Blog

A Day of Medium Voltage Jointer Training

August 10th, 2020Images Courtesy: Sjoerd Keijzer

A following sequence of photographs document a day of medium voltage training by some participants in the Jointer Training Center of GOA Leidingtechniek, The Netherlands.

The cable accessories used included NKT 72kV Cable Termination & Joint, Elcon Megarad 72kV Heatshrink Termination, SPS Heatshrink Joint, 3M Coldshrink Joint and Screened Separable Connector from Nexans Euromold.

Some things went very good, some went reasonable, and some things went completely wrong. But the motivation to learn and to do a very good job is perfect. And I told them again, you can’t learn experience, for that you need a lot of practice.

Nobody can be a cable jointer with a training course of 5 or 6 days.

For quality you need a lot of training and experience but I promise everyone that these guys will get there. You are going to be a great jointers. You only need time, motivation, practice, more time, more practice and love for your work.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Why Cable Manufacturers Want Their Jointers to be Certified

August 10th, 2020Republished with the Kind Permission of Sam Soady

Eccentricity Pty Ltd Director /HV Operator / Cable Jointer

Jointer Training & Certification

With cables and cable accessory technology on the rise, high voltage cables are becoming easier and easier to work with.

There was once a time where underground cable joints on old paper insulated cables was an incredibly involved task.

Some joints you had to pour melted solder into a lug connector to make an electrical connection. These days manufacturers have developed a much easier approach to jointing and terminating high voltage cabling.

Plastic XLPE cables are at the forefront of the industry, providing a more adaptable approach to the varying types of installations in the industry.

With a wide variety of cable accessories which now range from heat shrink, cold shrink or slide on components it has opened the door for unqualified personnel trying their luck with terminating and jointing high voltage cables.

Basic electricians on construction jobs around Australia were attempting to join and terminate these cables with minimal training or experience. This resulted in a multitude of cable failures once energized.

Contractors were trying to claim their manufacturer warranties under the assumption that the cable accessories were the cause for the failures. Once manufacturers began to dissect the installations it became evident that poor workmanship of the cable preparation for termination was the cause of the failures.

This put a lot of stress on the industry as it diminished the integrity of quality jointers and their high standards of workmanship.

Manufacturers began to provide training on cable preparation techniques suitable for specific types of cable accessories. No longer was it a requirement to have a jointers license to work on high voltage cables.

This had a severe negative effect on the industry as the quality of installations became worse and worse over time and more and more failures were occurring.

This forced some regulation into the industry requiring not only jointers to be fully qualified by obtaining a jointers license but also have manufacturer specific training on the cable accessories to be used on an installation. This then ensured that contractors utilising suitably qualified and trained personal would not void their warranty with the manufacturer.

For already fully qualified jointers this was a frustrating scenario as it forced them to obtain manufacturer specific training for products even when their licenses already proved their competency. Manufacturer training generally was not a cheap process however it did clean up the shotty workmanship in the industry rather quickly.

Contractors now generally do not consider training general electricians for specific tasks but rather hire suitably qualified and competent personal to ensure the integrity of their installation is maintained.

See further information about Jointer Training & Certification | 66kV Training | 11kV 33kV Jointer Training Nexans | 33kV MV HV EHV Training Pfisterer CONNEX

About Eccentricity

Eccentricity is a specialised Brisbane based company with a team of dual trade electricians and cable jointers. Our technicians are fully qualified to work on cables up to 66kV, including XLPE, PILC and EPR cables, backed by over a decade of industry experience.

With a modern and fully compliant fleet of industry vehicles, we are capable of accessing any high risk environment to perform works with a wide range of major MV HV cable jointing projects including, mining, oil, gas, renewable energy, and high voltage transmission networks.

Eccentricity has the capacity for small or large scale projects, providing reliability of power networks wherein client satisfaction is a top priority. We provide a high level of quality with all aspects of both installation and commissioning, ensuring we comply with all relevant regulations and legislative provisions.

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

Jointing, Earthing, Substation Electrical & Safety Equipment Distributors

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Access Chambers | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex

How To Locate An Oil Leak In A 12km Circuit Of LPOF PILC 115KV Direct Buried Cable

August 10th, 2020All Images Courtesy Of: Douglas Page (Instructor & Cable Splicer at Hydro One Training and Development Services)

High Voltage Cables

Fluid Filled Cable Leak Detection

33kV 66kV 132kV 245kV 400kV

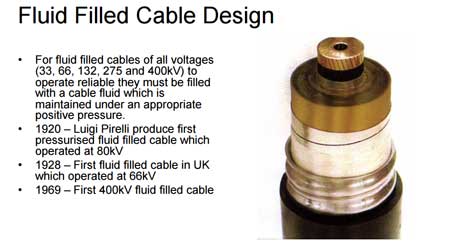

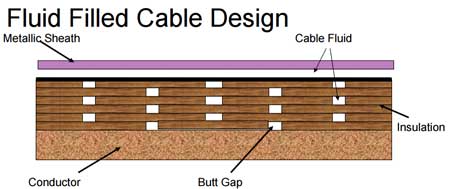

Fluid filled high voltage cables have been used for over 80 years with some circuits installed in the 1930’s still operating successfully today without any deterioration.

The fluid contained within a fluid filled cable has to be kept at a positive pressure under all conditions of loading and ambient temperature change.

Fluid filled cables rely on the presence of pressurised cable fluid to work efficiently – if the circuit suffers an oil leak the cable network is compromised.

The pressure used depends on a number of factors:

- Voltage and size of cable

- The length of the cable

- The route the cable follows

- Whether the cable has a leak

The fluid forms an integral part of the high voltage cable insulation and prevents the formation of voids in the lapped papers around the conductor – also the cable fluid aids the conduction of heat away from the conductor allowing the cable to be run efficiently than a cable without it.

The following photo sequence shows how to find a single drip of oil in approximately 12km of Single Core LPOF PILC 115KV direct buried cable.

LPOF Low Pressure Oil Filled

PILC Paper Insulated Lead Covered

1. Cathodic lead erosion is clearly visible on the EHV power cable – this is usually caused by ground factors such as gas mains, neighbouring cable circuits, water mains etc. The aged underground EHV cable is suffering natural degradation and overtime a deterioration in the cables normal cathodic protection has caused service issues with the cable circuit – the cable becomes the sacrificial anode and starts to break down.

2. Cable type: Transmission & Distribution Voltage – 115kV LPOF PILC Single Core.

3. LPOF EHV cables are monitored by gauges and pressurised by pre-pressurised tanks with internal baffles, that expand and contract with the cable, maintaining a constant pressure. If the pressure cannot be maintained, an alarm is triggered.

4. To find the oil leak in 10, 15, 20, or 100km of cable, it all starts the same way. Find the approximate centre of the cable circuit, excavate safely and install a cable freeze.

5. Very similar to a pipe type freeze, the coil must be installed on the bare lead.

6.

7. Along with a freeze, to monitor the temperature, the EHV jointer/splicer must install thermocouple temperature monitors which consist of two conductors of dissimilar metals that react to the temperature change differently allowing the monitors to display the actual temperature.

8. Then the freeze is insulated by the EHV cable/splicer.

10.

11. Once the freeze has been initiated, the gauges are monitored, the side that loses pressure, is flagged and deemed the side that requires further attention.

12. Freeze pit – once the leak has been narrowed to 50-100m length, the final excavation begins. Until signs of leaking cable oil are found.

14. After a lengthy search, this is what you are looking for, although opinions vary, constant drip can yield various amounts of accumulation. Some say it could fill a bathtub in 72 hours.

15. Once located a temporary EHV cable repair is made, while environmental remediation is done.

16. “Tinning” of the cable repair, so the lead will adhere to the cable.

17. The EHV cable repair is complete – after this the jointer must solder a copper lead connected to a sacrificial “anode” that erodes before the cable.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

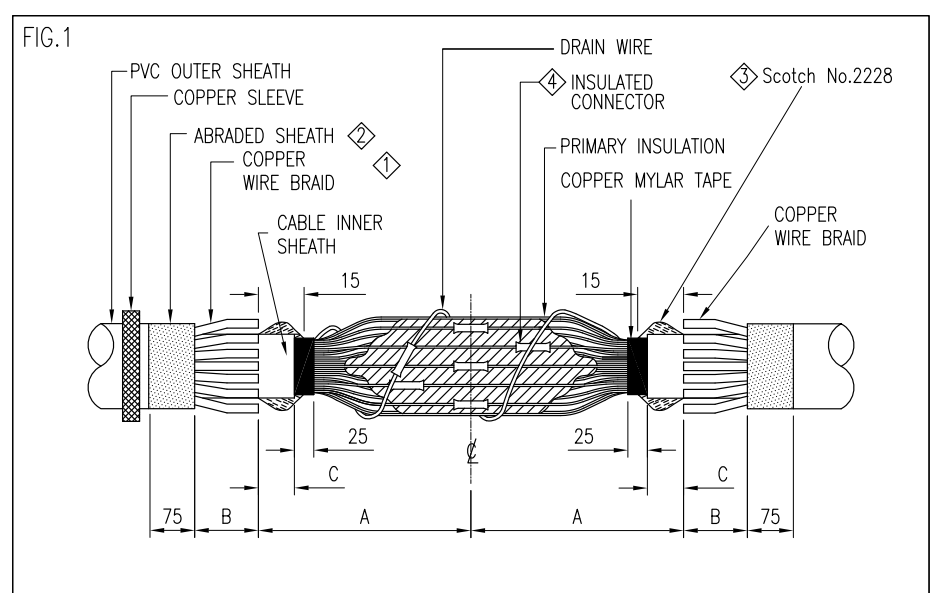

Jointing Instrumentation Cables with Mylar Screen

August 6th, 2020Thorne & Derrick supply 3M, Prysmian, Filoform and SPS low voltage cable joints suitable for connecting and jointing single and multi-core/pair power, control and instrumentation cables up to 600/1000V (3.3kV) in industrial and hazardous area locations – specialist applications include fire resistant, low smoke zero halogen, hydrocarbon resistant and utility cable joints.

Cable joints are available from stock in several technologies to suit the low voltage (LV) installation application and cable type to be repaired or jointed; this includes i) Cold Shrink ii) Heat Shrink and iii) Resin.

This includes Jointing Instrumentation Cables with Mylar Screen.

For the connection and jointing of the instrumentation cable conductors we can recommend Scotchlok 314 type Insulation Displacement Connector.

Jointing Instrumentation Cables with Mylar Screen

Cable Joints LV Low Voltage | Cold Shrink | Heat Shrink | Resin | 600/1000V 3.3kV

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Ellis Patents Lead The Way With Cable Cleat Calculator Innovation

August 6th, 2020

Ellis Patents Cable Cleat Calculator

Ellis Patents Cable Cleat Calculator

by Thorne & Derrick | Ellis Patents UK Distributor

Tool To Help With Cable Cleat Selection

Ellis Patents has once again demonstrated why they stands alone as the cable cleat market’s leading innovator – having developed an online calculator that will provide users with completely accurate specification information for any project in a matter of seconds.

The cable cleat calculator provides correctly specified cleat spacings with respect to short circuit conditions; and recommends the ideal products for that specific project. This is achieved through a pre-programmed calculation that takes into consideration cable formation, cable size, short circuit current and the installation environment.

The questions asked in this calculator are designed to provide Ellis with the proper information to specify the correct cable cleat for your project. The questions consider cable formation, cable size, short circuit forces and the installation environment only.

It should be noted that issues such as cable weight for vertical cable runs, thermo-mechanical forces, extreme environmental conditions (e.g. extreme temperatures, industrial pollutants etc.) and any other non-standard cable installation factors have not been considered.

Thorne & Derrick distributors for Ellis Patents should be made aware of these issues should they be present for your project.

PEAK VS RMS CURRENT

The formula uses peak current, however this is often unavailable with a Root Mean Square (RMS) value given instead. To calculate the peak current from the RMS, IEC 61439-1 Low voltage switchgear and controlgear assemblies is commonly referred to, which uses the following multiples:

10kA < I ≤ 20kA Multiply by 2

20kA < I ≤ 50kA Multiply by 2.1

50kA < I Multiply by 2.2

INTERMEDIATE Cable STRAPS

The use of intermediate straps are not considered within the calculator.

The below table details the straps suitable for each cleat whereby the cleat to cable strap spacing is the same as the calculated cleat spacing.

FLEXI-STRAP (SD) and PROTECT: VULCAN+, VULCAN+ QUAD, TRIDENT, ALPHA, VARI-CLEAT

FLEXI-STRAP (HD): EMPEROR, COLOSSUS

FIXED INTERVAL SPACING

For fixed interval spacing applications such as cable ladder, the calculated cleat spacing should be rounded down to the closest possible interval. In the example of standard cable ladder which provides a cleat mounting surface every 300mm, should the calculated spacing be 0.8m the spacing to suit cable ladder should be rounded down to 0.6m.

CALCULATION ASSUMPTIONS

- Multiplication factor of 2.2 used to convert RMS to peak (based on IEC 61439-1).

- Spacings given may only be suitable for a category 1 short circuit for certain products. Refer to Ellis to confirm whether category 2 criteria can be applied to the product spacing calculation provided.

- Spacings for No Bolts Cleat assume a worst case scenario of a stacked formation. Larger spacings can be achieved if the cleat is fastened separately, refer to Ellis for more details.

- Spacings for the 2F+ clamp assume the strength throughout the range is consistent. In reality it changes considerably and larger spacings may be achievable for larger cleats as the lowest strength has been assumed in this calculator.

- Ellis have strived to ensure that the results generated by the calculator are accurate and correct at the time of use, it is however recommended to contact Ellis to confirm the calculated spacing is suitable prior to order placement. All calculated spacings are based on the results of short circuit testing to IEC 61914.

Stephen Walton, Technical Director of Ellis Patents, said: “Correctly specifying cable cleats and the spacing that the cleats need to be installed at is vital in ensuring they function properly when called onto cable management systems. Until now, specifiers and planners needed to make the calculation using a complex formula, and then interpret these results into product type, quantity and exact spacing.”

“Our cable cleat calculator removes this complicated mathematical element from the specification process; and replaces it with a fool proof option that provides the correct cleat specification quickly and easily.”

Ellis Patents designs and manufactures all of its cable cleats in North Yorkshire, and has a global reputation for both its products, and its proven ability to solve problems through innovative thinking. This has seen the company create new products in live project situations for the likes of Balfour Beatty and Siemens; and cure a major health and safety installation headache for Network Rail.

“Our innovative approach to product and service development has served us well over the years; opening many doors that would have remained firmly shut to more traditional manufacturers,” continued Stephen.

“With the cable cleat calculator I’m confident this single online tool will have the biggest impact of any of our innovations to date; as it really does have the potential to be adopted as an industry essential across the globe.”

Ellis Patents Cable Cleats | UK Manufactured Cable Restraint & Support Products

FURTHER READING

- IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

- Fire Resistance & Cable Cleats – Surviving Fire, Flame & Extreme Heat

- Triplex Cleats – Selection Guide for Cleating 11kV BS7870 Part 4.10 Cables

- Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

- Ellis Patents Cable Cleats & Cable Basket Tray for Securing High Fault Level Cables

- Stainless Steel Cable Cleats v Ties – The Myths Debunked By Ellis Patents

- Cable Cleats from Ellis Patents | Better By Design

Thorne & Derrick | Ellis Patents UK Distributors

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV