Cable Cleats

Ellis Patents Cable Cleats for Major Power Plant Project

May 27th, 2025

21.5.2025

HOLDING POWER by Ellis Patents | 30,000+ Vulcan Cleats and Flexistraps shipped out today under the blazing Yorkshire sun. The cable cleats will provide short-circuit restraint to both 11kV and 33kV Medium Voltage Cable Networks.

This WIN demonstrates the high-value of collaborative, proactive and strategized Manufacturer-Distributor relationships; we look forward to co-creating a Case Study to highlight how together we have worked to secure this achievement and satisfy clients specification and technical application requirements.

The consignment is now to be delivered to SEB International Ltd, the UK’s leading manufacturer of Cable Pulling & Laying Equipment, and consolidated for shipment with a CD500S Cable Drum Trailer (Payload 20,000kgs | Max Drum Width 2400mm), TW5000 Cable Pulling Winch and CP700 Cable Pushing Unit to power-up an accelerated cable laying process.

The £750K project value to Thorne & Derrick demonstrates our ability to manage and deliver upon UK and international major projects from our robust world-class supply-chain.

The High Voltage 132kV Cables will be connected to Grid using GIS Dry-Type Terminations from Nexans while all Medium Voltage 33/11kV switchgear and transformer Connectors are completed using market-leading Euromold and Connex brands from Nexans Power Accessories and Pfisterer.

All Cleats & Cable Accessories supplied by Thorne & Derrick – the purchase contract was managed by Gary Amos (Thorne & Derrick Sales Engineer).

Ellis Patents | HOLDING POWER

Pictured | Carl Cox (Thorne & Derrick Sales Engineer | Rail) with Noman Shabir (Ellis Patents National Sales Manager). The Ellis Patents ranges of PADS Approved Cable Cleats & Tunnel Hangers provide advanced material performance for substation, trackside and tunnel applications; this includes the short-circuit restraint and support of LV MV HV power cables. Please do not hesitate to contact Thorne & Derrick should you require further info, Lunch n Learn, CPD or Joint Visit to discuss your next cable cleat project requirements.

Ellis Patents Emperor Cable Cleats | Single & Trefoil | cable cleats designed, developed, tested and manufactured by Ellis from the Emperor range in accordance with IEC 61914 suitable for single, trefoil and Quad cable configurations

Ellis Patents Centaur Cable Saddles | the Ellis Centaur cable cleat has been designed, developed, tested and manufactured in accordance with IEC 61914 (Cable Cleats for Electrical Installations). The cable saddles are designed to support High Voltage Power Cables with diameters from 100mm to 162mm. Centaur consists of an extruded and pressed aluminium saddle and a hinged aluminium over strap.

Ellis Patents Aluminium Cable Cleats | the Ellis 2A two hole cable clamps have been designed, developed, tested and manufactured in accordance with IEC 61914 (Cable Cleats for Electrical Installations). The cable clamps are available in a range of sizes with range taking ability to suit single cables – the clamp can be epoxy coated for use in harsh environments, such as sea air conditions.

Ellis Patents Vulcan Cable Cleats | the Vulcan cleats are available in a range of sizes with range taking ability to suit single and trefoil cable formations (also available in Quad formation). The frame of the cleat is manufactured from corrosion-resistant 316L grade stainless steel, the cable is supported by a liner manufactured from a low smoke zero halogen (LSOH) material.

Ellis Patents Colossus Cable Cleats | The Colossus cleat is available in a range of sizes with range taking ability to suit LV MV HV cables in trefoil formation. The frame of the cleat is manufactured from grade 316L stainless steel, and the body of the cable cleat is manufactured from a low smoke and zero halogen (LSOH) material.

Ellis Patents Trident Cable Cleats | cable cleat is available in a range of sizes with range taking ability to suit LV MV HV cables in trefoil formation. The cleat is manufactured as standard in LSF which is PFAS and halogen free, flame retardant and suitable for outdoor applications.

Further Reading

- Ellis Patents Extend Vulcan+ Cable Cleat Range To Accommodate Smaller Cables

- Polymer Cable Cleats | Holding Power with Ellis Patents

- Cable Cleats | A Device For Short Circuit Protection | CPD Course By Ellis Patents

Understanding The Critical Role Of Cable Cleats in Data Centres

March 31st, 2025

Do You Need Cable Cleats in Data Centres?

In an increasingly digital world, Cable Cleats in Data Centres are crucial in support of the backbone of global connectivity. Every click, transaction, and streamed video relies on complex Data Centre infrastructures operating seamlessly. As the demand for high-speed data and reliable uptime continues to grow, so too does the need for robust electrical infrastructure. Among the often-overlooked yet crucial components of Data Centre design is cable management – ensuring that LV MV HV Power Cables and data cables are installed, protected, and maintained to the highest standards.

What is a Cable Cleat?

Cable Cleats are devices used to secure, fix, strap and support electrical power cables in an installation, ensuring safe operation and prevention of damage or injury, specifically in the event of a short circuit. Cable Cleats in Data Centres are ultimately purposed to increase/enhanced safety, organisation, cable protection, containment and ensure optimal performance. Typically, Cable Cleats are designed to be attached to various surfaces, such as ladders, trays, struts, rails, or beams.

LV MV HV Power Cable Management in Data Centres

Modern data centres are high-density environments where vast amounts of power are distributed through extensive cabling systems. These installations face several key challenges:

- High Power Demand: Data Centres require vast amounts of electrical power, leading to high-capacity cabling systems that must be properly supported and secured.

- Thermal Management: Poor cable management with no Cable Cleat usage can obstruct airflow, leading to overheating and reduced efficiency.

- Fire Safety: Electrical faults, if not properly contained, can pose a serious risk to critical infrastructure and personnel. Regulations require secure cable installation to prevent short circuits and mitigate fire hazards.

- Maintenance and Upgrades: Well-organised cabling simplifies maintenance and reduces downtime as data centres are continually evolving.

Cable Cleats Critical Role in Ensuring Safety and Performance

Cable Cleats, Clamps & Hangers play a fundamental role in securing electrical power cables, particularly in high-voltage environments. While they may be a small component of the overall electrical system, their importance cannot be overstated. Cable Cleats in Data Centres provide vital protection by:

- Protection during Short Circuits and Electrical Failures: In the event of a fault, the forces generated by high-powered electrical cables can be immense. Without proper restraint, power cables can move violently, leading to catastrophic failures. Cable Cleats hold cables in place, mitigating these risks.

- Ensuring Compliance with Industry Standards: International regulations, such as IEC 61914 Power Cable Standards, set stringent requirements for cable fixing and restraint systems. High-quality cable cleats ensure compliance with these safety standards.

- Aiding Thermal Management: Securely spaced cables allow for improved airflow and more efficient heat dissipation, contributing to the overall energy efficiency of a Data Centre.

- Enhancing Longevity and Reliability: Properly restrained cables experience less wear and tear over time, reducing the likelihood of maintenance issues and unplanned outages.

How Do You Choose the Right Cable Cleats for Data Centres?

Not all Cable Cleats are created equal, and selecting the right product for a Data Centre environment requires careful consideration to provide optimal LV MV HV power cable support. Key factors include:

- Performance Under Fault Conditions: Cleats must be tested under high short-circuit conditions to ensure they provide adequate restraint in the event of a fault.

- Material Selection: Corrosion-resistant materials such as stainless steel or high-strength polymers are ideal for ensuring longevity.

- Installation Flexibility: Data centres often require custom cable arrangements, so cleats should allow for easy installation and adaptability to different configurations.

Cable Cleats, Clamps & Hangers

Cable Cleats in Data Centres aren’t necessarily the most visible component. However, Cable Cleats, Clamps & Hangers play an indispensable role in securing the power supply that keeps the digital world running from Data Centres. A well-designed support system incorporating compatible Cable Cleats protects infrastructure while contributing to operational efficiency and regulatory compliance.

Cable Clamps | Single & 2 Hole Clamps | Aluminium & Plastic | No-Bolts Cleats Stackable & Boltless LU Approved

Thorne & Derrick are stockists and suppliers of a complete range of Cable Cleats used to clamp and retain low, medium and high voltage cables in the event of a short circuit, including 11kV/33kV MV HV power cables – single-way cable cleats, trefoil cable cleats, quadrofoil cable cleats, emperor cable cleats and multiple bundled cable configurations can be cleated using Ellis Patents and Prysmian manufactured Cable Cleats in a choice of materials including nylon, stainless steel and aluminium.

Cable Clamps: The BAND-IT BAND-FAST Range – IEC61914 Tested

December 2nd, 2024

Cable Clamps

-

uploaded by: Chris Dodds Thorne & Derrick Sales & Marketing Manager

Short Circuit Restraint for Power Cables

BAND-FAST is a versatile Cable Clamping System for harsh, hazardous and high-performance industrial cable support applications – the cost-saving cable banding solution comprises stainless steel pre-cut banding with pre-assembled buckle.

This IEC61914 compliant cable management system provides installers with significant labour productivity gains of up to 30% and up to 75% material cost savings compared to cable cleats for the short-circuit retention and support of power cables.

Two options are available: a PPA Coated version and an Uncoated version with captive clip both manufactured from type 316 stainless steel – high strength, compact flat profile, space and weight saving, non-corrosive and fire resistant.

The cable clamps have successfully been utilised on the following applications:

- Onshore & Offshore Windfarms (including Converter Stations

- Solar Farms

- Data Centres

- Offshore Platforms / FPSO’s

- Shipbuilding & Marine

- Refineries / Petrochem

- Public Buildings

Specialist Subsea Cable & Pipeline Applications

BAND-FAST cable clamps are also available in highly corrosion resistance materials including: Monel®, Alloy 625, Zeron100 and 316 Stainless Steel for the attachment of polyurethane mouldings, saddles, protectors and piggy-back clamps in subsea energy projects.

BAND-FAST cable clamps

Advantages

- Purchase price is significantly lower

–Up to 75% material cost savings

- Installation time is dramatically reduced

–Reduce labour cost up to 50%

- Low smooth profile

–Space savings on construction

- More versatile

–Conforms to most shapes / cable configurations

- Large diameter reduction (one size fits all)

–Fewer SKU’s to order / stock

- No accessories required

–No nuts / bolts / packing blocks

- Lighter weight cable clamps

–Reduced weight on construction

–Easier to carry around site

–Safer during installation at height

Cable Cleat Standard IEC61914

The cable clamps are independently tested to the latest Cable Cleat Standard IEC61914 for resistance to electromechanical force.

Short Circuit Testing of BAND-FAST Clamps

Subjected to 2x Short Circuits and dielectric test after wetting

PPA Coated BAND-FAST Cable Clamps By BAND-IT

Tests conducted to IEC61914

“Tests for Resistance to Electromechanical Force” Section 6.4.3 and 6.4.4.

➡ The following tables enables the selection of the correct BAND-FAST cable clamp manufactured by BAND-IT based on 300mm spacing between clamps according to IEC61914. Request Test Data for 600mm spacing of BAND-FAST clamps.

| BAND-IT Part Number | Width | Band Ref/Material | Length (mm) | Clip/Ref Material | Single Wrap or Double Wrap | *Max Cable OD (Single cable config) | *Max Cable OD (Trefoil cable config) | *Max Cable OD (Quadrafoil cable config) | Pack qty Piece | Weight Per Piece (kg) | **Pass IEC61914 Short circuit test in trefoil up to (KA PEAK) |

| LFAC-F1015M030–A900 | 15.88mm (5/8”) | AE435 316 SS |

300 | AE455 316 SS |

Single | 40mm | 13mm | 12mm | 100 | 0.025 | 50.8kA |

| LFAC-F1015M040–A900 | 400 | 75mm | 28mm | 25mm | 100 | 0.030 | |||||

| LFAC-F1015M050–A900 | 500 | 100mm | 43mm | 37mm | 100 | 0.038 | |||||

| LFAC-F1015M060–A900 | 600 | 130mm | 57mm | 50mm | 100 | 0.045 | |||||

| LFAC-F1015M070–A900 | 700 | 160mm | 70mm | 60mm | 100 | 0.052 | |||||

| LFFC-F1015M040–A900 | 400 | LE155 316 SS |

1Double | 40mm | 13mm | 12mm | 100 | 0.030 | 76.3kA | ||

| LFFC-F1015M050–A900 | 500 | 55mm | 21mm | 18mm | 100 | 0.038 | |||||

| LFFC-F1015M060–A900 | 600 | 70mm | 28mm | 25mm | 100 | 0.045 | |||||

| LFFC-F1015M070–A900 | 700 | 85mm | 35mm | 31mm | 100 | 0.052 | |||||

| LFFC-F1015M080–A900 | 800 | 100mm | 42mm | 37mm | 100 | 0.060 | |||||

| LFFC-F1015M100–A900 | 1000 | 130mm | 57mm | 50mm | 100 | 0.075 | |||||

| LFFC-F1015M120–A900 | 1200 | 160mm | 70mm | 60mm | 100 | 0.090 | |||||

| Ref C075 Bantam Tool for application of all PPA Coated BAND-FAST® Clamps | 1.040 | ||||||||||

Uncoated BAND-FAST Cable Clamps installed with additional cushion sleeve

| BAND-IT Part Number | Width | Band Ref/Material | Length (mm) | Clip/Ref Material | Single Wrap or Double Wrap | *Max Cable OD (Single cable config) | *Max Cable OD (Trefoil cable config) | *Max Cable OD (Quadrafoil cable config) | Pack qty Piece | Weight Per Piece (kg) | **Pass IEC61914 Short circuit test in trefoil up to (KA PEAK) |

| LFEC-F1030M050 | 15.88mm (5/8”) | C405 316 SS |

500 | C455 316 SS |

Double | 55mm | 21mm | 18mm | 100 | 0.062 | 112kA |

| LFEC-F1030M060 | 600 | 70mm | 28mm | 25mm | 100 | 0.070 | |||||

| LFEC-F1030M070 | 700 | 85mm | 35mm | 31mm | 100 | 0.078 | |||||

| LFEC-F1030M080 | 800 | 100mm | 42mm | 37mm | 100 | 0.086 | |||||

| LFEC-F1030M100 | 1000 | 130mm | 57mm | 50mm | 100 | 0.103 | |||||

| LFEC-F1030M120 | 1200 | 160mm | 70mm | 60mm | 100 | 0.120 | |||||

| LFEC-F1230M050 | 19.1mm (3/4″) | C406 316 SS |

500 | C456 316 SS |

Double | 55mm | 21mm | 18mm | 100 | 0.078 | 120kA |

| LFEC-F1230M060 | 600 | 70mm | 28mm | 25mm | 100 | 0.088 | |||||

| LFEC-F1230M070 | 700 | 85mm | 35mm | 31mm | 100 | 0.098 | |||||

| LFEC-F1230M080 | 800 | 100mm | 42mm | 37mm | 100 | 0.108 | |||||

| LFEC-F1230M100 | 1000 | 130mm | 57mm | 50mm | 100 | 0.128 | |||||

| LFEC-F1230M120 | 1200 | 160mm | 70mm | 60mm | 100 | 0.150 | |||||

| Ref C001 Band-It® Tool for application of all Uncoated BAND-FAST® Clamps | 2.000 | ||||||||||

*Note: Maximum cable OD are for a guide only.

Short Circuit Test Videos

PPA Coated BAND-FAST® Cable Clamps with Clip. Test Video #33 70.1kA (2nd Shock – 600mm Spacings).

Thorne & Derrick are Specialist Distributors to international Utilities, UK DNO’s, ICP’s and HV Jointing Contractors of an extensive range of LV HV Cable Jointing, Substation, Tooling & Installation Equipment from 600V to 66kV – we service wind energy, solar power, battery storage, rail, utility, datacentre and the explosive atmosphere industries.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Ellis Patents Extend Vulcan+ Cable Cleat Range To Accommodate Smaller Cables

June 18th, 2024

Ellis Patents Vulcan+ Cable Cleat Range Extended

Thorne & Derrick | Cable Cleats Distributed from Stock | Approved Supplier | UK & Export Sales

Vulcan+ Cable Cleats

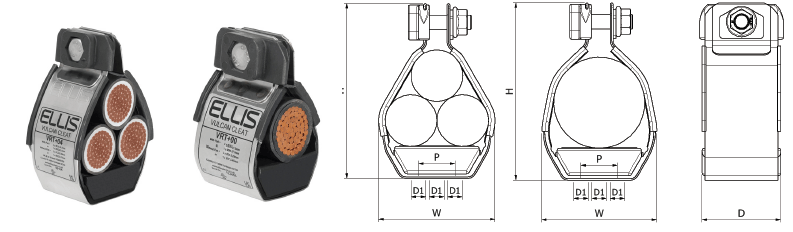

Due to popular demand, Ellis Patents have extended their VULCAN+ cable cleat range to include six new products that can accommodate cables from as small as Ø10mm in Quad formation, Ø15mm in Trefoil formation and Ø18mm in Single formation.

Thorne & Derrick International, based in the UK, stock and distribute the complete range of cable cleats and cable hangers manufactured by Ellis Patents including Vulcan cleats for short circuit retention and cable protection of LV (Low Voltage), MV (Medium Voltage) and HV (High Voltage) cable systems in single-way or trefoil or quad installation.

The Ellis Vulcan+ cable cleat has been designed, developed, tested and manufactured in accordance with IEC 61914 (cable cleats for electrical installations).

The frame of the cleat is manufactured from corrosion resistant 316L grade stainless steel, the cable is supported by a liner manufactured form a low smoke zero halogen (LSOH) material. The closure fixings are manufactured from A4-70 grade stainless steel. Vulcan+ can be fixed to the supporting structure by either one or two M10 fixings.

Ellis Patents VULCAN+

SINGLE/TREFOIL Cable Cleats

- 316L Stainless Steel Frame & Fixings

- Soft LSF Polymeric Liner Protects Cable Sheath

- Captive Closure Fixings For Fast Install

- Short Circuit & Mechanically Tested To IEC 61914

- ABS & DNV Type Approved & Also UL Listed

Vulcan+ Single or Trefoil Cable Cleat Dimensions

| Cable Cleat Part Number | Trefoil Cable Range Min Dia. mm | Trefoil Cable Range Max Dia. mm | Single Cable Range Min Dia. mm | Single Cable Range Max Dia. mm | Dimensions W mm | Dimensions H mm | Dimensions D mm | Dimensions P mm | Fixing Holes | Weight g |

|---|---|---|---|---|---|---|---|---|---|---|

| VRT+00B | – | – | 18 | 28 | 64 | 93 | 54 | N/A | 1 X M10 | 280 |

| VRT+00A | 15 | 18 | 26 | 30 | 64 | 93 | 54 | N/A | 1 X M10 | 287 |

| VRT+00 | 19 | 24 | 30 | 42 | 60 | 93 | 54 | N/A | 1 X M10 | 251 |

| VRT+01 | 23 | 28 | 38 | 50 | 63 | 98 | 54 | N/A | 1 X M10 | 258 |

| VRT+02 | 27 | 32 | 43 | 58 | 72 | 106 | 54 | N/A | 1 X M10 | 269 |

| VRT+03 | 30 | 35 | 49 | 64 | 79 | 112 | 54 | N/A | 1 X M10 | 279 |

| VRT+04 | 33 | 38 | 55 | 70 | 85 | 118 | 54 | N/A | 1 X M10 | 284 |

| VRT+05 | 36 | 42 | 58 | 75 | 96 | 125 | 54 | N/A | 1 X M10 | 319 |

| VRT+06 | 40 | 46 | 63 | 84 | 105 | 133 | 54 | N/A | 1 X M10 | 331 |

| VRT+07 | 44 | 50 | 73 | 90 | 112 | 140 | 54 | N/A | 1 X M10 | 391 |

| VRT+08 | 48 | 55 | 83 | 100 | 121 | 149 | 54 | N/A | 1 X M10 | 405 |

| VRT+09 | 51 | 58 | 86 | 104 | 126 | 154 | 54 | N/A | 1 X M10 | 411 |

| VRT+10 | 55 | 62 | 88 | 110 | 134 | 162 | 54 | 50 | 3 X M10 | 442 |

| VRT+11 | 59 | 66 | 90 | 115 | 143 | 170 | 54 | 50 | 3 X M10 | 453 |

| VRT+12 | 63 | 70 | 100 | 125 | 152 | 177 | 54 | 50 | 3 X M10 | 460 |

| VRT+13 | 67 | 74 | 107 | 132 | 161 | 185 | 54 | 75 | 3 X M10 | 524 |

| VRT+14 | 71 | 78 | 120 | 145 | 169 | 192 | 54 | 75 | 3 X M10 | 536 |

| VRT+15 | 74 | 82 | 125 | 150 | 176 | 199 | 54 | 75 | 3 X M10 | 542 |

| VRT+16 | 77 | 85 | 132 | 153 | 183 | 205 | 54 | 75 | 3 X M10 | 544 |

| VRT+17 | 81 | 89 | 136 | 156 | 190 | 216 | 54 | 75 | 3 X M10 | 618 |

| VRT+18 | 85 | 93 | 139 | 159 | 200 | 225 | 54 | 75 | 3 X M10 | 628 |

| VRT+19 | 89 | 97 | 142 | 162 | 200 | 235 | 54 | 75 | 3 X M10 | 637 |

| VRT+20 | 93 | 101 | 160 | 170 | 215 | 240 | 54 | 75 | 3 X M10 | 646 |

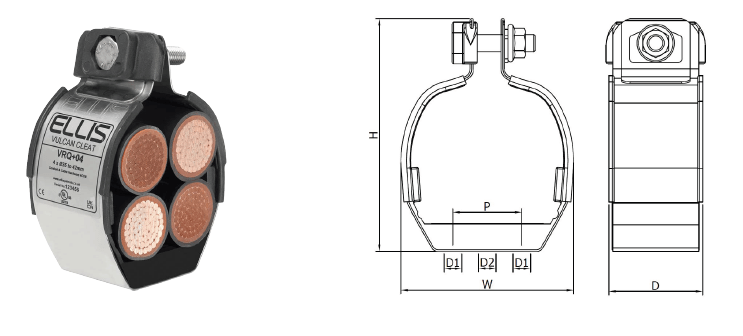

Ellis Patents VULCAN+

quad Cable Cleats

- 316L Stainless Steel Frame & Fixings

- Soft LSF Polymeric Liner Protects Cable Sheath

- Captive Closure Fixings For Fast Install

- Short Circuit & Mechanically Tested To IEC 61914

- ABS Type Approved & UL Listed

Vulcan+ Quad Cable Cleat Dimensions

| Cable Cleat Part No. | Cable Range Min Dia. mm | Cable Range Max Dia. mm | Dimensions W mm | Dimensions H mm | Dimensions D mm | Dimensions P mm | Fixing Holes | Weight g |

|---|---|---|---|---|---|---|---|---|

| VRQ+00C | 10 | 13 | 63 | 93 | 54 | N/A | 1 x M10 | 287 |

| VRQ+00B | 13 | 18 | 67 | 97 | 54 | N/A | 1 X M10 | 280 |

| VRQ+00A | 18 | 20 | 70 | 106 | 54 | N/A | 1 X M10 | 291 |

| VRQ+00 | 19 | 25 | 74 | 113 | 54 | N/A | 1 X M10 | 317 |

| VRQ+01 | 23 | 25 | 68 | 110 | 54 | N/A | 1 X M10 | 284 |

| VRQ+02 | 26 | 27 | 70 | 113 | 54 | N/A | 1 X M10 | 286 |

| VRQ+03 | 28 | 31 | 78 | 128 | 54 | N/A | 1 X M10 | 318 |

| VRQ+03A | 31 | 35 | 90 | 138 | 54 | N/A | 1 X M10 | 350 |

| VRQ+04 | 35 | 42 | 103 | 148 | 54 | N/A | 1 X M10 | 378 |

| VRQ+05 | 43 | 47 | 120 | 165 | 54 | N/A | 1 X M10 | 452 |

| VRQ+06 | 48 | 50 | 121 | 170 | 54 | N/A | 1 X M10 | 467 |

| VRQ+07 | 51 | 57 | 140 | 190 | 54 | 50 | 3 X M10 | 486 |

| VRQ+08 | 58 | 63 | 150 | 200 | 54 | 50 | 3 X M10 | 499 |

| VRQ+09 | 64 | 70 | 170 | 218 | 54 | 75 | 3 X M10 | 581 |

Further Reading

- Cable Cleats | Importance of Short Circuit Testing by Ellis Patents

- Cable Cleats | Importance, How To Specify & International Standards

- Important Factors You Need To Consider When Working With Cable Cleats

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Ellis Emperor Cable Cleats | Sunrise Wind Offshore Wind Farm Case Study

November 9th, 2023

Cable Cleats Offshore Windfarm

Windfarm cable cleats

Ellis Patents, a global leader in the manufacture and innovation of cable cleats, including the Emperor and Flexi Straps range are being installed in the first offshore windfarm in the USA to use a high voltage direct current system (HVDC) to deliver power onshore; the advantages of HVDC are as follows:

- the ability to interconnect networks that are asynchronous

- the ability to transmit power over long distances without technical limitations

- the ability to control power flows on the HVDC connection for all system backgrounds

- the ability to transmit power in either direction as desired by the network operator

- in certain cases the ability to improve AC system stability

The Sunrise Wind Offshore Wind Farm is a significant step towards New York’s clean energy goals. When it is completed the 800MW windfarm will power nearly 600,000 households with renewable electricity by 2025 and help New York accomplish a carbon-free energy grid by 2040.

Sunrise Wind Offshore Wind Farm

Ellis Patents Offshore Wind Project

Experts at Ellis Patents worked closely with the UK Design Team on this. This ensured the highest safety standards and optimal cable management on the offshore platform.

Furthermore, the platform is characterised by a steel jacket substructure and a topside deck housing essential electrical equipment and is the heart of the windfarms operations.

Kelly Brown Ellis Patent’s Sales Director made a statement on this. She said: “Sunrise Wind is a major project for the advancement of the wind sector in the US and having Ellis Cable Cleats installed gives us a huge feeling of pride to be involved in something on such a global scale. This clearly demonstrates the trust in Ellis’ expertise in cable management to enhance safety and efficiency in the offshore platform”.

The Offshore Converter Station is designed to collect the 66kV alternating current (AC) power generated by the wind turbines, relies on a robust subsea export cable that spans an impressive 100 miles to connect to the onshore converter station located at Holbrook on Long Island. The onshore converter station plays a vital role in converting the power back to AC before feeding it into the distribution grid, ensuring clean energy reaches homes, industries, and other end-users across New York.

Cable Management Solution for Sunrise Offshore Windfarm

Ellis provided a cable cleat and management solution tailored to the unique performance requirements of the Sunrise Wind Project.

The Ellis Patents Cable Cleats and Flexi-Straps were installed in the first offshore wind farm. This also played a pivotal role in securing and supporting the cables in the challenging offshore environment.

Emperor Cable Cleats

Ellis Patents Flexi Straps

Emperor Cleats

Manufactured by Ellis Patents, the Emperor Cable Cleats are designed for use where the highest levels of short circuit withstand are required, Ellis’ Emperor cable cleats are available for both trefoil and single cable applications. All products in the range are manufactured in type 316L stainless steel. This helps them provide ultimate corrosion protection, even in the harshest of environments.

Key Benefits of using Cable Cleats

- Low Smoke Zero Halogen Material & Grade 316 Stainless Steel – Corrosion Resistant

- Soft LSF Cable Liner – Cable Sheath Protection

- Captive Closure Fixings – Fast Installation

Thorne & Derrick | Cable Cleats | Ellis Patents UK Distributors

Specialist Distributors of High Voltage Jointing & Electrical Safety Equipment

Further Reading

- Polymer Cable Cleats | Holding Power with Ellis Patents

- Emperor Cable Cleats | Golden Eagle Offshore Platform

- Emperor Cable Cleats | Gwynt y Mor Offshore Wind Farm

Thorne & Derrick International are Specialist Suppliers of products to provide safe and reliable LV HV Cable Termination, Jointing, Installation & Power Systems up to 66kV.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.