Blog

Thorne & Derrick Partner With Powerstar | Smart Transformers & Energy Solutions

August 23rd, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales and Marketing Manager

Press Release

UK, County Durham – Thorne & Derrick International

Thorne & Derrick have partnered with Powerstar.

Powerstar are leading manufacturers of LV HV Transformers to enable safe and reliable distribution of Smart Power with online remote monitoring functionality, 600v to 11kV .

The Powerstar SO-LO® range of super low loss Smart Transformers are the only amorphous core transformers designed and manufactured in the UK.

SO-LO® transformers deliver higher energy efficiency, improved distribution reliability and lower power consumption than conventional transformers.

Going Smart

Chris Dodds, Sales and Marketing Manager at Thorne & Derrick, says: “We look forward to developing existing relationships with customers while also presenting the full portfolio of Powerstar transformers up to 11kV to new clients. The ability to provide bespoke smart energy solutions from concept to completion that efficiently manage energy use while lowering electricity consumption and costs is highly attractive. Replacing your site transformer with a low loss amorphous core could reduce core losses by up to 75% when compared to traditional CRGO transformers. Smart Grid is the future.”

The partnership will facilitate knowledge sharing between our two companies and enable us to collaboratively promote the range of fit-for-purpose energy solutions and services available to clients in the utility, renewable and power generation industries.

Dr. Alex Mardapittas, CEO at Powerstar, commented: “We are proud to partner with the renowned and reputable LV HV Electrical Equipment Distributor Thorne & Derrick. The partnership will heighten the visibility of smart transformers and enable a wide variety of organisations to learn how they can modernise their high voltage electrical power infrastructure.”

Smart Power, Smart Transformers – SO-LO transformers ensure real-time and remote asset monitoring to assess performance and operation.

The collaboration will be underpinned by the customer service offered by Thorne & Derrick and Powerstar to support and inform organisations on how they can further improve their LV MV HV infrastructure through customised recommendations such as the implementation of smart transformers that are Industry 4.0 ready.

Video: Powerstar HV MAX is a super low-loss amorphous core HV transformer combined with the award winning Powerstar technology. The product allows companies to save on electricity costs and reduce carbon emissions. Watch the video to see the Powerstar HV MAX installation:

Thorne & Derrick

Since 1985, Thorne & Derrick International, based in the UK, have been synonymous with the supply and distribution of tested, certified and accredited Electrical Equipment & Cable Accessories by leading manufacturers including ABB, 3M Electrical, Nexans Euromold, Pfisterer and Prysmian to guarantee the highest levels of reliability for LV MV HV Power Systems.

Promoting Good Practices For Cable Products Following The Grenfell Tower Report

August 21st, 2019

-

Blog Written By BASEC | 1 of 10 Articles

Thorne & Derrick collaborate with BASEC to advocate the importance of electrical safety and educating industry stakeholders about specifying and buying accredited, tested and certified cables and cable accessories.

We would like to thank BASEC for allowing us to republish a selection of articles aimed to protect and inform the electrical sector – together we promote compliance with industry standards, specifications and ultimately confidence in end installations to provide LV MV HV Cable Quality.

Sadly, it often takes a tragedy before questions are raised about the impact of poor-quality building materials. As cables are commonly the cause of fire, BASEC is keen to raise awareness and promote good practices for those responsible for the specification of these products.

Following the Grenfell Tower tragedy, an Independent Review of Building Regulations and Fire Safety: Final Report, known as the Hackitt report, prepared by Dame Judith Hackitt, was presented to Parliament.

The report claims that ignorance, indifference and inadequate regulation led to the Grenfell Tower disaster, not its cladding alone. In particular, the report highlights significant risks to safety that building regulations, at the time, had not provided adequate consideration for.

The report insists that buildings must be considered as systems, because the safety of building occupants depends on the use of a range of building materials that demonstrate effective fire resistance, rather than relying on the performance of just one material or product.

In the case of the Grenfell Tower, the impact of the fire was exacerbated by poor-quality materials used within the building.

While the use of the Aluminium Composite Material (ACM) cladding has been widely blamed, the presence of a Polyethylene (PE) core, which is a thermoplastic that melts and drips when exposed to fire, has also been identified as a contributing factor.

When the building was refurbished between 2012 and 2016, an architectural feature was installed on the roof which was made up of ACM cladding full of PE.

The fire was able to spread more readily once the PE set on fire, due to each panel of cladding having been hung over metal rails on the roof to create the architectural feature. This created multiple routes for the fire to spread when the PE was exposed directly to flames.

As a result of this design feature, the windows were also reduced in size and moved to sit flush with the new cladding.

Foam and rubber membrane materials, which were also flammable, were used to fill the voids that resulted around the design change. Prior to refurbishment, the building materials and construction were relatively safe, however, the modifications compromised the level of fire safety.

Following an initial investigation into the cause of the fire the government banned the use of combustible materials on external walls, especially on new build developments containing flats and exceeding 18m in height.

It is suggested that the use of another material within the cladding, instead of PE, would have minimised the impact of the fire. It is, therefore, extremely important that the quality of materials used in the overall construction of a building are considered in relation to the surrounding materials.

For example, if poor-quality cable products are used in a project because cable systems map the full infrastructure of a building, in order to provide power, this creates a significant fire risk. The cables are routed around the building which creates a path, by which any potential fire could spread.

Improving fIRE regulations and requirements

The Grenfell Tower tragedy highlighted the importance of using building materials that are fit-for-purpose. The report also demonstrated why the use of quality products is essential when refurbishing existing buildings.

Since the 1st July 2017, all power, data and communications cables that are part of permanent installations are required to adhere to Construction Products Regulations (CPR). This mandatory requirement came in to play following the 18th Edition update of BS7671, the wiring regulations, which included several key amendments to fire safety regulations.

One of the requirements is that, cable products must comply with and meet the boundary levels to achieve a fire performance classification from Fca through to Aca, when tested to the applicable range of tests (for the classification sought) including EN ISO 1716, EN 50399, EN 60332-1-1, EN 61034-2 and EN 60754-2 with regards to the product’s reaction to fire.

CPR affects all cable manufacturers, importers and distributors supplying European markets with any cable product designed to fit permanently into the structure of a building, including power distribution, final circuit wiring, control and instrumentation and data communications cables (copper and optical).

Another demonstrated amendment comes in the changes to Regulation 521.11.201, which set the requirement for support systems to be in place for escape route wiring systems only.

The regulation has been replaced by a Regulation 521.10.202, which now states a requirement for cable systems to be supported or fixed with fire resistant cable ties, cable grips and cable hangers, in order to enable the cable to hold its position and protect against their premature collapse in the event of a fire.

That is, where a PVC cable-tie could melt and cause the cable system to fall away from the wall or ceiling it is fixed to. This requirement is now applicable throughout the installation, not only in escape routes as specified originally and is relevant to all cable types.

As cable technology continues to evolve, new requirements for applications are emerging. Specialised compounds used in cable products, therefore, require a range of testing to understand how they will perform in conditions where stresses, such as extreme temperatures, could affect how they operate.

Did You Know? BASEC conducts a number of fire tests on cables. These tests are specified in cable and performance standards, and are required up for a variety of cable types to be compliant.

Good practices for cable product specification

The installation of highly flammable materials, used in the refurbishment of the Grenfell Tower created a high-risk scenario, therefore specifiers should take care when selecting products in order to minimise the potential risks.

Being mindful that the materials used in the construction of the project overall, and specifically with regards to the chosen cable products due to be installed in the construction of a public building or dwelling, is extremely important. As cable systems provide the ideal vehicle to transport fire quickly around a building, once ignited, special consideration must be made at the specification stages of any given project.

In addition to specifying high-quality cable products for construction projects, BASEC recommends the following good practices when making specification decisions.

The British Approvals Service for Cables (BASEC) is a recognised sign of assurance of independent cable testing and approval. As an independent body, BASEC has for nearly 40 years been a mark of reassurance to those specifying cable.

Top 5: Cable specification tips

1. Insist on using cable products that demonstrate high levels of fire resistance

Specifiers should check that the cable installed in their projects will provide adequate protection in the event of a fire. Some cable products may be marketed as fire resistant cables but they may not perform adequately in enclosed spaces, typical of many public buildings.

This requirement is particularly important when comparing Low Smoke and Fume (LSF) to Low Smoke Halogen Free (LSHF) cable products, as they both perform differently when burned. LSHF cable products are designed to release low emissions of smoke and fumes when burned. When compared to LSF cable products, which release toxic gases when burned, as they are manufactured using PVC compounds.

2. Specify cable products that exceed the requirements of regulations

Every effort should be made to use cable products of the highest quality to ensure that risks are minimised. Even when cable products meet regulations, the relevance of the standard is key, simply specifying a test for a cable product does not guarantee it will be suitable for the desired application.

This is especially true in the case of CPR, where a cable product is awarded a classification based on how it performs in a fire scenario. The lowest classification, the Fca, is demonstrated through the product’s resistance when exposed to a single flame.

Specifying cable products that exceed the minimum pass criteria, achieving higher classifications than those required as a minimum, ensures that the materials used will provide superior levels of protection.

3. Specify cable products that have been tested and approved by a third-party certification body

Specifying cable products that have been rigorously tested by a third-party certification body like BASEC ensures that they meet recognised industry standards and offer the highest levels of product quality and safety. Cable products should always be tested for performance using a range of tests as they may be suitable for use in some conditions and not others.

For example, a cable may demonstrate suitable fire resistance performance but may also bend or break easily when stretched. The second characteristic poses just as much of a safety risk as the first, because damage to the cable as a result of an exposed or cracked conductor could result in a secondary fire.

Secondary fires can ignite as a result of an electrical spark or the cable could simply fail to operate in a critical scenario, meaning fire alarms and systems will not perform their roles once the fire has started.

4. Increased awareness of the fire performance of cable products

Increasing awareness of the fire performance of cable products, ensures that the quality and safety of the cable products installed in public buildings is given serious consideration at specification stages.

As cable quality is often taken for granted, increasing awareness of the impact cable products can have in the event of a fire, ensures that more people are informed of the risks. Individuals and organisations can then insist on using classified and compliant products to ensure maximum levels of safety.

Not only does this provide end users and those involved in delivering the project with assurance of quality, it also provides those who occupy the building with peace of mind that the cable products installed in their homes meet the highest levels of quality and safety, and comply with recognised industry standards.

5. Encourage communication between manufacturers, distribution, specifiers, consultants, architects, buyers and installers

It is far too easy for specification decisions to be made in isolation. Encouraging communication between every touchpoint of the project delivery team, ensures that technical knowledge is readily transferred, and the full supply chain is aware of the impacts.

Prioritising this communication can save time during the construction process, as the required cable products can be specified before the construction begins.

This allows for discussions and areas for concern to be highlighted prior to them arising, product changes can be made via the supplier or manufacturer to ensure the right product, for the right application arrives when needed and construction is under way.

BASEC is facilitating these discussions through a series of seminars on Cable Quality, in order to provide those in these functions with a solid knowledge base for cable product testing requirements and the knock-on effects and implications of poor-quality cable.

Verifying building material quality

It is one thing to say that cable products meet industry standards, but it is another to firstly, evidence their levels of quality and secondly, to provide the end-to-end supply chain with confidence that the products will be safe to use and operate as intended to.

BASEC partners with cable manufacturers around the world to ensure that approved cables are fully compliant with the relevant standards, safe, reliable and fit for purpose.

With a dedicated and state-of-the-art large-scale vertical ladder fire test facility to deliver fire testing in compliance with CPR, EN50399, and all vertical ladder tests relating to IEC 60332-3-21/25, BASEC demonstrates full support of safe and compliant electrical installations in any industry application.

As a designated Notified Body (No 2661) for the CPR AVCP System 1+ and System 3, BASEC has delivered over 3,000 individual tests and classification reports for cable products in compliance with CPR.

Through these testing systems BASEC has enabled manufacturers and distributors around the world to comply with classification requirements and supply within the EU regulations.

Although CPR is mandatory for EU markets only, many other markets are using the CPR fire classifications as a benchmark to raise their levels of product safety.

Having extended and enhanced surveillance of the market, BASEC has designed a Registered Stockist scheme which enables the distribution network to assess their levels of quality and safety through assessment of their procurement and handling processes involved in the sourcing and selling of cable products.

Testing cable at the manufacturing source, as per BASEC’s traditional certification scheme that is designed to deliver a 3-year programme of auditing and product testing to obtain product specific approvals, coupled with testing at the point of sales means tighter end-to-end compliance to industry standards.

Testing before products enters the end user market facilitates maintained levels of product quality and monitoring in the market.

Conclusion

As the Hackitt report concluded, the quality of all materials used in the construction of a building have an impact on the safety of residents. Installing quality cable products throughout a building, therefore, is essential to ensure that cables and cable accessories demonstrates effective fire resistance and any risk, from the cable products, to life is minimised.

Poor-quality cable product has a higher risk factor, as non-approved products can act uncharacteristically to verified products and could cause fire to spread faster, release higher quantities of smoke, gas or heat, which can further escalate the impacts of fire.

Simply specifying quality cable products, however, does not offer a quick fix to ensuring safety. Ignorance, indifference and inadequate regulation within the overall construction of the building played a key role in the Grenfell Tower disaster.

Educating the construction industry, therefore, is equally as important to ensure that any fire risk to building inhabitants is minimised. In order to achieve this, BASEC is working with the full supply-chain, including manufacturers, specifiers, contractors and stockists to raise awareness of the importance of fire performance and of specifying approved cable products.

To enable confidence in the performance of the cable products selected and installed in residential buildings, BASEC approved cable products should be specified. BASEC’s mark of independently approved quality and safety is only awarded when cable products have been rigorously tested to meet the required industry recognised standards.

End users can find comfort in and gain assurance that the products installed are safe to use and compliant. BASEC’s product approval programme includes a comprehensive testing schedule for electrical, mechanical, material, chemical, fire and smoke performance characteristics.

BASEC – British Approvals Service for Cables

As industry experts in CPR (Construction Products Regulation) testing BASEC has issued over 3,000 CPR classification reports, delivered through in-house laboratory equipment and by working closely with manufacturers to raise cable product classifications for higher fire performance characteristics.

The British Approvals Service for Cables (BASEC) is a recognised sign of assurance of independent cable testing and approval. As an independent body, BASEC has for nearly 40 years been a mark of reassurance to those specifying cable.

Cable Quality Seminar

BASEC run a number of FREE Cable Quality Seminar’s across the country suitable for anyone and everyone who is working to deliver projects which include cable installations.

Do not miss your opportunity to build your awareness of cable quality.

Click here to register now.

Middle East Electricity 2020, Dubai

How Do You Measure Fire Resistance?

The video below shows that electrical failures and malfunctions are leading sources of ignitions for fires.

In the event of a fire, the resistance class of your electrical cable is critical to how much and how quickly the fire could spread.

54.4% of fires caused by electricity with an average of 4 fatalities per day. Specifying BASEC cables can help you to achieve higher fire classifications through independent cable testing.

THORNE & DERRICK

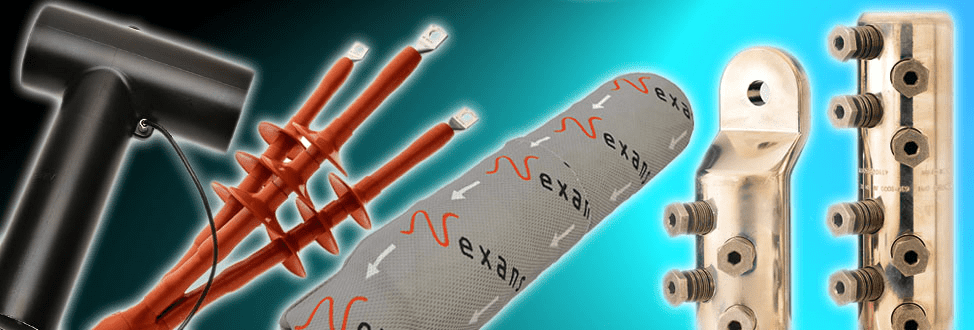

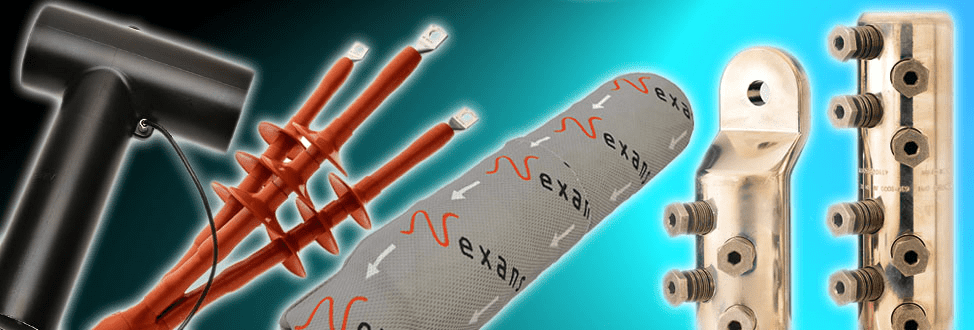

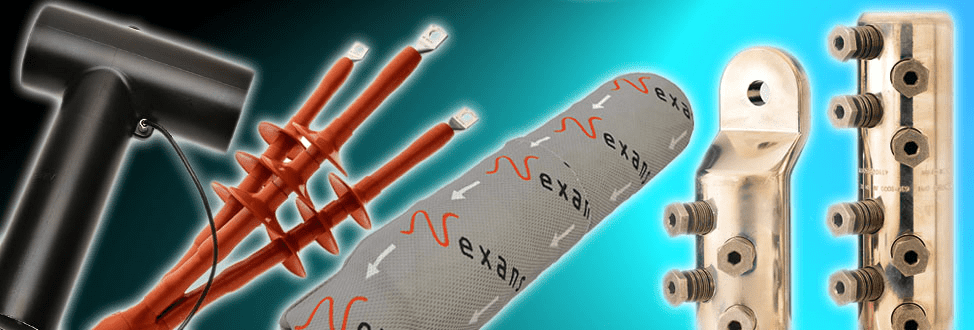

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

A Review of Medium Voltage Cable Accessories

August 21st, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales + Marketing Manager

In this series of 15 blogs we provide Chapter breakdowns for the Nexans published book, “Medium Voltage Cable Accessories, A Theoretical and Practical Approach”.

Today, we overview Chapter 19, A Review of Medium Voltage Cable Accessories

The book covers the installation of medium voltage cable terminations, separable connectors, cable joints and associated LV MV HV Power Cable Accessories such as cable glands, lugs and cable cleats.

Great emphasis is placed on failure modes of medium voltage cables and methods of preventing potential problems in service of electrical power systems operating typically at 11kV/33kV.

Essential reading for:

- Lead Electrical Engineers

- Electrical Project Engineers

- Principal Electrical Engineers

- Plant Engineers

- LV HV EHV Cable Jointers

- ATEX Inspectors

- Substation Commissioning Managers

- LV HV EHV Project Managers

- Buyers & Procurement Managers

- SAP’s

- Sales Managers & Engineers

The book is an instant hit with DNO’s, IDNO’S, ICP’s, MV HV Cable Jointers, Cable Contractors, Cable Jointer Training Centres, Electrical Contractors and Substation Engineers.

Chapter 19: A Review

From Medium Voltage Cable Accessories

- 19.1. Introduction

- 19.2. Dos and don’ts

- 19.3. The future

Nexans (Euromold) manufacture high voltage Screened Separable Connectors (Elbow & Bolted Tee), Cable Joints & Cable Terminations (Cold Shrink & Heat Shrink), Bushings and Surge Arresters are available to suit 11kV, 33kV and up to 66kV distribution networks.

Medium Voltage Cable Accessories Book Published By Nexans

- Format: Hardback

- Extent: 160pp

- Size: 300x215mm [Nexans 11kV 33kV Cable Jointers Book]

- ISBN: 978-0-9573785-0-6

- RRP: £79.99

- Illustrations: Nexans Power Accessories (UK)

- Publication Date: March 2013

Medium Voltage Cable Accessories Book Published By Nexans

NEXANS pOWER CABLE ACCESSORIES

In January 2018 Thorne & Derrick International, based in the UK, signed a UK Distribution Agreement with Nexans Power Accessories UK.

T&D are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the maintenance and installation of HV transformers and switchgear.

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Signing the new Nexans Power Accessories UK Distribution Agreement is a key part of Thorne & Derrick’s growth strategy for the next 5 years.

With T&D’s knowledge and experience of stocking and supplying Medium & High Voltage Cable Accessories this new partnership with Nexans delivers the most complete range of Joints, Terminations and Connectors for medium voltage power systems.

Training Courses & Services For Cable Jointers

Empower your CV and skill-set by grasping the 66kV Jointer Training opportunity. Jointers must currently be 33kV Competent and experienced to be ready to undertake the step-up to 66kV from 33kV. 11kV Jointer Training Courses also available.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Recent Developments In Medium Voltage Cable Accessories

August 21st, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales + Marketing Manager

In this first of a series of 15 blogs we provide Chapter breakdowns for the Nexans published book, “Medium Voltage Cable Accessories, A Theoretical and Practical Approach”.

Today, we overview Chapter 18, Recent Developments In Medium Voltage Cable Accessories.

The book covers the installation of medium voltage cable terminations, separable connectors, cable joints and associated LV MV HV Power Cable Accessories such as cable glands, lugs and cable cleats.

Great emphasis is placed on failure modes of medium voltage cables and methods of preventing potential problems in service of electrical power systems operating typically at 11kV/33kV.

Essential reading for:

- Lead Electrical Engineers

- Electrical Project Engineers

- Principal Electrical Engineers

- Plant Engineers

- LV HV EHV Cable Jointers

- ATEX Inspectors

- Substation Commissioning Managers

- LV HV EHV Project Managers

- Buyers & Procurement Managers

- SAP’s

- Sales Managers & Engineers

The book is an instant hit with DNO’s, IDNO’S, ICP’s, MV HV Cable Jointers, Cable Contractors, Cable Jointer Training Centres, Electrical Contractors and Substation Engineers.

Chapter 18

Recent Developments In Medium Voltage Cable Accessories

From Medium Voltage Cable Accessories

- 18.1. Medium Voltage Cable Terminations

- 18.1.1. Medium Voltage Push on Joints & Terminations

- 18.1.2. Medium Voltage Cold Shrink Joints & Terminations

- 18.2 Medium Voltage Cable Joints

- 18.3. Medium Voltage Separable Connectors

- 18.3.1. Larger Rated Systems

- 18.3.2. Reduced Size Of Products

Nexans (Euromold) manufacture high voltage Screened Separable Connectors (Elbow & Bolted Tee), Cable Joints & Cable Terminations (Cold Shrink & Heat Shrink), Bushings and Surge Arresters are available to suit 11kV, 33kV and up to 66kV distribution networks.

Medium Voltage Cable Accessories Book Published By Nexans

- Format: Hardback

- Extent: 160pp

- Size: 300x215mm [Nexans 11kV 33kV Cable Jointers Book]

- ISBN: 978-0-9573785-0-6

- RRP: £79.99

- Illustrations: Nexans Power Accessories (UK)

- Publication Date: March 2013

Medium Voltage Cable Accessories Book Published By Nexans

NEXANS pOWER CABLE ACCESSORIES

In January 2018 Thorne & Derrick International, based in the UK, signed a UK Distribution Agreement with Nexans Power Accessories UK.

T&D are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the maintenance and installation of HV transformers and switchgear.

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Signing the new Nexans Power Accessories UK Distribution Agreement is a key part of Thorne & Derrick’s growth strategy for the next 5 years.

With T&D’s knowledge and experience of stocking and supplying Medium & High Voltage Cable Accessories this new partnership with Nexans delivers the most complete range of Joints, Terminations and Connectors for medium voltage power systems.

Training Courses & Services For Cable Jointers

Empower your CV and skill-set by grasping the 66kV Jointer Training opportunity. Jointers must currently be 33kV Competent and experienced to be ready to undertake the step-up to 66kV from 33kV. 11kV Jointer Training Courses also available.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Cable Supports

August 21st, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales + Marketing Manager

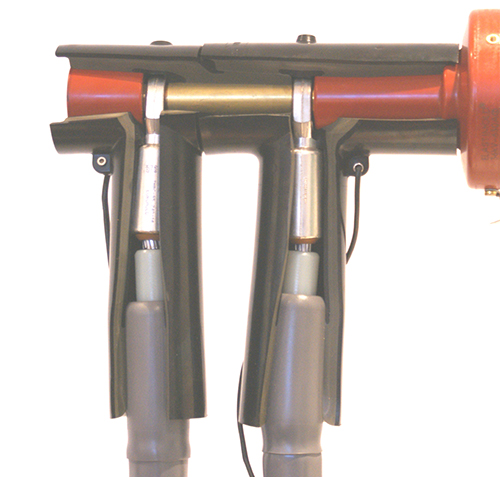

In this series of 15 blogs we provide Chapter breakdowns for the Nexans published book, “Medium Voltage Cable Accessories, A Theoretical and Practical Approach”.

Today, we overview Chapter 17, Cable Supports.

The book covers the installation of medium voltage cable terminations, separable connectors, cable joints and associated LV MV HV Power Cable Accessories such as cable glands, lugs and cable cleats.

Great emphasis is placed on failure modes of medium voltage cables and methods of preventing potential problems in service of electrical power systems operating typically at 11kV/33kV.

Essential reading for:

- Lead Electrical Engineers

- Electrical Project Engineers

- Principal Electrical Engineers

- Plant Engineers

- LV HV EHV Cable Jointers

- ATEX Inspectors

- Substation Commissioning Managers

- LV HV EHV Project Managers

- Buyers & Procurement Managers

- SAP’s

- Sales Managers & Engineers

The book is an instant hit with DNO’s, IDNO’S, ICP’s, MV HV Cable Jointers, Cable Contractors, Cable Jointer Training Centres, Electrical Contractors and Substation Engineers.

Chapter 17

Cable Supports

From Medium Voltage Cable Accessories

- 17.1. Introduction

- 17.2. Cleats

- 17.2.1. Requirements

- 17.2.2. Cleat spacing

- 17.2.3. Cleat specifications

- 17.2.4. Trefoil cables with low short circuit levels

- 17.2.5. Trefoil cables with moderate short circuit levels

- 17.2.6. Trefoil cables with high short circuit levels

- 17.2.7. Triplex cables

- 17.3. Short circuit test with correctly installed cleats

Nexans (Euromold) manufacture high voltage Screened Separable Connectors (Elbow & Bolted Tee), Cable Joints & Cable Terminations (Cold Shrink & Heat Shrink), Bushings and Surge Arresters are available to suit 11kV, 33kV and up to 66kV distribution networks.

Medium Voltage Cable Accessories Book Published By Nexans

- Format: Hardback

- Extent: 160pp

- Size: 300x215mm [Nexans 11kV 33kV Cable Jointers Book]

- ISBN: 978-0-9573785-0-6

- RRP: £79.99

- Illustrations: Nexans Power Accessories (UK)

- Publication Date: March 2013

Medium Voltage Cable Accessories Book Published By Nexans

NEXANS pOWER CABLE ACCESSORIES

In January 2018 Thorne & Derrick International, based in the UK, signed a UK Distribution Agreement with Nexans Power Accessories UK.

T&D are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the maintenance and installation of HV transformers and switchgear.

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Signing the new Nexans Power Accessories UK Distribution Agreement is a key part of Thorne & Derrick’s growth strategy for the next 5 years.

With T&D’s knowledge and experience of stocking and supplying Medium & High Voltage Cable Accessories this new partnership with Nexans delivers the most complete range of Joints, Terminations and Connectors for medium voltage power systems.

Training Courses & Services For Cable Jointers

Empower your CV and skill-set by grasping the 66kV Jointer Training opportunity. Jointers must currently be 33kV Competent and experienced to be ready to undertake the step-up to 66kV from 33kV. 11kV Jointer Training Courses also available.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV