Blog

Correct Installation of Hawke Cable Glands

May 16th, 2025

Thorne & Derrick | Distributed from Stock | Approved Supplier | UK & Export Sales

Hawke Cable Glands Installation

Installing Hawke cable glands correctly is essential to ensure the integrity, safety, and performance and cable termination of your LV MV HV electrical systems—especially in hazardous environments like oil & gas, petrochemical and industrial sectors.

In this guide, we’ll walk you through the correct method for installing Hawke cable glands, share common mistakes to avoid, and explain why proper installation matters.

Step-by-Step: How to Install Hawke Cable Glands Correctly

1. Select the Right Cable Gland

Identify the cable type and choose the correct Hawke gland suited to both your cable and application. For example:

-

501/453/Universal – for unarmoured cable

-

501/453/RAC – for armoured cable

Confirm compatibility with:

-

Cable diameter

-

Armour type (SWA, braid, tape, etc.)

-

Zone rating (Zone 1, Zone 2)

2. Prepare the Cable

-

Strip the cable sheath as specified

-

Ensure no damage to internal conductors or armour

-

Trim and shape armour to fit cleanly inside the gland

3. Assemble the Hawke Cable Gland

Follow Hawke’s installation sequence precisely. Key components include:

-

Entry item

-

Inner and outer seals

-

Armour cone and clamping ring (for armoured cables)

-

Compression nut

Install in the correct order and apply any IP sealing washers where required.

4. Tighten & Secure

Use two spanners:

-

One to hold the gland body

-

One to tighten the compression nut to the recommended torque

This ensures:

-

Proper grip on the cable

-

Correct compression of sealing elements

-

Safe electrical continuity and strain relief

The cable gland is permanently marked with various lines/numbers indicating the correct tightening level related to the cable diameter. Following the relevant cable gland Installation Instructions, the back seal should be tightened until a seal is formed on the cable outer sheath and then tightened one further turn

5. Final Cable Gland Checks

-

Confirm ingress protection (IP rating)

-

Check earth continuity for armoured installations

-

Inspect for visible damage or loose components

Common Installation Mistakes to Avoid

-

❌ Using the wrong gland type for the cable

-

❌ Over-tightening or under-tightening

-

❌ Incorrect sequence of gland components

-

❌ Poor cable preparation or incorrect stripping of cable

-

❌ Forgetting to earth the armour

What Makes Hawke Glands Different?

Hawke’s range of cable glands are globally recognised for their robust construction, Ex-rated safety, and easy-to-install designs.

Whether it’s Ex d (flameproof), Ex e (increased safety), or Ex nR (restricted breathing), Hawke has a solution that safeguards your installation integrity—whatever the environment.

Need Support Choosing the Correct Cable Gland?

At Thorne & Derrick, we help you get it right the first time. As trusted Stockists & Distributors of Hawke cable glands, we provide:

-

Technical support

-

Product selection advice

-

Same-day dispatch for stocked cable gland items

Contact our team today or explore our full range of Hawke cable glands.

Interface F Bushings & High Voltage Power Cable Connectors

April 23rd, 2025Author | Rialdo Suwandi

Founder at Aldora Electric | Expert in Renewable Electrical Engineering & Cable Systems | Problem Solver | FIEAust CPEng NER

HV Bushings & Connectors

What Are Interface F Bushings?

How Do To Select the Right Cable Connector?

As medium voltage (MV) power systems grow in scale and capacity, manufacturers have introduced electrical equipment, such as transformers and switchgear, capable of handling up to 1250A at 52kV and 2500A at 36kV.

To ensure interoperability across manufacturers, these Interfaces are standardised under EN 50180 and EN 50181 as Interface F Bushings.

Furthermore, EN 50673 standardises 630A and 1250A bushings at 72.5kV.

What Are Interface F Bushings Used For?

Interface F bushings are typically used to connect gas-insulated switchgear (GIS) and transformers to cable circuits using separable connectors distributing electrical power at 11kV, 33kV and up to 66kV – manufactured by Nexans Euromold the connectors are suitable for cable termination of polymeric (XLPE EPR) insulated cables with copper wire or copper tape screen, wire armoured (SWA/AWA), wire braided or unarmoured cables into MV-HV Electrical Equipment with Interface F bushings.

Advantages of Electrical Equipment Bushings

- Compact switchgear and transformer designs

- Interoperability across different manufacturers

Types of Interface F Bushings

As defined in EN 50180 and EN 50181:

F1 Bushings: Um ≤ 36 kV; Ir = 2500 A

F2 Bushings: Um ≤ 52 kV; Ir = 630 A

F3 Bushings: Um ≤ 52 kV; Ir = 1250 A

For 72.5kV high voltage power systems, EN 50673 defines the following:

F4 Bushings: Um = 72.5 kV; Ir = 630 A

F5 Bushings: Um = 72.5 kV; Ir = 1250 A

Note: F5 interfaces are commonly used in offshore wind applications but can adopted for large onshore installations as well.

Pictured | Nexans Q900AR-1Q900AR-2 Interface F Equipment Bushing 52kV MV HV

How to Select the Right High Voltage Separable Connector for Interface F Bushings

To ensure proper fit and reliable performance the following information must be established:

Interface type? e.g. F1

Maximum system voltage? e.g. Um = 36kV

Cable insulation type? e.g. XLPE

Conductor material and cross-section? e.g. copper, 800sqmm

Insulation over-diameter? e.g. 52.8mm

Number of circuits per phase? e.g. 2 circuits

Are surge arresters required? Confirm via an insulation coordination study

Interface F bushings enable safe, standardised, and high-capacity MV cable connections to GIS, and transformers, both for on-shore and off-shore applications.

Selecting the correct separable connector Interface F Connector —matched to interface type, voltage, current, cable type, and system design—ensures long-term reliability, safety, and maintainability.

Definitions of International Electrical Standards

EN 50180 | This European Standard is applicable to ceramic and resin insulated bushings having highest voltages above 1kV up to 52kV, rated currents from 250A up to 3150 A and frequencies from 15 Hz up to 60 Hz for insulating liquid filled transformers. This European Standard establishes essential dimensions, to ensure interchangeability of bushings and to ensure adequate mounting and interchangeability of mating plug-in separable connectors of equivalent ratings.

EN 50181 | This European Standard is applicable to insulated bushings for maximum voltages above 1kV up to 52kV, rated currents from 250A up to 2 500A and frequencies from 15 Hz up to 60 Hz for equipment other than liquid filled transformers. This European Standard establishes essential dimensions, to ensure adequate mounting and interchangeability of mating plug-in separable connectors of equivalent ratings.

EN 50673 | Extend the scope of the EN50180-1/2/3 and EN50181 for plug-in type bushings up to 72.5 kV

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX and Shrink Polymer Systems.

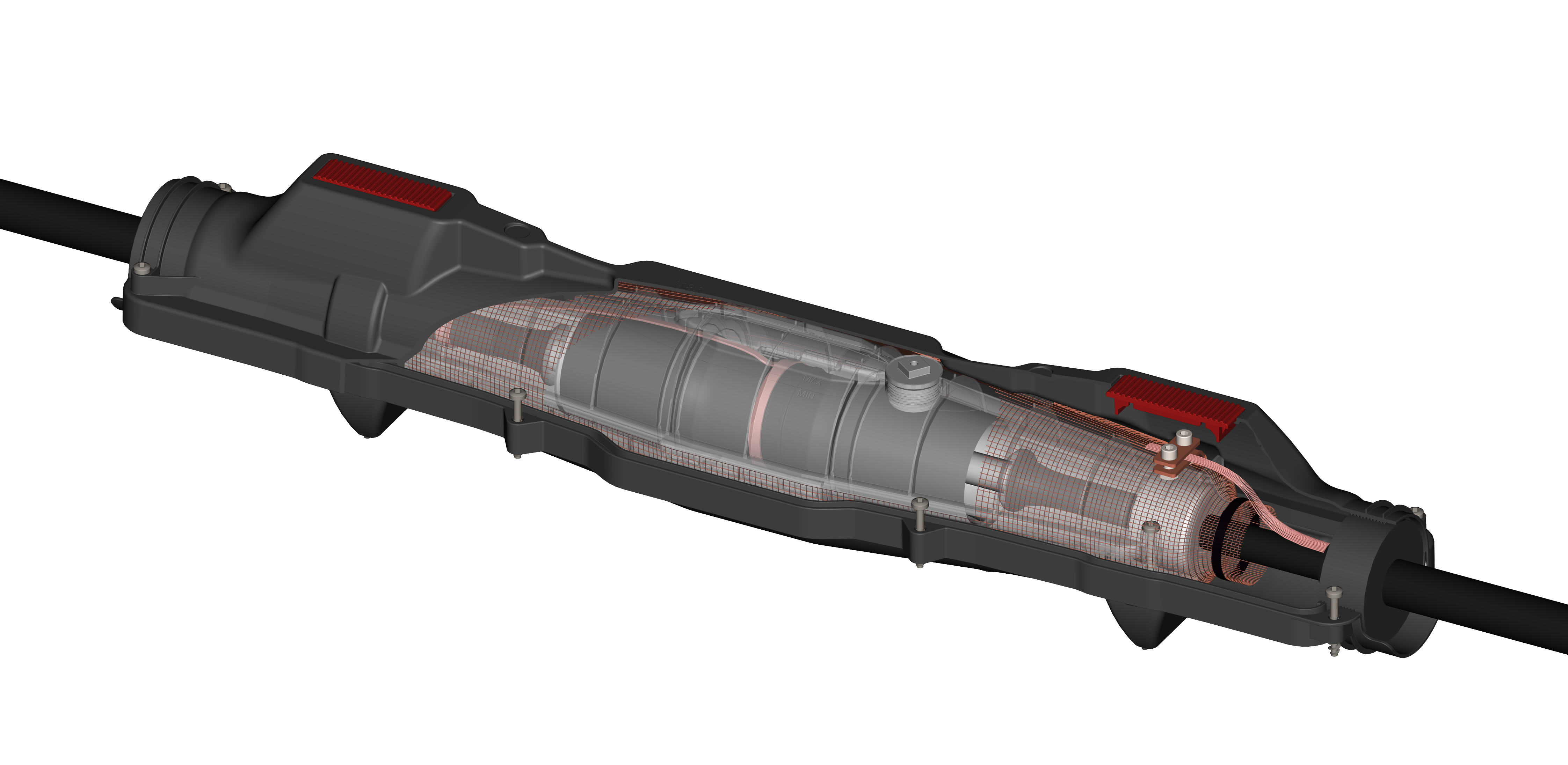

Lovink Cable Joints & Network Resilience at 11kV & 33kV

April 23rd, 2025Cable Jointing Solutions

Network resilience requires advanced technology solutions manufactured from highest performance materials; if high harmonics, Sine wave distortion, AD8 protection, abnormal thermal cycling, high-water table, ALE of legacy PILC or general cable failure prevention to critical 11/33kV circuits matters to you, then talk to us.

Where cables undergo dynamic cyclical load in high harmonic and non-linear load applications the Lovink range of cable joints demonstrate years of fault-free field performance in high temperature installations – additionally, the cable joints are “flame-free” and therefore safe for installation in potentially explosive atmospheres as no heating source or naked flame is required for the installation.

Resin encapsulation provides the highest levels of mechanical impact protection and electrical insulation eliminating voids, discharges and ionisation within the cable joint – the seawater resistant resin and “wet area” (2 bar at 20m water head) performance counters premature electrical cable joint failures in the renewable sector where damp soil conditions, flooded duct and water immersion can induce premature service failure to jointing solutions utilising other technologies.

The compact design permits reduced size joint holes reducing excavation and associated civil engineering preparation costs – ideal for confined space applications where volume displacement is a factor and close quarter working necessitates a compact profile solution.

Thank you to Stephen Davies (Lovink Enertech Account Manager) for todays emphatic Presentation and roundtable with our incredible Team.

Lovink Cable Joints

For straight, transition and branch connections of MV Power Cables – this includes 11kV and 33kV paper-insulated (PILC/PICAS) and polymeric (XLPE/EPR) cables up to 1000sqmm.

Lovink Cable Joints

CSD Sealing Systems for Critical Fire Protection of Substations

April 23rd, 2025From CSD Sealing Systems

The recent fire at the electrical substation next to Heathrow Airport, which led to its temporary closure and disrupted thousands of flights reminds the industry of the importance of critical fire protection measures in substation environments.

Thorne & Derrick are Approved Main UK Distributors for CSD Sealing Systems, specialising in advanced cable duct sealing solutions designed to enhance the safety and resilience of electrical substations.

The CSD Sealing Systems range of products, including the NOFIRNO range are engineered to prevent the spread of fire, smoke, and water, thereby safeguarding essential infrastructure and minimising the risk of catastrophic failures.

By integrating CSD’s pipe and duct sealing technologies, substation operators can significantly reduce the potential for fire-related disruptions, ensuring continuous operation and protecting both assets and the public.

Critical Fire Protection of Substations

Understanding The Critical Role Of Cable Cleats in Data Centres

March 31st, 2025

Do You Need Cable Cleats in Data Centres?

In an increasingly digital world, Cable Cleats in Data Centres are crucial in support of the backbone of global connectivity. Every click, transaction, and streamed video relies on complex Data Centre infrastructures operating seamlessly. As the demand for high-speed data and reliable uptime continues to grow, so too does the need for robust electrical infrastructure. Among the often-overlooked yet crucial components of Data Centre design is cable management – ensuring that LV MV HV Power Cables and data cables are installed, protected, and maintained to the highest standards.

What is a Cable Cleat?

Cable Cleats are devices used to secure, fix, strap and support electrical power cables in an installation, ensuring safe operation and prevention of damage or injury, specifically in the event of a short circuit. Cable Cleats in Data Centres are ultimately purposed to increase/enhanced safety, organisation, cable protection, containment and ensure optimal performance. Typically, Cable Cleats are designed to be attached to various surfaces, such as ladders, trays, struts, rails, or beams.

LV MV HV Power Cable Management in Data Centres

Modern data centres are high-density environments where vast amounts of power are distributed through extensive cabling systems. These installations face several key challenges:

- High Power Demand: Data Centres require vast amounts of electrical power, leading to high-capacity cabling systems that must be properly supported and secured.

- Thermal Management: Poor cable management with no Cable Cleat usage can obstruct airflow, leading to overheating and reduced efficiency.

- Fire Safety: Electrical faults, if not properly contained, can pose a serious risk to critical infrastructure and personnel. Regulations require secure cable installation to prevent short circuits and mitigate fire hazards.

- Maintenance and Upgrades: Well-organised cabling simplifies maintenance and reduces downtime as data centres are continually evolving.

Cable Cleats Critical Role in Ensuring Safety and Performance

Cable Cleats, Clamps & Hangers play a fundamental role in securing electrical power cables, particularly in high-voltage environments. While they may be a small component of the overall electrical system, their importance cannot be overstated. Cable Cleats in Data Centres provide vital protection by:

- Protection during Short Circuits and Electrical Failures: In the event of a fault, the forces generated by high-powered electrical cables can be immense. Without proper restraint, power cables can move violently, leading to catastrophic failures. Cable Cleats hold cables in place, mitigating these risks.

- Ensuring Compliance with Industry Standards: International regulations, such as IEC 61914 Power Cable Standards, set stringent requirements for cable fixing and restraint systems. High-quality cable cleats ensure compliance with these safety standards.

- Aiding Thermal Management: Securely spaced cables allow for improved airflow and more efficient heat dissipation, contributing to the overall energy efficiency of a Data Centre.

- Enhancing Longevity and Reliability: Properly restrained cables experience less wear and tear over time, reducing the likelihood of maintenance issues and unplanned outages.

How Do You Choose the Right Cable Cleats for Data Centres?

Not all Cable Cleats are created equal, and selecting the right product for a Data Centre environment requires careful consideration to provide optimal LV MV HV power cable support. Key factors include:

- Performance Under Fault Conditions: Cleats must be tested under high short-circuit conditions to ensure they provide adequate restraint in the event of a fault.

- Material Selection: Corrosion-resistant materials such as stainless steel or high-strength polymers are ideal for ensuring longevity.

- Installation Flexibility: Data centres often require custom cable arrangements, so cleats should allow for easy installation and adaptability to different configurations.

Cable Cleats, Clamps & Hangers

Cable Cleats in Data Centres aren’t necessarily the most visible component. However, Cable Cleats, Clamps & Hangers play an indispensable role in securing the power supply that keeps the digital world running from Data Centres. A well-designed support system incorporating compatible Cable Cleats protects infrastructure while contributing to operational efficiency and regulatory compliance.

Cable Clamps | Single & 2 Hole Clamps | Aluminium & Plastic | No-Bolts Cleats Stackable & Boltless LU Approved

Thorne & Derrick are stockists and suppliers of a complete range of Cable Cleats used to clamp and retain low, medium and high voltage cables in the event of a short circuit, including 11kV/33kV MV HV power cables – single-way cable cleats, trefoil cable cleats, quadrofoil cable cleats, emperor cable cleats and multiple bundled cable configurations can be cleated using Ellis Patents and Prysmian manufactured Cable Cleats in a choice of materials including nylon, stainless steel and aluminium.