Blog

EHV Cable Joint – LS Cable 240kV 3000 KCMIL XLPE Cable Circuit

October 9th, 2019

- Application: EHV Cable Joint – LS Cable 240kV 3000 KCMIL XLPE Cable Circuit

- Cable Type: LS Cable 240kV 3000 KCMIL XLPE Cable Circuit

- Cable Jointer: Andy O’Malley (IBEW 258 EHV Cable Jointer / Cable Splicer – Allteck Line Contractors)

EHV Cable Joint

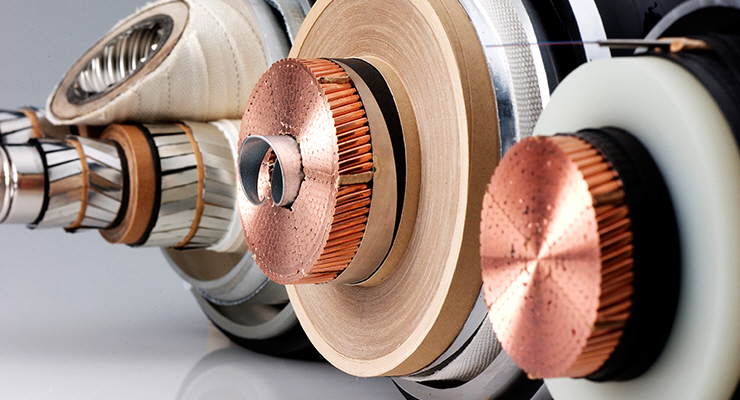

Clean joint bay and cable preparation with copper conductor, aluminium foil laminate with aluminium screen wires. Clean and perfectly straight cable installations such as this are unfortunately rare.

Cable jointing skill-sets are not automatically transferred up the voltage classes from 11kV to 33kV and onto 240kV.

Different techniques and technologies are applied to jointing EHV cables including polymeric, paper lead, oil, fluid-filled and transition jointing using ABB, Ericsson, Nexans, Brugg, Pfisterer Ixosil, Silec and Tyco type products.

Should you require any assistance with the selection or specification of cable joints or terminations please do not hesitate to contact us.

LS Cable & Systems

Extra-high voltage cables require the power network to go underground due to continuous increase of energy demand, larger transmission capacity, reliability of energy supply, safety and aesthetic issues. Among these cables, XLPE insulation cables are used widely due to their ease of handling, simpler jointing connectivity and maintenance, outstanding electrical features and other benefits.

XLPE Cables

The basic material for XLPE is polyethylene, which is chemically transformed to cross-linked polyethylene (XLPE) through the cross-link reaction of organic peroxides. The cross-link method for polyethylene was developed in the United States during the 1950’s and has since been continuously developed for application to higher voltage cables. Higher voltages are increasingly being required and now 500kV XLPE cables have already been commercialized by LS Cables.

Further Reading

- 132kV Termination Pfisterer IXOSIL EST SUB Cable Termination

- ABB NKT SMPGB Straight Cable Joint 420kV

- 3M Scotchcast Cable Joint – Resin & Taped Manhole Cable Splice 600/1000V

JOINTERS BLOG

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

15,000+ Subscribers. ➡

Cable Cleats – Costs v Quality

October 9th, 2019

Ellis Patents Cable Cleats

Cable Cleats

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

Ellis Patents based in the UK are world leading manufacturers of cable cleats and cable clamps used to clamp and support LV-MV-HV cables – this includes 11kV-33kV medium/high voltage power cables in single, trefoil or bundled formation.

Ellis Patents are global leaders in the innovation and manufacture of nylon cable cleats, aluminium cable cleats and stainless steel cable cleats – Ellis satisfy the operational requirements of the construction, oil, gas, rail, utilities, wind energy and power generation industries.

Stephen Walton Technical Director Ellis Patents

Stephen Walton, Technical Director of the world’s leading cable cleat manufacturer, Ellis Patents, recently bought a home in need of complete renovation. While pondering how he could extend the number of hours in a day in order to get the project finished, he also found himself asking the age old question – ‘Why don’t they build them like they used to?’

“Taking on a renovation project probably isn’t the most sensible thing I’ve ever done; especially when you consider I have a challenging full-time job and a rapidly growing son. But my wife and I had been in the same house for ten years, and it was fair to say we’d outgrown it.

We could have bought a brand new house on a nearby development, but instead we opted for a 1930’s property that needed fully refurbishing.

Why? Well, in my experience buildings today are built for a price, and not for the long term – a view that has been backed up by many of the tradesfolk who have been to the new house, and have all commented on the build quality of it compared to today’s new build homes.

I realise this sounds like I’m teetering on the edge of a grumpy old man rant about how things were better in the old days, but I’m not. I believe we live in the most exciting of times, and that the technology we have access to enhances our lives in a myriad of ways – whether at home, work, play or anywhere in between.

But advances in technology don’t necessarily mean improvements. In the 1930s, houses were built in a robust way as the mentality was different. Yes, cost was an issue, but longevity was key. Over the following 90 years industry mastered the art of producing products that will survive the required life span, but no more.

Described as the bathtub curve, this approach has been developed so costs can be cut to the bone, while products will only last as long as absolutely necessary. Some consider this is efficient, but for me it’s a clear case of going too far in the pursuit of margin.

The Hackitt Report, which was commissioned following the Grenfell Tower tragedy, takes a hard hitting attitude towards bathtub building methods; citing a lack of responsibility and commitment to safety in the industry.

The report insists on major change, in particular that systems as a whole are considered, rather than individual manufacturers testing their own products in isolation, which is very much accepted current practice.

Earlier in my career I worked in the subsea oil and gas industry, and during that time the Gulf of Mexico Macondo incident led to the kind of sweeping change that Dame Hackitt want to see.

The industry had become complacent and a series of failures contributed to the disaster. Post Macondo, documentation requirements increased significantly, and many more FMECA reports were needed.

Applauding what the subsea, oil and gas industry has achieved is easy, but a great deal of that has been down to exceptional internal housekeeping.

In contrast, the task the construction industry has been set requires wholesale change from manufacturers up – and once again that brings the bathtub curve back into play.

At Ellis we design, manufacture and supply cable cleats that are tried, tested and trusted around the world. We rigorously short-circuit test all of our cleats to ensure they will do the job they are designed for – that is to keep powerful electrical cables secured in short-circuit situations. And we don’t stop there.

We offer project specific testing, so that those specifying and installing our cleats do so safe in the knowledge that they are perfectly suited for that particular project. And still we don’t stop.

We are called in with increasing regularity by the likes of Siemens, Balfour Beatty and National Rail, to design bespoke solutions to solve problem installations or help consign health and safety issues to history.

Over the years we’ve banged the drum about the importance of cable cleats; reacted to a veritable flood of cheap and unsafe markets by focusing on the vital importance of correct specification; celebrated the introduction of British, European and International standards governing the use of cleats; and welcomed the arrival of others to into the market who read from the same hymn sheet as we do.

What this has all meant is that today I can confidently state the vast majority of cable cleats specified and installed in any major project, virtually anywhere in the world, are selected because of their proven quality as opposed to being selected solely on price. A position that certainly means the bathtub curve has been smoothed over.

But moving forward will this victory for quality over cost be enough? And if not, where does the responsibility for whole system testing fall? Individual manufacturers coming together to test and sell whole project solutions as opposed to their own, often highly specialised, products? Specifiers? Contractors? Installers?

Sitting in the stripped down shell of my 1930s refurbishment project, I feel whole system testing is a step too far. This house was built at a time when buildings were built to last, and the quality of products used during construction were deemed far more important than their cost.

If, post Hackitt, the building industry can return to those days – and thus shelve the cheap and often unsafe products that have been responsible for so much heartache –; then the question we’ll be asking in years to come will no longer be “why don’t we build them like we used to?”, but “why didn’t we always build them like this?”

Ellis Patents Cable Cleats

Further Reading

- IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

- Fire Resistance & Cable Cleats – Surviving Fire, Flame & Extreme Heat

- Triplex Cleats – Selection Guide for Cleating 11kV BS7870 Part 4.10 Cables

- Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

- Ellis Patents Cable Cleats & Cable Basket Tray for Securing High Fault Level Cables

- Stainless Steel Cable Cleats v Ties – The Myths Debunked By Ellis Patents

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

➡ Read: Thorne & Derrick Announce Distribution Agreement & Contract With Nexans

IECEx Cable Gland Selection Guide For Hazardous Area Zones

October 9th, 2019

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

In this Blog titled IECEx Cable Gland Selection Guide For Hazardous Area Zones we will cover the following sections of the classification and guidance document for the selection of cable glands for hazardous areas:

- Cable Type / Cable Gland Type

- Hazardous Area Protection Method

– When to use a Barrier Gland - Environmental Conditions

- Installation / Inspection Considerations

Credit to ➡ International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres (IECEx System).

Cable type & Cable gland type

Unarmoured

W – Single wire armour SWA

or Aluminium wire armour AWA

X – Braid

T – Pliable wire armour

Y – Aluminium strip armour

Z – Double steel tape armour

A – Single seal only

B – Armour clamp only

C – Armour clamp and seal on outer sheath

D – Armour clamp and seal on inner sheath

E – Armour clamp and seal on inner and outer sheath

Each cable gland type has sub-sets:

e.g.

E1W = E1W cable glands with IP66 seals on inner and outer cable sheath

E2W = As E1W type cable gland but E2W cable glands are with an electrical bond for a metallic inner sheath (e.g. lead sheathed cable)

Cable glands are often named to describe their function, e.g. E1FX, E1FW.

Cable Gland Size

The cable gland size must be selected to match the cable size.

IEC 60079-14:10.2 Selection of Cable Glands

The cable gland shall be selected to match the cable diameter. The use of sealing tape, heat shrink tube or other materials is not permitted to make the cable fit to the cable gland.

Hazardous Area Protection Method

Ex d / Ex e / Ex nR

The protection method MUST meet or exceed the protection level of the equipment that the cable gland is connected to. This is a requirement of IEC 60079-14: Clause 10.2.

Extract from Table 10 of IEC 60079-14

| Explosion Protection Technique For The Equipment | Cable Gland Protection Technique | ||

| Ex d | Ex e | Ex nR | |

| Ex d | X | ||

| Ex e | X | X | |

| Ex nR | X | X | X |

| Ex i Group II | X | X | X |

| Ex p | X | X | X |

When to use a barrier gland

Barrier glands are always certified Ex d, but can be used in an Ex e environment.

How do you know when to use them?

When to Use a Barrier Gland – Ex d

A barrier gland MUST be used in an Ex d environment unless the cables:-

- Circular and compact

- Have an extruded bedding or sheath

- Use non-hygroscopic fillers

Old Rules in IEC 60079-14

New Rules – Barrier Gland Ex d

The cable entry system shall comply with one of the following:

a) Cable glands sealed with setting compound (barrier cable glands)

b) Cables and glands meeting all of the following:

– cable glands comply with IEC 60079-1 and are certified as equipment

– cables used comply with 9.3.2(a)

– the connected cable is at least 3 m in length;

c) indirect cable entry using combination of flameproof enclosure with a bushing and increased safety terminal box;

d) mineral-insulated metal-sheathed cable with or without plastic outer covering with appropriate flameproof cable gland complying with IEC 60079-1;

e) flameproof sealing device (for example a sealing chamber) specified in the equipment

documentation or complying with IEC 60079-1 and employing a cable gland appropriate to the cables used. The sealing device shall incorporate compound or other appropriate seals which permit stopping around individual cores.

The sealing device shall be fitted at the point of entry of cables to the equipment.

The cable entry system shall comply with one of the following:

a) Cable glands sealed with setting compound (barrier cable glands)

b) Cables and glands meeting all of the following:

– cable glands comply with IEC 60079-1

– cables used comply with 9.3.2(a)

(They shall be circular and compact. Any bedding or sheath shall be extruded. Fillers, if any, shall be non- Hygroscopic)

– the connected cable is at least 3 m in length

The HSE in the UK has issued a bulletin stating that installations to the ‘new rules’ may not be safe and has suggested that the old flowchart used.

If in doubt USE A BARRIER GLAND.

➡ CMP PX2K-REX RapidEx – Revolutionary Sealing Solution for Barrier Cable Glands

Barrier Glands

When to use a Barrier Gland – Ex d

Barrier glands should also be used:-

- In Ex e applications when there is a risk of gas migrating down a cable. (IEC Ex 60079-14 clause 9.3.2)

- In Ex nR applications where the cable is not sealed. (IEC Ex 60079-14 clause 10.8)

Modern ‘liquid resin’ barrier glands are easy to install.

Environmental Conditions

Four main areas to cover in this section:

• Temperature

• Ingress protection (IP)

• Dissimilar metals

• Corrosive environments

Temperature

- Cable glands do not have a ‘T’ rating

- Under existing IEC Ex rules, the temperature rating of a cable gland does not have to include the thread sealing gasket

- Responsible cable gland manufacturers test and certify their cable glands and sealing gaskets together

Ingress Protection (IP)

A sealing gasket may be needed to maintain the IP rating of the assembly.

(IEC Ex 60079-14 clause 10.2)

Check that the thread sealing washer has been tested with the cable gland as part of the certification process. (The IP rating will be shown on the IEC Ex certificate.)

Dissimilar Metals

- Ideally the cable gland should be made of the same material as the equipment and the cable armour it is connected to

- For most equipment electroless nickel plated brass is the best option

Brass gland fitted to an aluminium enclosure

Superior Marine grade nickel plated brass gland fitted to an aluminium enclosure

Corrosive Environments

Corrosive environments may typically include:-

- Salt / salty water

- SO2

- NH3

For many corrosive environments a good quality nickel plated brass cable gland is the best choice

- Not all plating is equal

- Specify at least 10 microns of plating thickness

(The rules on plating thickness changed with the 2014 edition of IEC 60079-1. Clause 5.1 now allows a thickness greater than 8 microns.)

Not all electroless Nickel Plating is equal – Before & After Salt Spray Test

For highly corrosive environments the choices are either:-

- Stainless steel

- Specialist corrosion protected cable glands

Installation / Inspection Considerations

Choose cable glands that are:-

• Easy to install

• Don’t have parts that can get mixed up

• Don’t have loose parts

• Can be inspected easily

Further Reading

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick International, based in the UK, are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply

Protecting Substations Against Flooded Ducts by Roxtec

October 9th, 2019

Protecting Substations Against Flooded Ducts

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager article by Roxtec

Retrofitting a flooded substation

A flooded electrical substation. A run-down pump. And another switchgear failure.

Do you recognize the scenario? Would you like to avoid it?

Learn how to get it all right from the start.

Distribution network operators and maintenance contractors all over the world struggle against water and dust ingress in electrical assets such as substation basements and control rooms. Since humidity is often the cause of partial discharge activity, equipment damages, switchgear failures and costly power outages, they have a lot to win in keeping the basements dry. There are ways of sealing properly against water leakage through openings for cables and pipes using cable transits and thereby eliminate the risk.

Cable & Pipe Sealing Transits & Systems

1. Face the facts

Furseweld | The Furse System of Exothermic Welding

October 9th, 2019

Furseweld | The Furse System of Exothermic Welding

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

Furseweld

The Furse System of Exothermic Welding

Since 1893, Furse has provided world leading Earthing, Lightning and Electronic Systems protection solutions for electrical infrastructure, building services and LV MV HV substations.

FurseWELD exothermic welding is a cost efficient method of achieving high quality electrical connections.

FurseWELD is a simple, self-contained exothermic welding system that uses the high temperature reaction of powdered copper oxide and aluminium, within a mould, to form permanent electrical connections.

Exothermic welded connections are accepted according to the 11kV and 33kV substation earthing design and construction manuals by most UK DNO’s, including UK Power Networks (UKPN) – for instance earth welding copper to copper tape connections and copper tape to stranded cable earthing connections.

Typical Exothermic Welding Applications

- Earthing for power plants and high voltage substations (11kV-33kV)

- Telecommunications

- Transmission and power distribution lines

- Cathodic protection

- Rail connections

Exothermic Wedling Using the FurseWELD System

FurseWELD Earth System Benefits

- Requires no external power or heat source

- Creates high quality electrical connections

- Completely portable

- Can be used safely with minimum training

- Cost effective exothermic welding

- Can be used for over 45 standard connection configurations

FurseWELD Earth Connection Advantages

- Tolerant to repeated fault currents

- Highly conductive

- Does not loosen

- Excellent corrosion resistance

FurseWELD Exothermic Welding – contact T&D for Training & Certification Courses

FurseWELD connections have at least twice the cross-sectional area of the copper conductors being joined or welded, and an equivalent or greater current carrying capacity. Corrosion resistance is exceptional due to the very high copper content (> 90%) of the alloy.

Typical FurseWELD Applications

- Bar to Bar

- Bar to Earth Rod

- Cable to Bar

- Cable to Cable

- Cable to Earth Rod

- Exothermic Moulds & Joints

FurseWELD is suitable for earth rod connections to copperbond, solid copper and stainless steel earth rods – threaded porttion of copperbond earth rods must be removed prior to FurseWELD application.

Welding procedure

- Position the cleaned conductors in the mould after ensuring the mould is dry by pre-heating or making a test joint.

- Lock the mould with the handle clamp; if the mould does not close properly adjust the tension by removing the split pin and turning the eye bolt accordingly. Insert the steel disc into the mould crucible, ensuring it is centred over the tap hole.

- Pour the welding powder into the crucible; the starting powder is retained in the underside of the cartridge and identified by a red cap.

- Spread the starting powder evenly over the welding powder, placing a small amount on the top edge of the mould for easy ignition.

- Close the cover and ignite the starting powder with the flint gun; pull the gun away immediately to prevent fouling the flint. Wait a few seconds to allow the metal to solidify before opening the mould. Remove all slag and dust before making the next weld.

FurseWELD Exothermic Welding Moulds

FurseWELD system of exothermic welding uses moulds to contain the exothermic reaction that creates safe and robust connections. Different types of FurseWELD moulds are available, whose use depends on the requirements of the project.

- Graphite Moulds – Marketleading FurseWELD graphite moulds are extremely robust and capable of creating over 75 connections each.

- Mini-Moulds – FurseWELD mini-moulds are a cost effective alternative to full sized moulds, especially where lower numbers of connections are required. They are smaller overall, less robust and therefore lower priced. Care is required in order to achieve similar service lives to full sized moulds.

- Sureshot – the FurseWELD Sureshot system is a single use ceramic mould supplied complete with retaining disc and powders – It has been designed for use in applications where only a few exothermic welding connections are required.

FurseWELD – How to make a FurseWELD Joint Connection

1. Locate the copper conductors to be joined in the FurseWELD cavity and close the mould.

2. Locate the steel retaining disc in the base of the crucible, pour in the weld powder followed by the starting powder. Ignite starting powder with a spark gun.

3. The exothermic reaction reduces the weld powder to molten copper alloy which melts the retaining disc and flows into the weld cavity where it partially melts the conductors

4. The molten copper allow cools to leave a fusion weld of great mechanical and electrical integrity.

FURSEWELD TOOLS / ACCESSORIES

Furseweld Exothermic Welding Tools & Accessories

- Handle Clamp

- Flint Gun

- Toolkits including cable or tape cleaning brush, mould cleaning brush & mould scraping tool

- Gas torch (to preheat the mould)

- Optional toolbox & heat resistant mould jacket

Potential Hazards

As with all forms of welding the potential hazards are:

- Accidental contact with hot work.

- Spatter of molten metal.

- Eye irritation.

- Throat/chest irritation.

Frequently Asked Questions About Exothermic Welding

Could you tell me how many welds can be completed before replacement of the mould is required?

With regards to the Exothermic Welding Mould, the mould should be good for 40-50 joints at a minimum (they could easily do a lot more if they are maintained and used correctly).

Are the earth welding products classed or recognised as “explosives”, and should they be stored in a secure metal box and labelled as explosives?

- FurseWELD materials must be stored in a dry and secure place

- Only take onto site, sufficient materials to give continuity of work

- Fully discuss the operation with the client including site fire precautions. Note: A permit to work system may be required before work can be done

- Wear all of the above listed personal protective equipment and any other equipment which may be required for the job in hand

- Do not use flame or heat near flammable substances or atmospheres; this will include the following: paints, solvents, oils, petroleum, diesel, gasses, paper, rags

What are the training and competency assessments requirements and how often should this training be reviewed, refreshed or renewed?

Furse can offer Exothermic Welding Training and will supply a certificate at the end to show that the user has successfully completed a course of instruction and demonstrated competence in the process. This certificate will last for 4 years – contact Thorne & Derrick for further information.

PPE Requirements?

Safety Goggles & Heat Resistant Gloves

The following should always be worn:

- Safety Goggles

- Heat Resistant Gloves (welders gloves)

- Safety Boots (for site use)

- Safety Helmet (for site use)

- Fire Bucket or Extinguisher (if working near flammable materials)

In addition to the above, other equipment may be required dependent upon the location of and the nature of the job. This may include:

- Fire bucket/extinguisher (if working near flammable materials).

- Heat resistant board (to contain spillage or protect surfaces).

Further Reading

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV