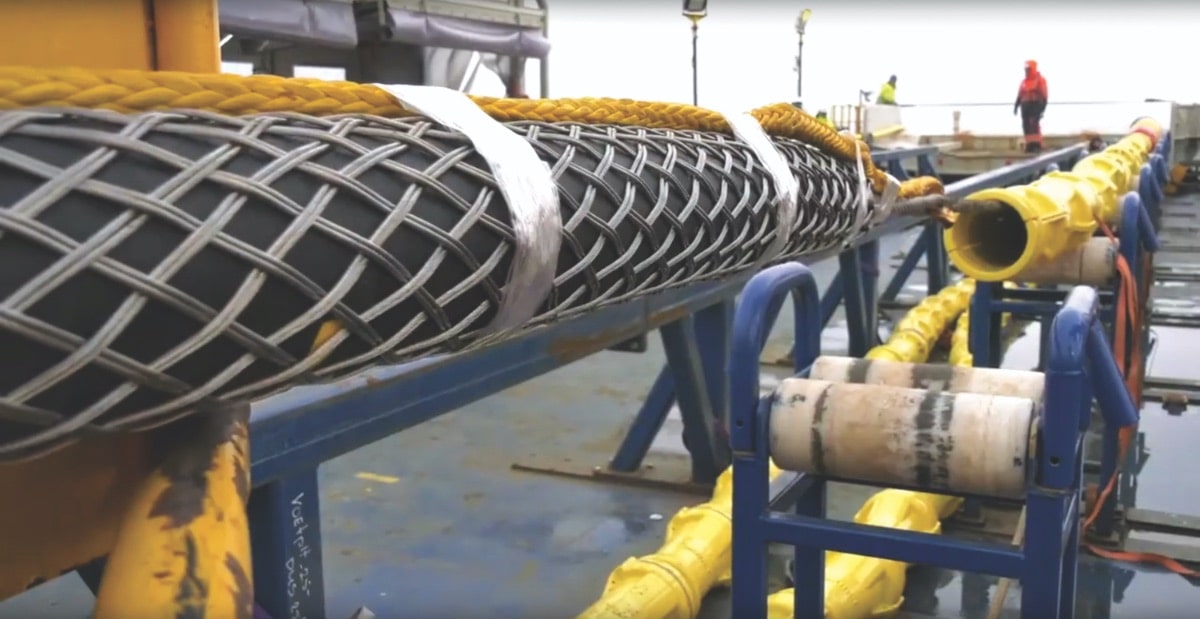

Slingco have developed these marine cable pulling socks for installation of inter-array and export cables for offshore wind farms. The new socks have expanded ranges to suit common cable sizes used in offshore applications and have increased break loads. All of the new socks have a new ‘two over / two under double weave’ on the lattice which tightens up the angle of deflection over the end of the cable.

Slingco offers an extensive range of marine and hose restraint cable socks for onshore and offshore cable installation, including the support of cables inside wind turbines and general cable management.

- Single Eye, Double Eye, Lace Up Cable Socks

- Max Break Load 10Te – 90Te+

- Galvanised, Stainless and Aramid Socks

- Complete range to suit Cable OD range 10mm-350mm+

- Test reports & certification

- Large project delivery

- Quick availability

- 40+ years’ experience

- Award winning company

Slingco also manufacture a speciality heavy duty cable socks, suitable for large underwater pulls. Galvanised steel construction for extremely heavy duty large diameter pulls. Single eye, double eye and lace up. Sizes range from 100mm (4″) to over 355mm (14″).

Marine cable socks are designed, manufactured and tested to exacting standards to ensure safe and reliable operation under the most challenging condition

Features Of New Slingco Marine Cable Socks

- Cable range of 90mm to 285mm

- Break load tested and independently witnessed at Lloyds Register

- Manufactured to high quality standards in the UK

- Length has now been standardised from 2.5m to 3.5m

- Loadings have increased by 30%

WHY SLINGCO FOR MARINE Cable PULLING SOCKS?

- Award winning UK manufacturing facility produces between 2,500 to 6,000 cable socks per month

- Options such as Thimble eye, Shoulders, and Anodes are now available on request (manufactured to order), as are stainless steel cable socks and aramid cable socks, both of which have better corrosion resistance for prolonged subsea lay down durations

- Range of non metallic socks made from high strength aramid fibre, with UV coating for fibre optic offshore applications

- We have an impeccable track record, with recent projects including: Kincardine, EastAnglia1 &2, Borssele 1 & 2, Hornsea 1 & 2, Akita, Triton Knoll, Hornsea 2, Moray East, St Nazaire, Dolwin 6, Ostwind 2

- Slingco are DEME & NKT approved supplier for Dogger Bank A & B, the world’s largest wind farm – array cable installation due to start this year

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Thorne & Derrick distribute a complete range of Cable Pulling Products to support the safe installation of LV, MV & HV cables into underground ducts, conduits and trenches – this includes products to enable safe cable drum handling, lifting and support for cables operating at LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

We service the Power Transmission & Distribution industry in the wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

This includes standard Pulling, Laying & Stringing Products for underground cables, subsea umbilicals and overhead line conductors and also innovations such as Catchblock – a patented overhead line catenary roller system that guarantees that, if a conductor breaks during the stringing process, there will be no need to obtain road or rail possession. This also means reduced need for scaffolding, reduced risk of an accident and an overall more efficient operation.

➡ See Also Further Reading

- Cable Laying, Installation & Support Products | MV HV Windfarm

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

- NOF Members Thorne & Derrick and Slingco Ltd Supporting Cables in the Offshore Wind Industry

Earlier this year, Thorne & Derrick welcomed Phil Day from Slingco Limited, the world-leading manufacturer of cable pulling and support socks, swivels, cable protectors, wire rope assemblies and accessories. Phil provided an Offshore Wind focussed company presentation to our Sales Team (pictured left-to-right Sarah Henderson, Carl Cox, Jonathan Hewitt, Phil Day, Jeff Jhanke, Natalie Lundie and Chris Dodds.

Cable Rollers | Duct Rods | Cable Jacks | Cable Lubricant | Duct Seals | Cable Duct

Hazardous Area Lighting Stock Investment by Thorne & Derrick

April 26th, 2022

Stocking Spartan

Customer service is the backbone of our business and it’s lifeblood is our ability to deliver correctly specified, competitively priced and certified products from stock.

To support increasing client demand we have now expanded and increased our stock levels of the SPARTAN range of Lighting for Hazardous Areas manufactured by Raytec – this enables us to satisfy emergency replacement, planned upgrade and project-scale orders from customers working in the explosive atmosphere industries.

We hold in stock an extensive range of standard and emergency light fittings certified according to ATEX to provide safe lighting in Zone 1/2 (Flammable Gas) and Zone 21/22 (Combustible Dust) explosive atmospheres.

Thorne & Derrick are your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas – this is underpinned by the day-to-day distribution of Equipment for Explosive Atmospheres to provide safe power, light, heat and ventilation.

We can specify and supply – our COMPEX Trained Sales Team are competent and conversant with ATEX Certification, DSEAR Compliance and the correct technical specification of products and equipment for installation in the hazardous area industries, from conventional oil/gas to biomass sectors.

Reducing Your Carbon Footprint By Several Sustainable Shoe Sizes

Businesses are proactively aligning their hazardous area lighting upgrade with sustainability strategies to reduce carbon emissions and support ambitious carbon neutrality targets agreed by the EU in 2019 – the upgrade and investment in LED lighting by businesses in pursuit of zero emissions status by 2050 has led to several multinational companies to accelerate the replacement of now retrograde fluorescent type lights with modern-technology light-emitting diode (LED) light fittings.

In the drive to go green the fading glow of traditional light fittings is fastly being replaced by the brilliant “White Light” illumination of energy efficient, modern technology light-emitting diode (LED) lighting systems.

Thorne & Derrick International, based in the UK, were voted Winners of the Award for ‘Best Customer Service’ at the annual HazardEx Gala Dinner on 6th October 2021. The competitive Award category at the prestigious event was for providing excellent customer service over the last two years.

Terry McDonald said, “It was an honour to collect the award for Excellence in Customer Service on behalf of Thorne & Derrick – we have a robust reputation for supporting our customers with the replacement and upgrade of end-of-life equipment to deliver significant operational safety and process improvements to their project or plant.

Lighting for Explosive Atmospheres

From stock, we can offer an extensive range of lighting products certified to provide safe and reliable light in explosive atmospheres, including Flammable Gas (Zone 1/2) and Vapour & Combustible Dust (Zone 21/22) according to ATEX UKEX Directive – this includes:

| SPARTAN Zone 1/21 Linear WL84 | ||

| SPX-WL84-T6 | SPARTAN Linear 2ft Light, T6, Zone 1/21, 2500lm | (2x18W / 2ft retrofit) |

| SPX-WL84-T6-EMX25 | SPARTAN Linear 2ft Light, T6, Zone 1/21, 2500lm- Emergency | (2x18W / 2ft retrofit) |

| SPARTAN Zone 2/22 Linear WL84 | ||

| SPZ-WL84 | SPARTAN Linear 2ft Light, Zone 2/22, 3400lm | (2x18W / 2ft retrofit) |

| SPZ-WL84-EMX25 | SPARTAN Linear 2ft Light, Zone 2/22, 3400lm- Emergency | (2x18W / 2ft retrofit) |

| SPARTAN Zone 1/21 Linear WL168 | ||

| SPX-WL168-T6 | SPARTAN Linear 4ft Light, T6, Zone 1/21, 5000lm | (2x36W / 4ft retrofit) |

| SPX-WL168-T6-EMX25 | SPARTAN Linear 4ft Light, T6, Zone 1/21, 5000lm- Emergency | (2x36W / 4ft retrofit) |

| SPARTAN Zone 2/22 Linear WL168 | ||

| SPZ-WL168 | SPARTAN Linear 4ft Light, Zone 2/22, 6800lm | (2x36W / 4ft retrofit) |

Thorne & Derrick

Specialist Electrical Distributors

Panels | Plugs | Isolators | Enclosures | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Fans | Security Locking & Access Control

April 2022 VOLTS!

April 22nd, 2022Welcome to our industry bulletin – VOLTS.

So what is VOLTS?

VOLTS is our monthly round-up of industry news, projects, videos, technical tips, training information, promotions, webinars and career opportunities from Thorne & Derrick. Take a moment to Follow Us on LinkedIn to receive future VOLTS.

pROJECTS & NEWS

Thorne & Derrick Secure New Renewable MV Cable Accessory Order

This month, Thorne & Derrick International were delighted to confirm receipt of a new purchase contract order for an offshore wind farm project – this is to supply 33kV Tee Connectors (Nexans Euromold) and Inline Cable Joints (3M ColdShrink) following several rounds of technical qualification, specification and commercial submissions.

Thorne & Derrick’s technical submission for the jointing of the 33kV cables was accepted by the Senior Lead Cable Specialist based upon their 3M QS2000 range – the cable joint designed utilises a unique Cold Shrink delivery system. The 3M Cold Shrink products are supplied pre-stretched on a removable core for efficiency and ease of installation by the jointer with an integral electrical field control device and faraday cage pre-installed in the insulation body to reduce complexity during the installation.

As Approved Vendors to Vattenfall, the Swedish multinational power company, Thorne & Derrick will be supplying a 33kV Inter-Array Cable Accessory Package including medium voltage joints, connectors and cable cleats to support the installation of 19/33 (36)kV Single Core Submarine Cable with 24 Fibres (IEC 60502-2). Read more here.

52kV Trackside Power

Pictured Termination: 3M 95EP-631-2 is a 52kV Single Core Outdoor Termination utilising QTIII Technology for 26/45(52) kV Cables. Here’s a pallet shot of a Network Rail project order we have shipped out from Thorne & Derrick in April. The 52kV Cable Terminations manufactured by 3M Electrical utilising their innovative Cold Shrink Technology are Network Rail (NR) certified and PADS Listed as meeting the requirements for installation on their electrical infrastructure.

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals.

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals.

From stock, we deliver HV Terminations to trackside or turbine – whatever the industry, wherever the cable.

Further Reading: Joints & Terminations for Network Rail High Voltage Electrification Projects | PADS Approved

Preserving The Heritage

A heritage studio revived for the 21st Century

We are currently working on an exciting project with a heritage film studio, that is undergoing work to expand. The studio plans to expand the complex with new studios and workshops to bring it into modern times and continue use.

Thorne & Derrick are working with the client to provide cable protection and ducting solutions to assist with the expansion project.

Cable protection covers and underground warning tapes are installed over LV, MV and HV power cables in trench and ducted cable installations with high visibility colour providing a visual warning of danger when excavating cables.

Read more about Cable Protection

Thorne & Derrick also stock and distribute a range of cable ducting solutions that are independently certified to British and European Standards and are used extensively for LV, MV & HV substation, highways, housing developments, commercial, retail and industrial infrastructure applications. ➡ View the complete range of Cable Ducts to provide underground cable protection of low, medium and high voltage power cables (LV MV HV) including 11kV and 33kV cable ducting.

Technical Tips

Thorne & Derrick are the Specialist Distributor & Stockist for Alroc in the UK for their ranges of manual and motorised Cable Preparation & Jointing Tools for the removal and stripping of outer cable sheath, semi-conductor screen and insulation from LV, MV, HV and EHV power cables.

The ORACL manufactured by Alroc and supplied by Thorne & Derrick enables the cable jointer or user to longitudinally score the peelable semiconductive layer from medium/high voltage cables (typically 33kV up to 1000sqmm) in order to peel it off carefully by hand – this is a key stage of MV HV cable preparation prior to the installation of Power Cable Accessories including joints, terminations and connectors.

The ORACL screen scoring tool covers most “easy-strip” peelable semicon thicknesses by having adjustable scoring depths of 0.4, 0.6, 0.9 & 1.1mm – contact us for prices, stock availability or further information.

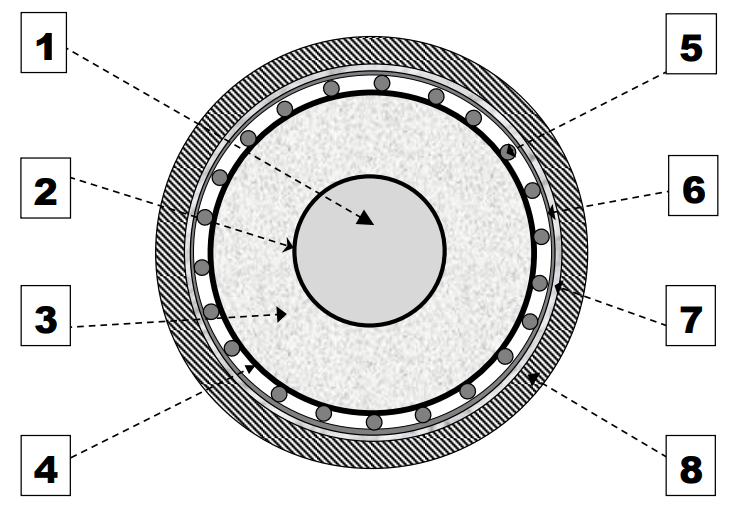

Anatomy of 33kV Cable

1 Aluminium Conductor with Water Blocking Protection | 2 Semiconducting Screen | 3 XLPE Insulation | 4 Semiconductng Screen | 5 Copper Wires Screen | 6 Copper Tape | 7 Water Blocking Tape | 8 PE Sheath

See Also from Alroc

- ALROC CWF3-60 – MV Peelable (Easy-Strip) Semicon Removal | Video

- ALROC CWB-18-60-MVS – MV Bonded Semicon Removal | Video

Stocked & Supplied by Thorne & Derrick

Featured Jointers

Read | Chris Barker |132kV Transition Cable Joint

Sector Spotlight

eXPLOSIVE aTMOSPHERES

Thorne & Derrick are Specialist Distributors to the Oil & Gas industry of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – since 1985 we have worked closely with EPC’S, E&P and related companies ensuring the highest levels of safety, reliability and maintainability of LV HV cable and power systems.

T&D hold the largest European stocks of 3M Hazardous Area Cable Accessories LV HV – this includes Cold Shrink and Scotchcast joints, terminations and abandonment kits for safe use in potentially explosive atmospheres up to 33kV.

Specialist Cable Joint & Repair Systems include submersible, hydrocarbon and fire resistant solutions for marine and offshore power, control and instrumentation cables.

We provide expert technical support and supply from a multi-million pound stock holding:

- Cable Joints, Terminations & Connectors

- Earthing & Lightning Protection

- Cable Accessories – Lugs & Glands

- Circuit Protection & Fuses

- Cable Cleats & Clamps

- Electrical Safety Equipment

- Cable Pulling & Laying Equipment

- Arc Flash Protection & Clothing

- Cable Duct Seals & Transit Systems

- Surge Arresters & Bushings

- Overhead Line & Substation Power Products

Selected Article | Repairing Damaged Cables, Cable Sheath & Jackets

Supporting Articles

- Submersible Cable Repair | Repair Damaged Offshore Firepump Cables

- Cable Repair Tape & Heat Shrink Sleeve From 3M Electrical For VFD Cables

- How To Abandon Cables Using 3M Cold Shrink Cable Abandonment Kits CSCAK

- 3M Cold Shrink Tubes For Electric Submersible Pump (ESP) Cable Repair

Shelf-to-Shelf

This April we shipped-out 50+ Resin-type low voltage power and instrumentation cable joints with hydrocarbon resistant Scotchcast resin suitable for installation in Zone 1/2 flammable gas atmospheres according to ATEX Directive – picked from the Bristol warehouse shelf destined overnight to the continental shelf of the North Sea.

If you need to joint, to terminate or to connect LV or HV cables, either onshore or offshore, whatever the cable, wherever the location: Thorne & Derrick can help.

Scotchcast Stocks | Jointing Systems for all types of Industrial Cables

Industry event

Dogger Bank Wind Farm: Meet the Buyer event

Jonathan Hewitt, Key Account Sales Engineer at Thorne & Derrick, enjoyed attending the Dogger Bank Wind Farm ‘Meet the Buyer Event’ organised by NOF. The event included presentations by Dogger Bank, Port of Tyne and North Star Renewables. The networking lunch and one-to-one meetings created a great opportunity to meet project managers and stakeholders to learn more about opportunities within the project.

About the Event

Dogger Bank Wind Farm and its Tier 1 Contractors are committed to the development and growth of a competitive UK supply chain. The meet the buyer event was held to showcase contract opportunities during the operations of this flagship UK development.

More about Dogger Bank

The Dogger Bank O&M Base is being constructed at the Port of Tyne and is due to be completed in Q4 2022. The project is the UK’s first HVDC connected wind farm and will feature the world’s first unmanned HVDC offshore platforms. North Star Renewables has been contracted to provide four Service Operation Vessels to the project. One rotation of GE’s Haliade-X turbine can power a UK household for two days. 277 units of the 13MW and 14MW turbines will be used on Dogger Bank.

Dogger Bank is a joint venture between SSE Renewables (40%), Equinor (40%) and Eni (20%).

Jonny Hewitt from Thorne & Derrick with Noman Shabir from Ellis Patents at the Dogger Bank – Meet The Buyer Event.

Top of The Posts

Prize Draw!

This month we are hosting a prize draw to win a PFISTERER special edition Centenary Book. We are delighted to celebrate 100 years of PFISTERER with the history of their role in the energy industry, dating back to 1921. Connecting power for the future.

Enter the prize draw here

PFISTERER meets future challenges with the knowledge that comes from one hundred years of experience. This expertise has developed continuously with advances in technology. Numerous innovations and patents continuously drive our growth with further investment in R&D planned for 2022 and beyond. Read more about our established relationship: Thorne & Derrick | Product Training With PFISTERER

Jobs

Meet Mane

Mane Contract Services are committed to working with their client partners to help create a greener and cleaner future. For over 20 years, they have provided project staffing solutions to the complete project lifecycle across all Energy sources. Mane have an extensive project and client portfolio across both cable manufacturing & installation, working across UK, EMEA, APAC and USA.

Stephen Stuart and his team at Mane and they are looking to expand their network within the Wind Energy Industry;

– HV Engineering & Installation – 33kV, 132kV, 155kV, 220kV, 400kV

– Commissioning Engineering / Commissioning Management

– Installation Management & Package Management

– Grid Connection and Cable Installation

– Project Management / Construction Management

– Client Representation

– Site Management & Support

– Document Control & Management

– Project Planning / Scheduling– Project Controls Management

– Health & Safety Management

If you are recruiting for yourself or looking for a new career move within the Renewables sector then please get in touch +44 (0) 1923 470 724 or email: [email protected]

For more information – visit their jobs page; https://www.mane.co.uk/energy/

With a network of international offices around the world and a large dedicated team of specialist Account Managers and Head Hunters, Mane are well placed to support your career development or recruitment requirements around the globe.

VOLTS! By,

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes Joints, Terminations & Connectors to enable the installation of low, medium and high voltage power cables into underground trench or duct.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Main UK Stockists for: 3M Electrical, PFISTERER Connex, Nexans Power Cable Accessories (Euromold), Alroc, Ellis Patents, ABB, Roxtec, Cembre & CATU Electrical.