Cable Pulling & Laying

Cable Laying & Pulling – Installing LV-HV Cables Into Duct

April 29th, 2021

Thorne & Derrick | Cable Laying & Pulling Equipment Distributors | LV MV HV

-

Uploaded By Chris Dodds – Thorne & Derrick Sales & Marketing Manager

Today, in Part 1 of a 2 part series covering Cable Pulling & Laying Equipment, Thorne & Derrick look at the equipment requirements and preparation for cable pulling when installing cables into ducts. In Part 2, we discuss the requirements for cable pulling and laying into cable trench.

Cable Pulling Equipment

& Preparation Duct

Cables installed into cable ducts are typically used on projects where the cable duct is buried deep into the ground, sometimes up to 1200mm depth – this includes LV Low Voltage, MV Medium Voltage or HV High Voltage ducted power cables.

Guidelines for the minimum depths for the installation of underground cables are stipulated by the DNO depending on whether cables are laid direct into cable trench or installed in suitable cable ducts depending on ground location types:

- Footways, Grass Verges Or Private Property

- Carriageways (including Road Crossings)

- Normal Agricultural Land

Arrangement of the cable trench will depend upon the cable voltages typically LV, 11kV, 20kV, 33kV, 66kV and 132kV.

LV cables could include Service Cables (Single Phase Concentric | 3 Phase Concentric | Split Concentric) and Mains Cables (3 Phase Waveform).

Auxiliary multi-core and multi-pair cables are usually laid at similar depths to the power cable with which they are associated. Pilot and telephone cables installed alongside 11kV and 33kV cable circuits shall normally be installed at LV cable minimum depths of cover.

So for instance, the installation of 33kV power cables into class 1 cable duct is usually covered in the local DNO’s Approved Equipment Register, Guidelines or Excavation and Cable Installation Manual. Additionally, engineering construction standards provided by UK DNO’s will cover the installation of new LV, 11kV, 20kV, 33kV, 66kV and 132kV cables, plus associated pilot and telephone cables.

For the protection of LV MV HV cables Thorne & Derrick distribute a complete range of underground protective cable ducting

Prior To Cable Pulling

Due to the nature of the cables that are often installed in these applications, there are a number of checks that must be carried out prior to beginning the cable pull:

- The cable duct lines must be checked for any obstructions and anything that is found must be removed. This is often done with the use of duct brushes or ‘foam pigs’ which are pulled through the duct.

- It is essential to ensure that the cable duct is of adequate size to accommodate the cable due to be pulled. This is done by pulling through a 3 metre length of cable through the duct which is subsequently checked for damage prior to the full cable being installed.

- If, during these checks, the 3 metre length of cable has any damage greater than half the depth of the outer sheath the duct route must be repaired before the full length cable is pulled through. This protects the integrity of the final cable.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

There are a number of items of cable pulling equipment to be used when installing cables into duct lines. Cables can vary in size and voltage, however the same process and equipment is used. When installing cables, there is typically up to 9 different pieces of equipment used.

- Cable Winch – the cable winch is used for physically pulling the cable through the duct, reducing the need for manpower and increasing productivity. Electrically powered, the cable winch is much safer and reliable than manually pulling cables through.

- Rope Guide Roller – the rope guide roller is exactly as the name suggests – a roller to guide the draw ropes or cabling ropes that are coming out of the jointboxes or manhole. This is to reduce the damage and strain put on the ropes therefore prolonging the lifespan of the equipment used. The rope guide roller is made from an aluminium roller mounted onto a frame that has been plated with zinc.

- Cable Bellmouth – the duct bellmouth is used as a means of providing additional protection to the cable when it is being pulled through the duct. The rollers on the bellmouth ensure that the cable can be pulled in any required direction without any damage being caused. The bellmouth is located at the exit of the cable duct through which the cable is being pulled.

- Cable Drum Trailer Or Cable Jacks – the cable drum trailers and cable jacks are used as a means of storing and transporting cable drums. Cable drums are large wooden wheels which are used to hold cable. Cable drum trailers make the transportation of extremely heavy cable drums easier, safer and more reliable. Often equipped with braking and road lighting, the cable drum trailers are attached to the back of an appropriate vehicle such as a tractor to assist in the transportation of cables. Cable jacks are used as a means of supporting and stabilising the cable drums. Cable drums are located at the edge of the manhole cover or opening when installing cable into underground ducts for the cable to be easily rolled off.

- Swivel Link – the swivel link is zinc plated, solid steel link that is attached to the winch rope. This link can, as the name suggests, swivel a full 360° allowing the rope to be pulled through without any twists occurring.

- Conduit Rod – the conduit rod is fed through the manhole cover opening and is used to install draw or winch ropes. The rod is manually fed through the underground duct and is extremely easy to handle. The conduit rod comes with a range of accessories available such as flexible guide tips, end connectors and rod repair kits.

- Cable Socks – cable socks or stockings can also be called cable socks or grips. These cable socks are used to support the pulling of cables through a duct. Attached to the end of a cable prior to pulling, the cable stocking is an efficient method of support when pulling the cable

- Manhole Roller – the manhole roller is specifically designed to be placed at the entrance of the manhole to assist in the guiding of the cable. Not only does the roller make the cable installation easier, it also protects the cable from being scraped on the edge of the manhole. The manhole roller is constructed of a steel frame and aluminium rollers. Complete range of cable rollers are available also for cable trench applications.

- Cable Lubricant – cable lubricant is applied to the outside of the cables when being pulled through the duct. The lubricant assists in the pulling process by removing friction between the cable and the rollers. This not only speeds up the process but also prevents snagging and therefore damage to the cable.

Pictured: Cable Laying & Pulling Equipment – Ducts

Duct rods provide a strong, lightweight, labour saving solution for installing cables into ducts or pipes with or without draw ropes.

Cable Protection

All cables and ducts should be over-protected by a cable protection cover or tape depending upon the highest voltage cable to be protected within the cable duct – typically in the UK the following cable protection tapes and covers are used for LV, MV and HV cables:

- LV Service Cable 40m x 200mm x 2.5mm Tile Tape

- LV Mains Cable 40m x 200mm x 2.5mm Tile Tape

- 11kV MV Cables 40m x 200mm x 2.5mm Tile Tape

- 22kV MV Cables 40m x 200mm x 2.5mm Tile Tape

- 33kV MV Cables 1000mm x 244mm x 9mm Stokbord

- 66kV MV Cables 1000mm x 244mm x 9mm Stokbord

- 132kV MV Cables 1000mm x 244mm x 9mm Stokbord

More info ➡ Tile Tape | Stokbord

Duct Seals

Where electricity, pilot and telephone cables are installed into electricity cable ducts the utility engineering standard would normally recommend all cable ducts entering substations and buildings to be duct sealed to prevent the ingress of water and gas – this also applies to 33kV, 66kV and 132kV high voltage substation cables where cable transits are required.

Thorne & Derrick distribute an extensive range of Duct Sealing & Cable Transit Systems to protect utility assets and provide flood protection to substations from water entry via unsealed cable ducts and building penetrations.

Cable Pulling & Cable Laying Equipment Suppliers & Distributors

Thorne & Derrick International distribute the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct – products also supplied for fibre optic blowing, subsea trenching, offshore umbilical installations and pulling armoured cables onto cable tray.

Cable Blowers | Cable Lubricant | Duct Rods | Cable Socks | Cable Jacks | Cable Rollers | Cable Protection Covers MV HV | Cable Joints MV HV | Duct Sealing

How To Remove Bitumen From Subsea Cables & Umbilicals Using Socomore Wipes

April 20th, 2021

Cable Cleaning Wipes

Cable Cleaning | Socomore PF-BR Bitumen Remover Wipes

Bitumen is field-proved to be a highly effective corrosion protection for steel armour wires in array cables, subsea power cables, umbilicals and power umbilicals.

Socomore (formerly PT Technologies) bitumen removal wipes are used for cleaning cables (power, subsea and submarine), umbilicals and electrical equipment including cable rollers and ROV’s – the electrical cleaning solvent wipes are used by cable jointing and technician teams for cleaning and wiping down cables and equipment in the power generation, transmission, distribution and renewable sectors.

PF-BR cleaning wipes from Socomore are extra large, heavily saturated wipes specifically designed for the bitumen removal process during electrical and cabling operations. Used for cable cleaning prior to cable jointing, termination and maintenance of cables, switchgear and network equipment operating at LV MV and HV up to 440kV.

Socomore PF-BR bitumen remover wipes easily remove oils, soils, tar and bitumen. The extra large cleaning wipe reduces the requirement for many smaller wipes, reducing time and wastage during cable preparation which results in cost savings.

The easy hold and grip on the extra large bitumen remover wipe also allows the operator to clean the whole diameter of the cable with one wipe, without touching the cable – suitable for use on static and live cables; low, medium and high voltage applications (up to 440kV).

The bucket wipe system eliminates the transport, storage and logistic issues commonly associated with flammable liquid solvents. Other benefits of the product include reduced solvent consumption and VOC emissions, improving your companies Health & Safety and environmental impact.

Cleanly Remove Bituminous Compound From Submarine Power Cables.

Socomore PF-BR Electrical & Cleaning Wipes – Key Applications

- Removal of bitumen protection

- Cable cleaning before cable jointing or cable splicing

- Cleaning and degreasing switchgear and network equipment

- Cable end preparation and construction of cable joints

- Cleaning and degreasing cable and moulded connectors

- Cleaning and maintaining large generators, insulators, transformers and motors

- Cleaning and degreasing of plastic and metallic tools

- Electrical equipment and components cleaning

- Degreasing assembly connectors on underground cables

- Cleaning connector interfaces

- General multi-purpose maintenance degreaser

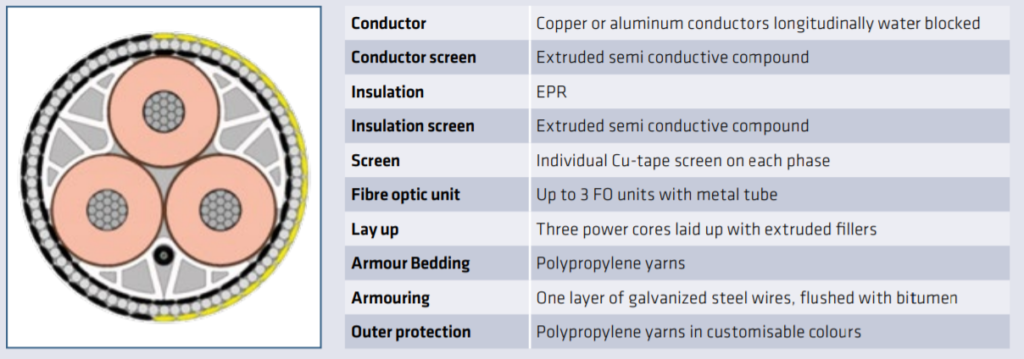

66kV Cable | Typical Offshore Wind Cable Construction | Image Prysmian

Bitumen Removal

from Subsea Cables & Umbilicals

Directions for Use

Bitumen Removal | Heat cable to soften bitumen. Holding an end of impregnated wipe lengthways in each hand, vigorously move the wipe up and down the cable until all bitumen is removed. Dispose of all jointers wipes in an appropriate bin.

General Usage | Apply a thin film of PF-BR using liquid or a pre-saturated wipe. Allow a few minutes for surface action to dislodge contaminants. Wipe off with the same pre-saturated wipe or with a clean, dry low lint cloth (recommended). Dispose of all jointers wipes in an appropriate bin.

Cable Cleaning (Jointing Operations) | Follow cable manufacturers guidelines for cable jacket stripping to semi-conductive shield peeling. Clean the cable with PF-BR – conduction and insulation – to remove residue and degrease. Always clean in the same direction from cable outward (conductor) to cable inward (semi-conductive shield) to avoid re-depositing residues already removed. Wipe off with a clean, dry low lint cloth (recommended). It is not necessary to wait for full evaporation before further working on the system. Solvent residues will not affect the subsequent full cure of epoxy resins in cable jointing systems (heat shrink or cold shrink). Dispose of all jointers wipes in an appropriate bin.

Cable Pulling & Cleaning Products

Thorne & Derrick International are the UK’s leading stockist and supplier of Cable Pulling & Cable Laying Equipment for the installation of underground land and subsea power cables and overhead lines up to 400kV – the products support cable pulling teams to install LV MV HV cables into trench, cable duct, risers and all forms of cable containment.

➡ Further Resources | Cleaning Cables In The Power Industry | PF SOLVENT

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

See how T&D support, supply and service the Renewable Energy industry.

MV HV 11kV 33kV 66kV | Cable Joints, Terminations & Connections | Distributors & Stockists for 3M Cold Shrink | Nexans Euromold | Pfisterer CONNEX

Cleaning Cables In The Power Industry | PF SOLVENT

April 14th, 2021 Cleaning Cables in the Power Industry

Cleaning Cables in the Power Industry

Electrical cables are everywhere for power distribution within cities or industrial areas.

They run within buildings but are also buried. Often forgotten, offshore marine cables are used under the ocean for power transmission too – this includes subsea and submarine cables which require bitumen removal prior to jointing, termination and connection to electrical equipment.

In sewer and water construction and maintenance, and in the energy and communications industries, we use cleaners to degrease cables and accessories during both installation and maintenance activities.

The main problems are the contaminants that accumulate during years of use, that can provide a path over the insulation and increase the risk of tracking. Solvent cleaners remove contaminants found on the cables before installation or jointing and termination.

PF SOLVENT manufactured by Socomore is a multi-purpose cleaner, available in liquid or as an impregnated cable cleaning wipe. It’s a perfect cable cleaning solvent that is specifically designed as an electrical solvent cleaner, including MV and HV.

Are you looking for an efficient power industry cleaner? Keep reading!

What differentiates PF SOLVENT?

Key Points of this Power Industry Solvent Cleaner

- Multi-purpose

- Multi-approved

- Reduction of installation faults for long-lasting cable life

- Solvent consumption, VOC emissions & costs reduction

- Wide range of power network materials compatibility

- With low lint pre-saturated wipe system: no hazardous storage, transport and logistical issues of loose flammable liquids

Cable Cleaners

Uses

Operations and Applications

PF SOLVENT is used for the cleaning and degreasing of cables during jointing and maintenance activities as well as on switchgear and network equipment.

Some companies also use it during substation cleaning and maintenance as well as the degreasing of overhead power lines in rail applications.

The fact that you can use this product liquid or pre-impregnated on wipes, as well as its cleaning effectiveness and capacity to endure use on high voltage/electrical cables makes its use very broad.

PF SOLVENT is suitable for the 3 families of cables:

- ground impregnated paper cables

- pressure cables

- extruded cables

It can be used to clean the cables but also specific parts of them or accessories like:

- cable oversheaths

- cable metallic sheaths

- connectors (conductor or not)

- termination components

Don’t forget generators or electrical transformers.

The product is a residue free solvent that removes:

- greases

- oils

- sealants

- cable jellies

- soils

- tar

- bitumen

It cleans semi-conducting insulation shield residue, silicone grease, dirt, joints, etc.

PF SOLVENT Approvals

PF SOLVENT is a multi-approved product. The electrical and cable cleaning product is used, recommended and approved by several energy key players including utility companies such as Electricity North West, ESB, Scottish Power, UK Power Networks, Scottish and Southern and Northern PowerGrid. This cable cleaning product is also approved for use by cable companies like ABB, Nexans, Prysmian, NKT Cables, Pfisterer, Sudkabel and Elastimold.

Characteristics

What are PF SOLVENT main characteristics?

One of the main characteristics is its high flash point.

Due to its intrinsic properties, it is suitable for high, medium and low voltage applications.

It is designed specifically following the recommendations of the Institute of Electrical and Electronics Engineers (IEEE).

Due to its key features and properties, this is an ideal replacement to traditional fast evaporating solvents. An example is the Trichloroethane.

Physical Properties

The appearance is a fluid liquid, you can also buy the product in pre-saturated wipes format.

The specific gravity is 0.765 for the liquid format, or >1 if you use pre-saturated wipes.

PF SOLVENT’s flash point is 61°C.

Cable Pulling & Cleaning Products

Thorne & Derrick International are the UK’s leading stockist and supplier of Cable Pulling & Cable Laying Equipment for the installation of underground land and subsea power cables and overhead lines up to 400kV – the products support cable pulling teams to install LV MV HV cables into trench, cable duct, risers and all forms of cable containment.

➡ Further Resources | How To Remove Bitumen From Subsea Cables & Umbilicals Using Socomore Wipes

Thorne & Derrick are Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

See how T&D support, supply and service the Renewable Energy industry.

MV HV 11kV 33kV 66kV | Cable Joints, Terminations & Connections | Distributors & Stockists for 3M Cold Shrink | Nexans Euromold | Pfisterer CONNEX

Cubis STAKKAbox™ Toby | The Telco Joint Box for Rural Roads

February 8th, 2021

access chambers & Joint Boxes

CUBIS STAKKAbox™ Toby

As a long-standing supplier of network access chambers and AX-S™ covers to the Telecommunication market, Cubis prides itself at being at the forefront of key development and innovations within the sector.

The NEW STAKKAbox™ Toby has been designed to provide a compact Telecoms joint box that can be installed in areas where it is congested with other utilities or there aren’t any pedestrian footpaths such as rural roads. The access chamber system can also be installed in the carriageway making it the ideal solution for your rural telco network.

System Components | STAKKAbox Toby & AX-S Ductile Iron Cover

New & Retrofit Network Installation

STAKKAbox™ Toby is available in a solid ring section that can be installed within a new network system or retrofitted into an existing network within the carriageway and has been tested and approved to BS5834 Grade A Heavy making it the ideal solution for EN124 carriageway Group 4 installations.

Easily Adaptable

The STAKKAbox™ Toby offers an easily adapted solution to on-site conditions that can be drilled with standard tools for duct entries on any side of the chamber wall and installed within new telco networks or retro fitted around existing utilities.

How it Works

The STAKKAbox™ Toby is made up of one 300mm deep section that has a 150mm x 150mm clear opening with integrated base section.

With one of the sections manufactured with an integrated base section and the other without, the STAKKAbox™ Toby sections can be stacked to accommodate for deeper installations.

Utilising a Ductile Iron cover, the twin-walled chamber provides a superior strength system for an easily accessed network.

Materials

Polypropylene (PP)

The STAKKAbox™ Toby system is moulded in talc-filled recycled Polypropylene (PP) which possesses excellent strength to weight properties.

Each section is manufactured with twinwall and internal ribbing for improved loading performance.

Available Sizes

The STAKKAbox™ Toby provides an access chamber with a clear opening of 150mm x 150mm.

The single ring section at 300mm deep is built up in conjunction with a 120mm deep ductile iron cover to provide an over 420mm telecoms joint box.

STAKKAbox™ Toby can also be supplied with an extra section for deeper installations providing up to 720mm maximum depth of chamber.

Load Rating

The STAKKAbox™ Toby is suitable for installation in environments rated to BS5834 Grade A Heavy.

Suitable for EN124 carriageway Group 4 installations.

STAKKAbox™ Chambers are significantly faster to install than conventional alternatives, with complete installations typically taking under one hour. This results in reduced costs for the installer and significant time saving. No specialist equipment or plant is required in order to install an access chamber and there is no need for specialist box builders.

With flexible installation, Cubis access chambers can be adapted to suit on-site conditions with standard tools to build over existing networks.

Cubis – Access Chambers, Access Covers, Cable Protection & Cable Accessories

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Slingco Take A Firm Grip on The Future With Cable Socks

February 8th, 2021

Slingco Cable Socks

Published in Wind Energy Network Magazine January 2021

You’re standing on a metal-decked platform, no land in sight, just the North Sea stretching as far as the eye can see. You know precisely how cold that water is. Of course you do – it’s a crucial factor. With years of preparation and hundreds of millions of pounds at stake, there’s no room for guess work.

You scan the sea – are those waves any longer or higher than the models predict?

Somewhere out there, coming closer every minute, is a remotely operated vehicle (ROV), it’s destination dependent upon those calculations made months ago, in an office hundreds of miles away.

The last link in a chain is about to connect: an underwater cable as thick as a tree trunk, spanning land to sea. Only when it does, can this wind turbine – the largest ever built – start spinning its massive rotor blades.

You realise you’re holding your breath!

- The stakes couldn’t possibly be higher

- This is no time to experiment

- It’s no time to take chances

- This is simply put, no time to lose your grip………and this is why you choose Slingco

Cable Socks & Typical Applications

- Array

- Export

- Submarine

- Umbilical Cable Pulling Installations

- Telecom

- Fibre

- Turbine & Wind Tower Cable Installations

- Flexible Hose Support & Restraints

Experience

For forty years this award-winning UK Heritage company has stepped into the breach. Wherever connections matter, where support is crucial, and where standards are absolute, they supply the missing link.

Construction of wind turbines and offshore high voltage stations rely on the successful installation of infield and export cables. Every one of the numerous disciplines, contractors and suppliers in this process must be impeachable.

When you choose Slingco, your choice is backed by state of the art facility, a dedicated research and development team, meticulous manufacturing, relentless testing, a peerless track record and fanatical customer service.

Preferred Partner

In this era of ever longer lengths and even greater loads, Slingco is the preferred partner for successful offshore cable socks and cable installations. They come by their reputation honestly – by dint of hard work, across generations of technology.

Back in the 1980’s, when mining operations relied on cable grips and supports, they were there. In the 90s, as telecommunication cables snaked under city street s, they were there. Now as the world harnesses the power of wind, Slingco helps meet the challenge through deep institutional memory and decades of proven innovation.

Slingco Cable Socks

Offshore Pulling Cable Socks At A Glance….

- Types of cable socks – Single eye, double eye, lace-up

- Materials – Galvanised, stainless steel, non- metallic aramid fibre

- Ferrules – Aluminium

- Length of lattice – 1500mm – 3500mm+

- Range – 100mm – 350mm+

- Configurations – Single weave, double weave, triple weave, quad weave

- Additions – Shoulders (single eye only), anodes

Offshore Pulling Cable Socks

Wide Ranging Solutions

The company has seen every possible variation of strength, cable gripping and environmental factors and have a wide range of solutions along each of these continuums.

Every product in Slingco’s range is rigorously tested, both internally and externally, to ensure accurate loads and reliable factors of safety. their break strengths are not theoretical; they’re proven, for the jobs where it has to be right the first time (and every other time).

Of course, designing the right product is no use without the capacity to faultlessly manufacture, constantly stock, and reliably deliver. At every step, the company have removed the guesswork.

To ensure uninterrupted stock levels, they maintain multiple supply channels, constantly auditing their supply partners to ensure ISO compliance. Their multi-million-pound investment in a new facility helps meet aggressive timelines for on time delivery.

Recent Projects

UK Sales Director Ian Harrison points to Slingco’s role in such recent, major windfarm installations such as Hornsea 2, Triton Knoll and Moray East commented:

‘More than ever, the world looks towards Renewable Energy (in particular, wind) to support the demand for more sustainable power. We have seen in the past few years an increase in the number of wind towers per field, larger turbines and more recently floating structures to push these farms further offshore.

Slingco’s strategy for growth over the next three years will enable us to maintain our status as the leading cable pulling grip supplier to the Wind Energy and Subsea market.’

All the cable socks are fully tested before they leave the factor to confirm MBL is actual, not calculated. Tests reports provided, certificate of conformity and mill certs to ensure traceability.

The company has their own fully certified test facility which allows comprehensive testing of all the cable socks prior to release. They design and manufacture to the highest specifications and test to destruction. Their lead times are competitive and they also offer a bespoke design service, courtesy of a dedicated UK R&D team.

Slingco’s new state of the art facility opening in February 2021

Cable Socks | Pulling Underground Cables & Stringing Overhead Conductors LV MV HV

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

➡ See Also Cable Laying, Installation & Support Products | MV HV Windfarm

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct