Cable Cleats

Cable Cleats | Importance of Short Circuit Testing by Ellis Patents

October 31st, 2023

Cable Cleats | Importance of Short Circuit Testing

Ellis Patents Short Circuit Testing

Short-Circuit Testing is critical to the performance, reliability and safety of cable cleats and management systems- Ellis Patents, a global leader in the manufacture and innovation of cable cleats ensure that all their cable support products are tested to the latest version of the IEC 61914 International Standard.

Conducting a short-circuit test is a reliable solution to prove that a cable cleat can be capable of withstanding a specific set of fault conditions.

During a Short Circuit Test specifiers, consultants and engineers should also request, as standard, a complete Test Report. The Short Circuit test Report should include before and after photographs, and a table of results demonstrating the Short Circuit Test conclusions.

Live Cables and Health & Safety Improvements

The initial problem encountered by Network Rail was that live cables were having to be removed from cable cleats, work carried on around them, and then somehow placed back between tightly spaced upright studs at regular intervals along an entire cable run. Ellis Patents addressed the issue by designing a brand new cable cleat that could be stacked and fixed with nothing more complicated than a quarter turn fixing lock.

This means additional cable runs can be added quickly and easily, without any need to tamper with existing cable installations. The rapid-fit nature of the Ellis No Bolts cleat is further enhanced by the replacement of fixing nuts with a push-fit locking mechanism that securely fastens the lower and top section of the clamp together. In addition to its PADS approval, the Ellis No Bolts cleat also meets the London Underground 1-085 approved material standard, and conforms with international cable cleat standard IEC 61914.

Cable Cleats & Short Circuit Testing

pURPOSE OF sHORT ciRCUIT tESTING

Ellis Patents conducts Short Circuit Testing as a reliable way of proving that their cable cleats are capable of withstanding any specific set of fault conditions.

Conducting a Short-Circuit Test is the industry trusted procedure to demonstrate a cable cleat is capable of withstanding a specific set of electrical fault conditions.

Ellis Patents insist that any claims of cable cleat strength and performance should be supported by a short-circuit test carried out in an independent and accredited laboratory and appropriately certified.

This methodology is becoming commonplace, but prior to the publication of the international standard IEC 61914 many cable cleats were not tested, and those that were had no standardised testing method by which to gauge success or failure. As a result, test results were open to a wide range of differing interpretations.

IEC 61914 has provided a standardised method for conducting a short-circuit test and a definition of the criteria for a pass. It does though allow for a significant degree of latitude and so caution must be employed when interpreting results. Note should also be taken of the full report as opposed to just its headline page.

In the below video the team from Ellis Patents are showing witnessing testing of their cable cleat products at a independent laboratory in the Netherlands- this ensures the safety and reliability of LV MV & HV power systems.

Cable Cleats

Fix, Clamp & Support Cables

Cable cleats are used to provide effective short circuit protection, support and retention to LV, MV and HV power cable systems. When installed at intervals to circuits cable cleats and hangers are used to secure and retain power cables from 600V to 132kV.

Cable cleats or cable clamps manufactured from nylon, aluminium or stainless steel are installed to retain cables in the event of a short circuit – custom designed and engineered single and trefoil cable cleats are available.

These specific correct cable cleats will withstand forces corresponding to the values of the peak prospective short circuit current.

Specialist application cable cleats are available from stock for high performance cable applications including fire resistant, low smoke zero halogen/LSF, flame retardant and with specific end-user UK DNO utility approvals for medium/high voltage power cable cleating applications such as Triplex cables.

Key Benefits of Short Circuit Testing

- Provides short circuit protection up to 235kA

- Custom designed trefoil cable cleats to retain cables in event of a short circuit.

- Identifies capability of withstanding a specific set of fault conditions.

Further Reading

- Polymer Cable Cleats | Holding Power with Ellis Patents

- Cable Cleats | Importance, How To Specify & International Standards

- Important Factors You Need To Consider When Working With Cable Cleats

More Case Studies

- Ellis Emperor Cable Cleats | Sunrise Wind Offshore Wind Farm Case Study

- Phoenix Cable Cleats | Canary Wharf Tower

- Emperor Cable Cleats | Gwynt y Mor Offshore Wind Farm

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects

BAND-IT Ultra-Lok Free End Clamp System Supplied To Wessex Water

September 25th, 2023

Thorne & Derrick | Stockists & Key UK Distributor Since 1985

PR | Uploaded by Natalie Lundie | Supply Chain: Marketing Lead at Thorne & Derrick

Thorne & Derrick, a UK Specialist Distributor for BAND-IT since 1985, have recently specified and supplied an engineered-solution to Wessex Water to improve workplace safety and site security across their pumping and sewerage treatment infrastructure in the UK – the Ultra-Lok Clamping System and PPA coated band system have been adopted by the water utility to protect both plant and people; reducing accidents and combating vandalism.

Application

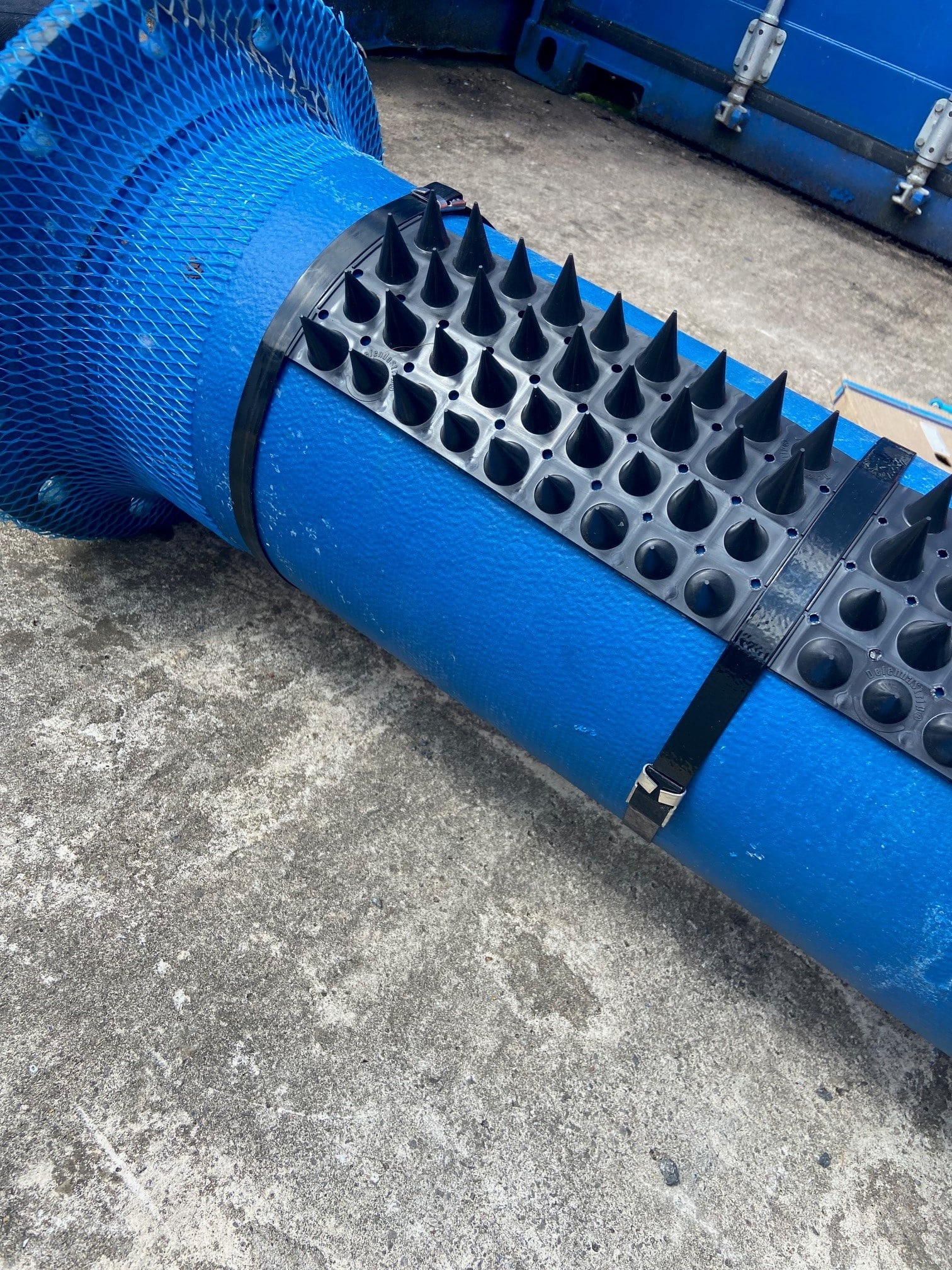

The Water Industry Company contacted Thorne & Derrick requiring a solution to secure various products and signs to their pipe crossings to prevent people climbing on them – Wessex Water were looking for a fast, strong, and effective way to attach anti-climb spikes and signs to water pipes that cross rivers and roads.

Initially, Thorne & Derrick recommended using stainless steel banding and strapping systems, as this would guarantee a strong and secure solution resistant to corrosion and other environmental factors whilst deterring people from climbing on the pipes.

Thorne & Derrick contacted BAND-IT, The Clamping Experts to commence a consultation with the water utility to identify the optimum solution – an immediate customer site visit was organised with Steve Franklin (BAND-IT – Business Development Manager) and subsequent product demonstrations and testing was conducted for evaluation.

Stainless Steel Banding System | BAND-IT

Solution

At the very start it was agreed that a combination of different strappings would be required in various widths and lengths to suit the various products and signs.

It was determined that a PPA Coated Band Strapping System (installed with the C075 Bantam Tool) could be quickly and effectively used to attach the anti-climb spikes, whilst the “No Climbing” sign brackets required additional strengthened support to resist potential vandalism.

C075 Bantam Tool Compact & Lightweight

For this application the client selected the Ultra-Lok Free End Clamp System.

The Ultra-Lok rechargeable tool enables the high strength Free End Clamp to be installed quickly and at a consistent pre-set tension.

The result was a neat and secure solution that met the requirements of the utility Engineering Team and provided a reliable long-term solution.

Installation was quick and simple, with the banding easily folding around the products and signs and secured using the buckles by the site engineers.

Thorne & Derrick together with BAND-IT also provided guidance on the best practice for installation and maintenance of the banding and buckles to ensure maximum longevity and effectiveness of the solution.

Steve Franklin, Business Development Manager at BAND-IT commented, “this is another example of the great relationship between BAND-IT, our Distributor Thorne & Derrick, and the end-user enabling the customer to quickly specify and use an effective clamping solution that will withstand harsh and safety critical environments.”

PPA Coated Banding System

Ultra-lok Clamps & Tools

Ultra-Lok clamps and tools are effective in attaching safety critical equipment on to pipes to prevent people from climbing on them. These clamps can be installed quickly and easily, without the need for welding or drilling. They provide a secure grip on the pipe, reducing the risk of accidents or damage caused by people climbing on them. They are durable, easy to install, and require minimal maintenance, making them a cost-effective solution for keeping people safe.

The Ultra-Lok clamps are made from high-quality materials and are designed to withstand harsh conditions. They are a flexible option for a wide range of pipe shapes and sizes. In addition to the clamps, Ultra-Lok System is installed using a rechargeable electric tool that makes installation fast and consistent with predetermined tension and repeatability.

Anti climb spikes and signs attached to water pipes that cross river and roads

About Wessex Water

Wessex Water is a water supply and wastewater treatment company based in the south west of England. It operates in an area of about 10,000 square kilometres, providing water to over 2.8 million customers and treating sewage from over 1.6 million households.

The company is responsible for maintaining the quality of drinking water, supplying clean water to homes and businesses, treating wastewater, recycling water, and protecting the environment. In addition, Wessex Water has a strong commitment to reducing its carbon footprint and promoting sustainable practices, such as generating renewable energy from sewage sludge. The company was founded in 1973 and is headquartered in Bath, England.

Thorne & Derrick & BAND-IT

Together, Thorne & Derrick and BAND-IT offer a comprehensive range of Banding & Strapping products, including:

- Stainless Steel Banding: Used for bundling, clamping and securing a wide range of objects including cables, pipes and hoses

- Banding Tools: A range of tools for tensioning, cutting, and crimping stainless steel bands, making installation quick and easy

- Brackets & Mounts: A range of brackets and mounts for securing objects such as signposts, cables, and pipes to walls and floors

- Cable Ties: A range of cable ties for bundling and securing cables, wires, and hoses, in a variety of materials and sizes

- Identification Solutions: A range of markers, labels, and tags for identifying objects and cables easily

Other Past Project Wins & Applications

- 2023 | Secured project specification and purchase order for the supply off 285,000 stainless steel cable ties to provide permanent management of LV power cables at a major new battery plant currently in construction in the UK

- 2023 | Following successful site demonstrations of the BAND-IT Stainless Steel Ball-Lok Cable Tie system to project managers, T&D supplied nearly 100,000 cable ties to the Drax Power, Ecostore Project. The scheme was one of the largest biomass co-firing projects in the world, capable of producing 12.5% of Drax power generation from co-firing and represents a key element of their goal to reduce CO² emissions

- Ongoing | BAND-IT Easy Read is used to identify cables and pipes being used throughout the London Underground. T&D are Approved Vendors to Network Rail & TfL London Underground (LUL) and have supplied many of the easy read cable and pipe marking system to the rail industry as they are ideal for ID tagging in inaccessible areas, harsh environments and wherever visibility is low.

BAND-IT | Cable Ties, Band & Buckle Clamping Systems – Stainless Steel

Further Reading

- BAND-IT Stainless Steel Cable Ties Supplied to New Battery Plant Project

- Stainless Steel Cable Ties Replace Plastic Ties In Harsh Environments

- BAND-IT Cable Clamping Products – Training Day at Thorne & Derrick

Tie Lok | Ultra-Lok | Ball-Lok | Multi-Lok | Reusable | Band & Buckles | Stainless Steel

Staff & Support Training Day | Steve Franklin (Business Development Manager – Cable Management from BAND-IT) has supported and managed Thorne & Derrick for over 25 years – here Steve is pictured providing product refresher training to focus our Sales Team on the new business opportunities that the market-leading BAND-IT IDEX provides.

LV HV | Jointing, Earthing, Substation & Electrical Eqpt up to 66kV | Specialist Distributors

Safeguarding Multi-Core Cables: Ensuring Short Circuit Protection

September 18th, 2023

Short-circuit Test Showing Conductors Piercing Through Multicore Cable

Safeguarding Multi-Core Cables

Ensuring Short Circuit Protection

A question Ellis Patents and Thorne & Derrick still get asked on a regular basis is ‘Is it really necessary to use cable cleats for multi-core cables?’ The assumption is that the cable’s inherent strength, with fully encapsulated cores, is sufficient to withstand short circuit forces. The short answer is ‘YES’.

Essentially, the same guidance widely accepted for protecting single-core cables, both in trefoil and single formation, also applies to multi-core cables. Unrestrained or inadequately restrained cables can undergo violent movements, potentially causing damage to nearby circuits, and infrastructure, or even endangering people.

Cable cleats are vital – cable ties alone cannot contain certain short circuit faults.

If you’re still in doubt as to whether this applies to multi-core cables, then this short-circuit test should convince you of the importance of cable cleats on multi-core cables.

As with single-core cables, evaluating multi-core cables for short circuit force withstand requires a comprehensive assessment of three essential considerations:

1. Short-Circuit Current

2. Conductor Spacing, and

3. Cable Type

Short Circuit Cable Video Fault

The below video produced by Ellis Patents shows the catastrophic outcome when multi-core cables attached to cable ladder using cable ties only are subjected to short circuit cable fault. Depending on fault levels cable cleats should be used to secure LV MV HV cables and to provide short circuit protection against disastrous cable faults, this includes the cable cleating of multi-core power cables.

Read More Here – IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

Together Ellis Patents & T&D, prioritise safety and strive to ensure the utmost protection for your electrical infrastructure. If you have any questions about protecting your cable installations from short-circuit faults, we’d love to hear from you.

Ellis Patents Vulcan | Alpha | Phoenix | Flexi-Strap | Triplex Cable Cleats | LV MV HV 11kV

Ellis Patents

Ellis Patents based in the UK are world leading manufacturers of cable cleats, hangers, hooks and cable clamps used to clamp and support LV-MV-HV cables – this includes cable support and management products to provide short circuit protection for 600V, 11kV-33kV-66kV and medium/high voltage power cables in single, trefoil or bundled formation up to 400kV.

BAND-IT Stainless Steel Cable Ties Supplied to New Battery Plant Project

September 6th, 2023

Thorne & Derrick | Stockists & Key UK Distributor Since 1985

PR | Uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

Thorne & Derrick, the UK Distributor for BAND-IT, have secured a new project specification and purchase order for the supply off 127,00 stainless steel cable ties to provide permanent management of LV power cables at a major new battery plant currently in construction in the UK.

Going through manufacture at BAND-IT in Chesterfield, UK the KE range of Ball-Lok stainless steel cable ties provide fast and reliable bundling of cables for maximum strength, reliability and retention of cables.

The corrosion and fire resistant stainless steel ties are typically used to bundle, tie or fasten cables in both onshore and offshore locations including industrial, substation and hazardous area locations, with potentially explosive atmospheres.

The BAND-IT IDEX electrical range of Cable Support & Management Systems are used extensively to manage cables in traditional (Oil & Gas), transitional (Renewable Energy) and emerging (Fuel Cell) markets where conventional non-metallic plastic type cable ties would overtime degrade and fail due to harsh industrial environment conditions.

The high performance cable ties also provide support and location of power, control and instrumentation cables to cable containment where resistance to chemical corrosion, UV and vibration is essential for long-term cable security and management.

BAND-IT worked closely with Thorne & Derrick to close-out the specification to competition and complete delivery of the Purchase Order on-time to allow the cable pulling and containment works schedule to continue without delay or disruption. The project was secured against intense commercial and technical competition from both established manufacturers and un-branded economy ranges.

Ball-Lok cable ties are available in two types: KE Premium ties and KT Standard ties – the smooth inside diameter of the KE ties further reduces the potential for damage to cabling or shielding during the tensioning process.

Made in the UK | Distributed by Thorne & Derrick | BAND-IT Cable Ties for LV MV HV Cables

BAND-IT | Cable Ties, Band & Buckle Clamping Systems – Stainless Steel

Further Reading

- Stainless Steel Cable Ties Replace Plastic Ties In Harsh Environments

- BAND-IT Cable Clamping Products – Training Day at Thorne & Derrick

Tie Lok | Ultra-Lok | Ball-Lok | Multi-Lok | Reusable | Band & Buckles | Stainless Steel

Staff & Support Training Day | Steve Franklin (Business Development Manager – Cable Management from BAND-IT) has supported and managed Thorne & Derrick for over 25 years – here Steve is pictured providing product refresher training to focus our Sales Team on the new business opportunities that the market-leading BAND-IT IDEX provides.

LV HV | Jointing, Earthing, Substation & Electrical Eqpt up to 66kV | Specialist Distributors

Polymer Cable Cleats | Holding Power with Ellis Patents

August 17th, 2023

Ellis Polymer Cleats | Innovation in Cable Management

The Ellis Patents range of cable cleats are manufactured from a range of special formulation polymers to meet the material performance requirements of cleats, clamps, hooks and hangers to suit all LV MV HV Cable Cleating & Management applications.

1. GFN : Glass-Filled Nylon

High-grade glass-filled black nylon polymer. Heat-stabilized for up to 120°C installations. LSF, UL94 V-0 classified, zero halogen, and phosphorus-free. Boasts excellent mechanical and electrical properties, along with outstanding UV performance.

2. LSF : Low Smoke & Fume

High-grade unreinforced nylon polymer. LSF with UL94 V-0 classification, zero halogen, and phosphorus-free. Offers great mechanical and electrical properties, plus exceptional UV performance.

3. LUL : London Underground Approved

Specially formulated polymer meeting London Underground 1-085 standards. The cable cleats comply with limited oxygen index, smoke density, and toxicity requirements.

4. CODE B : Black Polypropylene

Standard black polypropylene is known for toughness and durability. Impressive impact resistance, water, and chemical resistance, along with reliable UV performance.

When your environment demands it, Ellis Patents and Thorne & Derrick have a Polymer Cable Cleat to fulfil your cable management strategy. From GFN to LUL, each option assures performance, durability, and compliance.

Related Products | Cembre Lugs & CMP Glands | Low & Medium Voltage Cable Accessories for Power Cables 600V 66kV