Blog

Arc Flash PPE | 7 Top Considerations

February 3rd, 2020-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

The WRONG ARC FLASH PPE CAN COMPROMISE YOUR TEAM’S SAFETY

Personal Protective Equipment – There are lots of factors to consider when choosing and specifying the right arc flash PPE for your team. We highlight some of the areas that you might not have given as much thought, to help you make the best-informed decision for everyone involved.

This Blog gives an insight into some of the top considerations when it comes to PPE – delivered by experts ProGARM.

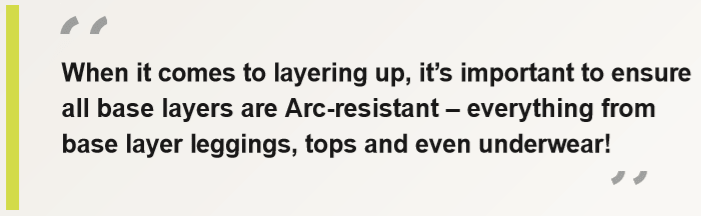

LAYERING

There can be serious consequences if arc flash protection (PPE) is compromised. All layers of clothing need to be considered when protecting against Arc Flash.

The material worn beneath an Arc Flash protective jacket is just as crucial as outer clothing.

Arc flash protective undergarments – The risk of mixing non-arc layers with arc-rated clothing

Making the right PPE choices for your team can be a real challenge. You must weigh up several factors: comfort, fit, durability and value for money to name but a few. But what can happen when you start to mix a variety of garments that offer different levels of protection or meet different standards?

While flames caused by an Arc Flash may not actually come into contact with the skin through protective outer layers, the extreme heat from the Arc Flash can melt materials used to manufacture everyday undergarments such as nylon, cotton and polypropylene. This will inflict burns on an operative and potentially cause non-Arc Flash protective undergarments to melt into the skin underneath their PPE.

ARC FLash PPE

Flame retardant VS. ARC FLASH CLOTHING

Flame retardant doesn’t mean arc flash resistant.

With all the different safety standards surrounding safety clothing, it can be confusing understanding the extent to which each standard covers in terms of protection. We outline how Arc Flash clothing differs from flame retardant garments and the reasons why.

There are separate safety standards for Arc Flash clothing and fire resistance, meaning that the level of protection provided by fire-resistant clothing does not match that or arc flash resistant personal protective clothing.

Products certified from May 2019 onward will use the new icon, which is on the right.

INHERENT VS. TREATED FABRIC

Not all Arc Flash clothing is made using the same fabric types, we help you identify the difference between inherent and treated fabrics so you’re up to speed with the clothing choices available to you.

The two phrases regularly used when shopping for appropriate PPE clothing are ‘treated fabric’ and ‘inherent fabric’. Treated fabric is made from fibres which are not flame retardant by nature but have undergone a chemical process to add a fire-resistance quality to them.

Download the full guide here for more tips on Arc Flash PPE considerations.

ProGARM delivers ultimate arc flash clothing and protection, conforming with the relevant industry and EN standards ensuring protection from arc flash incidents for workers carrying out installation or maintenance of LV Low Voltage, MV Medium Voltage or HV High Voltage power systems.

Arc Flash Protection

The dangers of Arc Flash incidents and the importance of protection from these hazards has never been as significant as it is today. This prominence will continue to increase over the next few years.

With multiple cable strikes every day in the UK and numerous major Arc Flash incidents, businesses are looking at how best to protect their team with the right Flame Resistant garments and accessories, including arc-rated gloves. The correct clothing can significantly reduce injury and save lives.

ProGARM and Thorne & Derrick are committed to continual research and improvement to innovate and develop their range of arc flash clothing as quickly as possible to bring you the best Arc Flash protection for your team – this includes hand protection against flash incidents using arc-rated gloves.

WHAT IS AN ARC FLASH?

An electric arc occurs whenever a circuit breaker, switch or isolator (Device) is opened and when there is current flowing in the circuit. However, most devices under normal operating conditions are designed to control the arc when opening or closing.

An arc flash may occur when the arc is uncontrolled and there is sufficient energy released to cause harm or damage.

Arc flashes occur both at high voltage and low voltage. There is little discrimination: low voltage arc flashes injuries are just as damaging at high voltage injuries.

Put simply: An arc flash is the light and heat produced from an electrical arc supplied with sufficient energy to cause significant damage, fire or injury.

An arc flash can cause minor injuries, third-degree burns and potential death as well as other injuries including blindness, hearing loss, nerve damage and cardiac arrest. Fatal burns can occur when the victim is several feet from the arc. Serious burns are common at a distance of 10 feet – arc flash can generate heat 4 times greater than the surface of the sun.

The dangers of an Arc Flash

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Cable Winch | Customised & Refurbished 5 Tonne Cable Pulling Winch

January 30th, 2020

Cable Winch

-

uploaded by Chris Dodds - Sales & Marketing Manager with Thorne & Derrick International

Thorne & Derrick, the Specialist Distributor of LV HV Jointing, Earthing, Substation & Electrical Eqpt have supplied a cable winch requirement to a leading provider of offshore power distribution to the renewable and oil/gas sectors.

The refurbished and customised 5 tonne cable winch was customised to enable the pull and installation of medium/high voltage power cables – the winch was delivered within 2 weeks from receipt of client order. The cable winch enabled the installation of cable runs up to 120 metres from the variable frequency drive (VFD) to the compressor junction box which goes from underground cable trench to above ground and onto the cable containment ladder racking system.

within 2 weeks from receipt of client order. The cable winch enabled the installation of cable runs up to 120 metres from the variable frequency drive (VFD) to the compressor junction box which goes from underground cable trench to above ground and onto the cable containment ladder racking system.

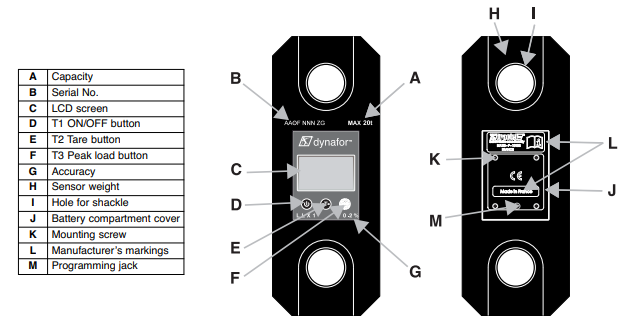

The cable winch modification was based on the standard SEB TW5000 version with additional cable tension dynamometer – the dynamometer continuously checks the cable pulling tension to ensure the forces do not exceed the recommended guidelines.

Additional features Pre-Set Load Function, Load Display, Test Certification & Load Cell.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and rollers.

Olex Cable Joints | 20kV

January 30th, 2020

Product Application & Solutions | Jointing & Terminating LV MV HV Cables

- Cable Manufacturer: Nexans

- Cable Brand: OLEX

- Cable Voltage: MV HV 12.7/22kV (20kV)

- Cable Description: Single Core 240sqmm Stranded Compacted H68 Aluminium, Semiconductive Conductor Screen (0.3mm), 12.7 / 22kV XLPE Insulated (6.6mm nom wall), Strippolex Insulation Screen (0.6mm min wall), Helical Copper Tape Screened, PVC (5V-90), Sheathed (2.8mm nom wall) generally to cable specification AS 1429.1

- Cable Joint Type: Heat Shrink

- Cable Joint Kit Installation: Instruction

- Manufacturer: Shrink Polymer Systems

- Customer Service: Same Day Kit & Despatch of custom specification Olex cable joints to suit above cable specification complete with mechanical shearbolt connectors.

- Client: Aughinish Alumina is Europe’s largest alumina refinery and technologically advanced and energy efficient facilities worldwide.

Olex Cable Joints

Joints & Terminations

➡ Shrink Polymer Systems heatshrink cable joints and terminations suit all types of MV-HV electrical cables (single or multi-core) with or without armour or lead sheaths – zero halogen and fire resistant cable joints are also available.

Olex Cable Joints

Bevelling The Edge Of The Core Insulation During Installation Of Nexans Euromold Connectors – Part 3

January 29th, 2020

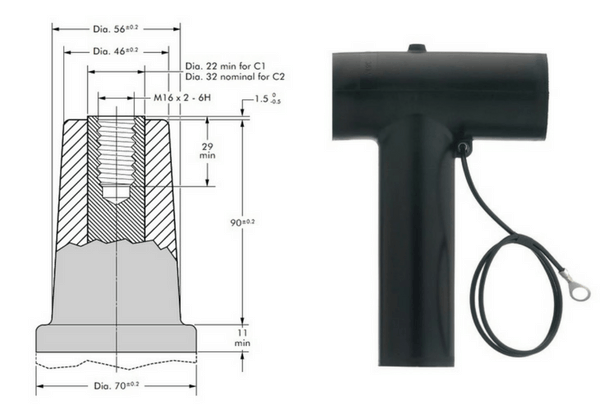

Euromold Connectors

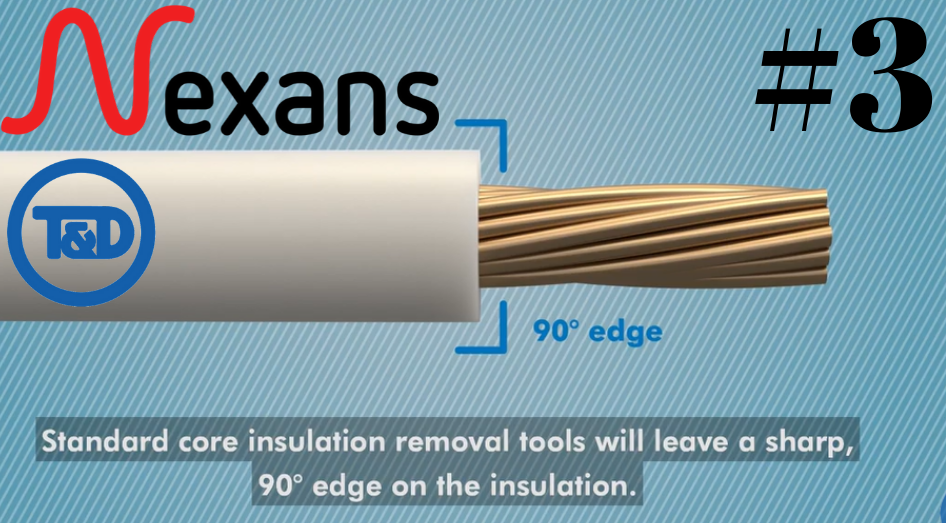

Bevelling The Edge Of The Core Insulation During Installation

In this Webisode Nexans discuss bevelling or chamfering the edge of the core insulation during installation of the Euromold connectors.

Carefully read the installation instructions that come with the separable connector kit in order to perform the correct preparation for the specific cable you have at hand. For most cable types, the first steps are the removal of the cable outer sheath and removal of the semi-conductor screen.

Then remove the core insulation from the conductor. Standard core insulation removal tools will leave a sharp, 90° edge of the insulation. If not taken care of, this might damage the inside of the cable accessory during installation.

A sharp edge will also scrape off silicone grease, making it more difficult to install the cable adaptor for the Euromold connector.

So to avoid cable damage and to assure an easy slip-on of the cable accessory, the edge of the core insulation should be bevelled using an appropriate tool. Tools that provide a 45º chamfer are often used in the field, but tools that provide a smooth radius are even better.

For some conductor sizes, an installation tool is available to further ease the installation of the cable adaptor.

Nexans Euromold Separable Connectors | 33kV MV HV Elbows Tees Plugs

Further Reading

- Water Sealing, IP Rating & Temperature Range Of Nexans Euromold Connectors

- Different Insulating Epoxy Plugs & How To Install The Cap On Nexans Euromold Interface C Compact Connectors

- Installation & Clamping Of Nexans Euromold Compact Connectors Onto Their Mating Bushings

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at medium/high voltages.

Thorne & Derrick hold large stocks of 11kV 33kV 66kV Joints & Terminations suitable for XLPE, PILC and EPR cables, in both heat shrink and Cold Shrink technologies, to service the medium/high voltage power cable accessory requirements of UK and international customers.

Different Insulating Epoxy Plugs & How To Install The Cap On Nexans Euromold Interface C Compact Connectors – Part 2

January 29th, 2020

Nexans Euromold Interface C Compact Connectors

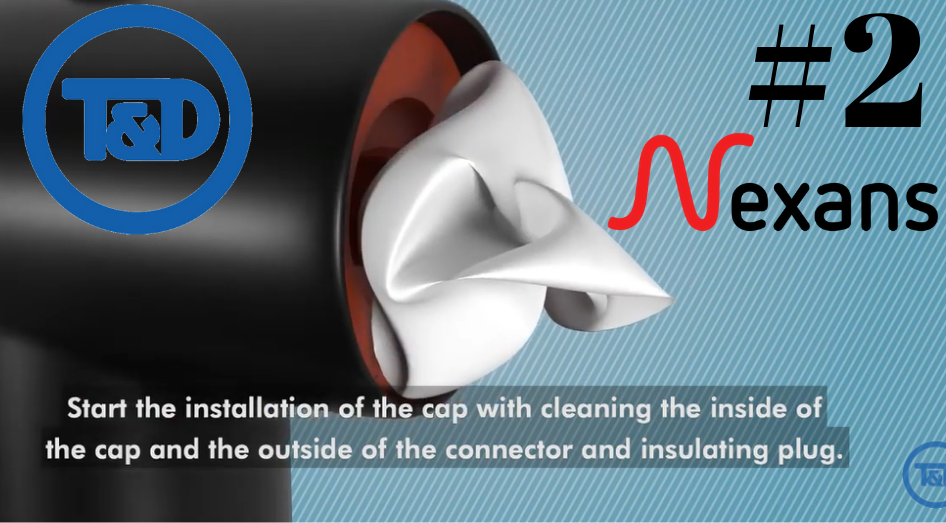

Different Insulating Epoxy Plugs & How To Install The Cap

In this Webisode Nexans will discuss the different Epoxy Plugs and how to install the cap on the Euromold Interface C Compact Connectors.

When your maximum medium voltage system is 24kV, you can see the Euromold BIPR insulating epoxy plug without locking point during the installation of the separable connector.

When the maximum medium voltage system is higher than 24kV, such as 33/36kV, you have to use the Euromold BIPA insulating plug. This epoxy plug has a metallic voltage detection point with a locking point on the top that must be connected to the cap.

- Start the installation of the cap with cleaning the inside of the cap and the outside of the Euromold connector and insulating plug

- Place the nylon vent rod along the insulating plug to exhaust air during cap assembly

- Then push the cap firmly over the connector and onto the insulating plug until it cannot advance any further. Only when use the BIPA insulating plug you have to press the centre of the cap onto the locking point until it snaps into place

- Press the cap on all sides to make sure it is well positioned over the connector. The pulling tab of the cap needs to be positioned downwards. Remove the nylon vent rod

- Re-press the centre of the cap onto the locking point to ensure it is still in place

Failure by the Jointer to observe the above procedure can lead to premature Partial Discharge development and consequently product failure of the Connector terminated onto the MV HV switchgear or transformer bushing interface.

Interface C Compact Bushings

Nexans Euromold Connectors, Plugs, Elbows, Bushings & Surge Arresters

Further Reading

- Water Sealing, IP Rating & Temperature Range Of Nexans Euromold Connectors

- Bevelling The Edge Of The Core Insulation During Installation Of Nexans Euromold Connectors

- Installation & Clamping Of Nexans Euromold Compact Connectors Onto Their Mating Bushings

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

Heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at medium/high voltages.

Thorne & Derrick hold large stocks of 11kV 33kV 66kV Joints & Terminations suitable for XLPE, PILC and EPR cables, in both heat shrink and Cold Shrink technologies, to service the medium/high voltage power cable accessory requirements of UK and international customers.