Blog

Stress Control | MV Cable Terminations by 3M Electrical

September 22nd, 2020

3M Electrical

Stress Control Methods

Choosing Cable Terminations to Reduce Electrical Stress

The following information has been republished with kind permission of 3M Electrical.

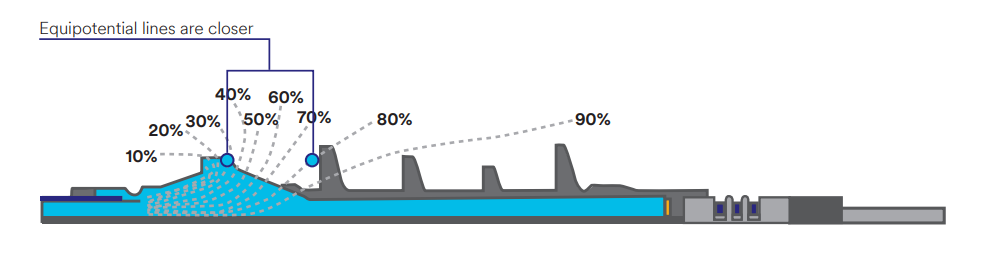

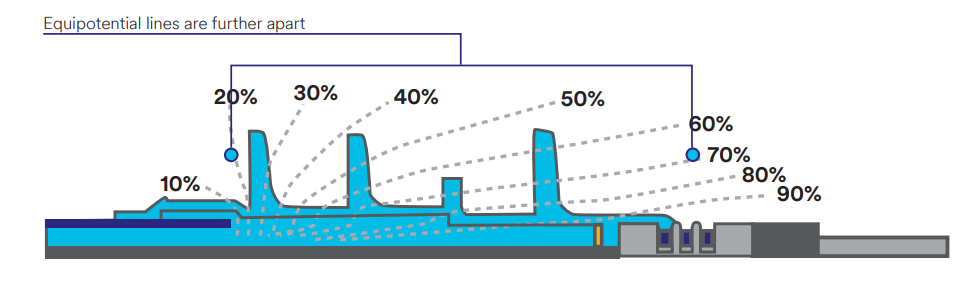

Traditional Geometric Stress Cone

This method reduces the electrical stress at the shield discontinuity by extending the shield and gradually increasing the thickness of insulation under the shield. The areas where there is a higher electrical stress receive additional insulation, as shown in Figure 2 below.

GEOMETRIC STRESS CONTROL

Geometric Stress Control – Figure 2

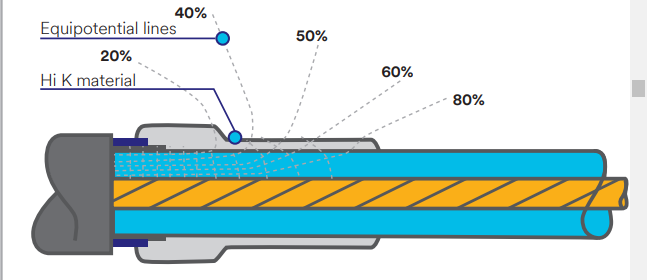

High Dielectric Constant (Hi K) Stress Control

This method lowers the electrical stress at the point of shield discontinuity by refracting the electrical stress. This allows the equipotential lines to spread out along the cable instruction interface. By doing this, the surface stress of the termination is greatly reduced, which improves cable termination performance and life expectancy shown in Figure 3 below:

CAPACITIVE STRESS CONTROL

Capacitive Stress Control – Figure 3

Geometric

Geometric

High Dielectric Constant

High Dielectric Constant

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

RISE NOFIRNO | DNV GL Approved Pipe Sealing Penetrations

September 22nd, 2020

RISE NOFIRNO System

Pipe Sealing With DNV GL Approval

RISE NOFIRNO sleeves and sealant by CSD Systems are made from the highest grade silicone materials, and have a tested service life of over 20 years. Unlike some competitive systems, the RISE NOFIRNO system contains no cheap calcium silicate or mineral wool blankets, which can absorb moisture and cause corrosion of the penetration collar and pipes inside the collar. This problem is referred to as “Corrosion Under Insulation” (CUI).

The CSD NORFIRNO is a Single & Multi Pipe Penetration Sealing System composed of a steel sleeve (length 180 mm or 250 mm) welded or bolted to steel deck or bulkhead, NOFIRNO Filler Sleeves filling the open space between sleeve and pipe – one of the most adaptive systems for sealing straight and angled pipe penetrations and can even accommodate multiple pipe runs, significantly saving in space and weight.

The NOFIRNO system is Type Approved for the harshest ratings for A, H and Jet Fire Class, and is also approved for watertight, gas-tight, blast and shock applications.

RISE NOFIRNO System Features

- Approved for harshest fire ratings for pipe penetrations (EN, A, H and Jet Fire class)

- Allows substantial movement of the ducted pipes within the conduit

- High pressure ratings – designed for gas and/or watertight penetrations

- Prevents “Corrosion Under Insulation” (CUI)

- Longest service life and best Total Cost of Ownership of any sealing system

- NOFIRNO® rubber sleeves and sealant will remain stable and not be consumed by fire

- Approved for any combination of cable and/or metallic, GRP or plastic pipes

For insulated copper pipe penetration, RISE/ULTRA shell of thickness 2.5 mm shall cover the insulated pipes over a length of 210 mm.

For Multi-Mix Pipe, RISE/ULTRA strips/sleeves around the plastic pipes.

The penetration is sealed on both ends with a layer of 20 mm NOFIRNO Sealant.

Rise Nofirno Application/Limitation

Single pipe penetrations

- Approved for A-0 penetrations for steel, copper and GRP service pipes of following maximum sizes:

Steel: Ø408 mm; Copper. Ø420 mm; GRP: Ø408 mm.

See drawings Nos. R0207E Rev.2 and R0213E Rev.1.

- Approved A-0 to A-60 penetrations for insulated (Armaflex AF or equivalent) copper pipes of outside diameter up to Ø54 mm and for Insulated steel pipes up to Ø168 mm.

Maximum sleeve size: Max. Ø273 mm.

See drawings Nos. R0246E Rev.1, R0247E Rev.1, R0248E Rev.1 and R0249 Rev. 0.

Multi-pipe penetrations

- Approved A-0 to A-60 single and multi-pipe penetrations for steel/stainless steel pipes up to Ø408 mm, for Cu/CuNi pipes up to Ø420 mm and GRP pipes up to Ø408 mm. Maximum sleeve size: Max. allowable surface area: 2500 cm2 (500 mm x 500 mm).

See drawings Nos. N0009E Rev. 2 and N0011E Rev. 2 - Approved A-0 to A-60 single and multi-pipe penetrations for steel/stainless steel pipes up to Ø168 mm and for Cu/CuNi pipes up to Ø108 mm.

Maximum sleeve size: Max. allowable surface area: 3000 cm2 (1000 mm x 300 mm).

See drawings Nos. N0018E Rev. 2 and N0020E Rev. 1 - Approved A-0 multi-pipe penetrations for steel/stainless steel pipes up to Ø219 mm.

Maximum sleeve size: Max. allowable surface area: 1800 cm2 (600 mm x 300 mm).

See drawings Nos. N0045E dated 04.06.12

Multi-Mix pipe + cable penetrations

- Approved A-0 to A-60 penetrations for a mix of cables up to Ø105 mm (incl. CLX and LAN cables), steel/stainless steel pipes up to Ø168 mm, for Cu/CuNi pipes up to Ø108 mm and plastic pipes (PVC, PP, PPR, HDPE, PB, PVDF) up to Ø160 mm.

Maximum sleeve size: Max. allowable surface area: 3000cm2 (1000 mm x 300 mm). See drawing No. N0015E Rev.2, N0016E Rev.2 and N0017E Rev. 2.

The installation of the pipe penetration is to be in accordance with the manufacturer installation manual and referenced drawings.

For A-0 divisions, no insulation is needed on the sleeves and the pipes.

Approved for watertight penetrations up to a design pressure of 1.66 bar. Approved for airtight penetrations up to a design pressure of 1.00 bar.

The penetration system is generally not to be used for penetrating boundaries of tanks.

When pipe penetrations is requested to be used in watertight bulkheads on passenger ships and Special

Purpose Ships (SPS), the pipe penetration system has to comply with the requirements given in SOLAS (2009) Ch. II-1 Reg. 13.2.3 c.f. IMO Res. MSC.429(98) Reg. 13.2.3.4. Pipe penetrations passing through watertight bulkheads are subject for separate examination.

Each product is to be supplied with its manual for installation/application and maintenance.

NOFIRNO is one of BEELE Engineering’s ‘rapid cable and pipe sealing systems’ for use on board ships, on offshore pipework installations, in building and construction and other environments where the safety of people and installations has to be guaranteed.

Type Examination Documentation

- Test report No. R0209 dated July 2008 from Efectis Netderland BV (TNO).

- Test report No. R0325 dated July 2008 from Efectis Netderland BV (TNO).

- Test report No. R0556 dated July 2008 from Efectis Netderland BV (TNO).

- Test report No. 0303-010 dated 21 March 2003 from Beele Engineering.

- Test report No. 0501-039 dated 11 January 2005 from Beele Engineering.

- Test report No. 0609-056 dated 19 September 2006 from Beele Engineering.

- Test report No. 0712-060 dated 12 January 2007 from Beele Engineering.

- Test report No. 0702-061 dated 01 February 2007 from Beele Engineering.

- Test report No. 0704-067 dated 18 April 2008 from Beele Engineering.

- Test report No. 0706-070 dated 26 June 2008 from Beele Engineering.

- Test report No. 0805-080 dated 21 May 2008 from Beele Engineering.

- Test report No. 1206-104 dated 05 June 2012 from Beele Engineering.

Pressure test report No. 0203-D056 dated 01 March 2005 from Beele Engineering.

Tests Carried Out

Tested according to IMO FTPC Part 3 (IMO Resolution A.754 (18)) and in accordance with IMO 2010 FTP Code Ch. 8.

Marking of Product

The product or packing is to be marked with name and address of manufacturer, type designation, fire technical rating, MED Mark of Conformity and USCG marking if applicable.

NOFIRNO System By CSD

Further reading

- A60 H120 Pipework Fire Protection For Offshore Bulkheads & Decks

- NOFIRNO – Cable & Pipe Sealing Systems

- NOFIRNO Sealant | Sealing For Cable & Pipes 2 Hour Jet Fire Tested

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

ALU Ship Connect System | Reducing Installation Times By At Least 40%

September 22nd, 2020

ALUShip Cables Used In Confined Spaces Reducing Installation Times By At Least 40%

ALUminium Cables

Ship Connect System

-

Republished with the kind permission of Hermod Iverson at Amokabel Norway AS

A new alternative to copper electrical cables is offering shipowners more flexibility and a potential weight reduction of 55% per ampere.

In the race towards more environmentally friendly shipping solutions, reducing a vessel’s weight is a good way to achieve that goal. Swedish cable manufacturing company Amokabel has developed the ALU Ship Connect System, aluminium power cables that offer vessel owners and operators significant benefits.

“Until now, it wasn’t common to use aluminium cables aboard vessels.” comments Amokabel Norway CEO Hermod Iversen. “The main reason for not using the aluminium cables before is that the IEC international standards for shipboard cables only accepted copper cables. After contacting DNV GL, it was agreed that alternative solutions, in this case aluminium cables, might be accepted onboard, provided equivalent technical safety was documented by thorough testing of the cables.”

Testing and qualification of the ALU Ship Connect System was completed in May 2018 and DNV GL subsequently issued the first type approvals for aluminium cables and connectors on vessels.

The amokabel Group is a private own company group consisting of three manufacturing cable companies with subsidiary companies, producing everything from automotive wire to covered conductors.

Significant Savings

Amokabel manufactures various kinds of wires, cables and consumer-packaged products.

The company has a strong focus on quality and minimal environmental impact, and these values are the foundation of the new system.

“The main reason we started looking into the possibilities with aluminium was the environmental aspect. Copper is much heavier and with the new type of vessels, any weight reduction option is worth looking into,” explains Mr Iversen.

“Compared to copper cables, you need more or bigger aluminium cables to get the same electrical load but even taking that into account, you can save up to 55% in weight per ampere by using aluminium cables. That is a big reduction and one that can make a significant impact on the fuel consumption of a vessel. Especially when you measure it over a vessel’s lifetime.”

This weight reduction is particularly attractive for the new type of environmentally-friendly vessel being built, Mr Iversen explains. “When you have a heavy containership, the weight savings are going to make a difference but it will be comparatively small. However, on a battery-powered vessel or a high-speed ferry, the weight reduction is going to have an enormous impact. Every kilo counts on electric vessels.”

Additional Benefits

It is not just the weight reduction that will have a positive impact on the environment. Aluminium is also a more environmentally friendly solution, states Mr Iversen, “The production of the cables is completely green, adding to the environments of using aluminium cable systems. Moreover, the cost of aluminium cables is significantly lower the copper cabling, because the material costs are much lower. Copper is a semi-precious metal. It is not cheap, and it seems a waste to just hide it on the boton of a ship for thirty years. Especially if there is a cheaper, lighter, and cleaner alternative available.”

Successful Installation

Amokabel has spent years developing the project, researching, carrying out tests, and getting certified with, and by DNV GL. The ALU Ship Connect System consists of aluminium cables and copper terminations from Mecatraction in France, “The whole system has been approved by DNV GL. The crimping technology (DBI) has been specially developed by Mecatraction and we worked very closely together to find the best solution for a reliable connection. The crimping technology is based on the combined experience from the aircraft and automotive industry.”

The aluminium power cables of the ALU Ship Connect System are much lighter and easier to install than traditional copper cables.

In 2015, Amokabel successfully installed the ALU Ship Connect System on an offshore service vessel in Norway. Another benefit of the aluminium cables became evident during installation. “Because the aluminium cables are so much lighter, they are easier to install,” details Mr Iversen. “It is not easy pulling cables inside a vessel due to the narrow and confined spaces in which they are often placed. I have received several positive comments from installers saying that our ALU cables make their job a lot easier. I would estimate that our cables can reduce installation times by at least 40%.”

Amokabel and DNV GL in March 2018 carried out a joint inspection on board the offshore vessel and found the cables were working perfectly. “There was no change in behaviour or rise in temperature in the cables,” comments Mr Iversen. Successful testing, both in laboratory and on board, showed equivalent safety levels compared with traditional copper cables.

This enabled DNV GL to issue the first type approvals for aluminium shipboard cables and terminations in 2018.” He concludes, “Our biggest challenge now is convincing ship owners and operators of the benefits of the ALU Ship Connect System. Rome wasn’t built in a day, or even a year. But we believe in our product and we believe others will too.”

Marine & Offshore Cable Accessories

THORNE & DERRICK are international distributors of LV, MV & HV Offshore & Marine Cable Installation, Jointing, Substation, Earthing & Electrical Equipment – we supply Joints, Glands, Cleats & Cable Accessories specified for use in harsh and hazardous areas to support the installation of marine and offshore fire resistant cables.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

DNV

DNV is a rigorous approval system for cable accessories including joints, glands and cleats – the DNV approval process assesses all of the evidence offered by the manufacturer and compares it to the requirements of the international standard, IEC61914. Once full compliance is proven DNV Type Approval is offered.

Cable Joints

DNV Approved

Hydrocarbon Resistant | Zero Halogen & Fire Resistant

Cable Glands

Hazardous Area Explosion Proof | Zero Halogen

Cable Cleats

Zero Halogen | Fire Resistant | Stainless Steel

Also ➡ Cable Labels, Cable Ties, Cable Transits and Cold Shrink

Contact Thorne & Derrick for further information and customer service – extensive range of DNV Approved Marine & Offshore Cables & Cable Accessories available for delivery to UK and international projects.

LV MV HV – 3.3kV 6.6kV 11kV 33kV

Circulating Currents | Screen Break MV Cable Joints for 33kV Cables

September 22nd, 2020“If you are encountering issues with circulating currents or standing voltages on extended circuit lengths of single core MV cables up to 33kV there is now a solution from Nexans to help control these unwanted and potentially dangerous issues by installing GTSIS.W screen break joints – these cable joints enable you to cross bond the screens of all three circuits in a safe manner that has been Tested and Certified to Cenelec HD 629.1 S2 & IEC 60502-4.

The screen break joints can help control circulating currents on medium voltage power systems and can accommodate MV cables up to 42kV using either compression or mechanical connectors – the joints do not eliminate circulating currents but they sufficiently reduce them to a safer and more manageable level (cable rating wise).

Contact Thorne & Derrick, the Main UK Distributor and Channel Partner for further information today.”

-

By David Rockall | Business Development Manager at Nexans Power Accessories (UK) Ltd

Screen Break Joints

Utilising heat shrink technology the GTSIS.W range of straight joints are compatible with unarmoured single core polymeric insulated cables with copper wire screens (35-1000sqmm) up to 33kV (42kV). Further Information here.

More from Nexans

- Nexans Euromold Screened Separable Connectors | Approval for Supply Within SSE’s Networks Business

- Nexans Euromold Connectors : EPDM Rubber Screened Separable Connectors For Medium Voltage Cables

- Facilitating Sensor Installation In Power Networks By Nexans MV Power Cable Accessories

- 66kV Connectors, Cables & Junctions Boxes – An Interview With Nexans

- Jointer Training Courses – 11kV 33kV 66kV Medium & High Voltage Jointer Competency Training

- 66kV Cable Jointer Training – A Question Of Competency Not Familiarisation

MV Cable Joints

Nexans NEW PRODUCT Launch

JST | Reliability & Safety at Reduced Cost – a modern generation of MV Heat Shrink Joint has been developed by Nexans for the UK utility and contracting industry – the primary application is for the jointing of 11kV BS7870 Triplex type medium voltage cables. The JTS cable jointing system now provides the most cost-competitive option to power contractors: the cable joints manufactured by Nexans, “The Global Expert in Cables & Cable Systems” are tested in accordance to CENELEC HD629.1.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

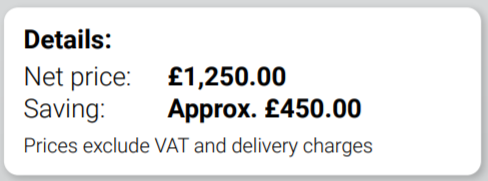

SPECIAL OFFER | GREENLEE LS 50 FLEX HYDRAULIC PUNCHING TOOL

September 16th, 2020HYDRAULIC PUNCHING TOOL – INCLUDES A set of punches ISO 16-40

The LS 50 FLEX is a battery powered hydraulic punching tool with a highly flexible rotating head and an integrated pressure sensor which increases the service life of the hole punch. The LS 50 FLEX has an automatic stop allowing the punching tool to last longer than competitors. |

|

Since 1996, Klauke has expanded its product portfolio with the Greenlee brand. With the focus on punching tools and cable management products.

Cable cutting and crimping tools, manufactured by Klauke and distributed by Thorne & Derrick, are known for their high-quality. Klauke manufacture a range of electrical connection tools for cable crimping, cutting and punching.

Thorne & Derrick, specialist distributors of Klauke cable crimping and cutting tools, are offering the LS 50 Hydraulic Punching Tool + a set of punches ISO 16-40, at the discounted price of £1,250. ex. delivery & VAT. Contact us to place your order.

Klauke LS 50 FLEX

LS 50 Cable PUNCHING TOOL FEATURES

- Choose your battery system: Bosch or Makita

- All data can be easily read via Bluetooth

- Balanced centre of gravity for easy handling and effortless operations

- LED for work area illumination

- Energy saving function with motor cut-out after successful operation

- Manual retract as required

- Always ready-to-use thanks to battery charge and service display

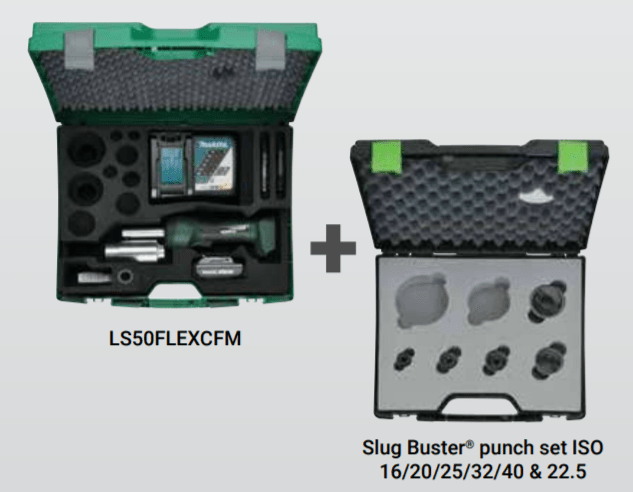

LS 50 Flex Punching Tool Kit Contents

The Slug Buster has a unique design which splits the produced slug into two parts, making removal quick & easy, and immediately ready for the next hole.

A slug split into 2 parts

The cable punching tool, as well as the Slug Buster punch set, is used extensively by Panel Builders and Electrical Contractors; perfect for enclosures & gland plates. The set reduces noise & vibration compared to hole-saws, to create exact sized holes with minimal swarf and no-deburring.

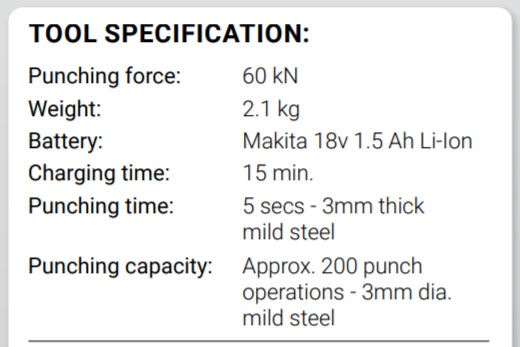

Ls 50 Cable Punching Tool Specification

The LS50Flex hydraulic punching tool can be used for stainless steel material, square and rectangular holes.

For the full technical specification visit ⮕ LS 50 Flex Hydraulic Punching Tool

Should you require technical support, product information or a UK demonstration of the LS 50 Cable Punching Tool please do not hesitate to contact us.

Hydraulic Punching Tool Klauke LS 50 FLEX BATTERY Powered

KLAUKE ORANGE

Klauke Orange Tools

Klauke have launched the Orange range of fully insulated cable crimping & cable cutting tools.

The Orange range of insulated tools is a technology advance in the development of battery-powered cabling tools for the cutting and crimping of overhead lines and underground cables.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV