Blog

A Model For Cable Containment

July 6th, 2021

Cable Support & Containment

-

Special thanks to Paul Darlington from Rail Engineer for kind permission to republish this article

MITA Powered by WIBE is a major multi-national company, operating in a wide range of sectors including Rail, Utility, Data-centre, Renewable, Oil & Gas and Process industries – the company’s extensive Cable Support range includes a market-leading range of GRP Elevated Cable Troughing & Accessories which are designed and manufactured in the UK.

GRP elevated cable troughing is an especially useful containment system for rail.

Ground Level Troughing (GLT) is used in signalling and telecoms schemes for the cable connections to lineside equipment such as points, train detection, signals and radio sites.

However, in many places, GLT cannot be used due to the ground profile and steep embankments and cuttings. GRP is an ideal alternative for such locations and it is also essential for large current-carrying power cables, such as medium voltage 25kV trackside power cables.

MITA WIBE is the leading “fit & forget” Cable Troughing & Management System manufactured in GRP with PADS Approval and specific material formula’s for trackside and tunnel applications on Network Rail infrastructure.

MITA are marker-leaders in the manufacture of GRP non-metallic troughing, GRP cable ladders, CABSYS cable trays, ducts, cable support channels and Fibastrut as the brand continues to lead the industry towards a sustainable future for a wide range of low (LV), medium (MV) and high voltage (HV) cable installation applications.

High quality manufacture

The MITA GRP is produced by pultrusion technology.

This uses a combination of unidirectional and cross-strand glass mat which is resin-impregnated and pulled through a hot die to produce a very solid, structurally sound profile with excellent mechanical rigidity.

Unlike some other troughing systems, MITA GRP does not contract or expand with heat causing the troughing route to distort. It is produced with a high quality of manufacture and modified by the use of additives to the resin, and with protection from ultra-violet light. The product is produced in either 3m or 6m lengths for easy transportation and installation.

MITA GRP is 70% lighter than steel and 90 times lighter than concrete; the cable trough is also corrosion resistant. It does not conduct heat and has excellent durability against adverse weather conditions. The rail cable management product offers excellent UV stability resulting in a cost-effective long-term solution.

The MITA GRP is provided in a wide range of trays, troughing and ladders which can support any type of cable – especially power and fibre cables which require a gentle bending radius. Unlike some competitors’ systems, MITA TM elevated troughing is provided with GRP support posts to increase its durability.

The troughing lids clip securely in place, providing cable theft protection. Further security can easily be added by installing stainless steel bands around the elevated route.

MitaTM GRP troughing in use on the East Coast Main Line

Network Rail approval

The MITA GRP elevated cable route has been fully approved by Network Rail under Certificate of Acceptance PA05/00442 issued in 2015 for use in locations unsuited to GLT. The Zero Halogen Low Smoke (ZHLS) version has also been approved for use in sub-surface stations and connecting tunnels.

Furthermore, the approval applies to a very impressive 42-page list of accessories, including bends, brackets, risers and transition/reducer pieces. Allowing connections to existing GLT cable routes, reducers are important and not always available in other cable containment systems.

London Underground has successfully used MITA GRP troughing. They were concerned that their sensitive signalling equipment was susceptible to contact by flakes of galvanisation from steel support systems and that their DC traction cabling system might create eddy currents within troughing ladders and supports if they were metallic.

MITA GRP troughing was chosen as it is non-magnetic and has non-conductive properties. The ZHLS version is also a requirement for London Underground’s sub-surface locations.

The cable containment system is not just used in rail, but has also been successfully employed in a wide range of industries including data centres, power industries, manufacturing, water treatment, food production, industrial buildings and oil and gas.

Working with GRP

Another particularly useful feature of the MITA GRP system is its ability to be integrated with the Bentley Raceway and Cable Management Building Information Modelling (BIM) tool.

This provides a complete layout, routing and material estimating function in a single, integrated system. It can be applied from the initial concept design through to detailed design and construction.

A user can create an accurate 3D model of the cable troughing route, making it easy to ensure that adequate space and clearances are available in confined locations, and for the detailed design and material requirements to be quickly and easily produced.

MITA GRP is a non-hazardous, inert product – the cable support system is lightweight and can be manually handled without difficulty, unlike concrete. In contrast to steel, GRP does not have to be deburred or given edge treatment before fitting, saving time and further reducing labour costs. During installation, any cutting, drilling, bonding and jointing can be easily undertaken and will not give rise to a hazardous situation, with any dust kept to a minimum.

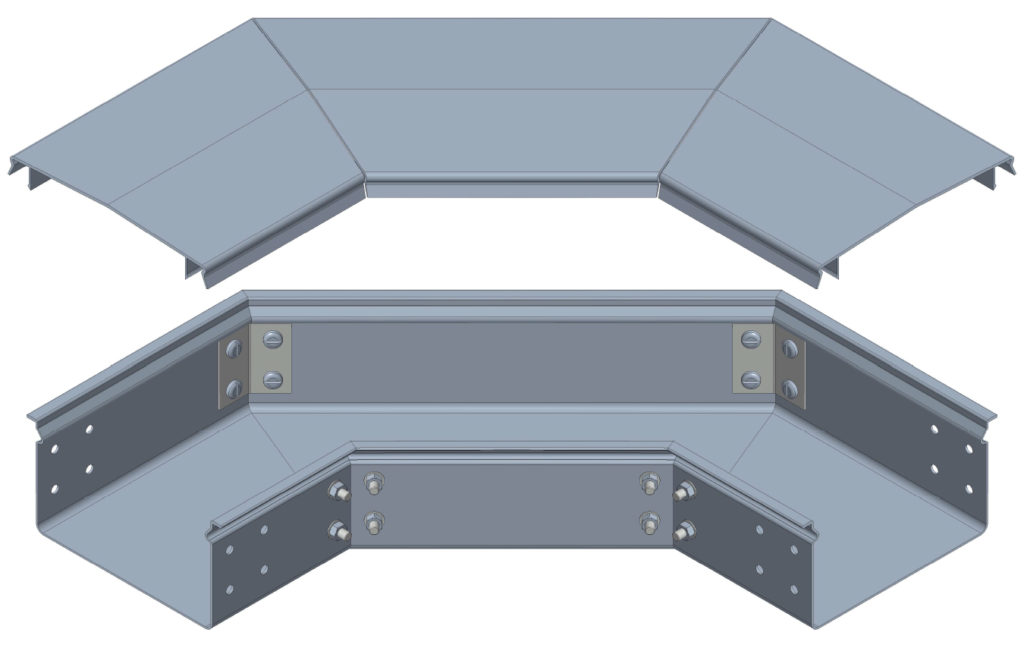

Sample Components of the MITA GRP Troughing System

Andrew Sillars, Contractor Specification Engineer, says: “Having supported the specification of Glass Reinforced Polymer cable containment since 2005, I have experienced its unique features such as light weight, long-life durability, no deburring, no earth bonding and many more. All these advantages of GRP Cable Containment support a cheaper, quicker and easier-to-install system that gives a true fit-and-forget solution.”

Original Source Rail Engineer Magazine article written by Paul Darlington

About Rail Engineer

Rail Engineer is the leading independent quality monthly magazine for engineers, project managers, directors and leading rail executive decision makers.

Besides publishing the latest up-to-date rail engineering news, our team of engineer writers report on the engineering and technical aspects of many of the major projects being undertaken day in, day out, above and below ground, and across the globe.

In the UK we work in close consultation with Network Rail, Docklands Light Railway and the Underground, where our team of rail engineers actively visit the project sites, meet project engineers and provide in-depth analysis on the engineering skills being used and the latest innovations.

From trams and fleet refurbishment to new rolling stock and high speed rail, the rail engineer reports on the engineering and environmental challenges for manufacturers and operators. Our engineers visit factories and depots, meeting with specialist engineers to bring you the latest engineering updates on all aspects of rolling stock, whether onboard technology or mechanical enhancements focussing on safety, energy and the passenger experience.

To Subscribe Click Here

RAIL ENGINEER MAY / JUNE 2021

View the latest edition below or click the following link where the original The Trackside Conduit Article can be found https://www.railengineer.co.uk/rail-engineer-may-june-2021-hs2s-largest-bridge-decarbonising-scotland-and-piccadilly-line-trains/

Thorne & Derrick are leading Specialist Distributors & Stockists of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment to the Rail industry.

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick stock and distribute an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Cable Joints, Terminations & Connections | Distributors & Stockists for 3M Cold Shrink | Nexans Euromold | Pfisterer CONNEX

ELLIS Solus Single Cable Clamps For Non Metallic Market

July 6th, 2021

Non Metallic Single Cable Clamps

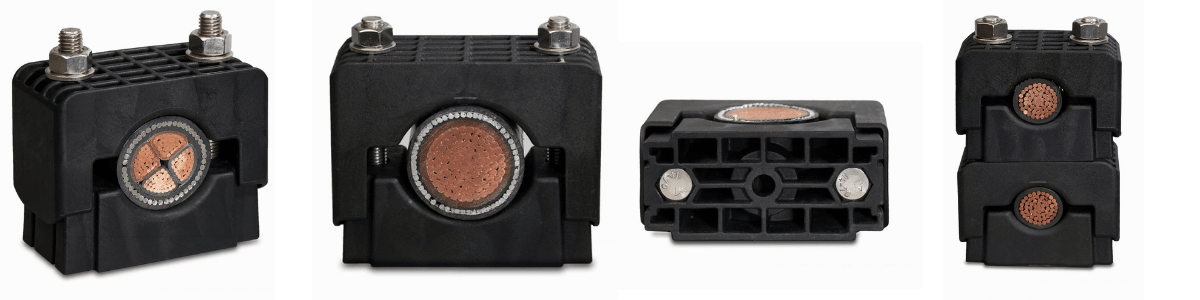

Ellis Solus Single Cable Clamps for Cleating Cables

Ellis Patents have boosted the strength of their cable clamps and cleats range with the launch of Solus single cable clamps. This range of non-metallic single cable clamps are suitable for cables from Ø25 to Ø75mm. Designed, developed and manufactured in-house by Ellis, Solus cable clamps are made from a high strength, glass-filled nylon and joins Trident – a trefoil clamp – as part of their expanding non-metallic product range.

Single Cable Clamps

Features

- Short circuit & mechanically tested in accordance with IEC61914

- Cleats manufactured from high grade heat stabilised polymer

- Suitable for indoor, outdoor and harsh environments

- Long design life

- Easily stacked cable clamps for multiple cables and circuits

- Large cable range (fewer clamps sized to stock)

Danny Macfarlane, Managing Director of Ellis Patents, said: “Non-metallic cable cleats have been very popular in mainland Europe for many years, and their use is now growing swiftly in the UK and many of the export markets we operate in around the world.”

“Their benefits are numerous but key is the fact that they have extremely long lifespans meaning the cleats can be used practically anywhere, including in extremely harsh environments.”

The reason for Solus’ extremely long lifespan is that the glass filled nylon material used is a high-grade engineering polymer. The new range of cable clamps is also fully stackable, meaning additions to cable runs can be made without having to disturb any cables already installed. Solus also features different mounting options that enhance its installation versatility; and because the product can accommodate a wide cable range, customers can stock small numbers of units to cover a wide range of cable sizes.

“Innovation is very much at the heart of everything we do, and Solus is the latest in a long line of new and improved cable management products to have come out the Ellis Patents Innovation Hub here in Rillington,” added Danny.

Key to Ellis’ ability to innovate is its ability to take products from initial ideas through to IEC61914:2015 compliant products; with its in-house Innovation Hub incorporating 3D printers, FEA analysis and a fully equipped testing laboratory.

Solus Single Cable Clamps

Specification

Ellis Solus Single Cable Clamps – Dimensions

| Ellis Solus Part Number | SL25-38GFN | SL36-52GFN | SL49-75GFN |

| Cable Range Min ∅ (mm) | 25 | 36 | 49 |

| Cable Range Max ∅ (mm) | 38 | 52 | 75 |

| Liner Size (mm) | 3 | 3 | 3 |

| Cable Range with Liner Min ∅ (mm) | 19 | 30 | 43 |

| Cable Range with Liner Max ∅ (mm) | 32 | 46 | 69 |

| Dimensions W (mm) | 100 | 116 | 138 |

| Dimensions H (mm) | 80 | 95 | 124 |

| Dimensions D (mm) | 60 | 77 | 77 |

| Dimensions A (mm) | 24 | 24 | 26 |

| Dimensions P (mm) | 60 | 75 | 95 |

| Dimensions ∅ | M12 | M12 | M12 |

| Weight (g) | 290 | 370 | 493 |

ELLIS Solus Cable Clamps

Further Reading

- IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

- Fire Resistance & Cable Cleats – Surviving Fire, Flame & Extreme Heat

- Triplex Cleats – Selection Guide for Cleating 11kV BS7870 Part 4.10 Cables

- Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

- Ellis Patents Cable Cleats & Cable Basket Tray for Securing High Fault Level Cables

- Stainless Steel Cable Cleats v Ties – The Myths Debunked By Ellis Patents

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Ellis Patents Vulcan, Atlas & Emperor Cable Cleats

Sealing Underground Cables & Pipes Under Constant Water Pressure

July 6th, 2021

Sealing Underground Cables & Pipes Under Constant Water Pressure

Cable Duct Seals

Do you want to prevent water ingress into building services or substation ducts?

Thorne & Derrick can specify and supply Roxtec duct seals to avoid the risk of costly downtime and power outages due to corrosion, damage to equipment or partial discharge. Roxtec UG (underground) solutions for cables and pipes protect your site against environmental ingress in both normal and flood conditions. The cable transit type seals withstand cable bending forces and are resistant to constant water pressure. Keep your equipment dry and safe by ensuring a long-lasting sealing barrier against flooding, gas, humidity and rodents.

User-friendly Flexibility

Roxtec UG™ seals are easy to install even in wet conditions and in environments with running water.

- Available for single or multiple cables and pipes

- Multidiameter™ by Roxtec – adapts to cable and pipe sizes through removable layers

- Built-in spare capacity for future needs

Retention Capabilities

The seals are tested and developed to provide excellent cable retention.

- Withstands pull force of up to 15 000 N and a weight load of up to 1 500 kg

- Withstands extreme cable bending

- Can expand up to 5 mm to aid installation and ensure a perfect fit

Tight and Resistant Cable Sealing

Roxtec UG™ solutions are IP 68 rated. They are tested for constant and catastrophic water pressure. Thanks to their high grade acid-proof stainless steel, they are suitable for the harshest of environments.

- Constant water pressure up to 0.3 bar (3mH2O)

- Catastrophic water pressure up to 1 bar (10mH2O)

- Gas pressure up to 0.3 bar

- Corrosion and rodent safe

Basic steps of a Roxtec knock-out sleeve installation

|

|

|

| Pour concrete into the mould | Knock out the lid | Insert the Roxtec cable seal |

Knock-out Sleeve Providing Spare Capacity

Use the Roxtec knock-out sleeve to block openings you might want to use later on. Plan your ducted openings, with the added benefit that any spare or unused duct is sealed without additional cost. You only need to buy seals for openings that accommodate cables.

This is an area efficient solution for reducing the footprint and for making sure the building is dry both during and after construction.

Think First

Include knock-out sleeves in the design work for a new building or kiosk. You decide if you want the seal on the inside or the outside and whether you want to connect sleeves into a cluster of openings. Then cast the sleeves into the structure, and knock them out when needed. Use sleeves to ensure consistent results in terms of position and formation of holes and avoid deformed ducts.

Basic steps of a Roxtec RS UG™ seal installation

|

|

|

| Make an aperture with a core drill | Insert pipe and RS UG halves | Tighten the seal |

Adaptable & Tailor-made Cable Duct Sealing Solutions

Roxtec UG™ solutions are perfect for use around existing cables and pipes, and the smart design simplifies retrofit. The seals fit into the knock-out sleeve as well as in conduits and core drilled holes.

The soft yet firm rubber adapts to uneven openings and ducts. Our openable seals do not suffer from failure in the same way as traditional methods do when the cables or pipes move and expand.

Customised Tools

If you have specific needs or face challenges that require special Roxtec UG™ seals, please contact our T&D and we will help you create tailor-made sealing solutions.

Sealing Underground Cables Application Areas

Roxtec UG™ seals are ideal for cables and pipes entering buildings via concrete foundations. They provide excellent cable retention, eliminate flooding and prevent humidity from damaging equipment. You can use them in vaults, duct banks or cable trenches.

Cable Types

- Power

- High Voltage Power

- Signalling

- Telecom

Pipe Types

- District heating

- District cooling

- Water

- Wastewater

- Plastic, steel and isolated pipes

|

|

|

|

| The Roxtec RS UG™ seal is designed for single cables and pipes entering buildings via foundations. | The Roxtec R UG™ transit is ideal for several cables of different sizes in one opening. It enables you to build in spare capacity. | Roxtec H3 UG™ seals are designed for cables in trefoil formations. The design simplifies retrofit installations. |

The Roxtec knock-out sleeve provides spare capacity and ensures tightness prior to cable routing. |

ROxtec

Thorne & Derrick are distributors for Roxtec, the leading manufacturer of sealing solutions for cables and pipes, to protect electricity Transmission & Distribution assets including substations against the potential catastrophic effects water, gas and fire.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

T&D Providers Of Jointer Training Courses By Pfisterer CONNEX & Nexans Euromold

Cable Drum Handling & Laying Cables | A Guide from Nexans

July 5th, 2021

Handling Cable Drums

Extract from Instructions for Transportation, Handling, Storage of the Drums & Laying of the Cables | Sept 2014

Cable Drum Handling

Deformation of Cable Sheath Jacket

When Handling Cables

The following information provides advice on the handling of cable drums published by Nexans – always consult with your client or local electric utility to ascertain local preferences and procedures for the Laying, Pulling & Handling of Cable Drums (LV – EHV).

- The cable must not be pulled with a tension above the maximum pulling tension

- The cable must not be subjected to a bend smaller than the minimum bending radius (given as the “minimum bending radius during installation” and not to be confused with the “minimum bending radius after installation”)

- The cable must not be subjected to lateral pressure that exceeds the sidewall bearing pressure

A combination or action of any of the above three items, even without exceeding any of the manufacturers recommendations, can result in the elongation of outer layer of the cable and form a “rucking” or “corrugation” of the cable sheath during installation. Deformation of the sheath during installation is known to occur when the sheath material is softened by elevated temperatures, such as the range of PVC sheathing materials, particularly when the cable is installed in warmer ambient temperatures (near and above 30°C).

Note that actual cable surface temperature can be higher than ambient temperature. It is also known to occur when the outer layer is thinner than a full sheath, such as may occur when installing a Nylon covered cable, which is covered by a thin Sacrificial Sheath.

Such deformation should be monitored to avoid an escalation to very severe puckering, which could induce the tearing of the sheath. Rucking, corrugation, and puckering can be reduced by the use of lubricating substances which will reduce the friction experienced at turns or bends on fixed deflectors and on rollers and even on long straight sections.

Note that longer runs and heavier cables will experience this deformation more often.

Corrective action includes the pausing of the installation pull and the easing of tension and pulling the affected cable length past the bend or roller or friction point that is causing the effect. Once the affected area is moved along, there is often a re‐settling of the elongated sheath and the effect is reduced. Stopping and allowing the cable to cool, will tend to set the corrugations in place and they will not easily be removed. Where this deformation takes place, there is a small reduction of the thickness where the material is stretched, but such deformation as a whole is considered to be of minor consequence. Usually, no repair or corrective action is required on the cable itself. Repair is only necessary when there is a breaking or tearing of the sheath – should you have any technical or commercial enquiries on the subject of Cable Drum Handling please do not hesitate to contact us.

➡ Download the Document | Instructions for Transportation, Handling, Storage of the Drums & Laying of the Cables | Sept 2014

Thorne & Derrick are Official & Approved GMP4 Contracted Distributors for Nexans Power Accessories (UK) Ltd.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Cable Drum Handling | Jack Towers for LV to EHV Power Cable Lifting & Site Handling

July 5th, 2021

Cable Drum Handling

Cable Jack Towers

Pictured: Despatched last week 5 sets of cable jack towers – the JT20 Cable Drum Jack Towers to support the safe on-site handling of LV-EHV cable drums at Western Power Distribution. Robust engineered construction with hydraulic jacks and adjustable height spindle support blocks.

Drum Lifting Jack Specification | JT20 20 Tonne Capacity SWL Per Pair, Minimum Drum Dia 1480mm, Maximum Drum Dia 3400mm, Base Area 1830x285mm, Weight Per Pair 370Kgs.

Thorne & Derrick | LV HV Cable Jointing & Electrical Equipment and SEB service the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors. For over a decade, we have provided competitive prices and technical support for the SEB range of exceptional quality, British manufactured Cable Pulling & Laying Equipment – this includes rollers, socks, jacks, winches and trailers to enable cables, umbilicals or pipes to be installed into ducts, trenches and tunnels up to 400kV.

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans